Introduction

In an era where safety and efficiency are paramount, non destructive inspection (NDI) has emerged as a vital process across various sectors. This technique allows for the thorough examination of materials and structures without causing any harm, making it an indispensable part of modern engineering and manufacturing practices. By leveraging advanced technologies, NDI ensures that internal and surface flaws are detected early, thereby preserving the integrity of critical components.

Understanding Non Destructive Inspection

Non destructive inspection refers to a range of techniques used to evaluate the properties of a material or structure without inflicting damage. Unlike traditional testing methods that may compromise the integrity of a specimen, NDI focuses on maintaining the object's usability while providing valuable insights into its condition. This approach not only enhances safety but also extends the lifespan of components by identifying potential issues before they escalate.

Importance of Non-invasive Examination

The significance of non-invasive examination cannot be overstated; it plays a crucial role in safeguarding lives and investments across industries. By detecting internal and surface flaws early on, organizations can mitigate risks associated with structural failures or product defects. Furthermore, this proactive approach fosters confidence among stakeholders by ensuring that products meet stringent quality standards throughout their lifecycle.

Applications of NDI in Various Industries

Non destructive inspection finds applications in diverse fields such as aerospace, automotive, construction, and energy sectors. In aerospace, for instance, NDI is essential for ensuring aircraft safety through regular inspections that identify material fatigue or cracks in critical components. Similarly, in manufacturing processes, quality control during manufacturing heavily relies on NDI techniques to uphold product integrity while minimizing waste and rework costs.

What is Non Destructive Inspection?

Non Destructive Inspection (NDI) is a vital process that allows for the assessment of materials and structures without causing any damage. This method focuses on the non-invasive examination of components to ensure their integrity and performance, which is crucial for safety in various industries. By employing NDI techniques, organizations can detect potential issues early, thereby preventing costly failures and enhancing operational efficiency.

Definition and Overview of NDI

At its core, non destructive inspection refers to a set of techniques used to evaluate the properties of a material or component without altering its future usability. This overview encompasses various methods such as ultrasonic testing, radiographic testing, and magnetic particle inspection that are tailored to identify flaws within materials. Understanding these methodologies is essential for professionals who aim to maintain high standards in quality control during manufacturing and ensure the longevity of assets through effective in-service inspection and maintenance.

Key Principles of Non-invasive Examination

The key principles behind non-invasive examination center around minimizing damage while maximizing information retrieval about material properties and structural integrity. Techniques are designed to detect internal and surface flaws without compromising the functionality or safety of an object being tested. This principle not only preserves the material but also provides critical insights into how it will perform under stress or over time.

Advantages of Non Destructive Inspection

The advantages of non destructive inspection are manifold; it enhances safety by identifying potential failures before they occur, thus protecting both people and investments. Additionally, NDI plays a pivotal role in characterizing material properties accurately, allowing engineers to make informed decisions based on reliable data. Moreover, implementing NDI methods during quality control processes ensures that manufacturing standards are upheld while facilitating ongoing asset management through effective in-service inspection and maintenance practices.

Common Non Destructive Inspection Methods

In the world of non destructive inspection, various methods are employed to ensure the integrity and safety of materials and structures without causing any harm. Each technique offers unique advantages in detecting internal and surface flaws, characterizing material properties, and maintaining quality control during manufacturing processes. Let's delve into three prevalent non-invasive examination methods: ultrasonic testing, radiographic testing, and magnetic particle inspection.

Ultrasonic Testing Techniques

Ultrasonic testing (UT) is a widely utilized method in non destructive inspection that employs high-frequency sound waves to detect internal flaws within materials. By sending these sound waves through a component, technicians can identify inconsistencies such as cracks or voids that may compromise structural integrity. The ability to provide real-time feedback makes ultrasonic testing an essential tool for quality control during manufacturing and in-service inspection and maintenance.

One significant advantage of UT is its versatility; it can be applied to various materials including metals, plastics, and composites. Additionally, ultrasonic techniques can also be used for thickness measurements, helping characterize material properties effectively. With advancements in technology, portable ultrasonic devices have made it easier for inspectors to conduct thorough examinations on-site.

Radiographic Testing Basics

Radiographic testing (RT) is another cornerstone of non destructive inspection that uses X-rays or gamma rays to visualize the internal structure of a component. This technique allows inspectors to detect hidden flaws such as weld defects or corrosion that could jeopardize safety standards. By creating detailed images of the internal features of a material, RT plays a critical role in the detection of internal flaws while ensuring quality control during manufacturing processes.

The beauty of radiographic testing lies in its ability to provide permanent records through film or digital imaging systems. These records not only serve as documentation but also aid in future evaluations during routine inspections or maintenance checks—making it invaluable for ongoing asset management strategies. Moreover, RT’s precision helps characterize material properties by revealing information about density variations within components.

Magnetic Particle Inspection Explained

Magnetic particle inspection (MPI) is an effective non-destructive examination method designed primarily for detecting surface and near-surface flaws in ferromagnetic materials like iron and steel. This technique involves magnetizing the object under test and applying ferrous particles suspended in liquid; any discontinuities will attract these particles, forming visible indications at flaw sites. Thus, MPI serves as a powerful tool for detecting surface defects while ensuring adherence to quality control standards during manufacturing.

One key benefit of magnetic particle inspection is its speed; inspectors can quickly assess large areas without extensive preparation time compared to other methods like radiography or ultrasonic testing. Additionally, MPI requires minimal equipment setup—making it accessible for both field inspections and controlled environments alike. As part of an overall strategy involving preventive maintenance practices, this method enhances reliability by identifying potential issues before they escalate into costly repairs.

Detection of Internal and Surface Flaws

Detecting internal and surface flaws is crucial in ensuring the integrity of materials and structures across various industries. Non-destructive inspection (NDI) techniques allow for the identification of these flaws without compromising the material's functionality, making it an essential part of quality control during manufacturing. By implementing effective detection strategies, organizations can prevent catastrophic failures that could arise from overlooked defects.

Techniques for Flaw Detection

There are several techniques employed in non-destructive inspection to detect both internal and surface flaws effectively. Ultrasonic testing uses high-frequency sound waves to identify inconsistencies within materials, while radiographic testing employs X-rays or gamma rays to reveal hidden defects. Magnetic particle inspection, on the other hand, is particularly useful for detecting surface flaws in ferromagnetic materials by revealing cracks or discontinuities through magnetic fields.

Each of these non-invasive examination methods has its own strengths and limitations, making it vital to select the appropriate technique based on the material properties being analyzed. For instance, ultrasonic testing is excellent for thick materials where internal flaws may be present, while magnetic particle inspection is ideal for surface-level defect detection in welds or castings. Ultimately, a combination of these techniques often yields the best results in flaw detection.

How Flaws Impact Structural Integrity

Flaws within a material can significantly compromise structural integrity and lead to potential failures if not detected early on through non-destructive inspection practices. Internal cracks can propagate under stress conditions, resulting in catastrophic breakdowns that could endanger lives and lead to costly repairs or replacements. Surface flaws may seem minor but can serve as initiation points for more severe issues over time if left unaddressed during routine quality control during manufacturing.

Understanding how these flaws impact material behavior is essential for maintaining safe operational standards across various industries such as aerospace, construction, and automotive sectors. The role of NDI becomes clear when considering that timely flaw detection not only enhances safety but also contributes to prolonged asset life through informed maintenance decisions during in-service inspection and maintenance phases. Thus, recognizing the implications of undetected flaws emphasizes the importance of robust NDI practices.

Real-World Examples of Flaw Detection

Real-world examples illustrate just how critical flaw detection through non-destructive inspection can be across different sectors. In aerospace engineering, a major airline once discovered micro-cracks in aircraft wings using ultrasonic testing just before a scheduled flight; this discovery prevented what could have been a disastrous incident mid-air due to structural failure from undetected fatigue cracks. Similarly, in civil engineering projects like bridge constructions, radiographic testing has been utilized effectively to ensure weld integrity—ensuring that no hidden imperfections could jeopardize public safety.

Another noteworthy example comes from oil and gas industries where pipeline inspections frequently employ magnetic particle inspection methods to detect corrosion or cracks that develop over time due to environmental stressors or operational fatigue. These real-world scenarios underscore how proactive measures such as flaw detection through NDI not only save lives but also protect investments by mitigating risks associated with material failure.

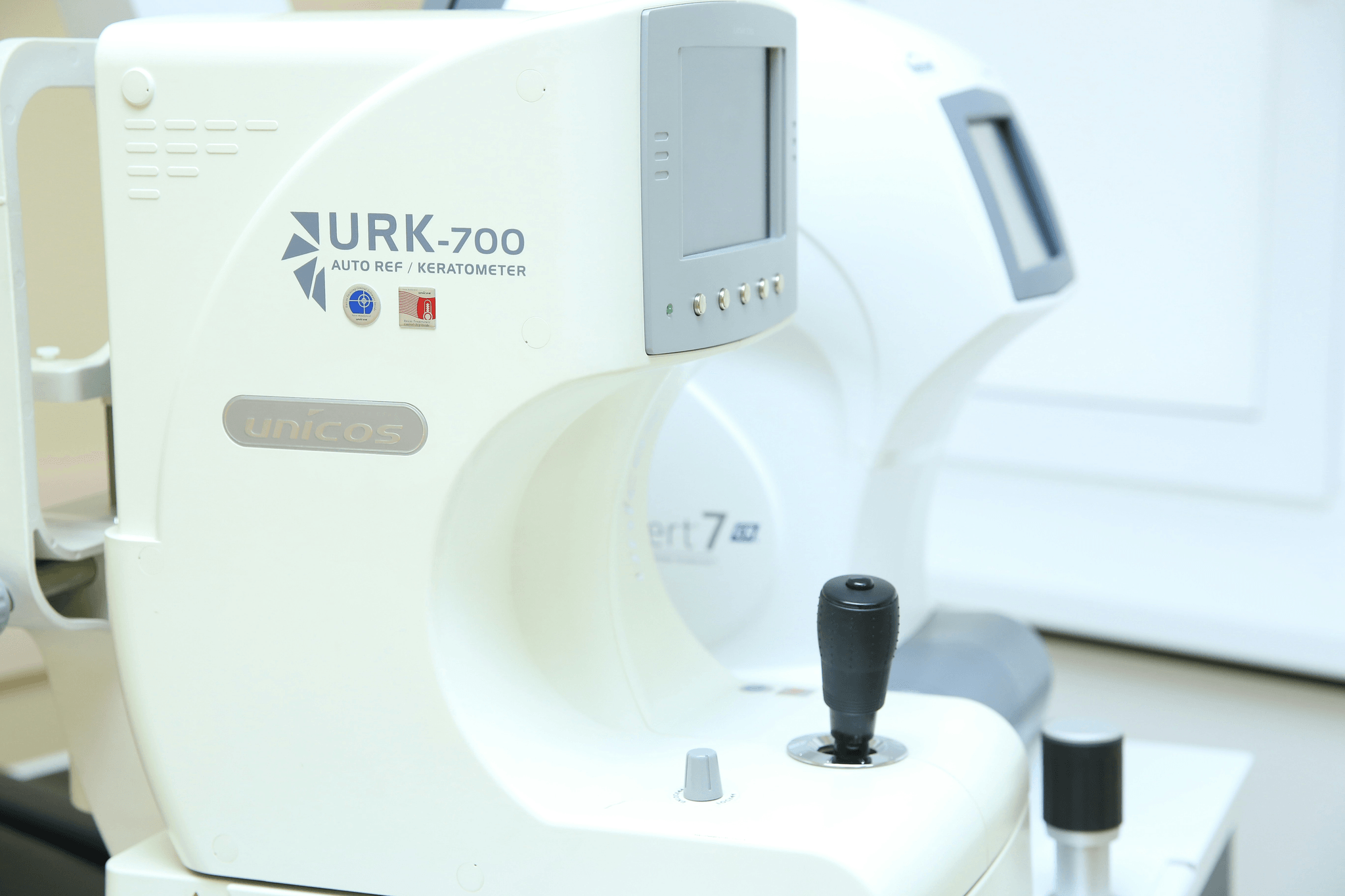

Characterization of Material Properties

Characterizing material properties is a crucial aspect of ensuring the reliability and safety of various structures and components. This process involves understanding how materials behave under different conditions, which is essential for both design and maintenance. Non-destructive inspection (NDI) methods play a vital role in this characterization, allowing for detailed analysis without compromising the integrity of the materials being tested.

Understanding Material Behavior

Material behavior refers to how different substances respond to external forces, temperatures, and other environmental factors. Understanding these behaviors is fundamental for engineers and manufacturers as it informs decisions regarding material selection and application in various industries. By utilizing non-invasive examination techniques, professionals can gain insights into the mechanical properties, durability, and potential failure points of materials without damaging them.

Role of NDI in Material Characterization

Non-destructive inspection serves as an invaluable tool in characterizing material properties by enabling the detection of internal and surface flaws that may not be visible to the naked eye. Techniques such as ultrasonic testing or radiographic testing allow inspectors to assess structural integrity while preserving the original state of the material. This role is particularly significant during quality control during manufacturing processes, where understanding material characteristics can prevent costly failures down the line.

Case Studies in Material Analysis

Several case studies highlight the effectiveness of non-destructive inspection in material analysis across diverse applications. For instance, in aerospace manufacturing, NDI techniques have been employed to evaluate composite materials used in aircraft wings; this ensures they meet stringent safety standards while remaining lightweight. Similarly, in civil engineering projects like bridge construction, NDI has been utilized for ongoing asset management by assessing concrete integrity over time—demonstrating how proactive maintenance through NDI can save resources and enhance safety.

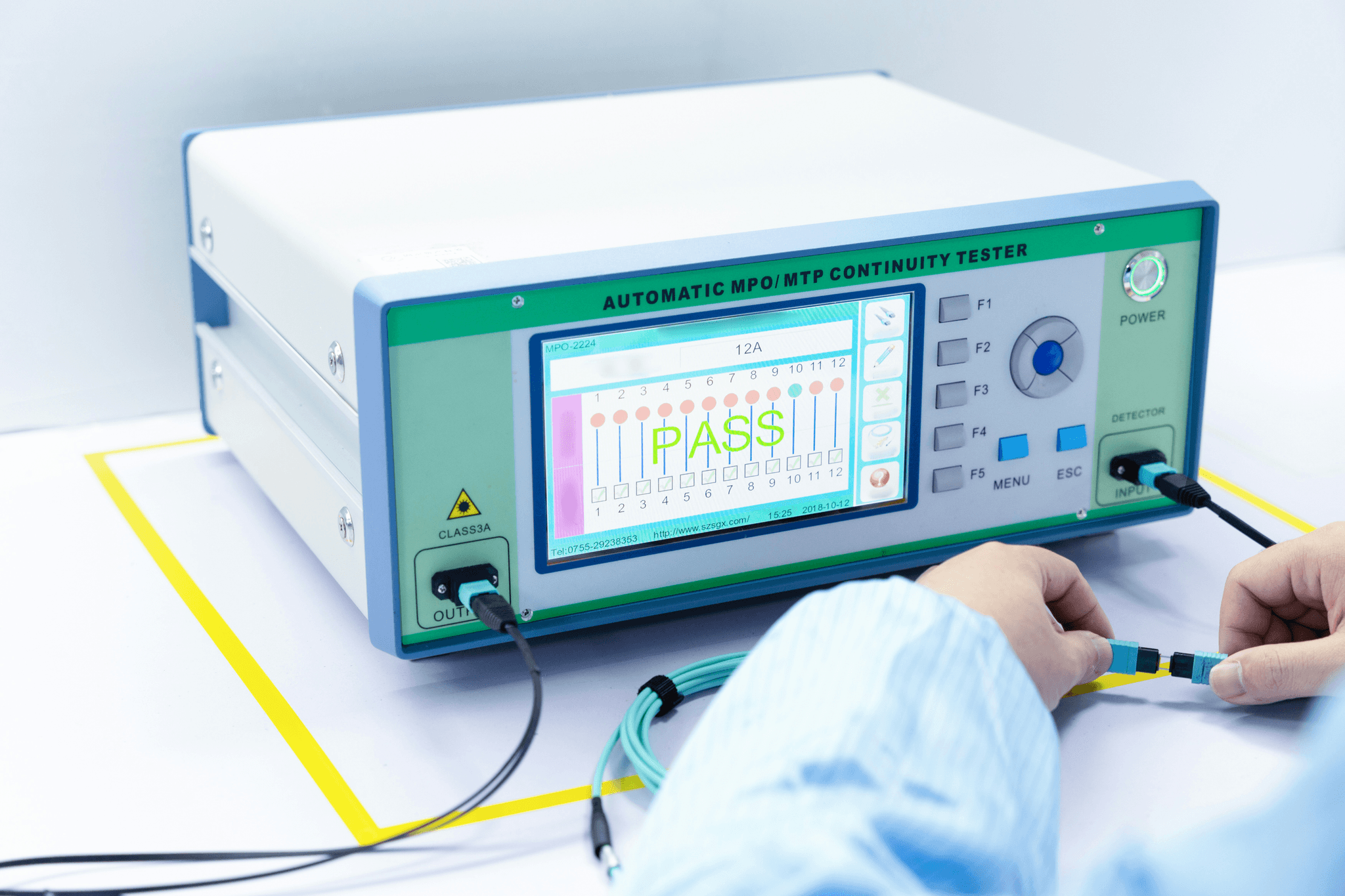

Quality Control During Manufacturing

In the world of manufacturing, maintaining high standards is crucial for producing reliable products. Non-destructive inspection (NDI) plays a pivotal role in quality control during manufacturing processes by ensuring that materials and components meet stringent specifications without causing damage. This non-invasive examination allows manufacturers to identify flaws early, reducing waste and enhancing overall product integrity.

Importance of NDI in Manufacturing Processes

The importance of non-destructive inspection in manufacturing cannot be overstated; it serves as a safeguard against defects that could compromise safety and performance. By employing NDI techniques, manufacturers can effectively detect internal and surface flaws that may go unnoticed until it’s too late. This proactive approach not only saves time and resources but also fosters consumer trust in the final product.

Furthermore, effective quality control during manufacturing hinges on the ability to characterize material properties accurately. Understanding how different materials behave under various conditions can inform design choices and production methods, ultimately leading to better products. Non-destructive inspection provides valuable insights into these material characteristics without altering or damaging them, making it an indispensable tool for manufacturers.

Best Practices for Quality Control

Implementing best practices for quality control during manufacturing is essential to maximize the benefits of non-destructive inspection techniques. Regularly scheduled inspections using various NDI methods—such as ultrasonic testing or magnetic particle inspection—should be integrated into the production process to ensure consistency and reliability throughout each stage of manufacturing. Additionally, training employees on these methods enhances their ability to recognize potential issues early on.

Documentation plays a critical role as well; maintaining records of inspections helps track trends over time and identifies recurring problems within specific processes or materials. By analyzing this data, manufacturers can refine their procedures and enhance overall efficiency while minimizing risks associated with undetected flaws. Ultimately, a culture of continuous improvement rooted in NDI practices leads to superior quality control outcomes.

Role of China Inspection Pro in Quality Assurance

China Inspection Pro has established itself as a leader in providing comprehensive non-destructive inspection services tailored specifically for various industries seeking robust quality assurance measures. With an emphasis on advanced technologies and methodologies, they ensure that every component meets rigorous standards through meticulous detection of internal and surface flaws during production cycles. Their expertise extends beyond simple inspections; they also assist clients in characterizing material properties effectively to optimize performance.

Moreover, China Inspection Pro prioritizes customer satisfaction by offering tailored solutions that align with specific project needs while adhering to international compliance regulations—an essential aspect when navigating global markets today. Their commitment to excellence reinforces the importance of integrating non-invasive examination into every phase of quality control during manufacturing processes across diverse sectors.

By employing such specialized services from China Inspection Pro, companies can confidently move forward with their production goals while ensuring safety, reliability, and compliance are at the forefront—all thanks to effective use of non-destructive inspection techniques.

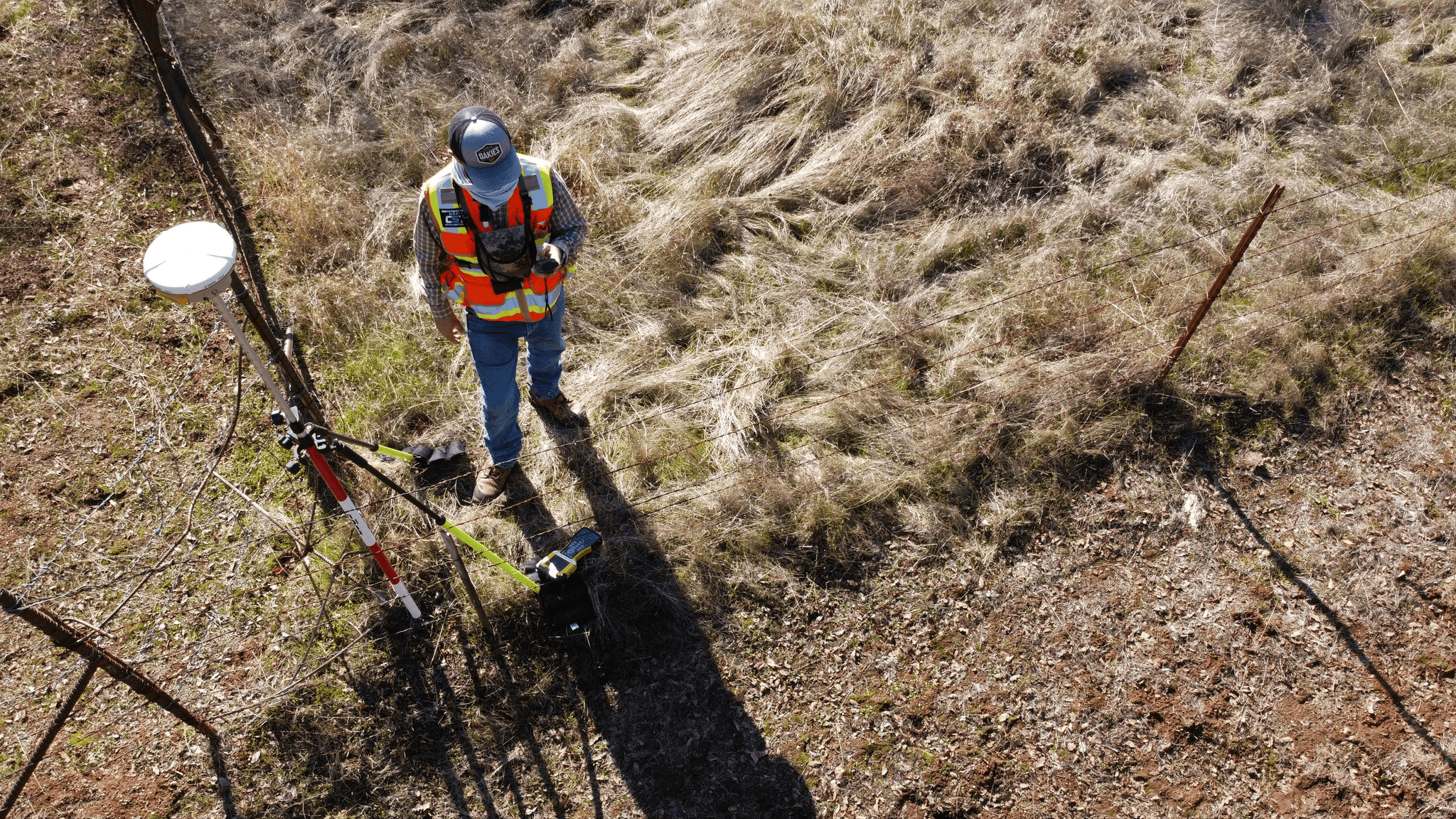

In-Service Inspection and Maintenance

In-service inspection and maintenance are critical components in ensuring the longevity and reliability of assets across various industries. By employing non destructive inspection (NDI) techniques, organizations can effectively monitor the condition of equipment without causing any harm or disruption to operations. This proactive approach not only enhances safety but also maximizes asset performance through timely interventions.

NDI for Ongoing Asset Management

Non destructive inspection plays a pivotal role in ongoing asset management by providing essential insights into the condition of materials and structures throughout their lifecycle. Through non-invasive examination methods, companies can detect internal and surface flaws before they escalate into costly failures or safety hazards. By integrating NDI into regular maintenance schedules, businesses can ensure that their assets remain compliant with industry standards while optimizing operational efficiency.

The beauty of NDI lies in its ability to assess material properties without altering them, allowing for continuous monitoring of structural integrity over time. This ongoing assessment helps organizations make informed decisions regarding repairs or replacements, ultimately extending the lifespan of critical assets. Moreover, with advancements in technology, the accuracy and reliability of NDI techniques continue to improve, making them indispensable tools for effective asset management.

Preventive Maintenance Strategies

Implementing preventive maintenance strategies that incorporate non destructive inspection is essential for mitigating risks associated with equipment failure. By regularly utilizing NDI methods, organizations can identify potential issues early on, reducing downtime and minimizing repair costs associated with unexpected breakdowns. This proactive stance not only enhances safety but also fosters a culture of reliability within teams.

Preventive maintenance driven by non-invasive examination techniques allows companies to schedule repairs during planned downtimes rather than facing emergency situations that disrupt operations. Utilizing data gathered from NDI helps prioritize maintenance tasks based on actual conditions rather than guesswork or routine schedules alone. As a result, businesses can allocate resources more effectively while maintaining high levels of productivity.

Furthermore, combining preventive maintenance with quality control during manufacturing ensures that any flaws detected are addressed before they compromise operational integrity. This holistic approach to asset management reinforces the importance of continuous improvement across all aspects of an organization’s processes.

Cost-Benefit Analysis of In-Service Inspection

Conducting a cost-benefit analysis of in-service inspection reveals significant advantages when incorporating non destructive inspection methods into asset management strategies. While initial investments may be required for implementing advanced NDI technologies, the long-term savings achieved through reduced downtime and enhanced safety far outweigh these costs. Organizations often find that proactive flaw detection leads to fewer catastrophic failures and lower repair expenses over time.

Moreover, when assessing characterizations of material properties through in-service inspections using NDI techniques, businesses gain valuable data that informs future investments in materials and manufacturing processes—ultimately leading to improved quality control during manufacturing phases as well as enhanced product reliability post-deployment. The benefits extend beyond immediate financial savings; reputational gains from consistent operational excellence contribute positively to customer satisfaction levels as well.

In conclusion, integrating non destructive inspection into preventive maintenance strategies not only improves asset longevity but also fosters a culture focused on quality assurance throughout an organization’s lifecycle—making it an invaluable investment toward sustainable growth.

Conclusion

In wrapping up our exploration of non destructive inspection (NDI), it’s clear that these methods are not just beneficial; they’re essential across various industries. The ability to conduct a non-invasive examination allows for the detection of internal and surface flaws without compromising the integrity of materials or structures. From manufacturing to maintenance, NDI techniques enhance safety, reliability, and efficiency, making them invaluable in today’s industrial landscape.

Benefits of Non Destructive Inspection Methods

The advantages of non destructive inspection methods are manifold and impactful. Firstly, they provide critical insights into the condition of materials without causing damage, ensuring that assets remain intact while also allowing for the detection of internal and surface flaws. Additionally, NDI contributes significantly to quality control during manufacturing processes by identifying defects early on, which can save companies both time and money in the long run.

Moreover, NDI plays a pivotal role in characterizing material properties—understanding how different materials behave under various conditions is crucial for informed decision-making in engineering and construction. This proactive approach not only enhances safety but also extends the lifespan of equipment through timely interventions during in-service inspection and maintenance. Ultimately, embracing non-destructive techniques fosters a culture of safety and excellence in any organization.

Future Trends in NDI Technology

As we look ahead, future trends in non destructive inspection technology promise exciting advancements that will further revolutionize this field. Innovations such as artificial intelligence (AI) and machine learning are set to enhance data analysis capabilities, enabling quicker detection of internal flaws with greater accuracy than ever before. Additionally, the integration of drones equipped with advanced sensors will facilitate remote inspections—ideal for hard-to-reach areas or hazardous environments.

Another trend gaining traction is the development of portable NDI devices that allow for real-time assessments right at the job site. This level of accessibility will streamline quality control during manufacturing processes while also improving efficiency during routine checks in service inspections. As these technologies evolve, we can expect even more sophisticated methods for characterizing material properties and ensuring structural integrity across diverse applications.

How to Choose the Right NDI Service Provider

Selecting an appropriate NDI service provider is crucial to reaping all these benefits effectively. Start by evaluating their expertise—look for providers with a solid track record in conducting thorough non-invasive examinations across your specific industry sectors. It's important they possess certifications that validate their proficiency with various methods like ultrasonic testing or radiographic testing.

Next, consider their technological capabilities; providers who utilize cutting-edge tools will likely offer more accurate results when detecting internal and surface flaws or assessing material characteristics. Finally, don’t overlook customer reviews—feedback from previous clients can provide valuable insights into their reliability and quality control during manufacturing services offered by potential partners.