Introduction

In today’s competitive market, the significance of quality inspection tools cannot be overstated. These tools are the backbone of any quality assurance program, ensuring that products meet stringent standards and specifications. With advancements in technology, the range of quality inspection tools available has expanded dramatically, making it easier than ever to maintain high-quality outputs.

Importance of Quality Inspection Tools

Quality inspection tools play a crucial role in identifying defects and inconsistencies in products before they reach consumers. Utilizing these tools not only helps in maintaining product integrity but also builds trust with customers who expect nothing less than excellence. In an era where customer satisfaction is paramount, investing in quality inspection tools is essential for any business aiming for long-term success.

How Tools Enhance Quality Assurance

The integration of quality inspection tools into manufacturing processes enhances overall efficiency and accuracy in quality assurance practices. Tools like Digital Calipers and Hardness Testers provide precise measurements that help identify potential issues early on, reducing waste and rework costs. Furthermore, efficient inspection software streamlines data collection and analysis, allowing teams to make informed decisions based on real-time insights.

Overview of Essential Tools

Among the essential quality inspection tools are Digital Calipers for precision measurement, Hardness Testers for evaluating material durability, and Spectrophotometers for color consistency analysis. Additionally, leveraging efficient inspection software can transform how businesses approach quality control by automating processes and improving data accuracy. Finally, customer feedback analysis tools serve as a vital link between product performance and consumer expectations, driving continuous improvement initiatives.

Understanding Digital Calipers

Digital calipers are essential quality inspection tools that provide precise measurements, ensuring that components meet specified tolerances. Their accuracy is crucial in various industries, from manufacturing to engineering, where even the slightest deviation can lead to significant issues. By employing digital calipers, quality assurance teams can enhance their measurement processes and maintain high standards of quality.

Precision Measurement in Quality Control

In the realm of quality control, precision is paramount, and digital calipers excel at delivering just that. These instruments measure internal and external dimensions with remarkable accuracy, often down to a thousandth of an inch or millimeter. This level of precision not only aids in maintaining product integrity but also minimizes costly errors during production.

Digital calipers come equipped with features like automatic shut-off and data output capabilities, further streamlining the measurement process. This efficiency allows teams to focus on analysis rather than manual data recording, making them indispensable among quality inspection tools. Ultimately, the precision offered by digital calipers directly contributes to improved overall product quality.

Leading Brands: Mitutoyo and Starrett

When it comes to digital calipers, two brands consistently rise above the rest: Mitutoyo and Starrett. Known for their durability and accuracy, these brands are trusted by professionals across various fields for their reliability in critical measurements. Mitutoyo offers a wide range of models tailored for different applications while maintaining exceptional build quality; Starrett is celebrated for its user-friendly designs and innovative features.

Both brands have made significant contributions to the development of digital measuring tools that cater specifically to quality assurance needs. Their products often incorporate advanced technology such as Bluetooth connectivity for seamless data transfer into efficient inspection software systems. Choosing either Mitutoyo or Starrett ensures that users have access to top-notch precision measurement instruments essential for effective quality inspections.

Practical Applications for Quality Inspections

Digital calipers find numerous practical applications within the field of quality inspections across diverse industries such as automotive, aerospace, and manufacturing. They are instrumental in verifying component dimensions during initial inspections as well as throughout production processes—ensuring parts fit together correctly before assembly occurs. Additionally, they help assess wear on components over time by measuring changes in size or shape.

Moreover, these versatile tools can be used alongside hardness testers or spectrophotometers when conducting comprehensive evaluations on materials or coatings—enhancing overall product assessments significantly. The integration of digital calipers with efficient inspection software further amplifies their utility by enabling real-time data analysis and reporting capabilities within organizations focused on continuous improvement through customer feedback analysis tools.

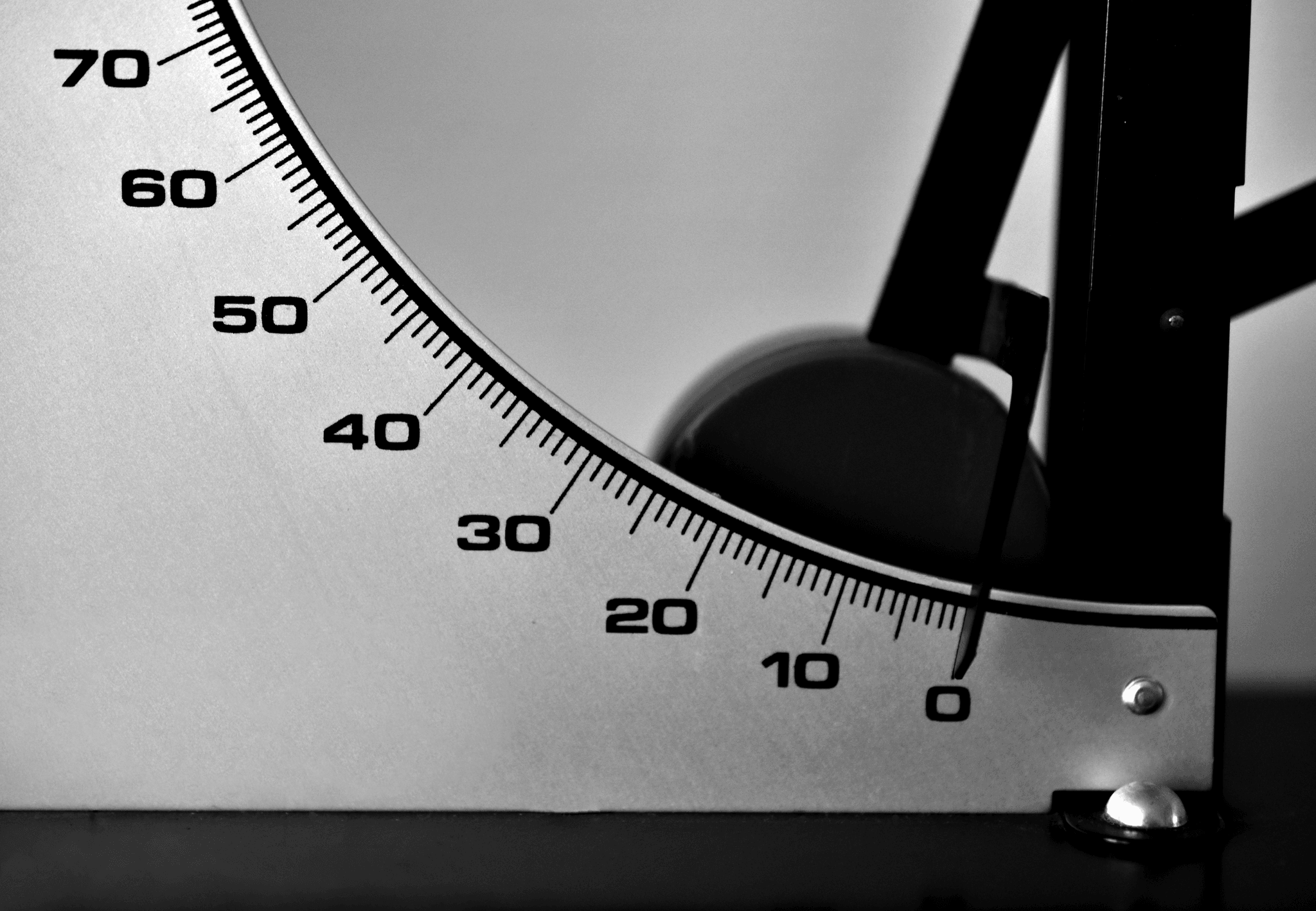

The Role of Hardness Testers

Hardness testers are indispensable quality inspection tools that measure the resistance of materials to deformation, providing critical data for quality assurance. Understanding how hard a material is can influence decisions in manufacturing processes, product design, and overall product durability. By ensuring that materials meet specified hardness levels, businesses can maintain high standards and reduce the risk of product failure.

Measuring Material Hardness Accurately

Accurate measurement of material hardness is essential for assessing the suitability of various substances in different applications. Hardness testers evaluate materials using established scales, allowing engineers and quality inspectors to determine if they meet required specifications. With precision being key in quality inspection tools, the ability to measure hardness accurately can significantly impact product performance and longevity.

Popular Models: Rockwell and Shore Hardness Testers

Among the most recognized hardness testers are the Rockwell and Shore models, each designed for specific types of materials. Rockwell testers are widely used for metals and plastics, offering quick results through a straightforward testing process. On the other hand, Shore hardness testers cater primarily to softer materials like rubber and elastomers, making them invaluable in industries where flexibility is crucial.

Why Hardness Testing Matters in Quality Assurance

Hardness testing is a cornerstone of effective quality assurance because it directly correlates with a material's performance under stress or wear conditions. By employing these quality inspection tools consistently throughout production processes, companies can identify potential weaknesses before products reach consumers. Ultimately, robust hardness testing not only enhances product reliability but also fosters customer trust—an essential element for any successful brand.

Unveiling the Spectrophotometer

In the realm of quality inspection tools, the spectrophotometer stands out as a vital instrument that measures light intensity at different wavelengths. This device plays a crucial role in ensuring color consistency and quality across various products, making it indispensable for industries where color accuracy is paramount. By analyzing how materials absorb and reflect light, spectrophotometers help maintain standards that customers expect and deserve.

Analyzing Color Consistency and Quality

Color consistency is essential for branding and product recognition; thus, manufacturers rely on spectrophotometers to achieve precise measurements. These instruments provide quantitative data about color attributes, allowing businesses to make informed decisions during production processes. With accurate color analysis, companies can minimize discrepancies that could lead to customer dissatisfaction or costly reworks—making them essential quality inspection tools in any serious operation.

Recommended Brands: X-Rite and Konica Minolta

When it comes to reliable spectrophotometers, X-Rite and Konica Minolta are two brands that consistently rise above the rest. Known for their cutting-edge technology and user-friendly interfaces, these brands offer various models tailored to different industry needs—from textiles to plastics. Their reputation for precision ensures that businesses using these quality inspection tools can trust their results, enhancing overall product quality.

Applications in Various Industries

Spectrophotometers find applications in a multitude of industries—from automotive paint matching to food safety testing—demonstrating their versatility as quality inspection tools. In textiles, they help ensure fabric colors remain consistent across batches; in printing, they guarantee that hues match design specifications perfectly. Moreover, industries like pharmaceuticals utilize these devices for ensuring the integrity of product appearance while adhering to regulatory standards—showing just how integral spectrophotometers are in maintaining high-quality outputs.

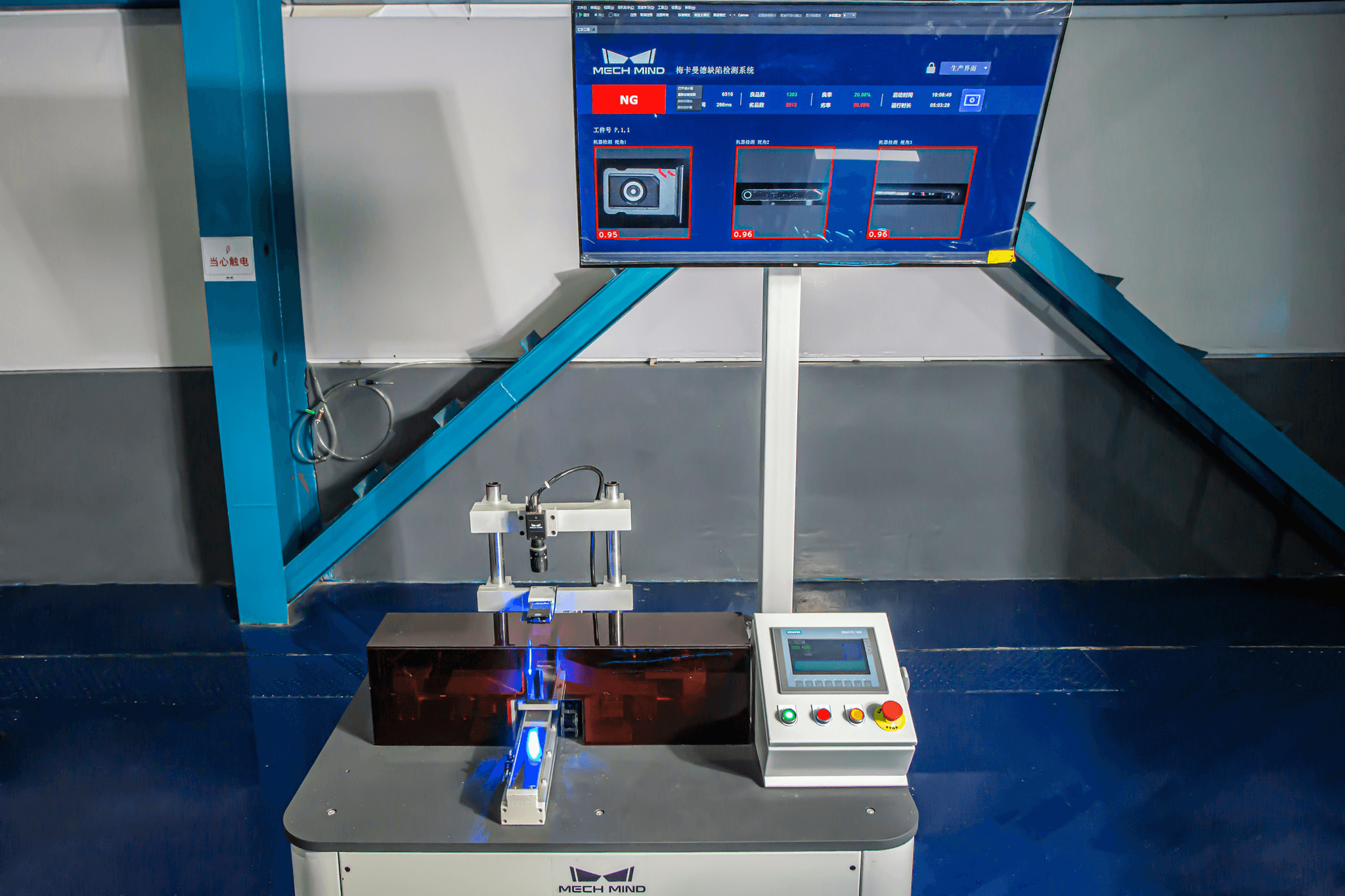

Leveraging Efficient Inspection Software

In today's fast-paced manufacturing environment, leveraging efficient inspection software is crucial for maintaining high standards of quality assurance. These digital tools not only streamline quality control processes but also enhance the overall effectiveness of quality inspection tools across various sectors. By integrating advanced technology into inspections, organizations can significantly reduce human error and improve accuracy.

Streamlining Quality Control Processes

Efficient inspection software simplifies the entire quality control workflow, ensuring that every step from measurement to reporting is seamless. With tools like Digital Calipers and Hardness Testers integrated into these systems, inspectors can easily input data and generate reports in real time. This streamlined process allows teams to focus more on analysis and decision-making rather than getting bogged down by paperwork.

Moreover, automation features within these software solutions help eliminate repetitive tasks, enabling inspectors to dedicate their time to more complex evaluations. For example, when using a Spectrophotometer for color consistency checks, the software can automatically log results and flag any deviations from set standards. This efficiency not only saves time but also enhances the reliability of quality inspections.

Top Solutions: QMS and InspectPlus

When it comes to selecting efficient inspection software, two standout solutions are QMS (Quality Management System) and InspectPlus. Both platforms offer robust features tailored for various industries needing effective quality inspection tools. QMS provides comprehensive modules that cover everything from document management to audit tracking, while InspectPlus focuses on user-friendly interfaces for easy data entry and analysis.

These solutions are designed with flexibility in mind; they adapt to different types of quality inspection tools such as Digital Calipers or Hardness Testers seamlessly. Users appreciate how both platforms support integration with existing hardware like Spectrophotometers for a holistic approach to quality assurance. In addition, these systems often come with customer feedback analysis tools that allow businesses to refine their processes based on real-time insights.

Benefits of Digital Integration in Quality Assurance

The benefits of digital integration in quality assurance extend far beyond mere convenience; they fundamentally transform how organizations approach product evaluation and improvement. By utilizing efficient inspection software alongside traditional methods like Hardness Testers or Digital Calipers, companies gain a 360-degree view of their operations—leading to better-informed decisions regarding product enhancements.

Furthermore, incorporating customer feedback analysis tools into this digital ecosystem allows businesses to pivot quickly based on consumer insights—an invaluable asset in today’s competitive market landscape. The synergy between these technologies ensures that every facet of production is aligned with consumer expectations while adhering strictly to industry standards for quality inspections.

In conclusion, embracing efficient inspection software not only streamlines workflows but also elevates the overall effectiveness of various quality inspection tools used throughout industries today.

Harnessing Customer Feedback Analysis Tools

In the realm of quality inspection tools, customer feedback analysis plays a pivotal role in shaping products that truly resonate with users. By tapping into consumer insights, businesses can identify strengths and weaknesses in their offerings, leading to improvements that enhance overall quality. This feedback loop not only informs product development but also fosters a culture of continuous improvement within organizations.

Improving Products Based on Consumer Insights

Understanding consumer preferences and pain points is crucial for refining products and services. Quality inspection tools like customer feedback analysis tools enable companies to gather valuable data directly from users, allowing them to pivot effectively based on real-world experiences. When businesses prioritize this input, they can tailor their offerings to meet market demands more accurately, ultimately driving higher satisfaction and loyalty.

Best Tools: Qualtrics and SurveyMonkey

These efficient inspection software solutions provide robust platforms for collecting insights through surveys and polls tailored to specific needs. With user-friendly interfaces and advanced analytics capabilities, they empower businesses to sift through data effectively—transforming raw consumer opinions into actionable strategies for improvement.

How Feedback Drives Quality Improvements

The impact of customer feedback on quality assurance cannot be overstated; it serves as a compass guiding product enhancements across various industries. By systematically analyzing responses gathered via quality inspection tools like Qualtrics or SurveyMonkey, organizations can pinpoint areas needing attention—be it design flaws or functionality issues related to Digital Calipers or Hardness Testers. In this way, feedback becomes the catalyst for innovation, ensuring that products evolve alongside consumer expectations while maintaining high standards of quality.

Conclusion

In wrapping up our exploration of quality inspection tools, it's clear that precision and reliability are paramount in any quality assurance process. From Digital Calipers to Hardness Testers, each tool serves a unique purpose that contributes to the overall integrity of products. Additionally, leveraging tools like Spectrophotometers and Efficient Inspection Software enhances the efficiency and effectiveness of inspections, ensuring that businesses meet their quality standards.

Key Takeaways on Quality Inspection Tools

Quality inspection tools are essential for maintaining high standards across various industries. Digital Calipers provide precise measurements, while Hardness Testers ensure material durability and performance. Moreover, incorporating Customer Feedback Analysis Tools into the process fosters continuous improvement by aligning product offerings with consumer expectations.

The Impact of Technology on Quality Assurance

The integration of technology in quality assurance has revolutionized how inspections are conducted. Efficient Inspection Software streamlines processes, reducing human error and accelerating workflows, which is critical in today's fast-paced market. Additionally, advancements in measurement technologies like the Spectrophotometer have made color consistency checks more accurate than ever before.

Partnering with Experts like China Inspection Pro

Collaborating with experts such as China Inspection Pro can significantly enhance your approach to quality inspection tools. Their expertise ensures that you not only choose the right tools—whether they be Digital Calipers or Hardness Testers—but also implement them effectively within your operations. This partnership can lead to improved product quality and customer satisfaction through informed decision-making based on data-driven insights.