Introduction

In a world where playtime is essential for childhood development, ensuring that toys meet high standards of safety and quality is paramount. Toy Quality Control plays a crucial role in safeguarding children from potential hazards associated with poorly made products. From the materials used to the final packaging, every aspect of a toy's journey demands rigorous scrutiny to ensure it meets both regulatory standards and consumer expectations.

Importance of Toy Quality Control

The significance of Toy Quality Control cannot be overstated; it protects not only the health and safety of children but also the reputation of manufacturers. With increasing consumer awareness and stringent regulations, companies must prioritize quality assurance to avoid costly recalls and legal issues. Ultimately, effective quality control fosters trust among parents who want nothing but the best for their little ones.

Overview of Toys Inspection Process

The Toys Inspection process is a multi-faceted approach designed to evaluate toys at various stages, from design to production and beyond. This comprehensive inspection plan ensures that each toy adheres to established safety guidelines while also meeting functional requirements. By implementing a thorough inspection process, manufacturers can identify potential issues early on, allowing for timely interventions that enhance overall product quality.

Key Players in Quality Assurance

Quality assurance in the toy industry involves several key players who contribute their expertise at different stages of production and inspection. Manufacturers, regulatory bodies, third-party inspectors, and even consumers all play vital roles in ensuring that toys meet safety standards and perform as intended. Collaboration among these stakeholders is essential for maintaining high levels of Toy Quality Control throughout the lifecycle of each product.

Understanding Regulatory Standards

In the world of Toy Quality Control, understanding regulatory standards is crucial. These guidelines not only ensure that toys are safe for children but also help manufacturers navigate the complex landscape of compliance. The ASTM and EN71 standards are two of the most recognized frameworks governing toy safety.

Overview of ASTM and EN71 Guidelines

The American Society for Testing and Materials (ASTM) provides a set of rigorous standards that govern toy safety, focusing on aspects like mechanical hazards, flammability, and chemical composition. Meanwhile, the European standard EN71 outlines similar safety requirements tailored to the European market, addressing everything from physical properties to toxic substances in materials. Both sets of guidelines emphasize the importance of thorough Toys Inspection processes to verify compliance and safeguard children's health.

Global Compliance Considerations

Navigating global compliance can feel like trying to assemble a toy without instructions—confusing at best! Different countries may have their own regulations in addition to ASTM and EN71, making it essential for manufacturers to stay informed about local laws wherever they operate. This multifaceted approach ensures that Toy Quality Control practices meet diverse consumer expectations while minimizing legal risks across international markets.

Importance of Adherence for Safety

Adhering to established regulatory standards is not just a box-ticking exercise; it's a fundamental aspect of ensuring safety in toys. Non-compliance can lead to serious consequences such as product recalls or even legal action, which can tarnish a brand's reputation overnight. By prioritizing adherence within their Toys Inspection protocols, manufacturers create safer products that foster trust among consumers—because when it comes to kids' toys, safety should always come first!

Material Safety Evaluations

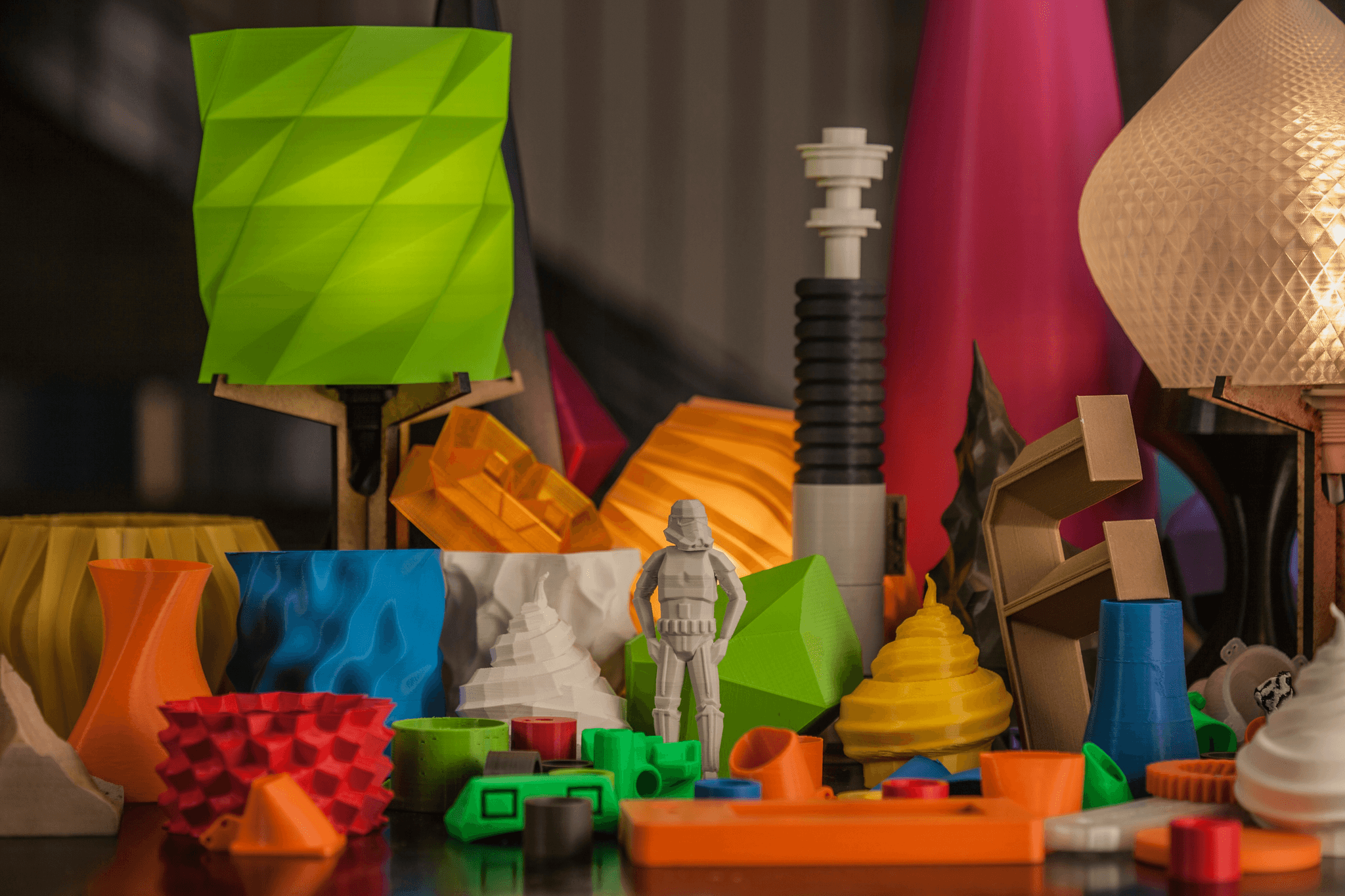

Types of Materials Used in Toys

Toys can be crafted from a variety of materials, each with its own set of characteristics and potential risks. Common materials include plastics, wood, metal, and textiles, each offering different benefits such as durability or tactile experience. However, not all materials are created equal; some may contain harmful substances or pose safety risks if not properly evaluated during the Toys Inspection process.

Manufacturers often choose plastics due to their versatility and cost-effectiveness, but certain types can leach toxic chemicals like phthalates or bisphenol A (BPA). Wood is often viewed as a safer alternative but requires proper treatment to avoid splinters or chemical finishes that can be harmful. Understanding these material properties is vital for Toy Quality Control teams to ensure they meet safety standards.

Testing for Toxic Substances

Testing for toxic substances is non-negotiable in the realm of Toy Quality Control; it’s where science meets safety head-on. Rigorous testing protocols are established to identify hazardous chemicals that could endanger children’s health—think lead content in paint or heavy metals lurking within plastic components. By employing advanced laboratory techniques such as gas chromatography or mass spectrometry, inspectors can detect minute traces of toxins that might otherwise go unnoticed.

Moreover, compliance with regulatory standards like ASTM and EN71 ensures that toys undergo stringent evaluations before hitting the market. This proactive approach not only safeguards children but also builds consumer trust—a win-win situation! Ultimately, thorough testing for toxic substances forms a foundational pillar in effective Toys Inspection practices.

Role of Material Transparency

Material transparency isn’t just corporate jargon; it's an essential component of Toy Quality Control that empowers consumers and manufacturers alike! When companies disclose information about the materials used in their products—especially regarding potential hazards—it fosters an environment of trust and accountability. Parents today are increasingly savvy; they want to know what goes into their children's toys so they can make informed choices.

This transparency also drives manufacturers to prioritize safer material selections during the design phase, knowing they'll be held accountable by discerning customers. Additionally, clear labeling helps facilitate better Toys Inspection processes by ensuring inspectors have access to accurate information about material composition—leading to more effective evaluations overall! In this age where knowledge is power, embracing material transparency can elevate a brand's reputation while enhancing toy safety.

Design and Prototype Testing

In the realm of Toy Quality Control, design and prototype testing are critical steps that ensure a toy not only meets safety standards but also delights its intended audience. This phase allows manufacturers to identify potential issues before mass production begins, saving time and resources while enhancing the overall quality of toys. By rigorously evaluating prototypes, companies can mitigate risks associated with design flaws and safety hazards.

Importance of Prototype Evaluation

Prototype evaluation is paramount in the Toys Inspection process as it serves as the first tangible representation of a toy's design. During this stage, various aspects such as usability, safety features, and aesthetic appeal are examined to ensure they align with both regulatory standards and consumer expectations. By investing time in thorough prototype evaluations, manufacturers can catch defects early on—preventing costly recalls or redesigns later in the production line.

Conducting Design Failures Analysis

Once prototypes are evaluated, conducting design failures analysis becomes essential in understanding how a toy might fail during actual use. This involves simulating various scenarios where weaknesses could arise—like stress tests or user interaction assessments—to pinpoint vulnerabilities that could compromise Toy Quality Control. By analyzing these failures systematically, designers can make informed adjustments that enhance durability and user experience before moving into full-scale production.

Feedback Loops for Improvement

Creating effective feedback loops is crucial for continuous improvement in both design and Toy Quality Control processes. After prototype testing concludes, gathering insights from testers—whether they be children or parents—provides invaluable information about what works well and what doesn’t. This iterative approach ensures that every new version of a toy benefits from previous learnings, ultimately leading to safer products that engage consumers more effectively.

Production Process Monitoring

In the realm of Toy Quality Control, ensuring that production processes are closely monitored is paramount for delivering safe and reliable toys. Effective monitoring during manufacturing helps identify potential issues before they escalate, thus safeguarding both the brand's reputation and children's safety. By implementing rigorous procedures, companies can maintain high standards throughout their Toys Inspection processes.

In-line Inspections during Manufacturing

In-line inspections serve as a critical checkpoint in the production process, allowing quality control teams to assess toys while they are being manufactured. These inspections involve examining materials, assembly methods, and adherence to design specifications in real-time, which significantly reduces the risk of defects reaching the final product stage. By catching issues early on, companies can save time and resources while ensuring compliance with established safety standards.

Moreover, in-line inspections foster a culture of accountability within manufacturing teams. Workers become more aware of quality expectations and are encouraged to take ownership of their roles in the Toys Inspection process. This proactive approach not only enhances product quality but also boosts employee morale as they contribute to creating safe toys for children.

Role of Quality Control Managers

Quality control managers play an indispensable role in overseeing production processes within Toy Quality Control frameworks. They are responsible for developing inspection protocols and training staff on best practices to ensure consistent adherence to safety standards throughout manufacturing operations. Their expertise ensures that any deviations from expected quality levels are promptly addressed before they can impact the final product.

Additionally, these managers act as liaisons between various departments—design, production, and marketing—to facilitate seamless communication regarding quality expectations and concerns. This collaboration is essential for maintaining high standards during Toys Inspection processes and ensures that all team members understand their responsibilities in upholding product integrity.

Furthermore, quality control managers analyze data collected from inspections to identify trends or recurring issues within production lines. This data-driven approach allows them to implement corrective actions swiftly and effectively while continuously improving overall toy safety measures.

Best Practices for Continuous Monitoring

To achieve optimal results in Toy Quality Control, manufacturers should adopt best practices for continuous monitoring throughout the production process. One effective strategy is implementing a robust feedback loop where insights from inspections inform subsequent manufacturing phases—this creates an environment of continuous improvement rather than reactive problem-solving after defects have been identified.

Regular training sessions for employees involved in Toys Inspection should also be prioritized; keeping everyone updated on new regulations or inspection techniques fosters a culture of excellence within the organization. Additionally, investing in advanced technologies such as automated inspection systems can enhance precision and efficiency during monitoring efforts.

Lastly, establishing clear documentation practices ensures that every step of the production process is traceable—this not only aids compliance with regulatory requirements but also provides valuable insights into historical performance data over time. By embracing these best practices for continuous monitoring, manufacturers can enhance their Toy Quality Control efforts significantly while delivering safer products to consumers.

Final Sampling Inspections

Final sampling inspections are a crucial component of the Toy Quality Control process, ensuring that products meet safety standards and consumer expectations before they hit the shelves. This stage acts as a final check, allowing manufacturers to identify any defects or inconsistencies in their toys. By implementing rigorous sampling techniques, companies can maintain high-quality standards and protect their brand reputation.

Importance of Random Sampling

Random sampling is essential in the Toys Inspection process, as it helps mitigate bias and ensures that every toy produced has an equal chance of being inspected. This method not only enhances the reliability of the results but also provides a more accurate representation of product quality across different batches. By employing random sampling techniques, manufacturers can confidently assess whether their toys meet established safety and quality benchmarks.

Evaluating Product Variability

Evaluating product variability during final sampling inspections is vital for understanding how consistent a toy's quality is across various production runs. Variability can arise from numerous factors such as material differences, manufacturing processes, or even design flaws; thus monitoring it helps identify potential issues early on. By closely analyzing these variations, companies can make informed adjustments to their Toy Quality Control strategies and ensure that every toy maintains its intended functionality and safety.

Role of Third-party Inspectors

Third-party inspectors play an invaluable role in the Toys Inspection process by providing an unbiased assessment of toy quality and compliance with regulatory standards. These independent professionals bring expertise and credibility to the inspection process, ensuring that manufacturers adhere to best practices in Toy Quality Control without any conflicts of interest. Their involvement not only enhances consumer trust but also helps companies avoid costly recalls due to undetected safety issues.

Functional Testing of Toys

Functional testing is a crucial aspect of Toy Quality Control, ensuring that toys not only meet safety standards but also perform as expected during play. This testing phase involves evaluating usability and durability, which helps identify any potential design flaws or weaknesses in the toy's construction. By rigorously assessing how toys function in real-world scenarios, manufacturers can ensure that their products provide safe and enjoyable experiences for children.

Assessing Usability and Durability

Factors such as size, weight, and ease of manipulation play significant roles in determining whether a toy is user-friendly. Durability is equally important; toys must withstand the rigors of daily play without breaking or posing hazards, thus reinforcing the importance of robust Toy Quality Control measures throughout the inspection process.

To evaluate durability effectively, toys undergo various stress tests simulating typical use conditions over time. This includes repetitive actions like pulling, twisting, and dropping to see if they maintain their integrity under pressure. By understanding these dynamics through precise usability assessments, manufacturers can make informed decisions about materials and design improvements that enhance overall product quality.

Safety Tests: Drop, Impact, and More

Safety tests are at the forefront of any comprehensive Toys Inspection plan because they directly relate to child safety during playtime adventures. Drop tests simulate accidental falls from varying heights to gauge how well toys resist damage while maintaining safety standards. Additionally, impact tests assess how toys respond when subjected to sudden force—because let’s face it: kids are not known for their gentle handling!

These rigorous safety evaluations help identify potential hazards like sharp edges or small parts that may pose choking risks if dislodged during typical use scenarios. Ensuring compliance with established safety guidelines not only protects children but also builds trust with parents who prioritize quality assurance when selecting products for their little ones. In this way, effective functional testing serves as a cornerstone for reliable Toy Quality Control practices.

Importance of Child-Friendly Design

Child-friendly design goes beyond aesthetics; it encompasses functionality that caters specifically to children's needs and capabilities while ensuring maximum enjoyment during playtime! A well-designed toy should be intuitive enough for kids to use independently yet stimulating enough to encourage creativity and exploration without compromising safety standards—a delicate balance maintained through thorough Toys Inspection processes.

Incorporating feedback from actual users—children—is essential in refining designs that resonate with young audiences while adhering strictly to Toy Quality Control protocols. Engaging children in the testing process allows designers to observe interactions firsthand and adjust features accordingly based on real-life experiences rather than assumptions alone! Ultimately, prioritizing child-friendly designs ensures not only compliance with regulations but also fosters joyful learning experiences through play.

Packaging Compliance

When it comes to Toy Quality Control, packaging is often the unsung hero. Safe packaging not only protects the toy during transit but also ensures that the product is safe for children once it reaches their eager little hands. A well-designed package can prevent accidents and enhance user experience, making it a crucial aspect of the Toys Inspection process.

Importance of Safe Packaging

Safe packaging is paramount in Toy Quality Control because it acts as the first line of defense against potential hazards. Packaging must be sturdy enough to withstand rough handling during shipping while also being free from harmful materials that could pose risks to children. Moreover, effective packaging design can help prevent choking hazards by ensuring that small parts are securely contained within.

Info Labeling and Instructions

Clear and informative labeling is essential in Toy Quality Control, as it guides consumers on how to use the product safely and effectively. Instructions should be easy to understand, considering that many toys are intended for young users who may not read yet; illustrations can bridge this gap. Additionally, labels must include age recommendations and safety warnings to ensure parents are fully informed before making a purchase.

Preventing Packaging-Related Hazards

Preventing packaging-related hazards is a critical component of the Toys Inspection process that cannot be overlooked. This involves assessing potential risks associated with materials used in packaging—such as plastic films or adhesives—that could harm children if ingested or mishandled. Regular audits and compliance checks ensure that all packaging meets safety standards, thus reinforcing overall Toy Quality Control efforts.

Post-Market Surveillance

In the world of Toy Quality Control, post-market surveillance is crucial for ensuring that toys remain safe and compliant after they hit the shelves. This phase involves ongoing monitoring and evaluation of products based on consumer feedback and market performance. By actively engaging in post-market surveillance, companies can swiftly address potential issues and enhance their Toys Inspection processes.

Feedback Collection and Analysis

Collecting feedback from consumers is an essential step in maintaining high standards of Toy Quality Control. Through various channels such as surveys, customer reviews, and social media interactions, manufacturers can gather valuable insights into how their toys are performing in real-world scenarios. Analyzing this feedback not only helps identify safety concerns but also sheds light on areas for improvement within the Toys Inspection framework.

The analysis of consumer feedback should be systematic and thorough, allowing companies to detect patterns or recurring issues that may warrant further investigation. For instance, if multiple customers report a specific toy malfunctioning or posing safety risks, it’s a signal that immediate action is needed. This proactive approach ensures that toys continue to meet quality expectations long after they leave the production line.

Handling Product Recalls and Safety Alerts

When it comes to Toy Quality Control, swift action during product recalls is paramount to protecting consumers and maintaining brand integrity. If a safety issue arises—whether due to design flaws or material hazards—companies must have a robust plan in place for effective recall management. This includes notifying retailers, communicating with customers about the risks involved, and providing clear instructions on how to return or dispose of affected products.

Safety alerts should be communicated transparently to build trust with consumers; honesty goes a long way when addressing potential dangers associated with toys. Additionally, having a dedicated team focused on handling recalls ensures that all necessary steps are taken promptly while minimizing disruption to business operations. A well-executed recall not only safeguards children but also reinforces the importance of meticulous Toys Inspection practices in preventing future issues.

Continuous Improvement in Quality Control

Continuous improvement is at the heart of effective Toy Quality Control strategies; it’s not just about meeting standards but striving for excellence beyond compliance. Companies should regularly review their Toys Inspection processes based on data gathered from feedback analysis and recall experiences to identify opportunities for enhancement. Implementing new technologies or methodologies can streamline inspections while ensuring that every toy adheres to safety regulations.

Training employees involved in quality control is equally vital; keeping them informed about industry changes and emerging threats enhances overall effectiveness in monitoring toy safety standards. By fostering a culture of continuous improvement within organizations, businesses can adapt more readily to changing regulations while producing higher-quality toys that parents trust wholeheartedly.

The commitment to ongoing evaluation not only benefits consumers but also positions companies as leaders in Toy Quality Control within an ever-evolving marketplace.

Conclusion

In the world of toys, ensuring safety and quality is paramount. Toy Quality Control is not just a regulatory requirement; it’s a commitment to the well-being of children everywhere. As we move forward, it's crucial for manufacturers to embrace comprehensive Toys Inspection processes that elevate standards and foster trust among consumers.

Next Steps for Toy Quality Control

The next steps in Toy Quality Control should focus on integrating advanced technologies into the inspection process. Utilizing AI and data analytics can enhance real-time monitoring, allowing manufacturers to identify potential issues before they escalate. Additionally, fostering collaboration between all stakeholders—from designers to suppliers—will create a more cohesive approach to maintaining high-quality standards.

Enhancing Toys Inspection Practices

To enhance Toys Inspection practices, companies must invest in ongoing training for their quality control teams. Regular workshops on the latest regulations and testing methodologies will keep everyone informed and prepared for any changes in compliance requirements. Moreover, implementing a culture of continuous improvement will encourage proactive measures rather than reactive fixes when issues arise.

Choosing the Right Inspection Partner

Selecting the right inspection partner is critical for effective Toy Quality Control; it can make or break your product’s reputation in the market. Look for partners with proven track records, industry certifications, and a deep understanding of both ASTM and EN71 guidelines. A reliable inspection partner not only ensures compliance but also provides valuable insights that help refine your products over time.