Introduction

In the fast-paced world of manufacturing, on-site quality control has emerged as a critical component in ensuring products meet established standards. This proactive approach not only enhances product reliability but also fosters consumer trust, which is paramount in today’s competitive market. By implementing effective quality control measures, manufacturers can define quality and uphold their commitment to excellence.

The Importance of On-Site Quality Control

On-site quality control serves as the frontline defense against defects and inconsistencies in production processes. By integrating rigorous quality management systems within the manufacturing environment, companies can swiftly identify issues before they escalate into costly problems. This focus on immediate oversight not only streamlines operations but also reinforces a culture of accountability among employees.

How Quality Affects Consumer Trust

The relationship between product quality and consumer trust cannot be overstated; when customers feel confident in a brand's commitment to excellence, they are more likely to remain loyal. Consistent adherence to established standards processes ensures that consumers receive dependable products, which builds long-term relationships based on reliability and satisfaction. Ultimately, investing in robust quality control practices translates into enhanced brand reputation and repeat business.

The Role of Standards in Manufacturing

Standards play a pivotal role in defining quality within the manufacturing landscape by providing benchmarks for performance and safety. By adhering to these standards, manufacturers not only improve their operational efficiency but also enhance their credibility with consumers who demand high-quality products. Establishing clear guidelines helps organizations maintain consistency across all levels of production while fostering innovation through continuous improvement efforts.

Understanding On-Site Quality Control

In the fast-paced world of manufacturing, on-site quality control is essential to ensure that products meet established standards and consumer expectations. Quality control serves as a systematic process to define quality throughout the production stages, aiming to catch defects before they reach customers. By implementing effective quality management systems, manufacturers can enhance their efficiency and reliability, ultimately leading to greater customer satisfaction.

Defining Quality Control in Manufacturing

To define quality control in manufacturing, we must recognize it as a set of practices designed to monitor and maintain product standards throughout the production process. This involves establishing benchmarks against which products are measured, ensuring that every item produced aligns with predetermined specifications. On-site quality control is crucial for identifying deviations and implementing corrective actions promptly, thus safeguarding the integrity of the final product.

Key Principles of Quality Control

The key principles of quality control revolve around consistency, measurement, and continuous improvement. First and foremost, consistency ensures that every product adheres to established standards; this is where effective manufacturing practices play a pivotal role. Measurement involves using specific metrics to evaluate performance against these standards; regular assessments help identify areas for improvement within the management system. Lastly, continuous improvement fosters an environment where feedback loops lead to enhanced processes over time.

Benefits of Implementing Quality Control

Implementing robust quality control measures brings numerous benefits that ripple through an organization’s operations. For starters, it significantly reduces waste by minimizing defects and rework—this not only saves costs but also enhances productivity across manufacturing practices. Moreover, maintaining high-quality standards builds trust with consumers; when customers know they can rely on a brand for consistent excellence, brand loyalty often follows suit.

Best Practices in Quality Control

In the ever-evolving world of manufacturing, on-site quality control stands as a pillar of excellence. Implementing best practices ensures that products meet the highest standards and instills confidence in consumers. By focusing on essential manufacturing practices, intelligent automation, and continuous improvement, organizations can elevate their quality control processes to new heights.

Essential Manufacturing Practices for Quality

To define quality in manufacturing, it's crucial to establish essential practices that serve as the foundation for effective quality control. These practices include rigorous inspections at every stage of production, adherence to standardized processes, and fostering a culture of accountability among workers. By integrating these manufacturing practices into daily operations, companies can significantly reduce defects and enhance overall product reliability.

Moreover, developing a robust management system that emphasizes communication and collaboration across departments is vital for successful quality control. This approach not only streamlines workflows but also encourages proactive problem-solving when issues arise. Ultimately, prioritizing these essential practices leads to improved efficiency and customer satisfaction.

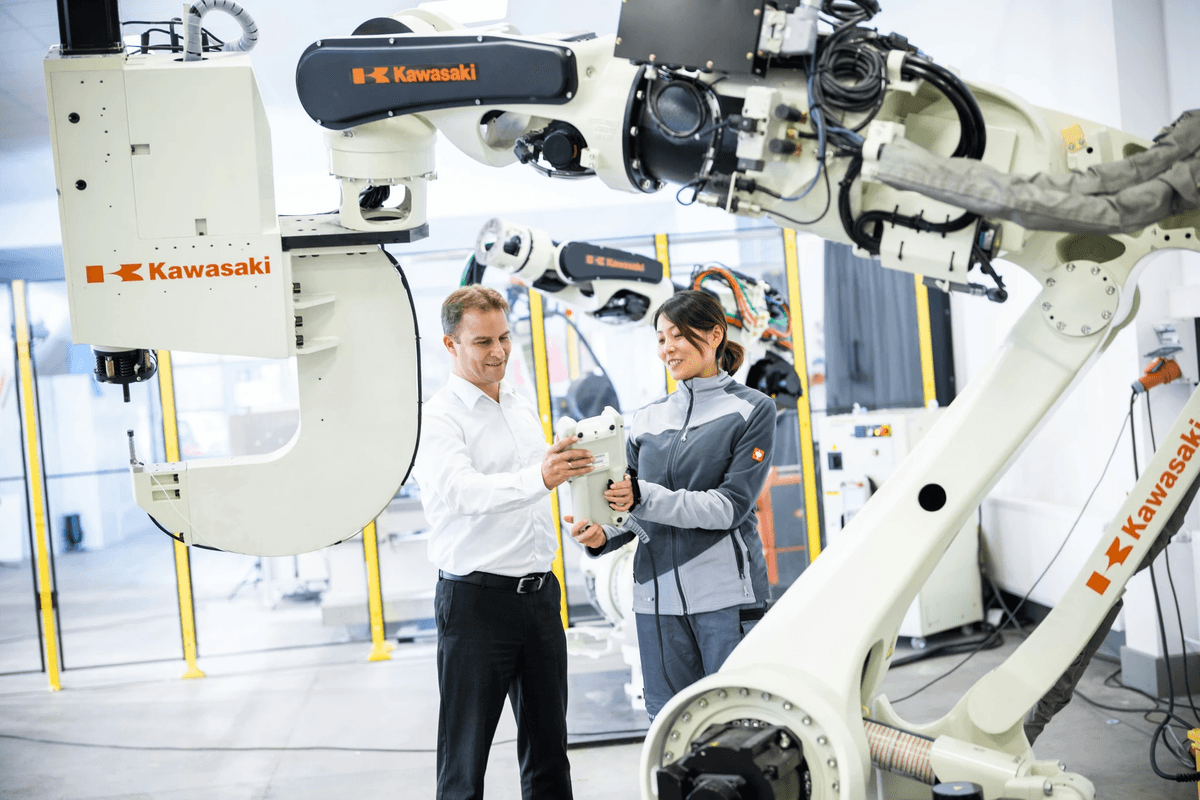

Intelligent Automation in Quality Management

Intelligent automation has revolutionized the way manufacturers approach quality management by incorporating advanced technologies into their on-site quality control processes. Utilizing data analytics and machine learning algorithms allows companies to identify patterns in production data that may indicate potential quality issues before they escalate. This proactive stance enables organizations to maintain high-quality standards while minimizing waste and operational costs.

Furthermore, automated inspection systems can quickly assess product conformity against predefined specifications with remarkable accuracy—far surpassing human capabilities in speed and precision. By embracing intelligent automation within their quality control framework, manufacturers can ensure consistent adherence to standards while freeing up personnel for more strategic tasks that require human insight.

Continuous Improvement in Quality Standards

The journey towards excellence in on-site quality control is never truly complete; it requires an unwavering commitment to continuous improvement of quality standards. Organizations should regularly review their existing processes and gather feedback from employees at all levels to identify areas ripe for enhancement. By fostering an environment where innovation is encouraged, companies can adapt swiftly to changing market demands while elevating their overall performance.

Implementing methodologies like Six Sigma or Lean Manufacturing can help streamline operations by systematically eliminating waste while focusing on delivering value to customers through superior products. Additionally, ongoing training programs ensure employees are equipped with the latest skills necessary for maintaining high-quality outputs consistently. In this way, continuous improvement becomes ingrained within the organizational culture—leading not only to better products but also heightened brand loyalty among consumers.

Real-World Applications of Quality Control

In the realm of manufacturing, real-world applications of quality control reveal the tangible benefits that on-site quality control can offer. Companies like Toyota, Apple, and Boeing have set exemplary standards in their respective industries by implementing robust management systems that prioritize quality at every stage. By examining these industry giants, we can glean insights into effective manufacturing practices that enhance product reliability and maintain consumer trust.

Case Study: Toyota’s Quality Control Approach

Toyota's approach to quality control is often lauded as a benchmark for excellence in the automotive industry. The company employs a rigorous on-site quality control system known as Toyota Production System (TPS), which defines quality not just as a final product attribute but as an integral part of every manufacturing process. This management system emphasizes continuous improvement (kaizen) and empowers workers to halt production if they identify any issues, ensuring that standards are met consistently.

The results speak for themselves; Toyota has built a reputation for reliability and durability in its vehicles, which directly correlates with consumer trust. By embedding quality control deeply into its culture, Toyota demonstrates how effective manufacturing practices can lead to long-term success and brand loyalty. Their commitment to quality serves as a powerful reminder that investing in a solid standards process pays dividends.

Insights from Apple’s Manufacturing Standards

Apple's manufacturing standards are another prime example of how on-site quality control can drive excellence in product development. The tech giant employs stringent quality control measures throughout its supply chain to ensure that every component meets its high expectations before assembly begins. This proactive approach not only defines quality but also enhances the overall user experience by minimizing defects and maximizing performance.

Apple's focus on meticulous attention to detail is evident in its products' design and functionality, reinforcing consumer confidence in the brand's offerings. By leveraging innovative technologies alongside traditional manufacturing practices, Apple continues to set new benchmarks for what it means to produce high-quality electronics consistently. Their ability to transform findings from inspections into actionable recommendations exemplifies how effective management systems can elevate product reliability.

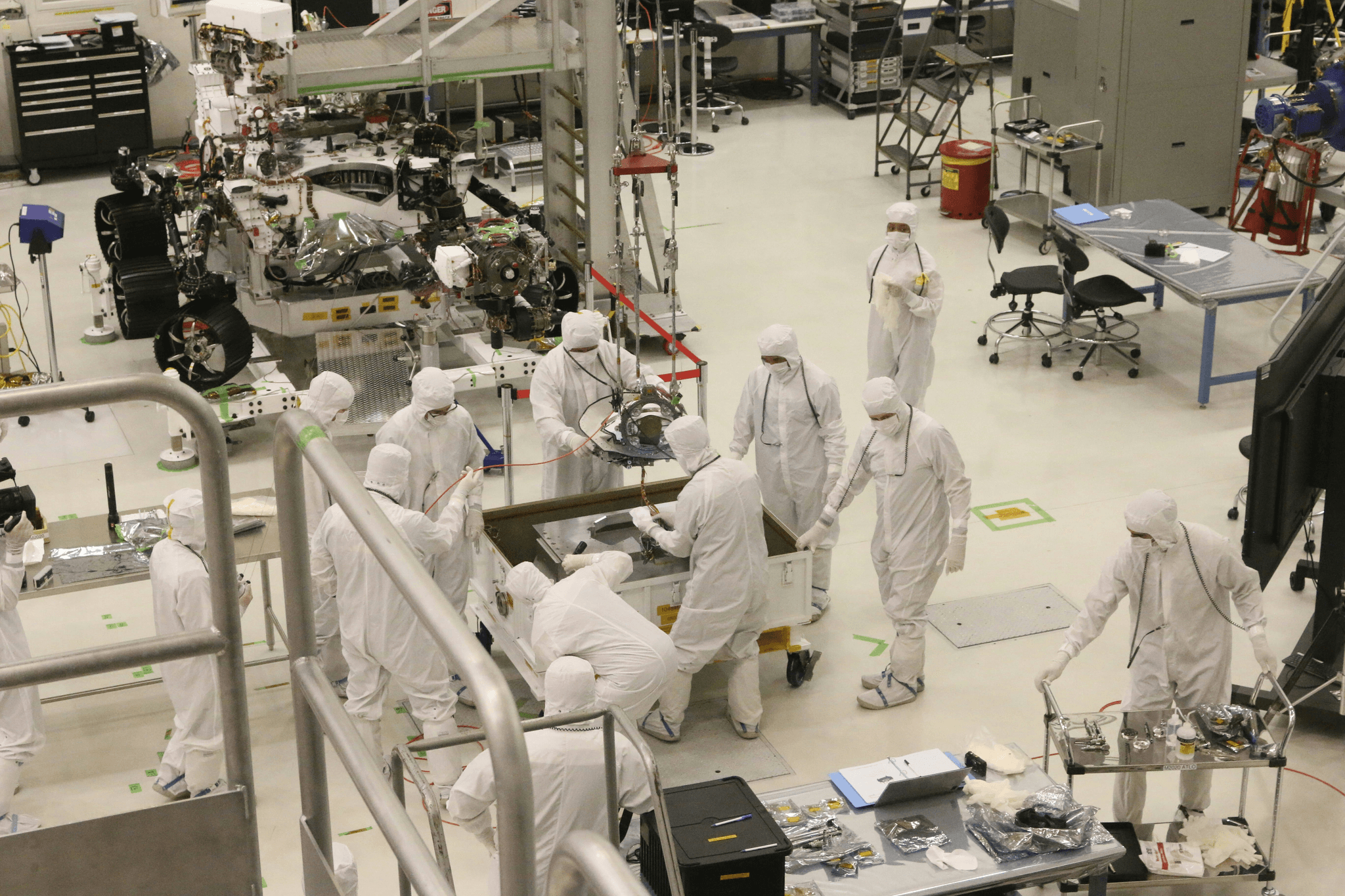

How Boeing Ensures Quality in Aircraft Production

Boeing operates under one of the most complex and regulated environments when it comes to ensuring safety and reliability in aircraft production; thus, their on-site quality control measures are nothing short of critical. The company has developed an extensive set of standards processes designed specifically for aerospace manufacturing—a sector where even minor defects can have catastrophic consequences. By employing advanced technology alongside rigorous training programs for employees, Boeing defines quality through precision engineering and strict adherence to safety protocols.

Moreover, Boeing’s commitment to continuous improvement ensures that their aircraft not only meet but exceed industry expectations over time—keeping passenger safety at the forefront while enhancing operational efficiency. Their systematic approach illustrates how integrating robust management systems within an organization fosters an environment where innovation thrives without compromising on safety or reliability. Ultimately, Boeing’s focus on comprehensive quality control reinforces consumer trust across global markets.

The Impact of On-Site Quality Control on Reliability

In today's competitive market, on-site quality control plays a pivotal role in establishing product reliability and consumer trust. By implementing effective manufacturing practices that prioritize quality control, companies can ensure their products meet or exceed customer expectations. This commitment to quality not only enhances brand reputation but also fosters long-term loyalty among consumers.

Building Consumer Confidence Through Quality

When consumers know that a company adheres to stringent on-site quality control standards, their confidence in the product increases significantly. This assurance stems from the understanding that the company has invested in a robust management system designed to define quality at every stage of production. As a result, customers are more likely to choose brands that prioritize quality over those that do not, leading to increased sales and market share.

Moreover, consumer confidence is directly linked to perceived value; when products are consistently reliable due to effective quality control measures, customers feel they are receiving their money's worth. This perception encourages repeat business and positive word-of-mouth referrals, which are invaluable for any brand's growth strategy. Ultimately, building consumer confidence through rigorous quality control translates into sustained profitability and success.

The Cost of Poor Quality in Manufacturing

The financial implications of neglecting on-site quality control can be staggering for manufacturers. Poor-quality products often lead to increased returns, warranty claims, and customer dissatisfaction—all of which contribute to a tarnished brand image. In fact, studies have shown that the cost of poor-quality manufacturing practices can exceed 20% of total production costs when factoring in lost sales and remediation efforts.

Additionally, companies may face legal repercussions stemming from defective products or safety issues if they fail to maintain proper standards throughout the manufacturing process. Investing in an effective management system focused on continuous improvement can mitigate these risks significantly by ensuring compliance with industry standards and regulations. Therefore, understanding the cost associated with poor quality is crucial for businesses aiming for long-term sustainability.

Enhancing Product Longevity with Quality Control

On-site quality control not only ensures immediate reliability but also contributes significantly to enhancing product longevity over time. By defining quality through rigorous testing and inspection processes during production, manufacturers can identify potential issues before they escalate into serious defects or failures down the line. This proactive approach ultimately leads to longer-lasting products that satisfy customers' needs.

Furthermore, integrating intelligent automation within the standards process allows manufacturers to monitor performance continuously and make necessary adjustments swiftly—keeping product longevity at the forefront of their operations. Consistently applying best practices in quality control ensures that every item produced adheres to high standards from inception through delivery stages while minimizing waste and maximizing efficiency. In this way, manufacturers not only enhance product reliability but also solidify their reputation as leaders committed to excellence.

Leveraging Professional Services for Quality Assurance

In today's competitive landscape, leveraging professional services for quality assurance is not just an option; it's a necessity. On-site quality control plays a vital role in ensuring that manufacturing practices meet stringent standards and deliver products that consumers can trust. By integrating expert services into the quality control process, companies can enhance their management system and streamline operations to achieve optimal results.

The Role of China Inspection Pro in Quality Control

China Inspection Pro stands out as a pivotal player in the realm of quality control, particularly for businesses sourcing from Asia. Their expertise helps define quality by establishing clear benchmarks that align with international standards, ensuring products are manufactured to meet both safety and performance requirements. By utilizing their services, companies can gain invaluable insights into their manufacturing practices, identifying potential issues before they escalate into costly problems.

How Quality Inspection Drives Excellence

Quality inspection is the backbone of effective on-site quality control and drives excellence across all facets of production. Through rigorous assessments, it ensures that every product adheres to established standards and specifications, mitigating risks associated with poor-quality outputs. This proactive approach not only enhances product reliability but also fosters a culture of continuous improvement within the management system.

Transforming Findings into Actionable Recommendations

The true value of professional inspection services lies in their ability to transform findings into actionable recommendations for manufacturers. After conducting thorough evaluations, experts provide tailored insights that redefine quality by pinpointing areas needing enhancement or adjustment within existing processes. This feedback loop empowers organizations to refine their manufacturing practices continually and elevate overall product reliability while adhering to best-in-class standards.

Conclusion

In the ever-evolving landscape of manufacturing, the significance of on-site quality control cannot be overstated. As companies strive to meet consumer expectations, the connection between quality and brand loyalty becomes increasingly evident. When organizations prioritize robust quality control measures, they not only enhance product reliability but also foster trust among consumers, paving the way for lasting relationships.

The Connection Between Quality and Brand Loyalty

Quality is a crucial determinant of brand loyalty in today's competitive market. Consumers are more likely to stick with brands that consistently deliver high-quality products, thanks to effective manufacturing practices and stringent standards processes. By defining quality through reliable on-site quality control mechanisms, businesses can cultivate a loyal customer base that values excellence over time.

Future Trends in On-Site Quality Control

The future of on-site quality control is poised for transformation as technology continues to advance. Intelligent automation will play a pivotal role in refining quality management systems, allowing manufacturers to detect defects earlier in the production process. Furthermore, as industries adopt data-driven decision-making, we can expect a shift towards predictive analytics that will redefine how we define quality and maintain high standards.

Final Thoughts on Elevating Product Reliability

Elevating product reliability hinges on an unwavering commitment to effective quality control practices throughout manufacturing processes. Organizations must embrace continuous improvement initiatives while leveraging professional services for comprehensive inspections that enhance their management system's effectiveness. Ultimately, prioritizing on-site quality control will not only boost consumer confidence but also solidify a brand's reputation as a leader in delivering superior products.