Introduction

In today’s competitive landscape, the importance of quality in production cannot be overstated. Quality is not just about meeting standards; it’s about exceeding expectations and building trust with customers. By focusing on quality management, organizations can enhance their reputation, reduce costs, and ultimately drive profitability.

The Importance of Quality in Production

Quality in production serves as the backbone of any successful business. It ensures that products meet customer specifications and regulatory requirements while minimizing defects and waste. When companies prioritize quality management, they create a culture that values excellence, leading to improved customer satisfaction and loyalty.

Why Quality Management Matters

Quality management is essential for streamlining operations and fostering long-term growth. It involves implementing effective management systems that monitor performance and facilitate continuous improvement processes. By leveraging quality management software, businesses can automate tasks, track metrics, and make data-driven decisions to enhance their overall quality strategy.

Steps to Achieve Continuous Improvement

Achieving continuous improvement requires a systematic approach that begins with assessing current quality standards. Organizations should evaluate existing management systems to identify gaps in their processes and engage teams in the assessment process for comprehensive insights. From there, companies can implement tailored solutions—such as QMS quality tools—that promote ongoing enhancement efforts throughout the organization.

Assess Current Quality Standards

To embark on the journey of how to improve quality in production, it's crucial first to assess your current quality standards. This step sets the stage for identifying what works and what doesn't within your management systems. Without a clear understanding of existing quality metrics, any effort toward enhancement may be misguided or ineffective.

Evaluate Existing Management Systems

Evaluating existing management systems is akin to taking a health check-up for your production processes. By thoroughly reviewing the frameworks already in place, you can pinpoint areas that are functioning well and those that require attention. Utilizing quality management software during this evaluation can streamline the process, making it easier to gather data and analyze performance against established benchmarks.

Identify Gaps in Quality and Processes

Once you've evaluated your management systems, it's time to identify gaps in quality and processes that may hinder continuous improvement efforts. These gaps could manifest as inefficiencies, outdated practices, or even compliance issues that need addressing. By recognizing these shortcomings early on, you can develop targeted strategies to enhance overall quality management and ensure smoother operations moving forward.

Engage Team in the Assessment Process

Engaging your team in the assessment process is essential for fostering a culture of continuous improvement within your organization. When employees feel involved and valued, they are more likely to contribute insights that reveal hidden challenges or opportunities for enhancement in quality management practices. Encourage open dialogue about how to improve quality in production; after all, those on the ground often have a unique perspective on potential improvements.

Implement Quality Management Software

In today's fast-paced production environment, implementing quality management software (QMS) is essential for organizations striving to improve quality in production. These tools streamline processes, enhance communication, and facilitate continuous improvement by providing a framework for managing quality effectively. By integrating a robust QMS into existing management systems, companies can ensure they are not just meeting but exceeding industry standards.

Overview of Popular QMS Quality Tools

There are numerous QMS quality tools available that cater to various business needs and sizes. Some popular options include ISO 9001 software for compliance management, Six Sigma tools for process improvement, and Lean management applications that focus on waste reduction. Each of these tools offers unique features designed to enhance quality and quality management practices while supporting the continuous improvement process.

When evaluating these tools, consider their capabilities in tracking defects, managing documentation, and facilitating audits. Cloud-based solutions like MasterControl or Greenlight Guru are particularly notable for their user-friendly interfaces and scalability. Ultimately, selecting the right QMS tool can significantly impact how effectively you manage quality within your organization.

Benefits of Automation in Quality Management

Automation in quality management brings several advantages that can drastically improve production processes. By automating routine tasks such as data collection and reporting, companies can reduce human error while freeing up valuable time for employees to focus on more strategic initiatives related to continuous improvement. This shift not only enhances efficiency but also fosters a culture where teams can collaborate more effectively on quality initiatives.

Additionally, automated systems provide real-time insights into performance metrics, allowing organizations to make informed decisions quickly—essentially putting the management back into your management systems! With accurate data at your fingertips, identifying trends or issues becomes much simpler than relying on manual methods alone. In short, automation empowers businesses to elevate their approach to both quality and quality management.

How to Choose the Right Software for Your Needs

Choosing the right quality management software requires careful consideration of your specific needs and objectives related to how to improve quality in production. Start by assessing what features are most critical for your organization—whether it's document control capabilities or advanced analytics functions—and prioritize those in your search criteria. Additionally, consider factors such as user-friendliness and integration with existing systems since a seamless transition is crucial for successful implementation.

Another essential aspect is vendor support; look for providers who offer robust customer service and training resources so that your team feels confident using the new software from day one. Don't forget about scalability; as your business grows or evolves its focus on continuous improvement processes may change over time—you’ll want a solution that adapts accordingly! Ultimately, investing time upfront will pay off when you find the perfect fit that enhances both productivity and overall product quality.

Foster a Culture of Continuous Improvement

Creating a culture that embraces continuous improvement is essential for any organization aiming to enhance quality in production. This culture thrives on the active participation of employees at all levels, making them feel valued and empowered to contribute ideas and solutions. By fostering an environment where feedback is encouraged, companies can tap into the collective knowledge of their workforce, leading to innovative approaches in quality management.

Encouraging Employee Involvement and Feedback

One effective way to improve quality in production is by involving employees directly in the continuous improvement process. When team members feel their opinions matter, they are more likely to share insights about existing management systems and suggest enhancements. Regular feedback sessions, suggestion boxes, or digital platforms can create channels for communication, enabling a flow of ideas that can significantly impact quality management.

Moreover, recognizing and rewarding contributions from employees can further motivate engagement. When individuals see their suggestions implemented or acknowledged, it reinforces a sense of ownership over the quality outcomes in their work environment. This not only enhances morale but also instills a commitment to ongoing improvement as part of the company culture.

Techniques to Promote Ongoing Quality Enhancement

To effectively promote ongoing quality enhancement within an organization, several techniques can be employed alongside the use of QMS quality tools. One such technique is implementing regular training sessions that focus on best practices for maintaining high-quality standards. These sessions should cover not only technical skills but also soft skills like communication and problem-solving which are crucial for collaborative efforts toward continuous improvement.

Another technique involves establishing cross-functional teams tasked with identifying areas for enhancement across different departments or processes. These teams can leverage insights from various perspectives, ensuring that improvements are holistic rather than siloed within specific functions. Additionally, utilizing data analytics through quality management software allows organizations to track performance metrics effectively; this data-driven approach supports informed decision-making regarding where improvements are most needed.

Case Study: Companies Excelling in Continuous Improvement

Several companies have successfully fostered a culture of continuous improvement by implementing robust strategies centered around employee involvement and feedback mechanisms. Take Toyota as an exemplary case; its renowned Toyota Production System emphasizes employee input at every level—a practice credited with significant enhancements in efficiency and quality management over decades. Their Kaizen philosophy encourages small incremental changes driven by frontline workers who understand processes intimately.

Another notable example is Amazon, which utilizes its vast array of data analytics tools within its QMS quality framework to continuously refine operations based on customer feedback and performance metrics. By combining technology with employee insights, these companies demonstrate how embracing a continuous improvement mindset leads directly to enhanced product quality and operational excellence—truly showcasing how to improve quality in production effectively.

Develop Clear Quality Metrics

In the quest for how to improve quality in production, developing clear quality metrics is essential. These metrics serve as the backbone of your quality management system, providing a concrete way to measure success and identify areas for continuous improvement. By establishing specific and measurable goals, you can create a roadmap that guides your team toward achieving excellence.

Setting Specific, Measurable Goals

Setting specific, measurable goals is the first step in developing effective quality metrics. These goals should align with your overall business objectives and be clearly defined so that everyone understands what success looks like. For instance, instead of saying reduce defects, aim for reduce defects by 20% within six months, which provides a clear target for your team to strive toward.

When teams have well-defined goals, it fosters accountability and encourages collaboration among members to achieve these objectives. This clarity also helps in evaluating the effectiveness of your management systems over time, allowing for adjustments as needed in your continuous improvement process. Remember, the more precise your goals are, the easier it will be to track progress using quality management software.

Tools for Tracking Quality Performance

To effectively track quality performance, leveraging modern tools is crucial in today’s production landscape. Quality management software can provide real-time insights into various aspects of production processes and help monitor compliance with established metrics effortlessly. From dashboards that visualize performance data to automated reporting features that save time and reduce human error, these tools are invaluable.

Additionally, many QMS quality tools offer functionalities such as trend analysis and alerts when metrics fall below acceptable levels. This proactive approach enables teams to address issues before they escalate into larger problems that could impact overall production quality negatively. By utilizing these tracking tools effectively, organizations can ensure they remain on course with their continuous improvement efforts.

Analyzing Data for Informed Decision-Making

Analyzing data collected from quality performance metrics is vital for informed decision-making in any organization focused on improving its production processes. Regularly reviewing this data allows teams to identify trends and patterns that may indicate underlying issues or opportunities for enhancement within existing management systems. The insights gained from thorough analysis can drive strategic changes aimed at boosting product quality.

Moreover, employing data analytics tools integrated with your QMS can facilitate deeper dives into performance outcomes—helping you understand not just what happened but why it happened too. This knowledge empowers teams to make evidence-based decisions rather than relying on gut feelings or assumptions about how to improve quality in production effectively. Ultimately, a strong focus on data analysis leads organizations down the path of sustainable continuous improvement.

Collaborate with Quality Inspection Experts

In today's competitive landscape, collaborating with quality inspection experts is a strategic move that can significantly enhance your production quality. By leveraging the expertise of professionals in the field, businesses can uncover insights on how to improve quality in production while ensuring adherence to established standards. This partnership not only strengthens quality management but also fosters a culture of continuous improvement throughout the organization.

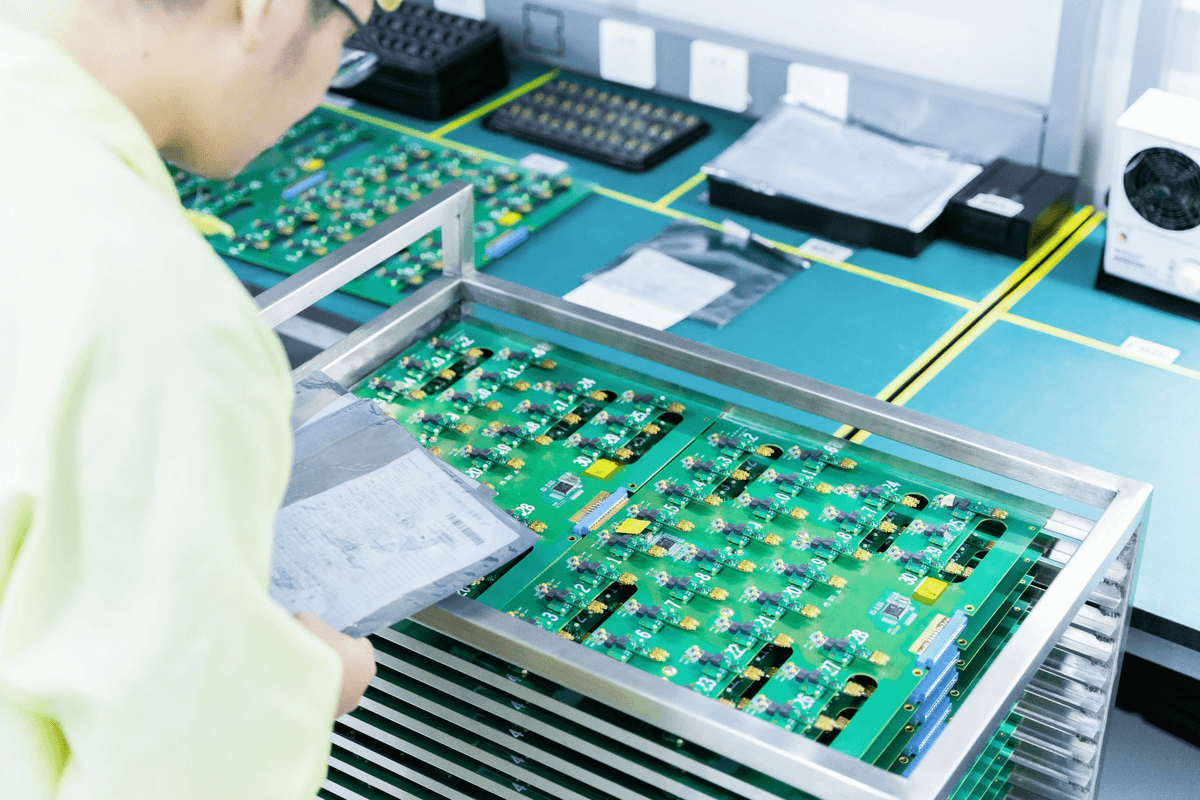

Benefits of Partnering with China Inspection Pro

Partnering with China Inspection Pro offers numerous benefits that can elevate your quality management systems to new heights. Their extensive experience in various industries allows them to provide tailored solutions that address specific challenges related to quality and quality management. Additionally, their insights into local manufacturing practices can help you identify gaps and streamline processes, ultimately leading to better outcomes and reduced costs.

When seeking ways on how to improve quality in production, working with a reputable inspection partner like China Inspection Pro ensures that your products meet stringent international standards. Their rigorous third-party inspections not only validate your internal processes but also boost customer confidence in your brand's commitment to excellence. Ultimately, this collaboration serves as a vital component of your continuous improvement process.

How Third-Party Inspections Can Enhance Quality

Third-party inspections are invaluable for enhancing overall product quality by providing an unbiased assessment of manufacturing practices and outcomes. These inspections serve as an additional layer of scrutiny beyond internal audits, revealing potential weaknesses and areas for improvement within existing management systems. By identifying issues early on, companies can take proactive measures to rectify problems before they escalate into costly defects or recalls.

Moreover, utilizing third-party inspection services aligns perfectly with the principles of continuous improvement by fostering accountability and transparency within the production cycle. When teams understand that their work will be evaluated externally, it encourages them to adhere strictly to established protocols and strive for excellence consistently. This collaborative approach not only improves product quality but also reinforces a culture where everyone is invested in achieving high standards.

Ensuring Compliance with Industry Standards

Ensuring compliance with industry standards is crucial for maintaining credibility and competitiveness in today's market landscape. Quality inspection experts play a pivotal role by helping organizations navigate complex regulations while implementing best practices associated with QMS quality frameworks. By partnering with these specialists, businesses can confidently demonstrate their commitment to maintaining high-quality output while minimizing risks associated with non-compliance.

Regular assessments through third-party inspections guarantee that all aspects of production align with industry benchmarks—making it easier for companies looking for ways on how to improve quality in production without sacrificing compliance or safety measures. Furthermore, this proactive approach helps build trust among stakeholders and customers alike who increasingly prioritize ethical sourcing and sustainable practices when choosing suppliers or partners.

By integrating expert insights into your operations through collaboration with inspection professionals like China Inspection Pro, you are well-equipped not just for today’s challenges but also future-proofed against evolving market demands and regulatory requirements.

Conclusion

In summary, improving quality in production is not just a checkbox exercise; it’s a continuous journey that requires commitment and strategic planning. By assessing current quality standards, implementing robust management systems, and fostering a culture of continuous improvement, organizations can lay the groundwork for sustainable success. The integration of quality management software can significantly streamline these processes, making it easier to track progress and adapt to challenges along the way.

Recap of Effective Quality Improvement Strategies

Effective quality improvement strategies hinge on a few critical components: thorough assessments of existing management systems, engaging employees in the continuous improvement process, and leveraging technology through QMS quality tools. Organizations need to identify gaps in their current practices and act on them swiftly; this proactive approach ensures that improvements are not only made but sustained over time. By developing clear quality metrics and collaborating with inspection experts, companies can create an environment where quality is prioritized at every level.

Emphasizing the Role of Technology in Quality Management

Technology plays an indispensable role in modern quality management by automating tasks that were once tedious and prone to human error. Quality management software enables organizations to collect real-time data on performance metrics, which is essential for informed decision-making within the continuous improvement process. As businesses increasingly rely on data-driven insights, integrating advanced QMS quality tools will be crucial for those looking to improve their production standards effectively.

Final Thoughts on Achieving Sustainable Quality in Production

Achieving sustainable quality in production requires more than just implementing new strategies; it demands a shift in mindset towards ongoing excellence and adaptability. Companies must understand that how to improve quality in production is an evolving challenge that benefits from employee involvement, innovative technologies, and consistent evaluation of processes. Ultimately, by embracing a culture centered around continuous improvement and leveraging effective management systems, organizations can ensure they not only meet but exceed industry standards for years to come.