Introduction

In a world where our furry friends are considered family, the importance of pet product quality control cannot be overstated. Pet owners are increasingly discerning, looking for products that not only meet their pets' needs but also adhere to safety and quality standards. This heightened awareness has made regulatory compliance tests for pet products a critical aspect of ensuring that items on the market are safe and reliable.

Why Pet Product Quality Matters

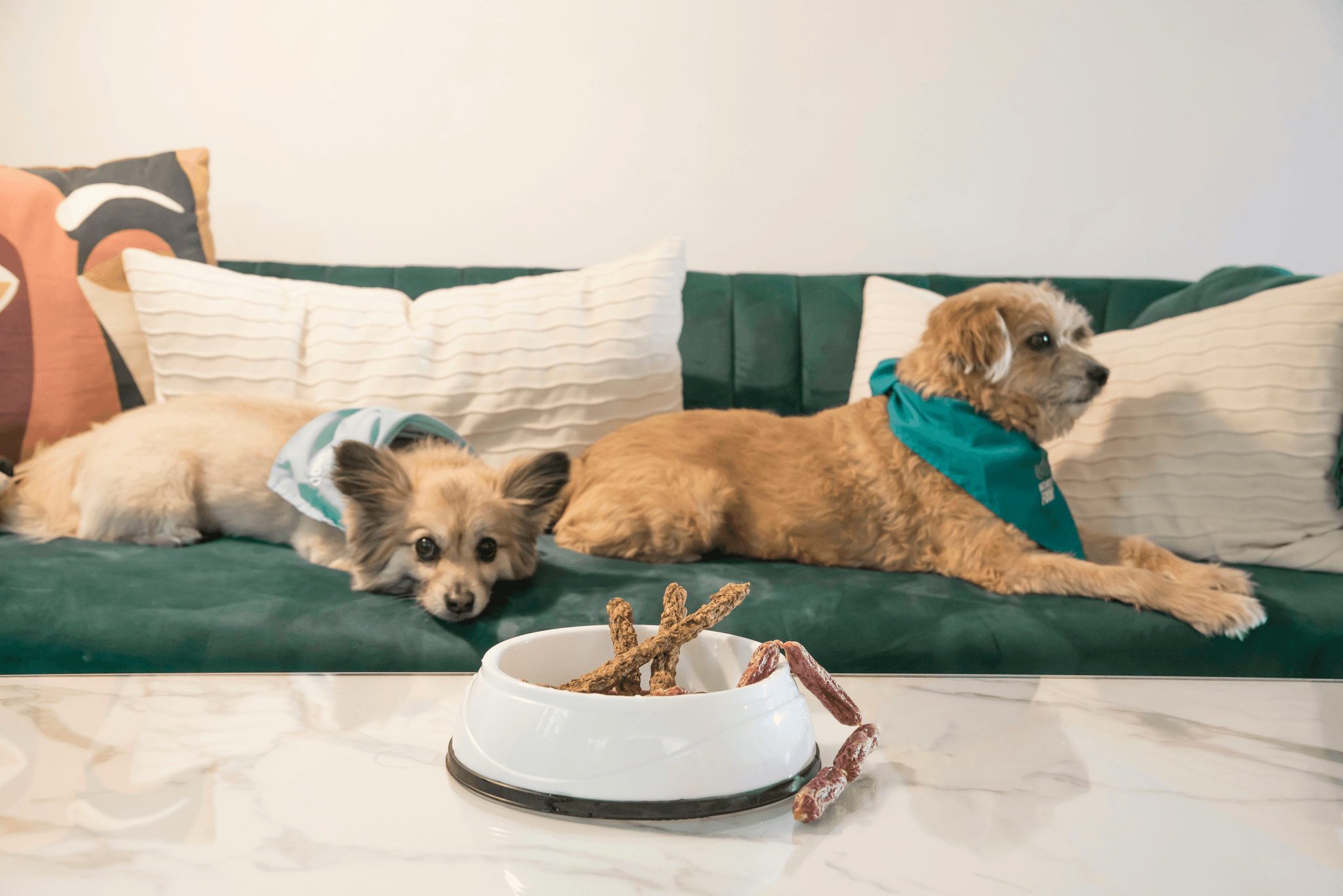

Quality matters because our pets depend on us to provide them with safe and effective products. Whether it's food, toys, or grooming supplies, the well-being of our companions hinges on the integrity of these items. Poorly made products can lead to health issues or accidents, making it essential for manufacturers to prioritize pet product quality control throughout their processes.

The Role of Regulatory Compliance

Regulatory compliance serves as the backbone of safety in the pet product industry, ensuring that all goods meet established guidelines before reaching consumers. These regulations help filter out harmful substances and unsafe designs that could jeopardize pets’ health and safety. By adhering to these standards, companies not only protect pets but also enhance their reputation in a competitive marketplace.

Key Testing Methods Explained

To maintain high standards in pet product quality control, various testing methods come into play—each designed to assess different aspects of a product's safety and effectiveness. Chemical and analytical tests evaluate potential toxins or harmful substances present in pet products, while physical and mechanical tests focus on durability and structural integrity. Performance and durability tests ensure that products withstand real-world use, providing peace of mind for both manufacturers and consumers alike.

Understanding Pet Product Quality Control

In the world of pet products, ensuring quality is not just a luxury; it's a necessity. Pet Product Quality Control plays a pivotal role in safeguarding our furry friends from potential hazards that might lurk in their toys, food, or accessories. By adhering to strict quality control measures, manufacturers can ensure that each product meets safety standards and performs as expected, ultimately fostering trust among pet owners.

Importance of Quality Control in Pet Products

Quality control in pet products is crucial for several reasons. First and foremost, it guarantees the safety and well-being of pets who use these items daily. Additionally, effective Pet Product Quality Control helps companies maintain their reputation and customer loyalty by consistently delivering reliable products that meet or exceed expectations.

Moreover, without stringent quality control processes in place, manufacturers risk producing subpar items that could lead to recalls or serious injuries to pets. This not only impacts the company's bottom line but also diminishes consumer confidence across the industry. Thus, investing in robust quality control measures is essential for both ethical considerations and long-term business viability.

Overview of Regulatory Compliance Tests

Regulatory compliance tests for pet products are designed to ensure that all items meet established safety standards before they hit the shelves. These tests cover various aspects of product safety, including chemical composition and physical durability—essentially scrutinizing every facet of what makes a product safe for pets to use. By passing these rigorous evaluations, manufacturers can confidently market their products while assuring customers about their reliability.

The landscape of regulatory compliance tests is continuously evolving as new materials emerge and consumer awareness grows about potential hazards associated with pet products. As such, staying updated on these regulations is vital for manufacturers aiming to remain competitive in an ever-changing market landscape. Ultimately, understanding these compliance requirements can significantly influence a company's production processes and marketing strategies.

Industry Standards and Guidelines

Industry standards and guidelines serve as the backbone for effective Pet Product Quality Control practices across the sector. Various organizations set forth specific benchmarks that manufacturers must adhere to when developing new products or updating existing lines—ensuring consistency in quality throughout the industry. Familiarity with these standards not only aids compliance but also empowers companies to innovate responsibly while prioritizing pet safety.

For instance, organizations like ASTM International provide comprehensive guidelines covering everything from material selection to testing methodologies applicable to pet products; this ensures that every item produced meets minimum safety requirements before reaching consumers' hands (or paws). Embracing these industry standards demonstrates a commitment to excellence while fostering goodwill among consumers who prioritize their pets' health and happiness.

Regulatory Compliance Tests for Pet Products

When it comes to ensuring that pet products are safe and effective, regulatory compliance tests are the gatekeepers of quality control. These tests help manufacturers adhere to established guidelines and standards, ultimately protecting both pets and their owners. In a market flooded with options, understanding these tests is crucial for discerning quality from mediocrity.

What Are Regulatory Compliance Tests?

Regulatory compliance tests for pet products are systematic evaluations designed to ensure that items meet specific safety and performance standards before they hit the shelves. These tests assess various aspects of a product, including its materials, chemical composition, and overall durability. By passing these rigorous assessments, companies can confidently assert that their offerings align with industry regulations and consumer expectations.

Moreover, these compliance tests cover a broad spectrum of categories—from chemical and analytical tests to physical and mechanical tests—each playing a vital role in the overall Pet Product Quality Control framework. For instance, chemical testing ensures that harmful substances are absent or within safe limits, while physical testing evaluates how well a product can withstand everyday use. In essence, these regulatory measures act as a safety net for both pets and their human companions.

Key Organizations and Their Standards

Several key organizations oversee regulatory compliance in the realm of pet products, each with its own set of standards governing safety and quality control. The American Society for Testing and Materials (ASTM) is one such entity that provides comprehensive guidelines on various testing protocols relevant to pet products. Additionally, the Association of American Feed Control Officials (AAFCO) sets nutritional standards specifically for pet food items.

These organizations not only define what constitutes acceptable quality but also help educate manufacturers about best practices in product development. Compliance with their standards often translates into enhanced credibility within the marketplace—consumers tend to trust brands that prioritize safety through rigorous testing methods like performance and durability tests or chemical analyses. Ultimately, aligning with recognized bodies fosters transparency in product claims while elevating overall industry integrity.

Impact on Marketability and Safety

The impact of regulatory compliance tests on marketability cannot be overstated; consumers today are more informed than ever about what goes into their pets' products. Brands that emphasize adherence to strict safety guidelines typically enjoy higher levels of consumer trust—which translates into better sales figures over time. When potential buyers see certifications or claims backed by thorough testing protocols like physical or chemical analyses, they feel more secure in their purchasing decisions.

Furthermore, ensuring compliance doesn't just boost market appeal; it also plays an essential role in safeguarding animal welfare by minimizing risks associated with low-quality goods entering the market. Products that have undergone rigorous performance and durability tests are less likely to fail under normal usage conditions—thereby reducing the risk of accidents or health issues arising from subpar items. In this way, effective Pet Product Quality Control serves not just as a selling point but as an ethical obligation toward responsible pet ownership.

Chemical and Analytical Tests

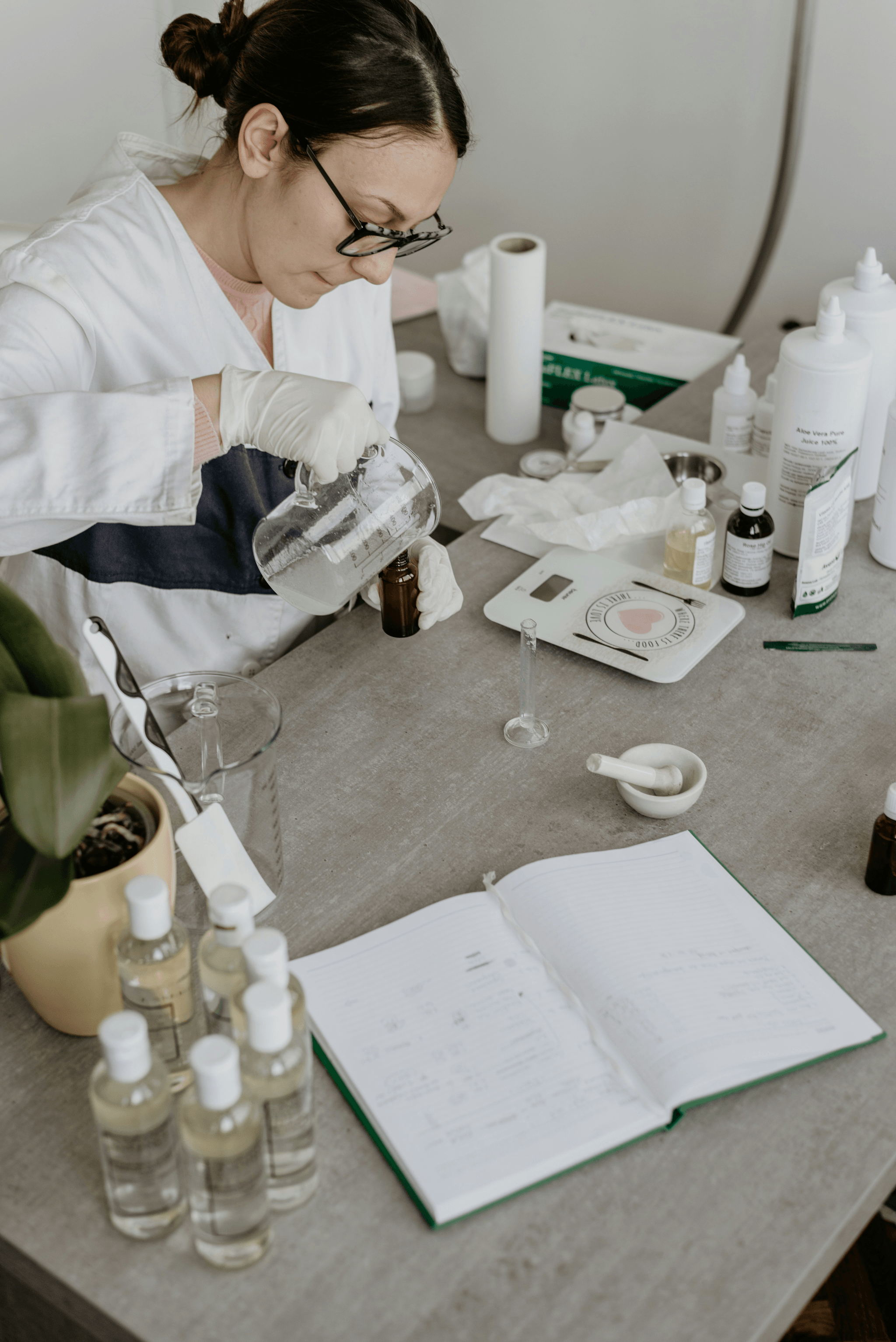

Chemical and analytical tests play a crucial role in ensuring pet product quality control. These tests identify harmful substances that could pose risks to pets, thus safeguarding their health and well-being. By adhering to regulatory compliance tests for pet products, manufacturers can assure consumers of the safety and quality of their offerings.

Why Chemical Testing is Essential

Chemical testing is essential because it helps detect potentially hazardous materials that may be present in pet products. From toys to food, various items can contain chemicals such as heavy metals or toxic additives that could harm pets if ingested or inhaled. Regulatory compliance tests for pet products often require thorough chemical analyses to ensure these items meet safety standards before they hit the shelves.

Common Chemicals Analyzed in Pet Products

In the realm of pet product quality control, several common chemicals are analyzed during testing procedures. Heavy metals like lead, cadmium, and mercury are frequently scrutinized due to their toxic effects on animals. Additionally, phthalates and bisphenol A (BPA), which can leach from plastic materials, are also monitored closely to prevent any adverse health impacts on furry companions.

Understanding Test Results and Implications

Understanding test results from chemical and analytical tests is vital for both manufacturers and consumers alike. A passing result indicates that the product meets safety standards established by regulatory bodies, while failing results can lead to recalls or reformulations—an important aspect of maintaining high standards in pet product quality control. For consumers, comprehending these results empowers them to make informed decisions about the safety of the products they choose for their pets.

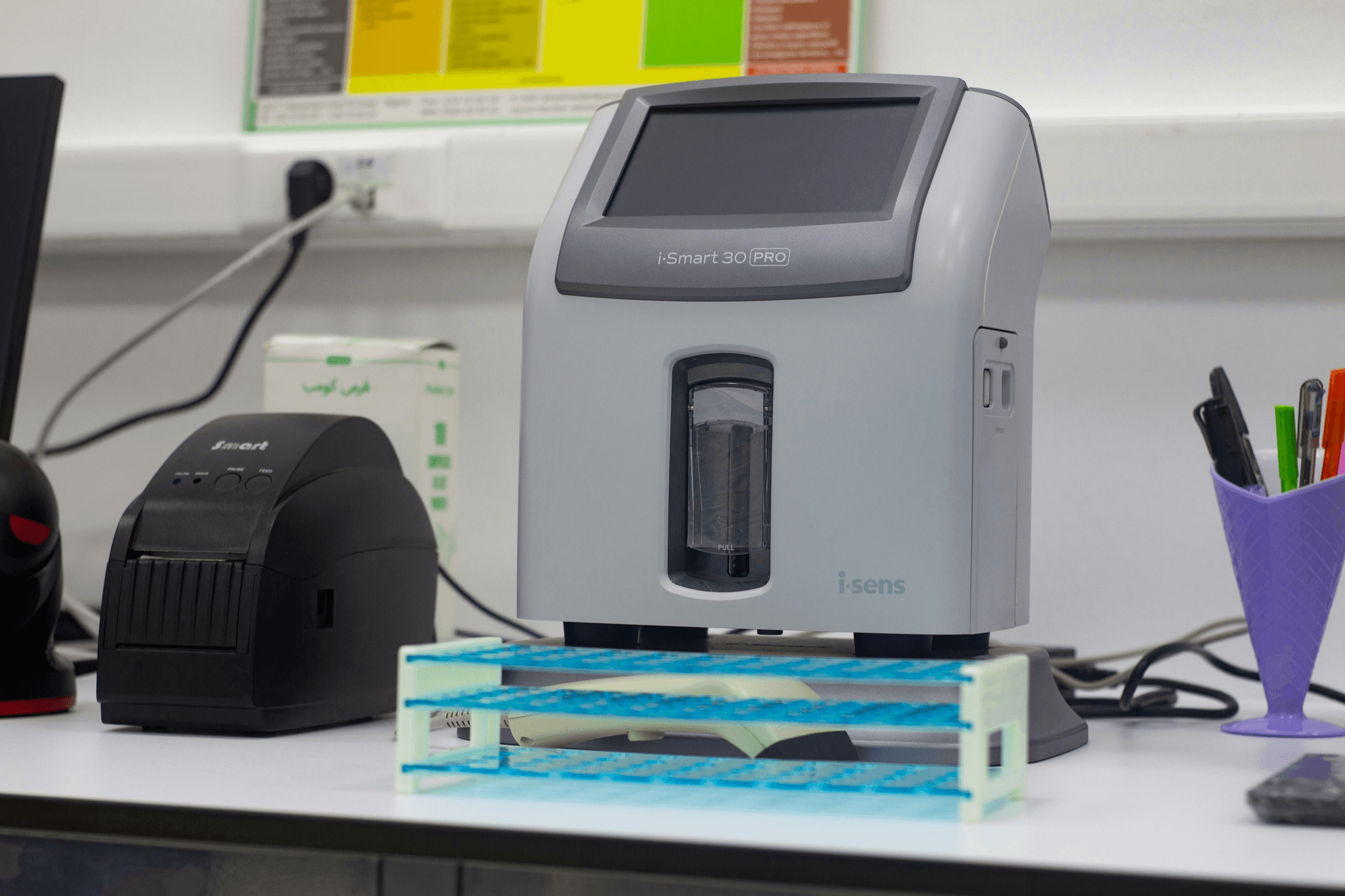

Physical and Mechanical Tests

When it comes to ensuring the safety and reliability of pet products, physical and mechanical tests play a pivotal role in Pet Product Quality Control. These tests assess the materials used in products, focusing on their durability and overall performance under various conditions. By understanding how these assessments work, manufacturers can enhance product design while meeting regulatory compliance tests for pet products.

Assessing Materials and Durability

Assessing materials is crucial for determining whether a pet product can withstand the rigors of daily use. Different materials exhibit varying levels of strength, flexibility, and resistance to wear; hence, a thorough evaluation is essential for ensuring long-lasting items that pets will love. In this context, durability testing not only safeguards pets but also aligns with industry standards set forth in regulatory compliance tests for pet products.

Common Physical Tests for Pet Products

Several common physical tests are employed to evaluate pet products effectively. These include tensile strength tests, which measure how much force a material can withstand before breaking, as well as abrasion resistance tests that determine how well a product holds up against wear over time. Such physical testing methods are integral to Pet Product Quality Control because they help identify weaknesses in design or material choice before reaching consumers.

How Testing Affects Product Design

The results from physical and mechanical tests have significant implications for product design in the pet industry. When manufacturers understand the outcomes of these assessments, they can make informed decisions about materials and construction methods that enhance durability while minimizing risks associated with failure during use. Ultimately, effective testing leads to higher quality products that meet both consumer expectations and regulatory compliance tests for pet products.

Performance and Durability Tests

When it comes to pet products, ensuring longevity is not just a nice-to-have; it's essential. Pet owners want products that can withstand the wear and tear of daily use, whether it’s a chew toy or a cozy bed. This is where performance and durability tests come into play, offering insights into how well these products hold up over time.

Ensuring Long-lasting Products

Performance and durability tests are crucial for maintaining high standards in Pet Product Quality Control. These tests assess how well a product can endure typical usage scenarios, helping manufacturers identify any weaknesses before the product hits the market. By investing in rigorous testing processes, companies not only protect their reputation but also ensure that pet owners receive reliable and safe products.

Types of Performance Tests Conducted

There are several types of performance tests conducted on pet products to verify their durability and effectiveness. Common assessments include stress testing, which evaluates how much pressure a product can handle before failing, and wear-and-tear simulations that mimic prolonged use over time. These tests often complement other quality control measures like chemical and analytical tests as well as physical and mechanical tests to provide a comprehensive view of product reliability.

Real-world Examples of Testing Outcomes

Real-world examples highlight the importance of thorough performance testing in ensuring pet safety and satisfaction. For instance, a popular brand of dog toys underwent extensive durability testing after reports surfaced about some toys breaking too easily during playtime; this led to design modifications that improved their lifespan significantly. Similarly, cat furniture that failed initial stress tests was redesigned for better stability, resulting in fewer customer complaints and higher sales—proof that investing in performance testing pays off.

Conclusion

In a world overflowing with options, the importance of choosing quality pet products cannot be overstated. Pet Product Quality Control is not just a buzzword; it’s a fundamental aspect that ensures our furry friends are safe and healthy. By investing in high-quality items, pet owners can rest easy knowing they’re providing the best for their companions.

The Importance of Choosing Quality Products

Selecting quality pet products goes beyond aesthetics; it directly impacts the well-being of pets. When products undergo rigorous Regulatory compliance tests for pet products, they meet essential safety standards that protect against harmful materials and design flaws. This level of diligence helps prevent accidents and health issues, making informed choices crucial for every pet owner.

Understanding Testing and Compliance Benefits

Testing and compliance benefits extend to both consumers and manufacturers alike. For consumers, knowing that a product has passed Chemical and analytical tests means they’re less likely to encounter harmful substances in their pets’ toys or food. Manufacturers who adhere to Physical and mechanical tests not only ensure durability but also enhance their reputation in an increasingly competitive market.

How China Inspection Pro Elevates Standards

China Inspection Pro plays a pivotal role in elevating standards within the pet product industry by enforcing stringent testing protocols across various categories, including Performance and durability tests. Their commitment to Pet Product Quality Control ensures that products are not only compliant but also reliable over time—something every responsible pet owner seeks. By partnering with organizations like China Inspection Pro, businesses can confidently market their products while ensuring the safety and satisfaction of pets everywhere.