Introduction

In the world of textiles and consumer goods, soft goods inspection plays a crucial role in ensuring that products meet the highest standards of quality and control. Quality management in this sector is not just a trend; it's a necessity that safeguards both manufacturers and consumers alike. By understanding the intricacies of quality control processes, businesses can foster trust and reliability in their offerings.

Understanding Soft Goods Quality Control

Soft goods encompass a broad range of products made from flexible materials, including clothing, upholstery, and home textiles. The quality control measures applied to these items are vital for maintaining brand integrity and customer satisfaction. Effective quality inspection ensures that every product not only meets regulatory standards but also aligns with consumer expectations for durability, safety, and aesthetic appeal.

The Importance of Quality Inspection

Quality inspection serves as the backbone of any successful production process in the soft goods industry. It identifies potential defects early on, thereby reducing waste and minimizing costly recalls or reworks down the line. By investing in thorough inspection services, companies can enhance their reputation while ensuring that they deliver products that resonate with quality-conscious consumers.

Key Players in Quality Management

Quality management involves various stakeholders including manufacturers, third-party inspectors, and certification bodies who collaborate to uphold high standards throughout the supply chain. Each player has a distinct role; manufacturers focus on production efficiency while inspectors concentrate on rigorous testing protocols to ensure compliance with established guidelines. This collaborative effort is essential for achieving excellence in soft goods inspection and maintaining robust quality control systems across all levels of production.

What Are Soft Goods?

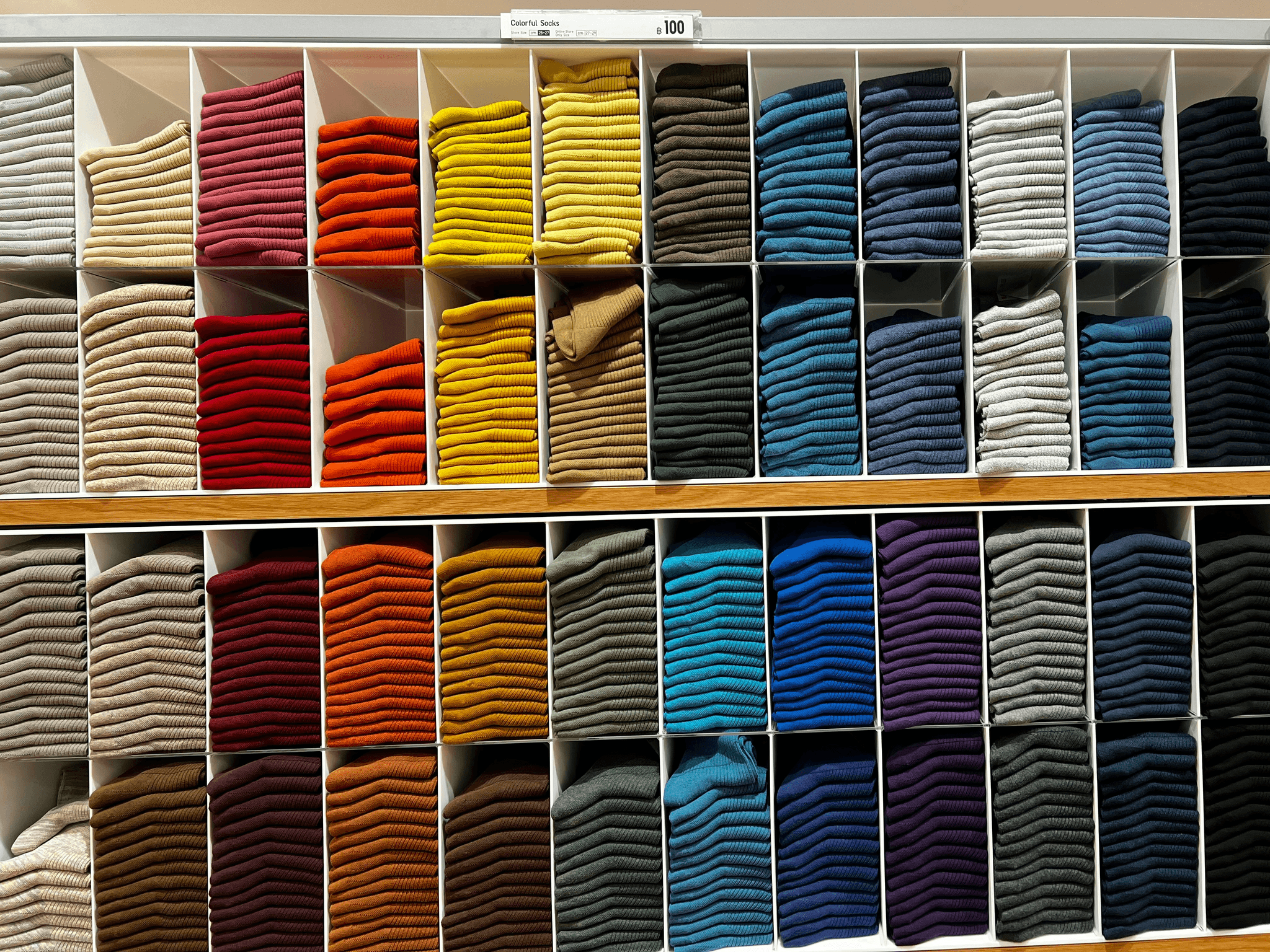

When we talk about soft goods, we're diving into a fascinating world of textiles and materials that are not only functional but also fashionable. Soft goods encompass a wide range of products made from flexible materials, typically textiles, and can include items like clothing, linens, upholstery, and even bags. These products play a crucial role in various industries—from fashion to home decor—making their quality control an essential aspect of the supply chain.

Definition and Examples

Soft goods are primarily defined by their material composition—soft fabrics or flexible materials that can be easily manipulated or shaped. Examples include garments like shirts and dresses, household items such as curtains and towels, and accessories like handbags or backpacks. Understanding these definitions is vital for effective quality management because it helps identify the specific quality control measures needed for each type of product.

The Role of Soft Goods in Supply Chains

In the grand scheme of supply chains, soft goods are pivotal players that connect manufacturers to consumers through various channels. They contribute significantly to economic activity by driving demand in retail sectors while also influencing logistics and inventory management practices. Effective soft goods inspection is necessary to ensure that these products meet consumer expectations for both quality and durability.

Importance of Quality in Soft Goods

Quality in soft goods isn't just a nice-to-have; it's a must-have that directly impacts customer satisfaction and brand reputation. Poor quality can lead to returns, negative reviews, and ultimately loss of business—making robust quality inspection processes vital for manufacturers. By prioritizing quality control throughout the production process, companies can enhance their reputation while ensuring long-term success through repeat customers who trust their brand.

The Soft Goods Inspection Process

When it comes to ensuring the quality and control of soft goods, a systematic inspection process is essential. Soft goods inspection not only assesses the physical attributes of products but also verifies adherence to industry standards and customer expectations. This structured approach helps in identifying defects early, thus minimizing costs associated with returns and rework.

Steps in Quality Inspection

The quality inspection process for soft goods typically follows several key steps that ensure thorough evaluation. First, pre-production inspections are conducted to review samples before mass production begins, allowing for adjustments based on initial findings. Next comes the in-line inspection during production, where inspectors monitor ongoing processes to catch any deviations from quality standards before they escalate into larger issues.

Finally, the post-production inspection wraps up the process by examining finished products for compliance with specifications. This step is crucial as it provides a final check before items are shipped out into the market, safeguarding against potential customer dissatisfaction. Each of these steps plays a vital role in effective quality management by ensuring that only products meeting high-quality standards reach consumers.

Common Inspection Services Used

In the realm of soft goods inspection, various services are employed to uphold quality control throughout the supply chain. Visual inspections are among the most common methods used; they allow inspectors to quickly assess fabric integrity, stitching accuracy, and overall appearance without complex equipment. Other popular services include functional testing—where items like zippers or buttons are tested for durability—and dimensional checks that confirm products meet specified measurements.

Moreover, laboratory testing can be utilized for more intricate assessments such as colorfastness or material composition analysis. These diverse inspection services work together to create a comprehensive quality management strategy that addresses different aspects of soft goods production efficiently and effectively. By employing a range of techniques tailored to specific needs, companies can ensure their products not only look good but also perform well over time.

Identifying Quality Issues During Inspections

Identifying quality issues during inspections is crucial for maintaining high standards in soft goods production and can often be a daunting task without proper training and resources. Inspectors must be vigilant in spotting inconsistencies—whether it's an uneven seam or incorrect fabric weight—that could affect product performance or customer satisfaction later on. Effective communication between inspectors and manufacturers is key; discussing potential concerns promptly can lead to swift resolutions before problems escalate.

Furthermore, leveraging technology during inspections can enhance accuracy and speed up issue identification significantly; digital tools help track defects systematically while providing real-time data analytics for better decision-making in quality management processes. By diligently identifying these issues early on through comprehensive inspection services, companies can uphold their reputation while delivering high-quality products consistently across their offerings.

Quality Control Standards for Soft Goods

In the realm of soft goods, quality control standards play a pivotal role in ensuring that products meet both consumer expectations and regulatory requirements. These standards are designed to safeguard the integrity of soft goods throughout the supply chain, from production to delivery. A robust understanding of these regulations is essential for manufacturers and retailers alike, as it directly influences quality management practices.

Overview of Industry Regulations

The landscape of industry regulations surrounding soft goods is vast and varied, encompassing everything from safety to environmental considerations. Regulatory bodies set forth guidelines that manufacturers must adhere to in order to ensure that their products are safe for consumer use and environmentally sustainable. Compliance with these regulations not only enhances product quality but also builds consumer trust, reinforcing the importance of effective quality inspection in the soft goods sector.

ISO Certification and Its Importance

ISO certification stands as a hallmark of quality assurance in many industries, including soft goods. Achieving ISO certification signifies that a company adheres to internationally recognized standards for quality management systems, which can dramatically enhance its reputation and operational efficiency. For businesses involved in soft goods inspection, obtaining this certification is not just about compliance; it’s a strategic move that can lead to improved product consistency and customer satisfaction.

How Standards Impact Quality and Control

Quality control standards have a profound impact on both product quality and overall management processes within organizations dealing with soft goods. By establishing clear benchmarks for performance, these standards help organizations identify areas needing improvement while fostering a culture focused on continuous enhancement. Furthermore, adherence to established guidelines ensures that inspection services are conducted systematically, minimizing risks associated with defects or non-compliance.

Challenges in Quality Management

Quality management in the realm of soft goods is a multifaceted endeavor, riddled with challenges that can significantly impact the overall quality and control of products. From inconsistent standards to communication gaps across global teams, these hurdles necessitate strategic approaches to ensure effective quality inspection and management. Addressing these challenges is crucial not only for maintaining product integrity but also for enhancing customer satisfaction and brand reputation.

Common Challenges in Soft Goods Quality Control

One prevalent challenge in soft goods inspection is the variability in quality standards across different manufacturers and regions. This inconsistency can lead to significant discrepancies in product quality, making it difficult for companies to enforce uniform quality control measures. Additionally, the complexity of materials used in soft goods—ranging from textiles to synthetic fibers—adds another layer of difficulty when implementing effective quality management practices.

Another issue often faced during inspections is human error, which can compromise the reliability of quality control processes. Inspectors may overlook defects or misinterpret guidelines due to fatigue or lack of training, ultimately affecting the overall effectiveness of quality inspection services. Furthermore, rapid production cycles can result in time constraints that hinder thorough inspections, leading to potential lapses in quality assurance.

Lastly, communication barriers between teams involved in production and inspection can exacerbate existing challenges. Misunderstandings regarding specifications or expectations may cause delays or errors during the manufacturing process, impacting the final product's quality and control. To mitigate these challenges effectively, companies must prioritize clear communication channels and ongoing training for all stakeholders involved.

The Impact of Global Supply Chains

The rise of global supply chains has transformed how soft goods are produced and distributed but has also introduced new complexities into quality management practices. With suppliers located worldwide, ensuring consistent adherence to established quality standards becomes increasingly difficult amidst diverse regulatory environments and cultural differences. This geographical spread complicates oversight efforts during soft goods inspection processes as companies struggle to maintain uniformity across various locations.

Moreover, logistical challenges associated with global supply chains can lead to delays that affect timely inspections and subsequent product launches. A delay at one point in the supply chain can cascade through various stages—ultimately compromising both product timelines and overall quality control measures implemented by organizations. As a result, businesses must remain vigilant about managing relationships with suppliers while simultaneously enforcing stringent inspection protocols.

Additionally, fluctuations in demand often lead companies to rely on multiple suppliers for their soft goods needs—further complicating efforts toward maintaining consistent product standards across diverse sources. Each supplier may have unique processes or materials that affect final output; thus establishing a cohesive approach toward quality management becomes paramount for success within this landscape.

Strategies to Overcome Quality Management Issues

To tackle common issues encountered during soft goods inspections effectively, organizations should consider adopting standardized protocols tailored specifically for their industry requirements. Implementing comprehensive training programs ensures that all personnel involved are well-versed on best practices related to both production techniques as well as effective inspection services aimed at identifying potential defects early on within processes—thereby enhancing overall efficiency throughout operations.

Leveraging technology plays a pivotal role when addressing challenges associated with global supply chains too; utilizing automation tools such as AI-driven analytics allows businesses greater visibility into various aspects surrounding their operations while facilitating real-time data sharing among teams located worldwide! This increased transparency enables quicker decision-making regarding necessary adjustments needed within production lines based upon insights gleaned from ongoing assessments conducted via automated systems designed explicitly around maintaining high levels of consistency throughout all phases related back towards achieving optimal outcomes concerning both performance metrics & customer satisfaction levels alike!

Lastly—but certainly not least—fostering strong partnerships with trusted third-party inspectors who specialize specifically within this domain proves invaluable! By collaborating closely alongside experts like China Inspection Pro who possess extensive knowledge about navigating complexities inherent within international markets while ensuring compliance remains upheld across every facet linked directly back towards delivering exceptional results consistently over time—it’s possible not only meet but exceed expectations surrounding desired outcomes when it comes down ultimately achieving superior levels pertaining directly towards desired goals revolving around enhanced overall perceptions tied closely together involving both brand loyalty & continued growth opportunities moving forward!

The Role of Technology in Quality Inspection

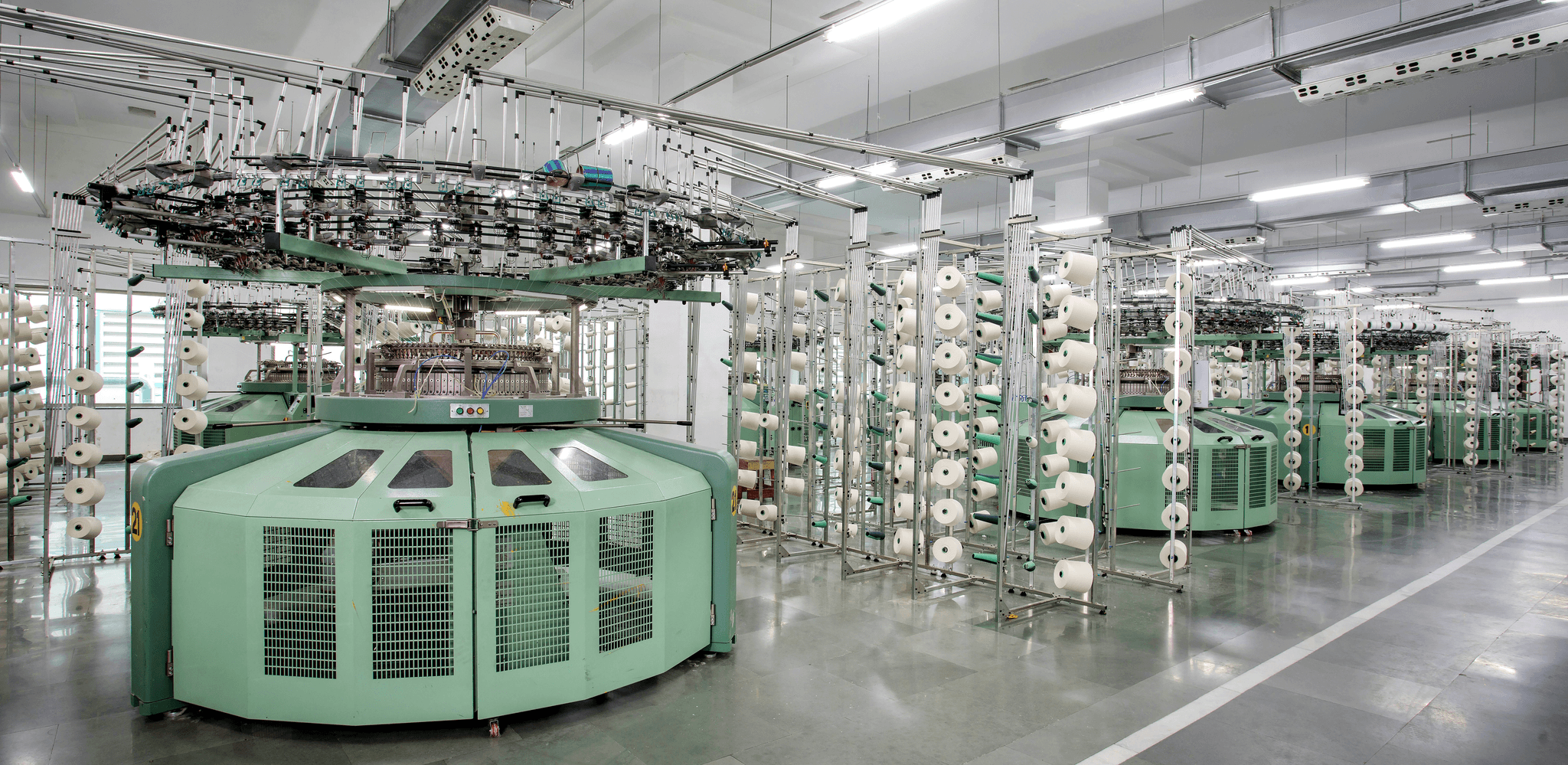

In today's fast-paced manufacturing environment, technology plays a pivotal role in enhancing the quality inspection process for soft goods. Innovations in inspection services are transforming how companies approach quality management, ensuring that products meet the highest standards before reaching consumers. With advancements such as AI and machine learning, businesses can now conduct more thorough and efficient soft goods inspections than ever before.

Innovations in Inspection Services

The landscape of soft goods inspection is continuously evolving, with new technologies emerging to streamline quality control processes. For instance, the use of digital tools like 3D scanning and image recognition software allows for real-time analysis of products during inspections. These innovations not only enhance accuracy but also reduce the time spent on manual inspections, leading to improved quality and control throughout the supply chain.

Moreover, mobile applications have made it easier for inspectors to document findings instantly and share them with relevant stakeholders. This immediate feedback loop fosters a culture of continuous improvement within organizations dedicated to maintaining high standards in quality management. Ultimately, these innovations help businesses stay competitive by ensuring that their soft goods consistently meet or exceed customer expectations.

The Benefits of Automation in Quality Control

Automation has revolutionized quality control by significantly reducing human error and increasing efficiency during the inspection process for soft goods. Automated systems can perform repetitive tasks at a speed and accuracy that far surpasses manual methods, allowing inspectors to focus on more complex evaluations that require human judgment. By integrating automation into their quality management strategies, companies can achieve higher levels of consistency in their product offerings.

Additionally, automated inspection services provide valuable data analytics that help organizations identify trends and potential issues before they escalate into larger problems. This proactive approach not only saves time but also reduces costs associated with rework or returns due to defective products. As businesses increasingly embrace automation in their quality assurance processes, they gain a competitive edge by delivering superior products while minimizing risks associated with poor quality.

Case Studies of Successful Technology Implementation

Several companies have successfully integrated technology into their soft goods inspection processes with remarkable results. For example, a leading apparel manufacturer adopted an AI-driven visual inspection system that reduced defect rates by over 30% within just six months of implementation. By leveraging machine learning algorithms capable of identifying inconsistencies more accurately than traditional methods, this company was able to enhance its overall quality management framework significantly.

Another notable case involves a home textiles company that utilized automated testing equipment for fabric durability assessments during production runs. This investment not only improved product reliability but also expedited time-to-market without compromising on quality control standards. These case studies illustrate how embracing technology can lead to substantial improvements in soft goods inspections while reinforcing commitment to excellence in quality management.

Conclusion

In wrapping up our exploration of soft goods quality control, it's clear that the landscape is both complex and critical. Quality management in this sector hinges on meticulous quality inspection processes that ensure products meet industry standards and consumer expectations. As we look toward the future, understanding the role of technology and expert partnerships will be essential for maintaining high-quality standards.

Key Takeaways in Soft Goods Quality Control

The journey through soft goods inspection reveals several key takeaways. First, a robust quality control system is vital to identify potential issues before they escalate into larger problems, ensuring that products are both safe and reliable. Additionally, the integration of technology into quality management practices can streamline inspection services and enhance overall efficiency.

Furthermore, collaboration with experienced partners can provide invaluable insights into best practices for quality and control. By prioritizing these elements, businesses can navigate the challenges inherent in soft goods production while safeguarding their brand reputation. Ultimately, a commitment to excellence in quality inspection fosters customer loyalty and drives long-term success.

The Future Outlook for Quality Management

Looking ahead, the future of quality management in soft goods appears promising yet challenging. As global supply chains evolve, companies must adapt their quality control strategies to address new risks associated with international sourcing and manufacturing. Innovations in technology will play a pivotal role in shaping how businesses approach quality and control moving forward.

Moreover, as consumer awareness grows regarding product safety and environmental impacts, there will be an increasing demand for transparency in quality inspections. This trend underscores the importance of maintaining rigorous standards to meet customer expectations while navigating regulatory requirements effectively. The integration of sustainable practices alongside traditional quality management approaches will likely become a defining characteristic of successful companies.

Partnering with Experts like China Inspection Pro

To thrive in this dynamic environment, partnering with experts like China Inspection Pro is crucial for effective soft goods inspection. Their extensive experience provides invaluable support through tailored inspection services designed to meet specific industry needs while ensuring compliance with international standards. By leveraging their expertise in quality management, businesses can significantly reduce risks associated with product defects or non-compliance.

Additionally, collaboration with seasoned professionals allows companies to stay ahead of emerging trends and technologies within the realm of quality control. This partnership not only enhances operational efficiency but also fosters innovation by integrating best practices from around the globe into local processes. In an increasingly competitive market landscape, aligning with experts ensures that your business remains committed to delivering high-quality products consistently.