Introduction

In the fast-paced world of manufacturing, ensuring quality and compliance is paramount. This is where Manufacturer Audits come into play, providing a structured approach to assess and enhance operational practices. Understanding what a manufacturing audit entails is essential for businesses striving for excellence in their production processes.

Understanding Manufacturing Audits

At its core, a manufacturing audit is a systematic examination of various aspects of the production process, aimed at identifying areas for improvement and ensuring adherence to established standards. These audits can cover everything from raw material sourcing to final product delivery, making them crucial for maintaining product integrity. By grasping what is a manufacturing audit, companies can better prepare themselves for the challenges that lie ahead.

The Importance of Auditing in Manufacturing

The importance of auditing in manufacturing cannot be overstated; it serves as a vital tool for compliance with industry regulations and standards. Regular audits help organizations identify potential risks and inefficiencies within their operations, paving the way for enhanced productivity and reduced costs. Ultimately, understanding why conduct a manufacturing audit translates into tangible benefits that contribute to long-term success.

Key Players in Manufacturing Audits

When it comes to who audits manufacturing companies, several key players are involved in this critical process. Internal auditors often work alongside external auditors and third-party inspection services to provide comprehensive assessments tailored to specific needs. Collaborating with experts like China Inspection Pro ensures that manufacturers receive detailed insights into their operations while adhering to all necessary guidelines and regulations.

What Is a Manufacturing Audit?

Manufacturing audits play a crucial role in ensuring that production processes meet established standards and regulations. These audits are systematic evaluations of various aspects of manufacturing operations, from compliance with safety protocols to the quality of the final products. Understanding what constitutes a manufacturing audit is essential for manufacturers looking to enhance their operational effectiveness and product quality.

Definition and Scope

A manufacturing audit is an examination of the processes, systems, and outputs within a manufacturing environment to assess compliance with internal policies and external regulations. The scope can cover everything from raw material sourcing to final product delivery, focusing on areas such as quality control, safety measures, and environmental impact. By conducting these audits, companies can identify weaknesses in their operations and take corrective actions before issues escalate.

Types of Manufacturing Audits

There are several types of manufacturing audits tailored to specific needs within the industry. Compliance audits ensure adherence to regulatory requirements, while process audits focus on evaluating efficiency and effectiveness in production methods. Additionally, supplier audits assess third-party vendors' capabilities and reliability—an essential aspect when considering how these relationships affect overall supply chain performance.

Common Standards and Regulations

Manufacturers must navigate a complex landscape of standards and regulations that govern their operations—think ISO certifications or OSHA guidelines for workplace safety. These standards provide frameworks for best practices that help ensure product quality, worker safety, and environmental responsibility. Staying compliant not only mitigates risks but also enhances credibility with customers who increasingly demand transparency in supply chains.

Understanding What Is a Manufacturing Audit? is just the beginning; knowing Who Audits Manufacturing Companies? follows closely behind as organizations seek qualified professionals for this critical function. Whether through internal teams or external partners like China Inspection Pro—who specialize in rigorous quality checks—ensuring thorough evaluations is key to realizing What Are the Benefits of a Manufacturing Audit?.

Who Audits Manufacturing Companies?

When it comes to Manufacturer Audits, understanding who conducts these evaluations is crucial for ensuring compliance and quality within the manufacturing process. Manufacturing audits can be performed by various entities, each with distinct roles and responsibilities that contribute to a comprehensive assessment of operations. This section will explore the different types of auditors involved in manufacturing audits, including internal auditors, external auditors, regulatory bodies, and third-party inspection services.

Internal Auditors vs. External Auditors

Internal auditors are typically employees of the manufacturing company who focus on evaluating compliance with internal policies and procedures. They have an intimate understanding of the organization’s processes and can identify areas for improvement from within. Conversely, external auditors are independent professionals or firms hired to assess compliance with industry standards and regulations objectively; they bring a fresh perspective that can uncover issues that may be overlooked by internal teams.

Both internal and external auditors play essential roles in What Is a Manufacturing Audit? Their findings can inform critical decisions about operational enhancements, risk management strategies, and overall business performance. Ultimately, leveraging both types of audits provides manufacturers with a well-rounded view of their processes while maximizing the benefits derived from conducting a manufacturing audit.

Roles of Regulatory Bodies

Regulatory bodies serve as watchdogs in the manufacturing sector to ensure compliance with established laws and standards. These organizations often set guidelines that manufacturers must adhere to regarding safety protocols, environmental practices, and product quality specifications. By conducting regular inspections and audits themselves or overseeing third-party assessments, regulatory bodies help maintain industry integrity.

The involvement of regulatory bodies is vital when discussing Why Conduct a Manufacturing Audit? Their oversight not only guarantees adherence to legal requirements but also instills confidence among consumers about product safety and quality. This relationship between manufacturers and regulatory agencies ultimately fosters an environment where continuous improvement is prioritized across the industry.

Third-Party Inspection Services

Third-party inspection services offer manufacturers an independent evaluation of their operations through specialized expertise in various industries. These organizations conduct thorough assessments based on established criteria outlined in the Manufacturing Process Audit Checklist—ensuring that all aspects of production meet required standards before products reach consumers or retailers. The independence of these services adds credibility to audit findings since they are not influenced by company politics or biases.

Utilizing third-party inspection services is increasingly seen as essential for manufacturers looking to enhance their reputation while ensuring adherence to What Are the Benefits of a Manufacturing Audit? These inspections provide actionable insights into operational efficiency while also identifying potential risks before they escalate into significant issues. Partnering with experts like China Inspection Pro further strengthens this approach; their rigorous examination processes guarantee that products meet or exceed industry benchmarks.

Why Conduct a Manufacturing Audit?

Manufacturing audits are essential for maintaining high standards within the production process. By systematically evaluating operations, manufacturers can ensure compliance with regulations and identify areas for improvement. Ultimately, these audits are crucial for reducing risks and enhancing overall efficiency in manufacturing practices.

Ensuring Compliance with Standards

One of the primary reasons to conduct a manufacturing audit is to ensure compliance with industry standards and regulations. Non-compliance can lead to severe consequences, including fines and damage to reputation, making it imperative that manufacturers regularly assess their processes. By engaging in regular Manufacturer Audits, companies can stay ahead of regulatory requirements and maintain their competitive edge.

Moreover, understanding What Is a Manufacturing Audit? helps clarify the importance of adhering to established standards. These audits not only verify compliance but also highlight any gaps that may exist in current practices. By addressing these gaps proactively, manufacturers can avoid potential pitfalls before they become costly issues.

Identifying Improvement Opportunities

Another critical aspect of conducting a manufacturing audit is identifying opportunities for improvement within existing processes. The insights gained from these audits can be transformative; they often reveal inefficiencies that may not be apparent during day-to-day operations. Manufacturers who embrace this practice often find themselves better positioned to optimize their workflows, ultimately leading to enhanced productivity.

The Manufacturing Process Audit Checklist serves as a valuable tool in this regard, guiding auditors through key areas that require attention. By systematically reviewing each component of the manufacturing process, companies can pinpoint specific areas where enhancements are needed or where resources may be wasted. This proactive approach fosters an environment of continuous improvement that benefits both employees and customers alike.

Reducing Operational Risks

Reducing operational risks is another compelling reason for conducting manufacturer audits regularly. In today's fast-paced market environment, even minor oversights can lead to significant disruptions or product failures down the line. A thorough audit process helps mitigate these risks by identifying vulnerabilities within the supply chain or production methods before they escalate into larger problems.

Furthermore, understanding Who Audits Manufacturing Companies? provides insight into how various stakeholders contribute to risk management efforts across the supply chain. Internal auditors play a vital role in monitoring ongoing operations while external auditors provide an objective perspective on compliance and performance metrics. Together, they help create a robust framework that safeguards against operational risks while promoting transparency throughout all levels of production.

In conclusion, conducting regular manufacturing audits is not just about ticking boxes; it's about fostering a culture of excellence within your organization. The benefits extend far beyond mere compliance; they encompass improved quality assurance and stronger relationships with suppliers—ultimately leading to greater customer satisfaction and loyalty over time.

What Are the Benefits of a Manufacturing Audit?

Manufacturing audits offer a plethora of benefits that can significantly enhance the overall performance and reliability of manufacturing companies. When considering What Are the Benefits of a Manufacturing Audit?, it becomes clear that these audits are not merely regulatory checkboxes but essential tools for continuous improvement. From enhancing product quality to boosting operational efficiency, the advantages are manifold and impactful.

Enhancing Product Quality

One of the primary benefits of conducting Manufacturer Audits is the enhancement of product quality. By systematically examining processes and outputs, manufacturers can identify defects or inconsistencies that may compromise their products before they reach consumers. This proactive approach ensures adherence to industry standards and customer expectations, ultimately leading to higher satisfaction rates and fewer returns.

Furthermore, regular audits help in establishing a culture of quality within an organization. Employees become more aware of quality standards and compliance requirements when faced with routine assessments, fostering accountability at every level. As a result, organizations that prioritize auditing often see marked improvements in their final products' consistency and reliability.

Ultimately, investing in rigorous auditing processes translates into tangible benefits for manufacturers seeking to uphold their reputation in a competitive marketplace. With services like those offered by China Inspection Pro, manufacturers can ensure every detail meets or exceeds industry standards, reinforcing their commitment to excellence.

Boosting Operational Efficiency

Another significant advantage lies in boosting operational efficiency through comprehensive audits. By evaluating workflows and identifying bottlenecks or inefficiencies during How Is the Manufacturer Audit Conducted?, businesses can streamline operations for optimal performance. This not only reduces waste but also allows organizations to allocate resources more effectively.

Moreover, addressing inefficiencies discovered during audits often leads to cost savings over time—something every manufacturer strives for! Enhanced efficiency means faster production cycles and improved turnaround times, which are crucial for meeting market demands swiftly without sacrificing quality. As companies learn from their findings during these evaluations, they become adept at refining processes continuously.

This focus on operational efficiency also strengthens internal communication among teams as they work together to address identified issues collaboratively. Ultimately, manufacturers who engage regularly in auditing practices position themselves favorably against competitors by maximizing productivity while minimizing costs.

Strengthening Supply Chain Relationships

Lastly, manufacturing audits play an essential role in strengthening supply chain relationships—an aspect vital for long-term success in any manufacturing operation. When manufacturers conduct thorough evaluations as part of Who Audits Manufacturing Companies?, they gain insights into their suppliers' practices and compliance levels as well as their own operations' alignment with best practices.

These insights foster transparency between suppliers and manufacturers—a key ingredient for building trust within partnerships! When both parties understand each other's strengths and weaknesses through audit findings, they can collaborate more effectively towards shared goals while mitigating risks associated with non-compliance or poor-quality materials entering production lines.

Additionally, strong supply chain relationships lead to improved negotiation power regarding pricing or terms due to established trustworthiness based on consistent performance metrics derived from audit results over time—everyone wins! Therefore investing time into understanding Why Conduct a Manufacturing Audit becomes paramount if one wishes to cultivate robust networks across all stages of production.

In conclusion, embracing manufacturer audits yields numerous benefits that extend beyond mere compliance checks; it fosters an environment focused on quality enhancement, operational excellence, and fortified partnerships throughout supply chains—all crucial components needed today’s fast-paced business landscape!

How Is the Manufacturer Audit Conducted?

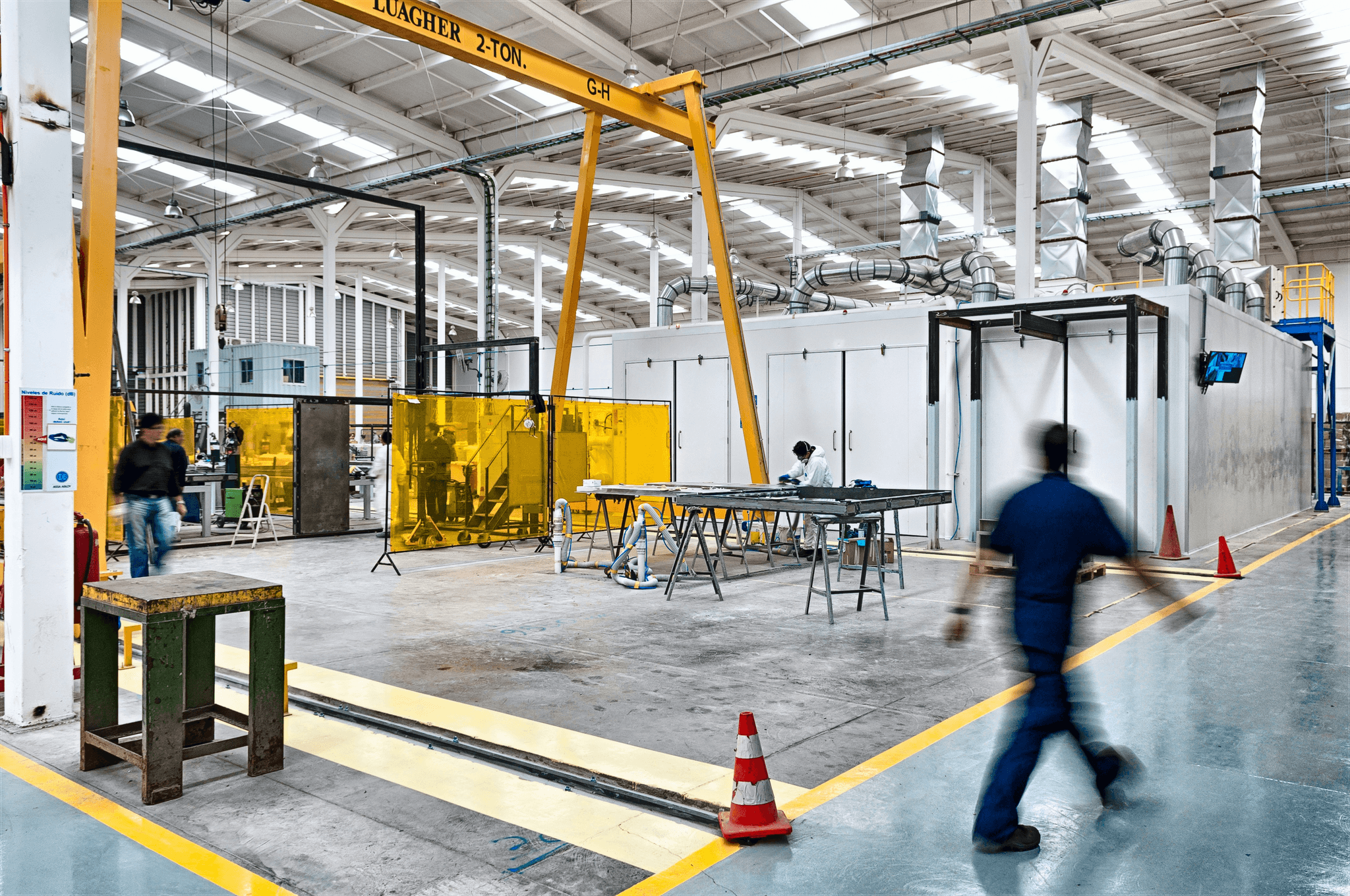

Conducting a manufacturing audit is a structured process that ensures compliance, identifies inefficiencies, and enhances overall quality. The audit journey typically begins with preliminary assessments and planning, moves into rigorous on-site processes, and culminates in comprehensive reporting and follow-up actions. Each step is critical in determining the effectiveness of manufacturing operations and ensuring adherence to standards.

Preliminary Assessments and Planning

Before diving headfirst into the audit waters, it’s essential to conduct preliminary assessments that set the stage for success. This involves understanding the specific objectives of the audit—whether it's compliance verification or identifying improvement opportunities. During this phase, auditors will review existing documentation related to What Is a Manufacturing Audit? along with performance metrics to develop a tailored approach that addresses unique operational needs.

Planning is equally crucial; it determines how resources are allocated during the audit process. Auditors outline key areas to inspect based on previous findings or known weaknesses while adhering to a Manufacturing Process Audit Checklist that ensures no stone is left unturned. By establishing clear goals and timelines at this stage, manufacturers can significantly enhance their chances of reaping What Are the Benefits of a Manufacturing Audit? such as improved efficiency and quality assurance.

On-Site Auditing Processes

Once planning is complete, auditors embark on on-site auditing processes where theory meets practice. This hands-on phase involves observing operations firsthand, interviewing staff members, and inspecting equipment—all vital components in answering Who Audits Manufacturing Companies? Internal teams may work alongside external auditors for a comprehensive view of practices against established standards.

During these on-site visits, auditors utilize their checklist to ensure all critical areas are thoroughly examined—from production lines to safety protocols. They assess compliance with common industry regulations while also identifying potential risks that could impact operational efficiency or product quality—key reasons for Why Conduct a Manufacturing Audit. The insights gathered here form the backbone of any recommendations made post-audit.

Reporting and Follow-Up

After all observations have been recorded and analyses completed, it’s time for reporting—a pivotal step in any manufacturing audit process. The auditor compiles findings into detailed reports that highlight strengths as well as areas needing improvement; this transparency helps stakeholders understand both current performance levels and future opportunities for enhancement related to What Are the Benefits of a Manufacturing Audit?

Follow-up actions are equally important; they involve not just presenting findings but also outlining actionable recommendations based on those insights gathered during audits. This could include strategies for improving supply chain relationships or boosting operational efficiency—both crucial elements in achieving long-term success in manufacturing environments like those serviced by China Inspection Pro. Their expertise ensures that recommendations are practical and aligned with industry standards.

Manufacturing Process Audit Checklist

A comprehensive Manufacturing Process Audit Checklist is essential for ensuring that every aspect of the manufacturing process is scrutinized. This checklist serves as a roadmap, guiding auditors through critical areas that require attention during the audit. By systematically addressing these key elements, companies can effectively answer the question: What Is a Manufacturing Audit?

Key Areas to Inspect

When conducting a manufacturing audit, there are several key areas to inspect that can significantly impact overall performance and compliance. First, the production processes themselves should be evaluated for efficiency and adherence to established protocols. Next, equipment maintenance records must be examined to ensure all machinery operates at peak performance and meets safety standards—this is crucial in answering Who Audits Manufacturing Companies? Lastly, employee training records should also be reviewed to verify that staff members are adequately trained in their respective roles.

Documentation Requirements

Proper documentation is vital in any manufacturing audit and serves as evidence of compliance with industry standards and regulations. Auditors need access to quality control documents, production logs, and inspection reports to evaluate processes effectively. Additionally, maintaining clear records of any corrective actions taken after previous audits helps demonstrate continuous improvement—a key aspect in understanding Why Conduct a Manufacturing Audit.

Performance Metrics and KPIs

To gauge the effectiveness of manufacturing processes during an audit, it's essential to establish specific performance metrics and Key Performance Indicators (KPIs). These metrics provide quantifiable data that can highlight areas needing improvement or confirm successful operations—ultimately showcasing What Are the Benefits of a Manufacturing Audit? Common KPIs include defect rates, production cycle times, and overall equipment effectiveness (OEE). By analyzing these figures post-audit, manufacturers can make informed decisions on how best to enhance operations.

In summary, utilizing a detailed Manufacturing Process Audit Checklist ensures thorough evaluation across all critical areas within your operations while also reinforcing compliance with necessary standards. Partnering with experts like China Inspection Pro can elevate this process further; their professionals deliver meticulous inspections focused on product excellence while providing actionable insights for continuous improvement.

Conclusion

In the fast-paced world of manufacturing, audits are not just a box to check; they are essential for ensuring quality, compliance, and continuous improvement. The long-term value of manufacturing audits extends beyond mere regulatory compliance; they serve as a roadmap for operational excellence. By understanding the nuances of what is a manufacturing audit and its benefits, companies can leverage these assessments to enhance their overall performance.

The Long-Term Value of Manufacturing Audits

Manufacturer audits provide invaluable insights that can lead to significant improvements in processes and products. By regularly conducting these audits, organizations can stay ahead of industry standards and regulations while also identifying areas for enhancement. Moreover, the benefits of a manufacturing audit resonate throughout the organization, fostering a culture of quality and accountability that ultimately leads to customer satisfaction.

Best Practices for Successful Audits

To ensure that manufacturer audits yield meaningful results, it’s crucial to follow best practices throughout the auditing process. Start with a well-defined scope that addresses specific areas outlined in your manufacturing process audit checklist; this ensures thorough coverage during evaluations. Additionally, engaging all stakeholders from management to floor workers fosters transparency and cooperation, making the audit process smoother and more effective.

Partnering with Experts like China Inspection Pro

When it comes to navigating the complexities of who audits manufacturing companies or how is the manufacturer audit conducted, partnering with professionals like China Inspection Pro can make all the difference. Their team specializes in delivering quality inspection services focused on product excellence—rigorously examining every detail to ensure compliance with industry standards. With their expertise guiding you through why conduct a manufacturing audit and translating findings into clear recommendations, you can confidently enhance your operations while meeting market expectations.