Introduction

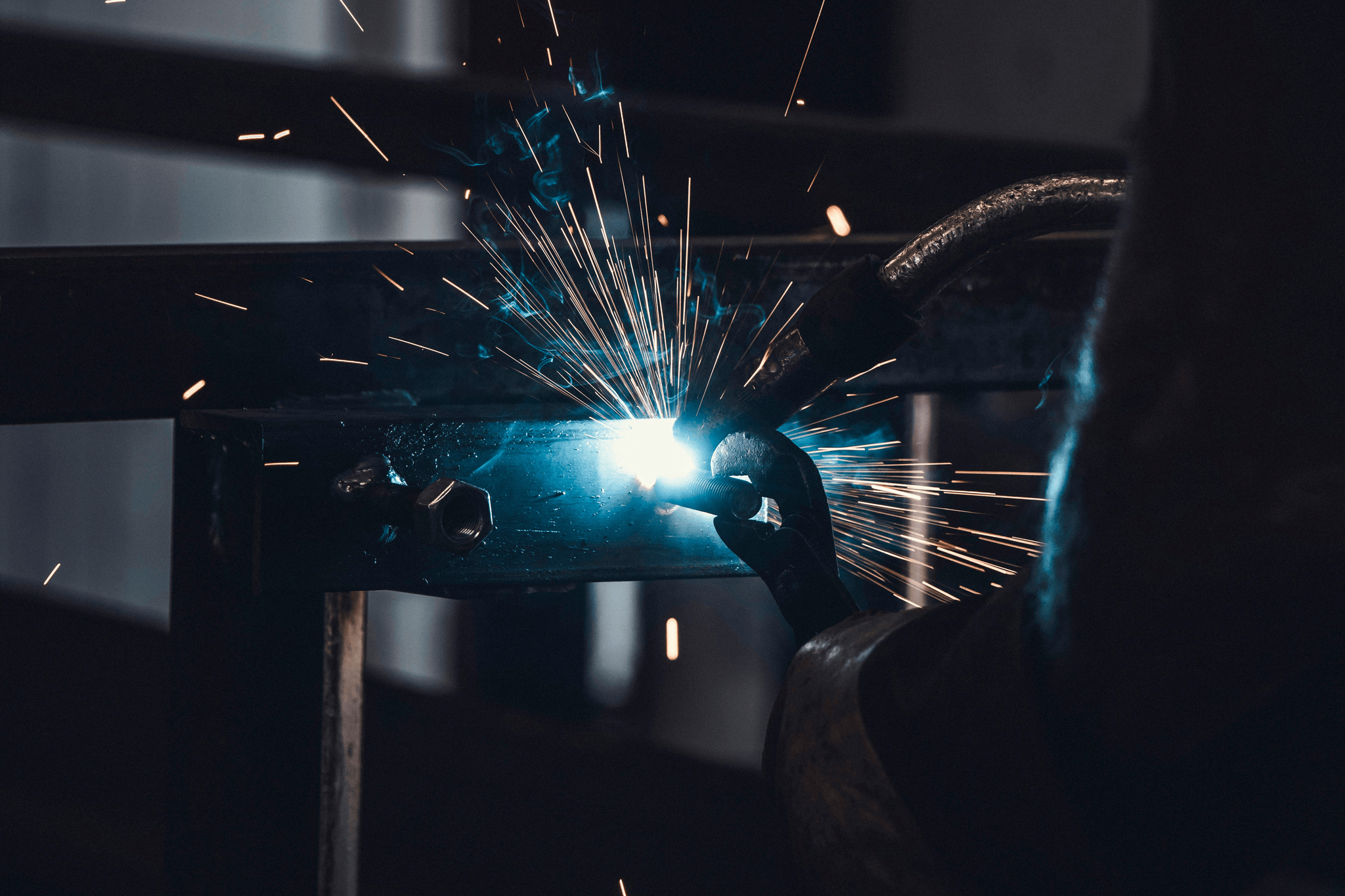

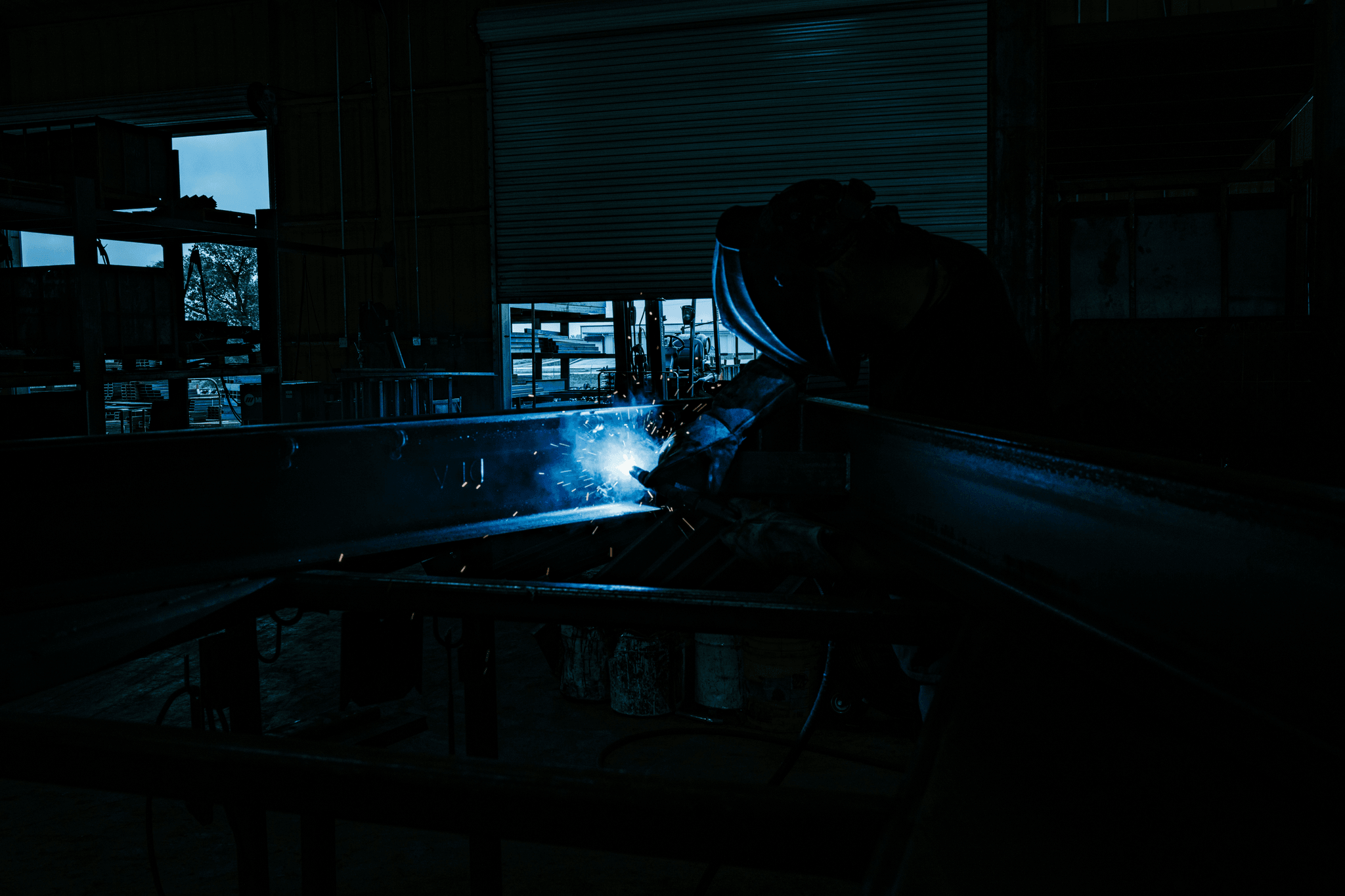

Welding is a critical process in various industries, from construction to manufacturing, where the quality of joints can significantly impact the durability and safety of structures. Thus, the inspection of welding plays a vital role in ensuring that welds meet established standards and function as intended. A thorough understanding of welding types and their specific requirements is essential for maintaining high-quality outcomes.

Importance of Welding Quality Inspection

The inspection of welding is not just a bureaucratic hurdle; it’s a safeguard against potential failures that could lead to catastrophic consequences. By identifying defects early through rigorous quality inspections, companies can prevent costly rework and ensure compliance with safety regulations. This proactive approach not only protects lives but also enhances a company’s reputation for reliability in their products.

Overview of Welding Types

Welding encompasses various techniques, each suited for different applications and materials—ranging from traditional arc welding to modern laser welding methods. Understanding these welding types is crucial for inspectors, as different processes come with unique challenges and potential defects that must be monitored closely during the inspection process. Each method requires specific knowledge and skills, making the role of the certified welding inspector indispensable in achieving optimal results.

The Role of the Certified Welding Inspector

A certified welding inspector acts as both an educator and an enforcer within the realm of welding quality assurance. They are responsible for verifying that all welds conform to industry standards through meticulous inspections using both non-destructive inspection techniques and visual assessments. Furthermore, obtaining certified welding inspector certification equips professionals with the necessary skills to identify issues early on, ensuring that projects remain on track without compromising quality or safety.

Understanding Welding Standards

Welding standards are the backbone of quality assurance in the welding industry. They provide guidelines that ensure consistency, safety, and reliability across different welding types. For a certified welding inspector, understanding these standards is crucial for effective inspection of welding processes and outcomes.

Key Industry Standards for Inspection of Welding

There are several key industry standards that govern the inspection of welding, including those set by organizations like the American Welding Society (AWS) and the International Organization for Standardization (ISO). These standards outline specific requirements for various welding types, ensuring that welds meet structural integrity and safety criteria. A certified welding inspector must be well-versed in these standards to effectively assess weld quality through methods such as non-destructive inspection.

Importance of Welding Certification

Welding certification serves as a benchmark for quality assurance, validating that welders possess the necessary skills and knowledge to perform their tasks competently. For companies, employing certified professionals not only enhances their credibility but also ensures compliance with industry regulations during inspections of welding projects. Furthermore, having a certified welding inspector on board can significantly improve project outcomes by identifying potential issues before they escalate.

Global Variations in Welding Standards

While there are universal guidelines for welding certification and inspection of welding practices, variations exist across different regions due to local regulations and industry needs. For instance, European standards may differ from those in North America or Asia, affecting how laser welding is approached in various markets. Understanding these global variations allows certified welding inspectors to adapt their methodologies accordingly while maintaining high-quality outcomes regardless of location or specific requirements.

Key Inspection Methods

When it comes to ensuring the integrity and quality of welded joints, the inspection of welding plays a pivotal role. Various methods exist, each tailored to assess different aspects of welding quality. Understanding these techniques allows certified welding inspectors to effectively evaluate welds and maintain industry standards.

Overview of Non-Destructive Inspection Techniques

Non-destructive inspection (NDI) techniques are essential tools for certified welding inspectors aiming to assess weld integrity without damaging the material. These methods include ultrasonic testing, radiographic testing, magnetic particle testing, and dye penetrant testing, among others. By utilizing NDI techniques, inspectors can detect flaws like cracks or inclusions that may compromise the strength of a weld while preserving the functionality of the component.

The beauty of non-destructive inspection lies in its ability to provide immediate feedback on weld quality across various welding types, from MIG and TIG to stick welding. Inspectors can conduct these tests during different stages of production or even after fabrication is complete, ensuring that any issues are identified early on. This proactive approach not only enhances safety but also reduces costly rework down the line.

Benefits of Laser Welding Inspections

Laser welding has gained popularity due to its precision and efficiency; however, it requires specialized inspection methods to ensure optimal results. One significant benefit of laser welding inspections is their ability to detect minute defects that traditional methods might overlook. The high-resolution imaging provided by laser technology enables certified welding inspectors to analyze weld profiles with remarkable accuracy.

Additionally, laser inspections can be integrated into automated systems for real-time monitoring during production processes—an invaluable asset in high-volume manufacturing environments. This integration ensures that any deviations from desired specifications are caught instantly, allowing for quick corrective actions before defective products reach customers. Ultimately, this leads to enhanced product reliability and customer satisfaction.

Moreover, laser welding inspections contribute significantly to maintaining compliance with various industry standards associated with welding certification requirements. By employing these advanced techniques as part of their toolkit, certified welding inspectors can uphold rigorous quality assurance protocols while showcasing their commitment to excellence in the field.

When to Use Visual and Destructive Testing

Visual inspection remains one of the most straightforward yet effective techniques employed by certified welding inspectors when assessing welds' external characteristics. It involves examining welded joints for surface imperfections such as undercuts or excessive reinforcement—issues easily visible without complex equipment. While visual inspections provide valuable insights into overall weld quality, they should be complemented by other methods for a comprehensive evaluation.

Destructive testing comes into play when more detailed analysis is necessary; this method involves physically breaking down samples to evaluate their mechanical properties under stress conditions. Certified welding inspector certification often covers destructive testing procedures because they yield critical data about a material’s performance under load—information crucial for safety-critical applications such as aerospace or construction industries where failure is not an option.

Choosing between visual inspection and destructive testing ultimately depends on factors like project requirements and budget constraints; both have their place within an effective inspection strategy tailored specifically for each unique application within various types of welded structures.

Preparing for Inspections

When it comes to the inspection of welding, preparation is key. A well-structured approach not only ensures compliance with industry standards but also enhances the quality of the final product. In this section, we will delve into the essential documentation required for certified welding inspector certification, a pre-inspection checklist to ensure weld quality, and the tools and equipment necessary for effective inspection.

Essential Documentation for Certified Welding Inspector Certification

To become a certified welding inspector, specific documentation is essential. This includes proof of education and training in various welding types, along with a record of experience in the field. Additionally, maintaining current welding certification is vital as it demonstrates ongoing adherence to industry standards and practices related to the inspection of welding.

The application process typically requires submitting forms that detail your qualifications and experience in non-destructive inspection methods. Supporting documents may also include references from employers or mentors who can vouch for your skills as a certified welding inspector. Gathering this documentation not only streamlines your certification process but also reinforces your commitment to high-quality inspections.

Finally, staying current with advancements in laser welding technology can significantly enhance your credentials as a certified welding inspector. Regularly updating your knowledge base helps you remain competitive in an ever-evolving industry while ensuring that you are equipped to handle various types of welds effectively.

Pre-Inspection Checklist for Weld Quality

Before diving into any inspection of welding projects, having a pre-inspection checklist is crucial for ensuring weld quality. This checklist should include verifying that all necessary documentation is available—such as welder certifications and engineering drawings—that outline project specifications clearly. Ensuring these documents are in order sets the stage for an effective inspection process.

Next on the checklist should be reviewing relevant codes and standards applicable to the specific project at hand; this includes understanding which non-destructive inspection techniques will be utilized during evaluation. Additionally, it's wise to confirm that all materials used meet specified requirements before commencing any inspections or tests on welds.

Lastly, conducting preliminary visual inspections can help identify any obvious defects or irregularities before more advanced testing takes place. This proactive approach allows inspectors to focus their efforts on critical areas during detailed assessments while enhancing overall quality assurance practices within the organization.

Tools and Equipment Needed for Effective Inspection

Equipping yourself with the right tools and equipment is paramount when preparing for inspections of welded joints. Essential tools often include calipers, gauges, micrometers, and other measuring instruments designed specifically for assessing weld dimensions accurately; these ensure compliance with specified tolerances across various types of welds being inspected.

In addition to measuring devices, having access to non-destructive testing (NDT) equipment such as ultrasonic testers or radiographic machines will enable you to perform comprehensive evaluations without damaging welded structures—especially important when dealing with laser-welded components known for their precision requirements. Each tool plays an integral role in identifying potential flaws that could compromise structural integrity over time.

Lastly, don’t underestimate the importance of personal protective equipment (PPE) during inspections; safety glasses and gloves protect against hazards inherent in many industrial settings where welding occurs frequently! Investing time into preparing both yourself and your toolkit ensures effective inspections while upholding safety standards throughout every stage of work.

Common Welding Defects

Welding defects can compromise the integrity of structures and components, making the inspection of welding crucial for safety and performance. Understanding these common issues allows certified welding inspectors to identify vulnerabilities before they escalate into serious problems. This section explores various defects, their implications, and how effective inspection practices can mitigate risks.

Identifying and Analyzing Common Defects

Common welding defects include porosity, cracks, undercutting, and incomplete fusion. Porosity occurs when gas is trapped in the weld pool, leading to weak points that can jeopardize structural integrity. Cracks may develop due to thermal stresses or improper cooling rates during the welding process; thus, a certified welding inspector must be adept at recognizing these signs early on.

Undercutting refers to a groove formed along the edge of a weld bead that reduces its strength, while incomplete fusion indicates that two pieces of metal did not bond properly during the welding process. Each defect type requires careful analysis to determine its cause—whether it's related to specific welding types or techniques employed—ensuring that appropriate corrective measures are taken during inspections.

How to Mitigate Defects Through Inspection

The key to mitigating defects lies in rigorous inspection protocols conducted by certified welding inspectors using non-destructive inspection methods. Techniques such as ultrasonic testing or radiographic examination allow inspectors to evaluate weld quality without compromising structural integrity. By employing these advanced methods alongside visual inspections, potential flaws can be identified before they lead to significant failures.

Additionally, implementing laser welding technology can enhance precision and reduce common defects associated with traditional methods. Regular training and certification updates for inspectors ensure they remain knowledgeable about evolving standards and technologies in the field of welding certification.

Importance of Rework and Repair Procedures

Rework and repair procedures are vital components of maintaining high-quality welds after defects have been identified through thorough inspections. Addressing issues promptly not only enhances safety but also ensures compliance with industry standards essential for certification success. Certified welding inspector certification emphasizes the importance of following established protocols for rework so that repairs do not introduce new weaknesses into previously affected areas.

Moreover, documenting all rework processes is critical for quality assurance; this creates a comprehensive record that can be reviewed during future inspections or audits. By fostering a culture of continuous improvement through effective rework strategies, organizations can significantly enhance their overall welding quality outcomes while minimizing risks associated with defective welds.

Post-Inspection Procedures

In the world of welding, post-inspection procedures are crucial for ensuring that all findings are accurately documented and that quality remains a top priority. A certified welding inspector plays a vital role in this phase, as they must meticulously compile reports that reflect their observations during the inspection of welding processes. These reports not only serve as a record for compliance but also guide future improvements in welding practices.

Documenting Findings and Reporting

Documenting findings after inspections is an essential step in maintaining high-quality standards in various welding types. Each report should detail the inspection results, including any defects identified through non-destructive inspection methods or laser welding assessments. Moreover, clear and concise reporting helps stakeholders understand the quality levels of their welds, facilitating better decision-making regarding rework or repairs.

When creating these reports, it's critical to include all relevant data, such as measurements, photographs of defects, and references to applicable welding certification standards. This level of detail not only enhances transparency but also bolsters the credibility of the certified welding inspector's evaluation. Ultimately, thorough documentation fosters accountability within teams and promotes continuous improvement across projects.

Best Practices for Quality Assurance

Implementing best practices for quality assurance after inspections can significantly enhance overall welding outcomes. One key practice involves conducting regular training sessions for certified welding inspectors to keep them updated on current standards and inspection techniques relevant to various welding types. This ongoing education ensures that inspectors remain proficient in identifying defects using both traditional methods and advanced non-destructive inspection techniques.

Another best practice is establishing a robust feedback loop between inspectors and welders to address issues promptly when they arise during inspections. By fostering open communication about findings from laser welding evaluations or other assessments, teams can collaboratively develop solutions that minimize defects in future projects. Additionally, maintaining an organized repository of past inspections allows for trend analysis over time – a valuable resource for continuous improvement.

Leveraging China Inspection Pro for Continued Excellence

For organizations striving to uphold exceptional standards in their inspection of welding processes, leveraging tools like China Inspection Pro can be transformative. This platform offers comprehensive resources tailored specifically for certified welding inspectors looking to enhance their efficiency and accuracy during evaluations across various types of welds. With features designed to streamline documentation and reporting processes, it empowers inspectors to focus more on quality rather than administrative tasks.

Moreover, utilizing such specialized software aids companies in staying compliant with international standards while adapting to global variations in certification requirements related to non-destructive inspection practices or laser welding technologies. By integrating innovative tools into their workflow, organizations can ensure consistent adherence to high-quality benchmarks throughout all stages of production – from initial inspections through final reporting.

In conclusion, effective post-inspection procedures not only solidify compliance with established norms but also pave the way towards achieving high-quality outcomes across all aspects of the welding industry.

Conclusion

In wrapping up our discussion on welding quality inspection, it’s clear that a robust understanding of various inspection techniques is crucial for ensuring the integrity of welded structures. From non-destructive inspection methods to the nuanced approaches required for laser welding, each technique plays a pivotal role in assessing weld quality. A certified welding inspector must be well-versed in these methods to effectively identify potential defects and maintain high standards.

Summarizing Key Inspection Techniques

The inspection of welding encompasses a variety of techniques designed to evaluate weld quality without compromising the integrity of the workpiece. Non-destructive inspection methods, such as ultrasonic testing and radiography, allow inspectors to detect internal flaws without damaging the material, while visual inspections provide immediate feedback on surface conditions. Laser welding, with its precision and efficiency, also requires specific inspection protocols to ensure that welds meet stringent industry standards.

Ensuring Compliance with Welding Standards

Compliance with established welding standards is non-negotiable for any project involving certified welding inspectors. These standards not only dictate the acceptable quality levels but also guide inspectors in their evaluation processes through recognized criteria like those outlined by AWS or ISO certifications. By adhering to these guidelines during inspections, companies can ensure that their welds are not only functional but also safe and reliable.

Steps to Achieve High-Quality Welding Outcomes

Achieving high-quality welding outcomes begins with thorough preparation and training in certified welding inspector certification programs. Inspectors should familiarize themselves with various welding types and their specific requirements to effectively apply appropriate inspection techniques tailored to each scenario. Additionally, implementing a rigorous pre-inspection checklist can help mitigate common defects early on, paving the way for successful project completion.