Introduction

Manufacturing in Italy holds a prestigious position on the global stage, blending tradition with innovation across various sectors. With a rich history and a commitment to quality, Italy has become synonymous with excellence in craftsmanship, particularly in industries such as automotive, fashion, and machinery. This introduction will explore key Italian manufacturing sectors, highlight why manufacturing in Italy matters today, and outline essential supplier evaluation practices.

Key Italian Manufacturing Sectors Explored

The landscape of manufacturing in Italy is diverse and vibrant, featuring key sectors that showcase the country's strengths. From the iconic automotive industry known for its luxury brands to the world-renowned fashion houses that set trends globally, these sectors exemplify Italy's unique blend of artistry and engineering prowess. Additionally, machinery and equipment production reflects Italy's commitment to technological advancement while maintaining traditional craftsmanship standards.

Why Manufacturing in Italy Matters

Understanding why manufacturing in Italy is crucial goes beyond mere economic statistics; it taps into the cultural identity that shapes Italian products. The emphasis on quality craftsmanship ensures that goods produced here are not only functional but also carry an aesthetic appeal that resonates with consumers worldwide. Moreover, as global markets evolve, the strategic advantages of manufacturing in Italy—such as skilled labor and innovative design—make it an attractive option for businesses looking to thrive.

Supplier Evaluation Essentials

Evaluating suppliers effectively is vital for any business venturing into manufacturing in Italy or collaborating with local producers. A thorough assessment involves researching supplier credentials to ensure they meet industry standards while also conducting site visits for firsthand insights into their operations. Embracing technology can further enhance this process by streamlining assessments and facilitating communication between partners across borders.

Overview of Manufacturing in Italy

Italy is renowned for its diverse and robust manufacturing landscape, which has earned a stellar reputation on the global stage. The country is home to a myriad of Key Italian Manufacturing Sectors that span traditional craftsmanship to cutting-edge technology. This blend not only showcases Italy's rich heritage but also highlights why manufacturing in Italy continues to attract businesses worldwide.

Italy's Global Manufacturing Reputation

Manufacturing in Italy is synonymous with quality and innovation, making it a preferred destination for companies seeking excellence. Italian manufacturers are celebrated for their meticulous attention to detail and commitment to superior craftsmanship, which has positioned them favorably in international markets. This reputation extends across various sectors, from automotive to fashion, underscoring why manufacturing in Italy remains an attractive proposition.

Traditional and Modern Industries

Italy boasts a unique fusion of traditional industries and modern advancements within its manufacturing sector. While age-old practices like artisanal leatherwork and fine textiles thrive, there's also significant growth in high-tech fields such as robotics and aerospace engineering. This dynamic interplay between tradition and innovation illustrates the adaptability of Italian manufacturing, revealing what requires caution when manufacturing in Italy: balancing heritage with modernization.

Economic Impact on Local Communities

The economic impact of manufacturing in Italy stretches far beyond factory floors; it plays a pivotal role in local communities' livelihoods. Jobs created by key Italian manufacturing sectors contribute significantly to regional economies, fostering growth and stability within these areas. Moreover, the focus on sustainable practices within these industries enhances community well-being while reinforcing the value of controlling product quality in Italy.

Key Italian Manufacturing Sectors

Italy is renowned for its diverse and vibrant manufacturing landscape, which encompasses several key sectors that contribute significantly to the economy. From automotive innovations to the elegance of fashion and the precision of machinery, these sectors not only showcase Italy's rich heritage but also its forward-thinking approach to production. Understanding these key Italian manufacturing sectors is essential for anyone looking to tap into Italy's value in a global manufacturing landscape.

Automotive Industry Innovations

The automotive industry in Italy stands as a beacon of innovation, blending traditional craftsmanship with cutting-edge technology. Brands like Ferrari and Lamborghini are not just names; they symbolize excellence in engineering and design, setting benchmarks for quality that resonate globally. Why Manufacturing in Italy is particularly appealing here lies in the unique combination of skilled labor, advanced research facilities, and a culture that celebrates speed and style.

However, navigating this sector does require caution when manufacturing in Italy due to stringent regulations and competitive pressures from both local and international players. Evaluating suppliers effectively becomes crucial; understanding their capabilities can make or break your project’s success. With an emphasis on controlling product quality in Italy through rigorous inspections, companies can ensure their automotive products meet the highest standards without compromising on innovation.

Fashion and Textile Production

Italy’s fashion industry is synonymous with luxury, creativity, and unparalleled craftsmanship—qualities that have made it a global hub for textile production. Renowned cities like Milan serve as epicenters for fashion design where tradition meets modernity, resulting in collections that are both timeless and trendsetting. The allure of manufacturing in Italy within this sector lies not only in aesthetic appeal but also in the meticulous attention to detail evident from fabric selection to final stitching.

When exploring this vibrant market, it’s essential to understand cultural nuances that influence consumer preferences—what requires caution when manufacturing in Italy might include misinterpreting local trends or failing to appreciate regional styles. To ensure success here, one must consider how to evaluate a supplier in Italy effectively; building relationships with reputable manufacturers can lead you down a path filled with opportunities for collaboration on unique designs. Moreover, controlling product quality in Italy remains paramount since even minor flaws can tarnish a brand's reputation built over decades.

Machinery and Equipment Excellence

Italy has carved out an impressive reputation for machinery and equipment excellence across various industries—from food processing to industrial automation systems. Known for producing high-quality machines that combine durability with innovative technology, Italian manufacturers have become leaders by consistently pushing boundaries while adhering to strict quality standards. This focus on precision engineering makes why manufacturing in Italy an attractive proposition for businesses seeking reliable machinery solutions.

While exploring this sector offers immense potential, companies must remain vigilant about what requires caution when manufacturing in Italy—such as ensuring compliance with EU regulations regarding safety standards or environmental impact assessments. Effective supplier evaluation becomes critical here; researching credentials thoroughly helps mitigate risks associated with subpar equipment or unexpected delays during production cycles. By prioritizing controlling product quality in Italy through established inspection services, businesses can maintain operational efficiency while safeguarding their investments.

Why Manufacturing in Italy is Attractive

Manufacturing in Italy has long been synonymous with excellence, craftsmanship, and innovation. The unique blend of tradition and modernity found in key Italian manufacturing sectors makes it a coveted destination for businesses worldwide. Understanding why manufacturing in Italy is attractive can help companies leverage its benefits while navigating potential challenges.

Quality Craftsmanship and Design

Italy's reputation for quality craftsmanship and design is unparalleled, making it a leader in various industries. From luxurious fashion to precision machinery, the meticulous attention to detail ensures that products not only meet but exceed global standards. This commitment to excellence enhances brand value and consumer trust, which are vital components in today's competitive landscape.

In the realm of fashion and textiles, the artistry involved reflects centuries of cultural heritage intertwined with contemporary trends. This unique approach allows manufacturers to create products that resonate with consumers on an emotional level while maintaining high-quality standards that are essential for success. Thus, when considering manufacturing in Italy, one can't overlook the undeniable allure of its quality craftsmanship.

Access to Skilled Labor

One of the most significant advantages of manufacturing in Italy is access to a highly skilled labor force. The country boasts a rich educational system focused on engineering, design, and technical skills tailored to meet industry demands. This pool of talent enables companies to innovate continuously while maintaining high standards across various key Italian manufacturing sectors.

Moreover, Italian artisanship has been passed down through generations, ensuring that traditional skills remain alive even as industries evolve. This blend of historical knowledge and modern techniques fosters an environment where creativity thrives alongside technical proficiency. As such, businesses looking to evaluate a supplier in Italy will find an abundance of skilled workers ready to bring their visions to life.

Strategic Location in Europe

Italy's geographic location offers strategic advantages for businesses engaged in international trade and logistics. Situated at the crossroads of Europe, it provides easy access to major markets across the continent and beyond—making shipping more efficient than ever before. Companies can capitalize on this location by establishing strong supply chains that facilitate timely delivery without compromising quality.

Additionally, being part of the European Union allows manufacturers operating in Italy to benefit from reduced tariffs and streamlined regulations when exporting goods throughout Europe. This not only enhances competitiveness but also encourages foreign investment—a critical factor when considering what requires caution when manufacturing in Italy or any other region globally. Ultimately, this strategic positioning adds significant value within the broader context of Italy's value in a global manufacturing landscape.

How to Evaluate a Supplier in Italy

When engaging in manufacturing in Italy, evaluating potential suppliers is crucial to ensure quality and reliability. The process involves thorough research, site visits, and the use of technology to make informed decisions. This section will guide you through these essential steps for effective supplier evaluation.

Researching Supplier Credentials

Before diving into any agreements, it's vital to research supplier credentials meticulously. Start by assessing their experience within key Italian manufacturing sectors; this will give you insight into their expertise and reliability. Additionally, check for certifications and industry standards that demonstrate their commitment to quality—after all, why manufacturing in Italy is revered largely hinges on the craftsmanship that suppliers bring to the table.

Utilizing online resources such as industry directories and trade associations can also be beneficial. Look for reviews or testimonials from previous clients; they often provide a window into the suppliers' operational integrity. Remember, a well-researched supplier can significantly impact your success when navigating what requires caution when manufacturing in Italy.

Conducting Site Visits Efficiently

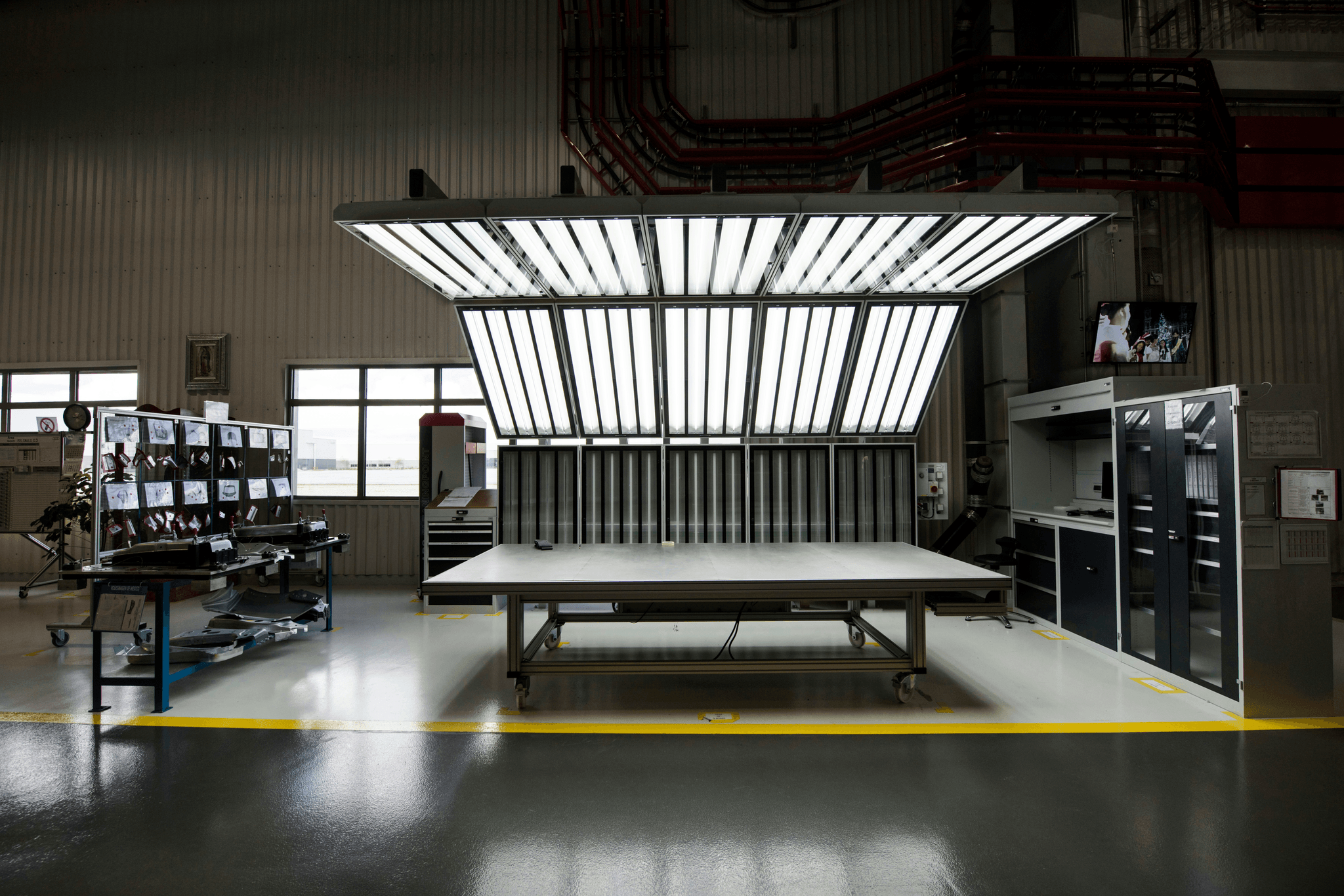

Once you've narrowed down your list of potential suppliers, conducting site visits is an indispensable step in evaluating them effectively. A personal visit allows you to assess not only the facilities but also the working conditions and overall culture of the company—factors that play a significant role in controlling product quality in Italy.

Prepare a checklist before your visit that includes aspects like machinery condition, workforce engagement, and adherence to safety standards. This preparation ensures that you maximize your time during these visits while gathering valuable insights into how well they align with your expectations for quality manufacturing.

Moreover, don’t hesitate to engage with employees during your visit; their feedback can reveal much about daily operations and reliability as partners. This hands-on approach will help you gauge whether the supplier can meet your needs consistently while reinforcing why manufacturing in Italy holds its esteemed reputation.

Utilizing Technology for Assessments

In today's digital age, leveraging technology can streamline supplier evaluations significantly when considering manufacturing in Italy. Tools such as virtual inspections or video conferencing allow for real-time assessments without necessitating travel—a boon especially if you're juggling multiple potential suppliers across various regions of Italy’s vibrant industrial landscape.

Additionally, employing data analytics tools enables you to analyze production metrics and performance indicators efficiently over time—essential elements when determining long-term partnerships within key Italian manufacturing sectors. These technologies not only save time but also offer objective insights that are crucial for making informed decisions regarding which suppliers align best with your operational goals.

Lastly, consider using project management software designed specifically for tracking supplier performance metrics over time; this continuous assessment helps ensure that any red flags are identified early on—keeping you one step ahead of what requires caution when manufacturing in Italy.

Controlling Product Quality in Italy

In the realm of manufacturing in Italy, controlling product quality is paramount to maintaining the country's esteemed reputation. Consistency and adherence to established standards not only bolster a brand's image but also ensure customer satisfaction and loyalty. As industries evolve, especially within key Italian manufacturing sectors, maintaining high-quality benchmarks becomes increasingly critical for competitiveness.

Importance of Consistency and Standards

Consistency in product quality is essential for any manufacturer aiming to thrive in Italy’s competitive landscape. Adhering to stringent standards guarantees that products meet both local and international requirements, fostering trust among consumers and partners alike. When considering why manufacturing in Italy is advantageous, one cannot overlook the role that rigorous quality controls play in sustaining excellence across various sectors.

Role of Quality Inspection Services

Quality inspection services are indispensable when it comes to ensuring that products manufactured in Italy meet the highest standards. These services provide an objective assessment of production processes, identifying potential issues before they escalate into costly problems. By integrating these inspections into their operations, businesses can enhance their credibility while navigating what requires caution when manufacturing in Italy.

How China Inspection Pro Ensures Reliability

China Inspection Pro stands out as a reliable partner for manufacturers looking to uphold quality standards while operating within Italy's dynamic market environment. With a focus on thorough evaluations and consistent follow-ups, they help companies maintain control over product quality throughout the supply chain process. Their expertise not only simplifies how to evaluate a supplier in Italy but also reinforces the overall value of manufacturing in Italy within a global context.

What Requires Caution When Manufacturing in Italy

Manufacturing in Italy can be a rewarding endeavor, but it comes with its own set of challenges that require careful navigation. Understanding these potential pitfalls is crucial for businesses looking to thrive in this vibrant landscape. From regulatory hurdles to cultural nuances, being aware of these factors can help ensure a smoother manufacturing journey.

Navigating Regulatory Challenges

When considering manufacturing in Italy, one cannot overlook the complex web of regulations that govern the industry. The Italian government has established strict guidelines regarding labor laws, environmental standards, and product safety that must be adhered to at all times. Failing to comply with these regulations can lead not only to fines but also to reputational damage and operational delays, making it essential for companies to stay informed about current laws and compliance requirements.

Moreover, different regions within Italy may have their own specific regulations that can affect various key Italian manufacturing sectors. For example, the automotive industry may face different standards compared to fashion or machinery production. Therefore, understanding regional variations is vital when evaluating how to evaluate a supplier in Italy and ensuring your business operations align with local expectations.

Understanding Cultural Differences

Cultural differences play a significant role when engaging in manufacturing in Italy. Italians place great value on relationships and trust; hence establishing strong connections with suppliers and partners is paramount for success. A casual lunch meeting or a friendly chat over coffee can often pave the way for better collaboration than purely business-oriented discussions.

Additionally, communication styles may differ significantly from what you might be accustomed to elsewhere; Italians tend to be more expressive and direct than many other cultures. Being aware of these cultural subtleties not only aids in building rapport but also helps mitigate misunderstandings that could arise during negotiations or project execution—key elements when controlling product quality in Italy.

Markets and Competition Insights

The competitive landscape for manufacturing in Italy is both rich and diverse; however, it requires keen insight into market dynamics to navigate effectively. Many key Italian manufacturing sectors are saturated with well-established players who have maintained their prominence through innovation and quality craftsmanship—qualities synonymous with Why Manufacturing in Italy matters so much on the global stage.

Understanding your competition isn’t just about knowing who they are; it’s about grasping their strengths, weaknesses, pricing strategies, and market positioning as well. This knowledge will empower you when evaluating suppliers or determining how best to differentiate your products within this bustling marketplace while ensuring alignment with local consumer preferences.

Conclusion

As we wrap up our exploration of manufacturing in Italy, it’s clear that the country holds a unique position in the global manufacturing landscape. Renowned for its rich heritage and innovative spirit, Italy's value lies not only in its historical craftsmanship but also in its ability to adapt and thrive amidst changing market demands. The key Italian manufacturing sectors—from automotive to fashion—illustrate the diverse talents and capabilities that make this nation a powerhouse of production.

Italy's Value in a Global Manufacturing Landscape

Italy's value in a global manufacturing landscape is underscored by its reputation for quality and design excellence. The fusion of tradition with modern techniques has allowed Italian manufacturers to remain competitive while producing some of the finest goods available today. With an emphasis on artisanal skills combined with technological advancements, manufacturing in Italy continues to attract attention from international markets seeking superior products.

Ensuring Success Through Rigorous Inspections

Ensuring success when engaging with manufacturing in Italy requires rigorous inspections at every stage of production. By implementing thorough evaluation processes, businesses can effectively control product quality in Italy, ensuring that they meet both local and international standards. This diligence not only safeguards investments but also enhances trust between suppliers and buyers, ultimately leading to long-term partnerships.

Final Thoughts on Manufacturing in Italy

In conclusion, while there are numerous benefits associated with manufacturing in Italy, it’s essential to consider what requires caution when manufacturing in Italy as well. Navigating regulatory challenges and understanding cultural nuances can be daunting; however, these factors are crucial for success. By leveraging effective strategies for evaluating suppliers and maintaining high-quality standards, businesses can unlock the full potential of what Italian manufacturing has to offer.