Introduction

In the bustling world of food production, maintaining high standards of quality is non-negotiable. Food industry quality control serves as the backbone for ensuring that products are safe, nutritious, and consistent. As consumers become increasingly health-conscious and discerning, the role of food auditing companies has never been more critical in safeguarding public health and enhancing brand reputation.

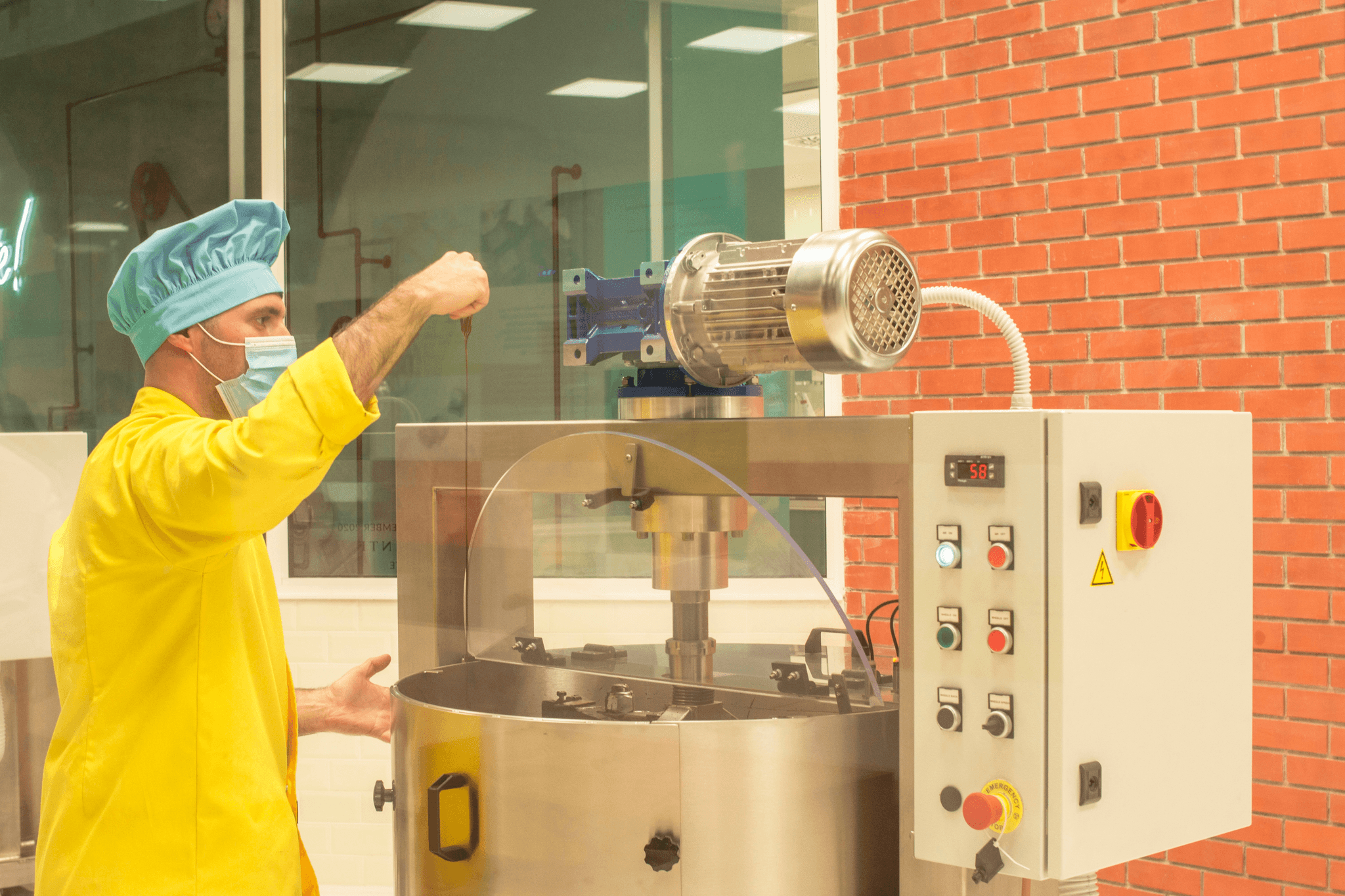

Understanding Food Industry Quality Control

At its core, food industry quality control encompasses a range of processes designed to monitor and improve the safety and integrity of food products. This includes everything from raw ingredient sourcing to final product packaging. By employing rigorous standards and techniques, businesses can identify potential hazards and ensure compliance with regulatory requirements—ultimately fostering trust among consumers.

Importance of Quality in Food Production

Quality in food production is paramount not only for consumer satisfaction but also for brand loyalty and market competitiveness. When companies prioritize quality control, they reduce risks associated with foodborne illnesses while enhancing their overall operational efficiency. Moreover, adhering to high-quality standards can significantly impact a company's bottom line by minimizing waste and avoiding costly recalls.

Overview of Quality Control Methods

A variety of methods exist within the realm of food industry quality control to address different aspects of production safety and efficiency. Techniques such as Statistical Process Control (SPC) allow businesses to analyze data trends for continuous improvement, while Hazard Analysis and Critical Control Points (HACCP) focus on identifying critical points where risks may arise during processing. Additionally, sensory evaluation methods provide valuable insights into consumer preferences, helping brands tailor their products to meet market demands effectively.

Fundamentals of Food Industry Quality Control

Understanding the fundamentals of food industry quality control is essential for ensuring safe and high-quality food products. The principles behind quality control not only safeguard consumer health but also enhance the reputation of businesses involved in food production. With various techniques and regulatory standards in place, companies can effectively manage their processes to maintain a consistent level of excellence.

Definitions and Key Concepts

At its core, food industry quality control refers to the systematic processes that ensure food products meet established standards for safety, quality, and compliance. Key concepts include monitoring production processes, testing raw materials, and conducting inspections at various stages of food processing. These measures are crucial in identifying potential hazards early on and preventing them from affecting the final product.

Quality control also emphasizes continuous improvement through feedback loops and data analysis. By utilizing metrics such as defect rates or customer satisfaction scores, businesses can refine their processes over time. This proactive approach not only enhances product quality but also fosters a culture of accountability among staff members engaged in food production.

Role of Quality Control in Food Safety

Quality control plays a pivotal role in maintaining food safety across the supply chain. By implementing rigorous testing protocols and adhering to guidelines set by regulatory bodies, companies can mitigate risks associated with contamination or spoilage. This is where third-party food safety audit companies come into play; they provide an unbiased assessment of a company's practices to ensure compliance with industry standards.

Moreover, effective quality control helps build trust between consumers and producers by demonstrating a commitment to safety and transparency. When customers know that stringent measures are in place to protect their health, they are more likely to choose brands that prioritize quality assurance over those that do not invest in robust auditing practices. Thus, establishing a solid foundation for food industry quality control is vital for fostering consumer confidence.

Regulatory Standards for the Food Industry

Navigating the complex landscape of regulatory standards is crucial for any business operating within the food sector. Various organizations—such as the FDA (Food and Drug Administration) in the United States—set guidelines that dictate acceptable practices related to hygiene, labeling, packaging, and overall product safety. Compliance with these regulations is non-negotiable; failure to adhere can lead not only to legal consequences but also significant damage to a brand's reputation.

Food auditing companies specialize in helping businesses understand these regulations while assessing their current practices against established benchmarks. By engaging with reputable third-party food safety audit companies, organizations can identify gaps in compliance before they escalate into larger issues down the line. Consequently, staying informed about evolving regulatory requirements ensures that businesses remain competitive while prioritizing consumer health.

Common Quality Control Techniques

In the food industry, quality control techniques are vital for ensuring products meet safety and quality standards. These methods not only help in maintaining consumer trust but also in complying with regulatory requirements. Let's dive into some of the most effective techniques used in food industry quality control.

Statistical Process Control

Statistical Process Control (SPC) is a powerful tool that utilizes statistical methods to monitor and control food production processes. By analyzing data from various stages of production, companies can identify variations that may indicate potential problems before they escalate. This proactive approach helps food auditing companies ensure that products consistently meet quality standards, reducing waste and improving efficiency.

Incorporating SPC into a quality control plan allows businesses to make data-driven decisions, leading to better outcomes. Furthermore, third-party food safety audit companies often recommend SPC as part of their evaluation criteria, showcasing its importance in maintaining high-quality standards. Ultimately, this technique empowers organizations to enhance their operational performance while ensuring compliance with industry regulations.

Hazard Analysis and Critical Control Points

Hazard Analysis and Critical Control Points (HACCP) is a systematic approach designed to identify and manage potential hazards in the food production process. This method focuses on critical points where risks can be controlled or eliminated, making it essential for any effective food safety audit company’s framework. Implementing HACCP not only ensures compliance with regulatory standards but also boosts consumer confidence in product safety.

Food audit companies often emphasize the importance of HACCP during assessments because it addresses biological, chemical, and physical hazards directly at the source. By establishing clear protocols for monitoring these critical points, businesses can significantly reduce the likelihood of contamination or spoilage throughout their supply chain. In turn, this leads to improved overall quality assurance within the realm of food industry quality control.

Sensory Evaluation Methods

Sensory evaluation methods involve assessing products based on human senses—taste, smell, sight, touch—and are crucial for understanding consumer preferences and product quality perceptions. These evaluations help businesses refine their offerings by identifying areas for improvement or confirming that a product meets market expectations before launch or rebranding initiatives. Food auditing companies recognize the value of sensory evaluations as part of a comprehensive strategy for maintaining high-quality standards.

Engaging consumers through sensory panels provides valuable feedback that can inform product development decisions while enhancing brand loyalty among customers who appreciate consistent quality experiences. Additionally, third-party food safety audit companies often include sensory evaluations as part of their audits to ensure that products not only meet safety requirements but also deliver an enjoyable experience for consumers. Ultimately, incorporating sensory evaluation methods plays a significant role in achieving excellence within the scope of food industry quality control.

Role of Food Auditing Companies

In the intricate web of food industry quality control, food auditing companies play a pivotal role in ensuring safety and compliance. These specialized firms conduct thorough evaluations of food production processes, helping businesses maintain high standards and adhere to regulatory requirements. As the stakes in food safety continue to rise, understanding the types of food audit companies available is essential for any business looking to enhance its quality control measures.

Types of Food Audit Companies

Food audit companies come in various shapes and sizes, each specializing in different aspects of quality assurance within the food industry. Some focus on compliance with specific regulations, such as those set by the FDA or USDA, while others may offer broader assessments that include environmental impact or ethical sourcing practices. Additionally, third-party food safety audit companies are often employed to provide an unbiased perspective on a company’s operations, ensuring that quality control measures are not just lip service but are effectively implemented.

Importance of Third Party Food Safety Audits

Third-party food safety audits serve as a critical check-and-balance system within the realm of food industry quality control. These audits help businesses identify potential weaknesses in their processes and provide actionable insights for improvement without any internal bias clouding their judgment. Engaging reputable third-party food safety audit companies can bolster consumer trust by demonstrating a commitment to transparency and accountability—essential ingredients for maintaining brand integrity in today’s market.

Selecting Reputable Food Auditing Companies

Choosing the right food auditing company can feel like finding a needle in a haystack, but it doesn’t have to be daunting! Start by looking for firms with credible certifications and industry experience; these indicators often reflect their expertise in executing effective audits tailored to your specific needs. Moreover, seeking reviews or testimonials from other businesses that have utilized these services can provide valuable insights into which food audit companies truly deliver results when it comes to enhancing your organization’s quality control efforts.

Case Studies of Quality Control Success

In the food industry, quality control is not just a box to check; it's the backbone of consumer trust and safety. Major food brands have paved the way in demonstrating effective quality control practices, showcasing how robust systems can prevent crises and enhance brand reputation. These case studies provide invaluable lessons for businesses aiming to improve their own food industry quality control measures.

Lessons from Major Food Brands

Major food brands have faced their share of challenges regarding quality control, but many have turned these challenges into opportunities for growth and improvement. For instance, when a large brand faced a recall due to contamination, they swiftly implemented more rigorous testing protocols and enhanced their relationships with food auditing companies. This proactive approach not only mitigated risks but also reinforced consumer confidence in their commitment to safety.

Another lesson comes from brands that prioritize transparency in their supply chains, often working closely with third-party food safety audit companies to ensure compliance with stringent regulations. By fostering open communication about sourcing and production processes, these companies can build stronger relationships with consumers who increasingly demand accountability. Ultimately, the key takeaway is that investing in comprehensive quality control not only safeguards public health but also enhances brand loyalty.

How McDonald’s Manages Quality Control

McDonald’s has long been recognized as an industry leader in food safety and quality control practices. The fast-food giant employs a multifaceted approach that includes rigorous supplier audits conducted by reputable food audit companies to ensure compliance with their high standards. This commitment extends beyond mere compliance; McDonald’s regularly trains its staff on best practices in food handling and preparation, ensuring everyone is on board with maintaining exceptional standards.

Moreover, McDonald’s utilizes advanced technology for monitoring temperature controls and ingredient freshness throughout its supply chain—a critical aspect of effective food industry quality control. Their strategic partnerships with third-party food safety audit companies further bolster their credibility by providing unbiased assessments of operations across various locations worldwide. This comprehensive system not only protects customers but also enhances operational efficiency by minimizing waste and ensuring consistency across all outlets.

Nestlé’s Approach to Food Safety

Nestlé's approach to food safety exemplifies how a global brand can integrate robust quality control measures into every facet of its operations. The company places immense emphasis on adhering to international regulatory standards while continuously improving its internal processes through collaboration with specialized food auditing companies. By conducting regular audits and engaging third-party experts for objective evaluations, Nestlé ensures that it meets or exceeds established benchmarks for safety and quality.

In addition to systematic audits, Nestlé invests heavily in research and development aimed at innovating safer processing methods while maintaining product integrity—demonstrating that innovation can go hand-in-hand with stringent quality controls within the food industry. Their commitment extends beyond products; they actively engage consumers through educational campaigns about nutrition and safe consumption practices, fostering an informed customer base willing to trust their offerings fully. As such, Nestlé stands as a testament to how comprehensive strategies involving both internal policies and external partnerships can lead to unparalleled success in maintaining high standards of food safety.

Implementing Quality Control in Your Business

Establishing robust food industry quality control is essential for any business involved in food production. A well-structured quality control plan serves as the backbone of your operations, ensuring that every product meets safety and quality standards. This plan should be tailored to your specific processes, incorporating methods from reputable food auditing companies to enhance its effectiveness.

Developing a Quality Control Plan

Creating a quality control plan starts with identifying critical points in your production process where quality can be monitored and improved. Utilize insights from third party food safety audit companies to establish benchmarks and best practices that align with industry standards. By integrating these elements, you create a roadmap that not only ensures compliance but also enhances overall product quality.

Next, determine the metrics you will use to measure success—these could range from temperature controls during storage to sensory evaluations of finished products. Regularly revisiting and refining this plan is crucial as it allows for adjustments based on changing regulations or emerging trends in food safety audits. A dynamic approach keeps your operations responsive and aligned with the latest developments in food industry quality control.

Training Staff on Quality Procedures

An exceptional quality control plan is only as effective as the people implementing it; hence, training staff on these procedures is vital. Begin by organizing comprehensive training sessions that cover all aspects of your quality control protocols, emphasizing the importance of adherence to established guidelines from reputable food audit companies. This not only empowers employees but also fosters a culture of accountability regarding food safety.

Utilize real-world examples—perhaps case studies from successful brands—to illustrate how effective training has directly impacted product integrity and consumer trust in other organizations. Encourage staff engagement by soliciting feedback on training content; this can lead to improvements in both understanding and execution of procedures. Remember, an informed team is key to maintaining high standards across all levels of production.

Continuous Improvement and Feedback Loops

Quality control isn’t a one-and-done affair; it requires ongoing assessment and refinement through continuous improvement practices. Establish feedback loops that allow employees at all levels to report issues or suggest enhancements related to food industry quality control processes easily. Engaging with third party food safety audit companies can provide an external perspective on areas needing attention or enhancement.

Incorporating regular reviews into your operational routine can help identify patterns or recurring issues that may arise over time, allowing for timely interventions before they escalate into larger problems. Moreover, fostering an environment where feedback is valued encourages innovation among staff who may have unique insights into improving processes further based on their day-to-day experiences. Ultimately, this commitment to continuous improvement will solidify your reputation within the competitive landscape of the food sector.

Conclusion

As we wrap up our exploration of food industry quality control, it's clear that maintaining high standards is not just a regulatory requirement but a cornerstone of consumer trust and brand reputation. Quality control methods are essential for ensuring safety, consistency, and compliance in food production processes. The integration of various techniques—from statistical process control to sensory evaluations—helps companies mitigate risks and enhance product quality.

Key Takeaways on Quality Control Methods

One major takeaway is the critical role that quality control plays in the food industry; it ensures that products meet safety standards while also satisfying customer expectations. Understanding the various methods available, including those employed by third party food safety audit companies, can significantly improve a company's operational efficiency and reliability. Moreover, investing in robust quality control systems not only protects consumers but also strengthens a brand's market position.

Future Trends in Food Industry Quality Control

Looking ahead, one can anticipate significant advancements in technology influencing food industry quality control practices. Automation and artificial intelligence are set to revolutionize how companies monitor compliance and track quality metrics in real-time. Additionally, as consumer awareness grows regarding sustainability and ethical sourcing, food auditing companies will need to adapt their frameworks to incorporate these emerging priorities into their audits.

How China Inspection Pro Can Enhance Quality Assurance

China Inspection Pro stands out among food audit companies by providing comprehensive services that align with international standards for food safety audits. Their expertise helps businesses navigate complex regulatory landscapes while ensuring adherence to best practices in quality management. By leveraging the capabilities of third party food safety audit companies like China Inspection Pro, organizations can enhance their overall quality assurance processes and build greater trust with consumers.