Introduction

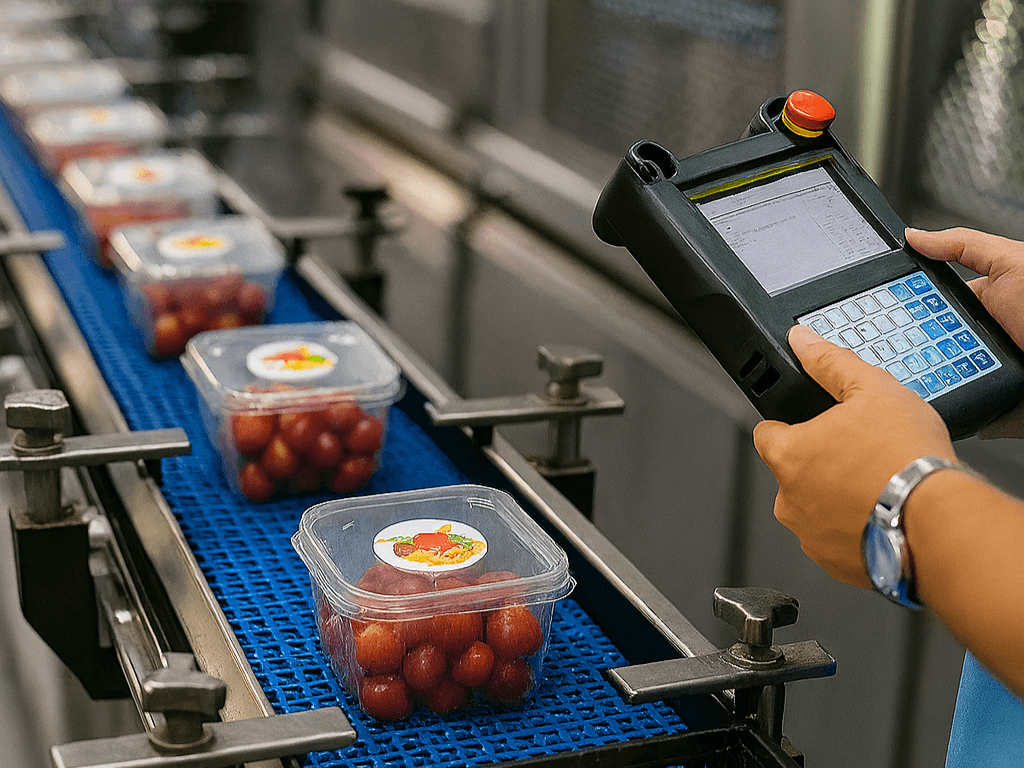

In an era where food safety is paramount, understanding the mechanisms behind Food Safety Audits is crucial for both producers and consumers. These audits serve as a vital checkpoint to ensure that food products meet regulatory standards and safety certifications, thereby safeguarding public health. With increasing scrutiny from regulatory bodies, the significance of robust food safety inspections cannot be overstated.

Understanding Food Safety Audits

Food Safety Audits are systematic examinations of various processes within the food supply chain to ensure compliance with established standards. They assess everything from hygiene practices to manufacturing protocols, playing a pivotal role in maintaining food quality and safety. By identifying potential risks and areas for improvement, these audits help organizations align with best practices in food certification.

Importance of GHP and GMP

Good Hygiene Practices (GHP) and Good Manufacturing Practices (GMP) are foundational to achieving high standards in food production. GHP focuses on maintaining cleanliness throughout the production process, while GMP ensures that manufacturing methods consistently produce safe products. Together, they form the bedrock of effective safety certifications that not only protect consumers but also enhance brand reputation.

The Role of Third-Party Inspections

Third-party inspections add an extra layer of credibility to Food Safety Audits by providing an unbiased assessment of compliance with industry regulations. These independent evaluations can highlight discrepancies that internal teams might overlook, ensuring a more thorough examination of facilities and processes. Engaging trusted partners like China Inspection Pro can elevate your audit process by delivering expert insights into your operations, ultimately resulting in improved product quality and adherence to safety certifications.

What Are Good Hygiene Practices?

Good Hygiene Practices (GHP) are essential components of food safety that ensure food products remain safe for consumption. They encompass a set of guidelines and procedures designed to maintain cleanliness and prevent contamination throughout the food production process. Adhering to GHP not only protects consumers but also strengthens the integrity of food safety audits and certifications.

Definition and Key Principles

Good Hygiene Practices refer to the protocols that govern personal hygiene, equipment sanitation, and facility cleanliness in food handling environments. These principles include proper handwashing techniques, maintaining clean work surfaces, and ensuring that food contact surfaces are sanitized regularly. By establishing these fundamental practices, facilities can significantly reduce the risk of foodborne illnesses and enhance their compliance with safety certifications.

GHP Impact on Food Safety

The impact of Good Hygiene Practices on overall food safety cannot be overstated; they serve as the first line of defense against microbial contamination. Implementing GHP effectively minimizes hazards that could lead to unsafe products, which is critical during food safety inspections or audits. Moreover, organizations demonstrating strong hygiene practices often find it easier to achieve favorable outcomes in third-party food safety audits, ultimately enhancing their reputation in the market.

Practical Implementation in Facilities

Implementing Good Hygiene Practices within facilities requires a strategic approach focused on training staff and creating a culture of cleanliness. Regular training sessions should be conducted to ensure employees understand the importance of hygiene standards and how to apply them daily. Additionally, facilities must establish clear protocols for cleaning schedules, waste management, and monitoring compliance with GHP—ensuring that every corner meets industry standards set forth by regulatory bodies like China Inspection Pro.

What Are Good Manufacturing Practices?

Good Manufacturing Practices (GMP) are essential guidelines that ensure the consistent production of safe and high-quality food products. These standards are designed to minimize the risks involved in food production and processing, ultimately protecting consumers from potential hazards. By adhering to GMP, companies can enhance their operational efficiency and maintain compliance with food safety audits.

Definition of GMP Standards

GMP standards encompass a set of regulations and practices that govern the manufacturing process in the food industry. These guidelines cover various aspects, including facility cleanliness, equipment maintenance, employee hygiene, and proper documentation procedures. Compliance with these standards is crucial for obtaining food safety certification and ensuring that products meet regulatory requirements.

GMP’s Role in Quality Control

GMP plays a pivotal role in quality control by establishing a framework that helps organizations monitor their production processes effectively. By implementing GMP protocols, companies can identify potential issues early on, reducing the likelihood of product recalls or safety inspections due to non-compliance. This proactive approach not only safeguards consumer health but also enhances brand reputation through consistent quality assurance.

Compliance and Best Practices

Achieving compliance with GMP involves understanding both local regulations and international standards applicable to food safety audits. Best practices include regular training for employees on hygiene protocols, routine equipment checks, and thorough documentation of all processes. Organizations can also benefit from third-party food safety audits conducted by trusted partners like China Inspection Pro, which provide an unbiased assessment of compliance levels while offering actionable insights for improvement.

The Importance of Food Safety Audits

Food safety audits are essential for ensuring that food products meet the necessary health and safety standards. These audits not only help identify potential hazards but also play a critical role in maintaining consumer trust and brand integrity. With the increasing scrutiny on food safety, understanding their importance cannot be overstated.

Objectives of Food Safety Inspections

The primary objective of food safety inspections is to evaluate compliance with established regulations and standards, ensuring that food products are safe for consumption. By conducting thorough assessments, these inspections aim to identify areas for improvement and mitigate risks associated with foodborne illnesses. Ultimately, they serve to protect public health while enhancing operational efficiency within the industry.

Another key objective is to prepare facilities for obtaining food safety certification, which can significantly enhance their marketability. Achieving certification demonstrates a commitment to quality and safety, making businesses more attractive to consumers and partners alike. Additionally, regular inspections help organizations stay ahead of regulatory changes by keeping them informed about evolving standards.

Common Audit Methodologies

Food safety audits employ various methodologies tailored to specific industries and regulatory requirements. Common approaches include checklist-based assessments, risk-based evaluations, and process-oriented reviews that focus on critical control points throughout production. These methodologies ensure comprehensive evaluations that address both Good Hygiene Practices (GHP) and Good Manufacturing Practices (GMP).

Third-party food safety audits often utilize standardized frameworks like ISO 22000 or HACCP principles to guide their assessments. This consistency allows businesses to benchmark their practices against industry best practices while fostering accountability through external validation. By incorporating these methodologies into their operations, companies can improve their overall compliance with food safety regulations.

Consequences of Non-Compliance

The consequences of non-compliance with food safety standards can be severe, ranging from financial penalties to reputational damage that may take years to recover from. Failing a food safety inspection can lead directly to product recalls or shutdowns, creating significant disruptions in supply chains and eroding consumer confidence in brands involved. In some cases, non-compliance might even result in legal action against the company involved.

Additionally, without proper adherence to GHPs and GMPs during audits, businesses risk losing valuable certifications necessary for market access or export opportunities—effectively locking them out of lucrative markets altogether! Moreover, when consumers learn about lapses in a company's food safety practices through media coverage or social channels, it can lead to long-lasting damage that may deter future customers from engaging with the brand.

To navigate these challenges effectively—and ensure your business remains compliant—it’s wise to partner with trusted experts like China Inspection Pro who specialize in professional services focused on product excellence! Their rigorous examination processes provide actionable insights into improving your operations while safeguarding your reputation against potential pitfalls associated with non-compliance.

Navigating Food Safety Certification

Navigating the maze of food safety certification can feel like trying to find a needle in a haystack, but it doesn't have to be daunting. Understanding the different types of food certifications available is crucial for businesses looking to enhance their credibility and ensure compliance with industry standards. With the right guidance, organizations can streamline their path toward achieving essential safety certifications.

Overview of Food Certification Types

Food certification types vary widely, each designed to address specific aspects of food safety and quality. Common certifications include Hazard Analysis Critical Control Point (HACCP), ISO 22000, and Safe Quality Food (SQF) certification, among others. Each type serves distinct purposes; for instance, HACCP focuses on preventing hazards during production, while ISO 22000 provides a comprehensive framework for managing food safety throughout the supply chain.

Understanding these various certifications helps organizations identify which aligns best with their operational goals and customer expectations. Additionally, some certifications cater specifically to certain markets or regions, making it vital for businesses to choose wisely based on their target audience and regulatory requirements. By selecting appropriate food safety certifications, companies can enhance their reputation and improve consumer trust.

Benefits of Obtain Certification

Obtaining food safety certification offers numerous benefits that extend beyond just compliance with regulations. First and foremost, certified facilities often experience improved operational efficiency as they implement standardized practices that reduce waste and minimize risks associated with foodborne illnesses. Furthermore, these certifications can serve as powerful marketing tools that differentiate products in a competitive marketplace.

Another significant advantage is enhanced consumer confidence; when buyers see recognized safety certifications on packaging or promotional materials, they are more likely to trust the brand's commitment to quality and safety. This trust often translates into increased sales and customer loyalty over time—an invaluable asset in today’s market landscape. Ultimately, achieving robust food safety audits through proper certification not only safeguards public health but also boosts overall business performance.

How to Choose a Certification Body

Choosing the right certification body is akin to selecting a trusted partner in your quest for excellence in food safety inspections. Start by evaluating the accreditation status of potential certifying agencies; reputable bodies should be recognized by relevant authorities such as the International Organization for Standardization (ISO) or local regulatory agencies overseeing food safety standards.

Next, consider the body’s expertise in your specific industry sector; some organizations may specialize in particular niches such as organic foods or export markets like China Inspection Pro which ensures compliance with international standards while focusing on product excellence through rigorous examination processes. Lastly, look at reviews from other companies regarding their experiences with different certification bodies—this feedback can provide insight into reliability and service quality that will help you make an informed decision.

The Role of Third-Party Food Safety Audits

In the realm of food safety, third-party food safety audits play a crucial role in ensuring compliance and quality. These audits are conducted by independent organizations that specialize in evaluating food safety practices against established standards. By utilizing third-party auditors, companies can gain an unbiased perspective on their operations, fostering trust among consumers and stakeholders alike.

Understanding Third-Party Auditors

Third-party auditors are professionals who assess a facility's adherence to food safety regulations and best practices without any conflicts of interest. They bring expertise from various sectors within the food industry, allowing them to provide comprehensive evaluations that internal teams might overlook. Engaging with these auditors not only enhances credibility but also serves as an essential step in obtaining food certification.

Benefits of External Inspections

External inspections through third-party food safety audits offer numerous advantages for businesses striving for excellence in food safety certifications. First and foremost, they provide an objective assessment that helps identify gaps in compliance and operational efficiency, ultimately leading to improved practices. Additionally, these audits can bolster a company’s reputation by demonstrating a commitment to maintaining high standards in food safety inspections.

Furthermore, the insights gained from third-party evaluations can guide organizations toward better risk management strategies, reducing the likelihood of costly recalls or legal issues down the line. This proactive approach to addressing potential problems solidifies consumer confidence and loyalty—an invaluable asset in today’s competitive market.

Choosing a Trusted Partner

Selecting the right partner for third-party food safety audits is critical for achieving desired outcomes and ensuring ongoing compliance with industry standards. Start by researching potential auditing firms like China Inspection Pro, known for delivering professional services focused on product excellence through rigorous examination processes. Look for certifications held by the auditing body itself; reputable organizations should be accredited by recognized bodies specializing in food safety certification.

When evaluating options, consider factors such as experience within your specific sector and customer testimonials that reflect past performance during inspections. A trusted partner will not only conduct thorough assessments but also offer actionable recommendations based on their findings—turning complex challenges into clear pathways toward enhanced quality assurance.

Conclusion

In conclusion, the significance of Good Hygiene Practices (GHP) and Good Manufacturing Practices (GMP) cannot be overstated in the realm of food safety audits. These practices serve as the backbone of effective food safety inspections and play a crucial role in ensuring that food products are safe for consumption. By adhering to these standards, businesses not only comply with regulations but also foster trust with consumers, paving the way for successful food certification.

Key Takeaways on GHP and GMP

Good Hygiene Practices focus on maintaining cleanliness and preventing contamination throughout food handling processes. Coupled with Good Manufacturing Practices, they ensure that facilities operate efficiently while minimizing risks associated with foodborne illnesses. Ultimately, both GHP and GMP are essential components that contribute to successful food safety audits and certifications.

Steps Towards Effective Food Safety

To achieve effective food safety, organizations should prioritize regular training for staff on hygiene protocols and manufacturing standards. Implementing a systematic approach to food safety inspections can help identify potential hazards before they escalate into serious issues. Partnering with trusted providers like China Inspection Pro can enhance compliance by delivering expert insights into regulatory requirements and best practices for obtaining safety certifications.

The Future of Food Safety Standards

As consumer awareness grows regarding food quality and safety, it’s likely that future standards will become even more stringent. Innovations in technology will also play a pivotal role in shaping the landscape of food certification processes, making it easier for businesses to maintain compliance through automated systems and real-time monitoring solutions. Embracing these changes will be essential for companies aiming to stay ahead in an increasingly competitive market where transparency is paramount.