Introduction

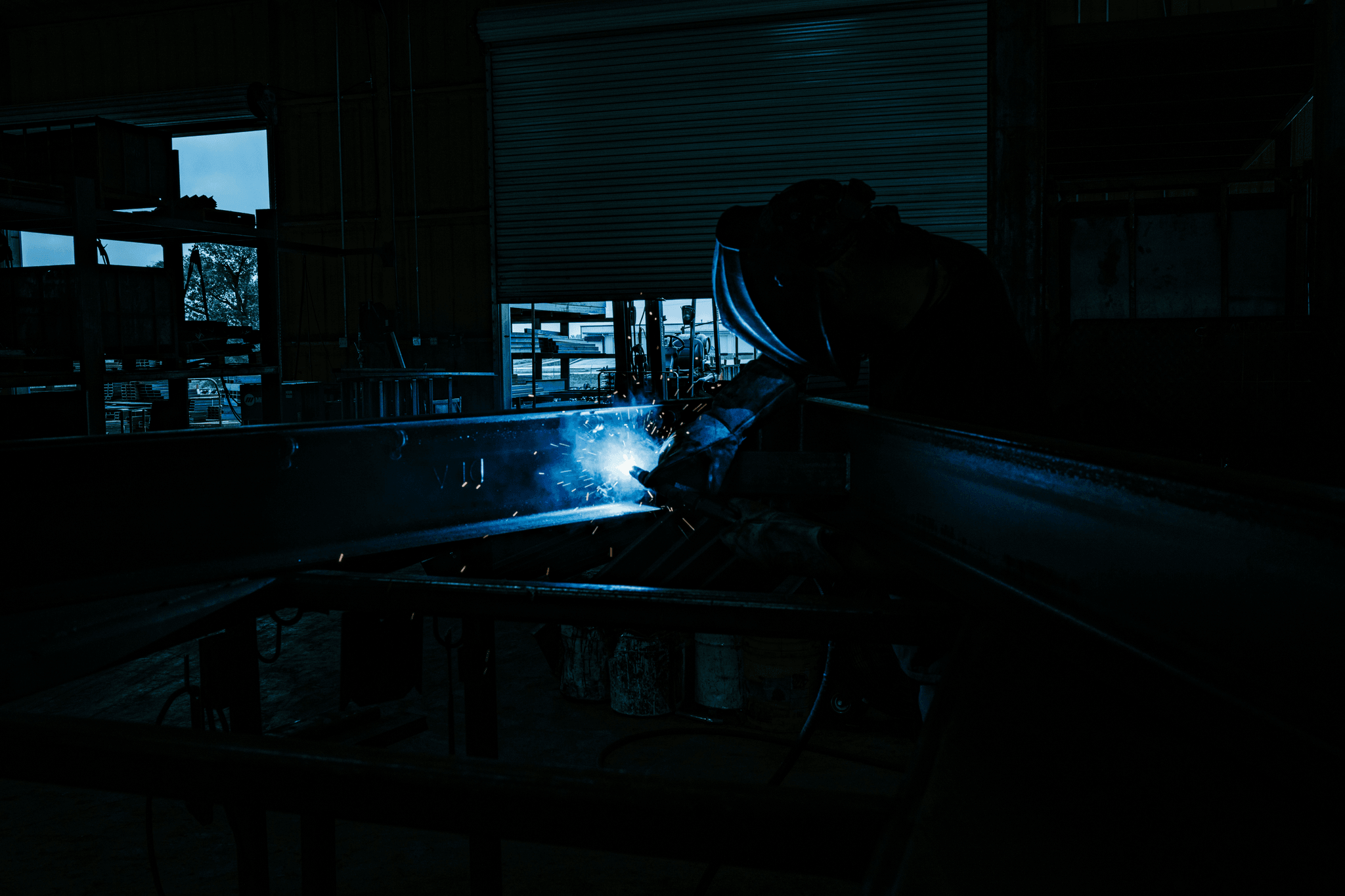

In the world of construction and manufacturing, ensuring that every weld is up to standard is crucial for safety and durability. This is where a certified welding inspector comes into play, serving as the gatekeeper of quality in welding projects. With their expertise, they not only identify potential issues but also help maintain compliance with industry standards.

What Is a Certified Welding Inspector

A certified welding inspector (CWI) is a professional who has undergone rigorous training and testing to ensure they possess the necessary skills to evaluate welds effectively. These inspectors are well-versed in various welding processes and techniques, making them invaluable assets on any job site. Their certification signifies that they have met specific industry standards, such as those set by the American Welding Society (AWS) or the American Society of Mechanical Engineers (ASME).

Importance of Welding Inspections

Welding inspections are essential for maintaining structural integrity and safety in any project involving welded joints. A qualified welding inspector can identify defects early on—such as cracks or incomplete fusion—that could lead to catastrophic failures if left unchecked. By conducting thorough inspections, these professionals not only protect lives but also save companies from costly rework and liability issues down the line.

Overview of Certification Process

Becoming a certified welding inspector involves several steps designed to ensure candidates are adequately prepared for the challenges they'll face in the field. Aspiring inspectors typically undergo specialized training programs that cover both theoretical knowledge and hands-on experience with various welding techniques, including pipe welding certification. Once they've completed their training, candidates must pass a comprehensive exam that tests their understanding of industry standards and inspection practices before earning their certification.

Role of a Certified Welding Inspector

Certified welding inspectors play a pivotal role in ensuring the integrity and safety of welded structures. Their expertise is essential in various industries, from construction to manufacturing, where the quality of welds can directly impact performance and safety. By adhering to industry standards, they help maintain high levels of quality control and compliance.

Key Responsibilities

The responsibilities of a certified welding inspector are as diverse as the projects they oversee. Primarily, they inspect welded joints for defects and ensure that all work meets established codes and specifications. Additionally, they often review welding procedures, conduct tests on materials, and maintain detailed documentation to track compliance with industry regulations.

Another important duty involves collaborating with welders and engineers to provide guidance on best practices for pipe welding certification and other specialized processes. This collaboration not only helps improve overall workmanship but also fosters a culture of safety within the workplace. Ultimately, these responsibilities ensure that every weld contributes to the structural integrity of the final product.

Skills Required for Success

To thrive as a certified welding inspector, one must possess a unique blend of technical skills and interpersonal abilities. First and foremost, an in-depth understanding of welding processes is crucial; this includes familiarity with various techniques such as MIG, TIG, and arc welding. Additionally, inspectors must be adept at reading blueprints and interpreting technical drawings to accurately assess project specifications.

Communication skills are equally vital since certified welding inspectors often serve as liaisons between different teams—engineers, welders, project managers—and must convey complex information clearly. Attention to detail is paramount; even minor flaws can lead to significant problems down the line if not identified early in the inspection process. Combining these skills ensures that certified welding inspectors can effectively uphold industry standards while fostering teamwork.

Importance in the Industry

The importance of certified welding inspectors cannot be overstated; they serve as guardians of quality within the welding industry. Their expertise helps prevent costly mistakes that could arise from poor workmanship or non-compliance with established codes like AWS or ASME standards. By ensuring that welds meet stringent requirements through thorough inspections, these professionals contribute significantly to public safety.

Moreover, their role extends beyond mere compliance; certified welding inspectors actively promote continuous improvement within organizations by identifying areas for skill enhancement or procedural adjustments during inspections. This proactive approach leads not only to better quality but also enhances overall productivity across projects involving pipe welding certification or other specialized tasks. In essence, their presence elevates industry standards while safeguarding both workers and end-users alike.

Certification Process Explained

Becoming a certified welding inspector isn’t just a matter of waving a magic wand; it requires dedication, training, and a clear understanding of the certification process. This section will illuminate the steps you need to take to become a certified welding inspector, ensuring you’re well-prepared for this crucial role in the welding industry. From training requirements to reputable organizations offering certification, we’ve got you covered.

Steps to Becoming Certified

The journey to becoming a certified welding inspector typically starts with gaining relevant experience in the field of welding. Most candidates are required to have several years of hands-on experience in various welding processes or related roles before diving into the certification waters. Once you've gathered sufficient experience, you'll need to choose an appropriate certification program that aligns with your career goals and interests.

Next, you’ll want to prepare for the specific requirements set by certifying organizations like AWS (American Welding Society) or ASME (American Society of Mechanical Engineers). This may involve completing coursework or attending workshops that cover essential topics such as weld quality assessment and inspection techniques. Finally, after meeting all prerequisites and preparing thoroughly, you can register for and take the certification exam.

Exam and Training Requirements

Before stepping into the exam room as a hopeful certified welding inspector, it's crucial to know what’s expected of you regarding training and examination. The training often includes both theoretical knowledge and practical skills; candidates are usually required to demonstrate their understanding through hands-on assessments in real-world scenarios. A solid grasp of industry standards like AWS D1.1 or ASME Section IX is also vital for success.

The exam itself typically consists of multiple-choice questions covering various aspects of welding inspection practices, codes, standards, and defect identification techniques. Passing this examination is no small feat; it demands not only knowledge but also critical thinking skills under pressure. Moreover, some programs may require ongoing education or re-certification every few years to ensure that inspectors stay updated on new technologies and methodologies.

Organizations Offering Certification

Several organizations provide pathways for aspiring certified welding inspectors looking to validate their expertise in the field. The American Welding Society (AWS) is perhaps one of the most recognized certifying bodies globally; they offer various certifications tailored for different types of inspectors including those focusing on pipe welding certification specifically designed for professionals working with piping systems.

Another notable organization is ASME which offers certifications based on their stringent codes that govern welded constructions across many industries including power generation and construction sectors. Additionally, other regional bodies may offer specialized certifications focusing on local regulations or specific industries—ensuring there’s something out there suitable for everyone interested in becoming a skilled welding inspector.

Standards and Codes in Welding

Welding is a craft that demands precision, safety, and adherence to established standards. The backbone of quality welding lies in the guidelines set forth by organizations like the American Welding Society (AWS) and the American Society of Mechanical Engineers (ASME). Understanding these standards is crucial for anyone aspiring to be a certified welding inspector or working within the industry.

Understanding AWS and ASME Standards

The AWS and ASME standards serve as essential blueprints for welding practices across various sectors. AWS focuses on welding techniques, materials, and safety protocols, while ASME emphasizes engineering design and construction codes. For a certified welding inspector, familiarity with these standards is not just beneficial; it’s necessary for ensuring that welds meet both quality and safety requirements.

Certified welding inspectors must navigate through various specifications laid out by these organizations to ensure compliance during inspections. This includes understanding different types of welds, joint designs, and material properties that are outlined in their respective codes. Moreover, a solid grasp of these standards helps inspectors identify potential issues before they escalate into costly problems.

Importance of Compliance

Compliance with AWS and ASME standards is vital not only for safety but also for project success. When projects adhere to these established codes, it minimizes risks associated with structural failures or accidents due to poor workmanship. A certified welding inspector plays a pivotal role in this compliance process by conducting thorough inspections that validate adherence to required specifications.

Non-compliance can lead to severe repercussions including legal liabilities, project delays, or even catastrophic failures in extreme cases. Therefore, ensuring that all welds meet industry standards protects not just the integrity of structures but also the reputation of companies involved in those projects. Hiring a qualified inspector who understands these regulations can save time and money while enhancing overall project quality.

How Certified Welding Inspectors Ensure Quality

Certified welding inspectors employ a variety of methods to ensure that every weld meets stringent quality criteria dictated by AWS and ASME guidelines. They conduct visual inspections as well as more advanced non-destructive testing techniques such as ultrasonic or radiographic testing to detect any flaws hidden beneath the surface. This multifaceted approach allows them to catch defects early on—before they become costly headaches down the line.

Moreover, certified welding inspectors provide invaluable feedback during the fabrication process itself by identifying potential issues related to technique or material selection early on. Their expertise ensures that all aspects of pipe welding certification are adhered to throughout every phase of production—from planning through execution—to guarantee lasting results. By maintaining rigorous inspection protocols aligned with industry standards, they contribute significantly toward achieving high-quality outcomes for any project.

Common Challenges in Welding Inspection

Welding inspection is not without its hurdles, and certified welding inspectors often face a variety of challenges that can impact the quality and safety of welded structures. From identifying defects to navigating complex projects, these professionals must be well-equipped to tackle the unexpected. Understanding these common challenges is essential for both inspectors and those who rely on their expertise.

Identifying Defects and Flaws

One of the primary responsibilities of a certified welding inspector is to identify defects and flaws in welds that could compromise structural integrity. This task requires a keen eye for detail, as even minor imperfections can lead to significant problems down the line. Inspectors utilize various techniques, including visual inspections and non-destructive testing methods, to ensure every weld meets stringent standards.

The challenge lies in differentiating between acceptable imperfections and critical flaws that require remediation. A certified welding inspector must be knowledgeable about different types of defects, such as porosity or lack of fusion, which may not always be visible at first glance. Continuous training and hands-on experience are crucial for inspectors to refine their skills in detecting these issues effectively.

Dealing with Complex Projects

Complex projects often introduce additional layers of difficulty for welding inspectors, particularly when multiple materials or intricate designs are involved. For instance, pipe welding certification may require specialized knowledge about various alloys and joint configurations that differ from standard practices. This complexity demands that inspectors remain adaptable and well-versed in industry standards applicable to each unique situation.

Moreover, tight deadlines can exacerbate the challenges faced by certified welding inspectors during complex projects. Rushed inspections might overlook critical flaws or lead to inadequate documentation, ultimately jeopardizing project outcomes. Therefore, effective communication with project managers and other stakeholders becomes essential to ensure thorough inspections without compromising timelines.

Solutions from Industry Experts

To navigate these common challenges successfully, industry experts recommend several strategies for certified welding inspectors looking to enhance their effectiveness on the job. First and foremost is ongoing education; staying updated on emerging technologies and inspection techniques can significantly improve an inspector's ability to identify defects accurately. Workshops, webinars, and certification courses are excellent resources for continuous learning.

Collaboration with other professionals in the field also proves beneficial when tackling complex projects or unique materials requiring specialized knowledge. By fostering relationships with engineers or fabricators familiar with specific requirements—such as those associated with pipe welding certification—inspectors can gain insights that enhance their evaluations' accuracy and reliability.

Lastly, leveraging technology can streamline inspection processes significantly; utilizing advanced tools such as drones for hard-to-reach areas or software applications designed for documentation helps ensure comprehensive assessments are conducted efficiently without sacrificing quality.

The Future of Welding Inspection

The landscape of welding inspection is undergoing a significant transformation, driven largely by advancements in technology. Certified welding inspectors are increasingly utilizing innovative tools and techniques that enhance the accuracy and efficiency of their inspections. From drones to advanced imaging systems, these technologies are not only streamlining processes but also elevating the standards of quality assurance in welding.

Technology's Impact on Inspections

Technology is reshaping how certified welding inspectors conduct their evaluations. For instance, non-destructive testing (NDT) methods such as ultrasonic testing and radiographic inspection allow for detailed analysis without compromising the integrity of the welds being assessed. This means that a welding inspector can identify potential issues early in the process, ensuring that projects adhere to safety standards while minimizing costly repairs down the line.

Moreover, digital documentation tools have revolutionized record-keeping practices for certified welding inspectors. Instead of relying on paper records, inspectors can now use mobile applications to log findings in real-time, making it easier to track compliance with industry standards like AWS and ASME. This shift not only improves efficiency but also enhances communication among teams involved in complex projects.

Emerging Trends in Certification

As technology continues to evolve, so do the certification processes for welding inspectors. Pipe welding certification programs are becoming more specialized, focusing on specific techniques and materials used within various industries such as oil and gas or construction. This trend reflects a growing need for certified professionals who possess targeted skills tailored to meet industry demands.

Additionally, online training platforms are gaining traction among aspiring certified welding inspectors. These platforms offer flexible learning options that cater to busy schedules while providing access to comprehensive resources needed for certification exams. As more individuals choose this route, we may see an increase in qualified professionals entering the field who are well-versed in modern inspection techniques.

The Role of Companies like China Inspection Pro

Companies like China Inspection Pro play a pivotal role in shaping the future of welding inspection by providing essential services that uphold quality standards across various sectors. Their expertise not only aids organizations in meeting regulatory requirements but also ensures that projects maintain high levels of safety and reliability through thorough inspections conducted by certified professionals.

Furthermore, these companies often invest in training programs designed to elevate the skills of both existing and new certified welding inspectors within their ranks. By fostering an environment where continuous education is prioritized, they contribute significantly to maintaining industry standards while preparing inspectors for future challenges posed by technological advancements.

In conclusion, as we look toward the future of welding inspection, it's clear that technology will continue to be a driving force behind improvements in certification processes and overall quality assurance practices within the industry.

Conclusion

In the world of welding, hiring a certified welding inspector is not just a smart choice; it’s an essential one. These professionals ensure that every weld meets industry standards, which can significantly impact the safety and longevity of your projects. When you invest in a certified welding inspector, you’re investing in peace of mind.

Why Hire a Certified Welding Inspector

A certified welding inspector brings expertise and an eye for detail that can make or break your project. They possess the training and qualifications to identify flaws that might go unnoticed by others, ensuring that every weld is up to snuff. With their knowledge of codes and standards, they help navigate complex regulations, making the entire process smoother and more efficient.

Key Benefits for Your Projects

The benefits of hiring a certified welding inspector extend beyond mere compliance; they enhance overall project quality. With their keen insights into pipe welding certification and other specialized areas, these inspectors can prevent costly mistakes before they happen. Additionally, having a certified professional on board can boost your project's credibility with clients and stakeholders alike.

Ensuring Quality in Every Weld

When it comes to ensuring quality in every weld, a certified welding inspector is your best ally. They systematically evaluate each weld against stringent standards to guarantee structural integrity and performance under stress. By prioritizing quality through rigorous inspections, you not only meet industry benchmarks but also foster trust with your clients—because nothing says reliability like knowing your work has been inspected by the best in the business.