Introduction

In the ever-evolving world of welding, productivity is paramount. As industries strive for efficiency and quality, understanding welding productivity improvements becomes essential. The integration of performance reviews serves not only to enhance skills but also to elevate overall output.

Understanding Welding Productivity Improvements

Welding productivity encompasses various factors that contribute to the efficiency and quality of welds produced. By focusing on continuous improvement, welders can refine their techniques and minimize waste, leading to significant cost savings. Ultimately, enhancing welding productivity is a collaborative effort that involves both skilled labor and effective management practices.

The Role of Performance Reviews in Welding

Performance reviews play a crucial role in shaping a welder's career by providing structured feedback on their work. These evaluations help identify strengths and weaknesses, ensuring that welders are aligned with the tasks at hand. Moreover, regular performance reviews foster an environment where continuous learning is encouraged, paving the way for improved welding practices.

Why On-site Reviews Matter

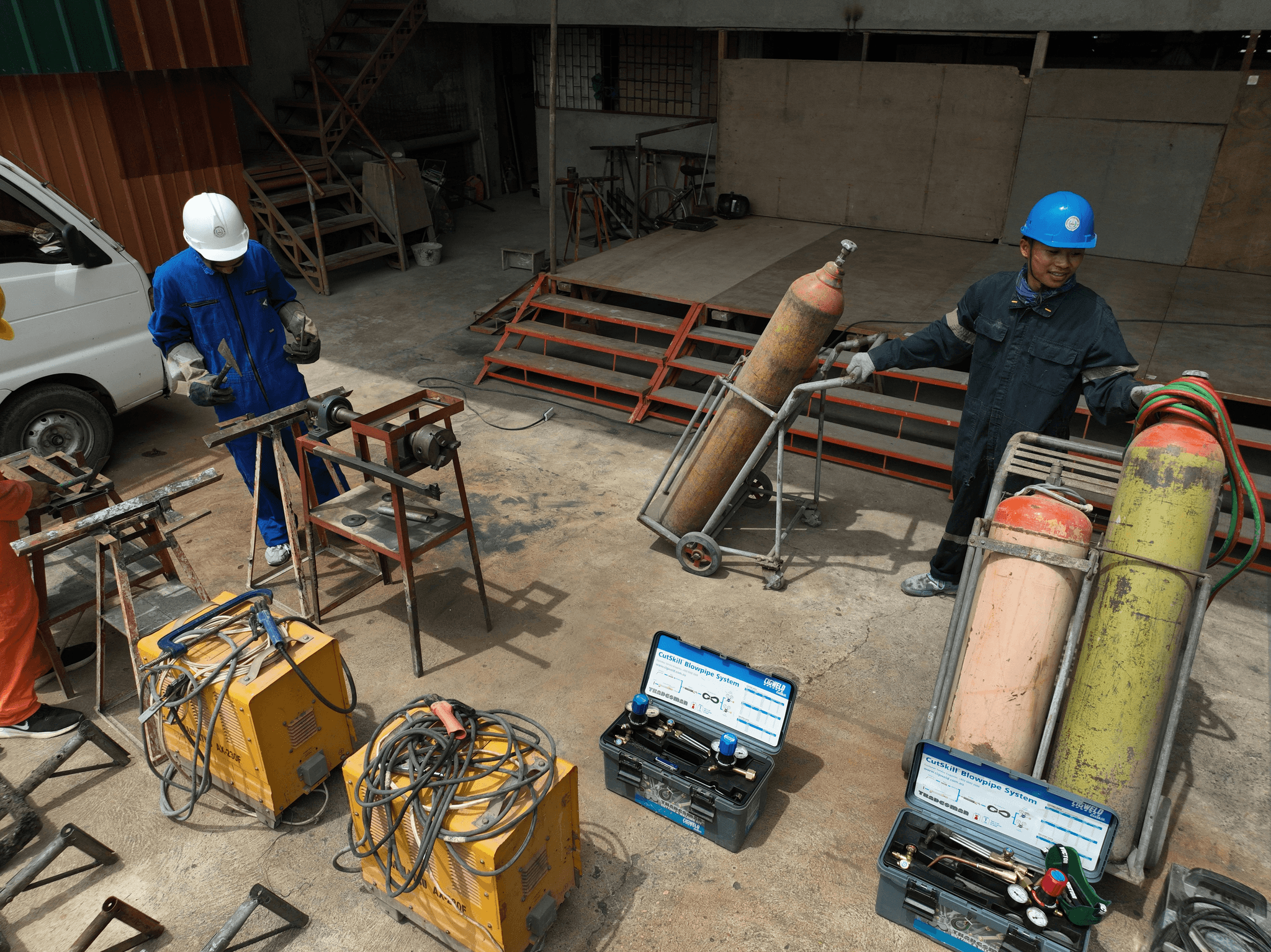

On-site reviews bring an added layer of immediacy to performance evaluations by allowing supervisors to assess welders in real time. This hands-on approach not only facilitates instant corrections but also enhances communication between teams working on complex projects. By prioritizing on-site reviews, companies can boost morale and motivation among welders while driving significant improvements in welding productivity.

The Importance of Performance Reviews

Performance reviews in the welding industry are not just a formality; they are essential for enhancing welding productivity and ensuring high-quality outputs. By systematically evaluating welders' skills and techniques on-site, organizations can identify strengths and areas for improvement, creating a culture of continuous development. These reviews serve as a vital tool to align individual performance with organizational goals, ultimately leading to superior results.

Setting Clear Expectations for Welders

Setting clear expectations is crucial in the welding profession, where precision and adherence to standards can make or break a project. On-site reviews help establish these benchmarks by providing welders with specific guidelines regarding their tasks and performance metrics. When expectations are clearly communicated, welders can better understand what is required of them, leading to improved welding productivity and reduced errors.

Aligning Skills with Tasks

One of the key benefits of performance reviews is the ability to align welders' skills with the tasks they are assigned. Through careful observation during on-site inspections, supervisors can assess whether a welder's abilities match the demands of their current assignments. This alignment not only enhances overall efficiency but also fosters job satisfaction as welders feel more competent and capable when performing tasks suited to their skill levels.

Establishing Accountability in the Workplace

Accountability is paramount in any successful workplace, especially in welding where safety and quality are non-negotiable. Performance reviews create an environment where individuals take ownership of their work by regularly evaluating their contributions through constructive feedback during on-site inspections. This sense of accountability drives welders to uphold high standards, ultimately boosting both morale and overall welding productivity across teams.

Analyzing Welding Techniques

In the ever-evolving world of welding, analyzing techniques is crucial for enhancing productivity. Through systematic evaluation and on-site reviews, welders can identify specific areas where skill enhancement is needed. This not only boosts individual performance but also contributes to overall welding productivity across the team.

Identifying Areas for Skill Enhancement

The first step in refining welding techniques involves pinpointing where improvements can be made. On-site reviews serve as an invaluable tool for supervisors to observe welders in action, identifying gaps in skills or techniques that could hinder efficiency. By documenting these areas for skill enhancement, teams can develop targeted training programs that elevate the quality of work and foster a culture of continuous improvement.

Utilizing Feedback for Progress

Feedback is a powerful catalyst for progress in any field, and welding is no exception. Constructive criticism gathered during on-site reviews allows welders to understand their strengths and weaknesses better, enabling them to focus on specific aspects of their craft that require attention. By regularly utilizing feedback from welding inspections and performance evaluations, teams can track their development over time and make necessary adjustments to enhance overall performance.

Strengthening Best Practices in Welding

Establishing best practices is essential for maintaining high standards in welding productivity. On-site reviews provide a platform to share successful techniques among team members while fostering an environment where learning from one another becomes second nature. Strengthening these best practices not only leads to improved quality but also ensures compliance with industry standards—ultimately raising the bar for all involved.

The Impact of On-site Reviews

When it comes to enhancing welding productivity, on-site reviews play a pivotal role in refining processes and outcomes. These evaluations allow for immediate feedback, ensuring that any discrepancies are addressed promptly. By integrating real-time adjustments into the workflow, teams can significantly improve their overall performance and output quality.

Real-Time Corrections and Adjustments

On-site reviews provide welders with the opportunity to receive immediate corrections during the welding process. This instant feedback loop is crucial for identifying mistakes before they escalate into costly errors or rework, ultimately saving time and resources. By focusing on real-time corrections, teams can enhance their welding productivity while maintaining high-quality standards through consistent inspection practices.

Enhancing Communication Between Teams

Effective communication is essential for successful welding operations, and on-site reviews foster this connection among team members. When welders receive direct feedback from supervisors or peers during inspections, it encourages an open dialogue about techniques and best practices. This collaborative environment not only boosts welding productivity but also helps create a culture of continuous improvement across the workforce.

Boosting Morale and Motivation

On-site reviews do more than just improve processes; they also have a significant impact on team morale and motivation. When employees see that their efforts are recognized through constructive feedback during inspections, they feel valued and empowered to enhance their skills further. This positive reinforcement ultimately leads to increased job satisfaction among welders, driving them to strive for excellence in every project they undertake.

Quality Control with China Inspection Pro

In the fast-paced world of welding, maintaining high standards is paramount for ensuring safety and efficiency. This is where China Inspection Pro comes into play, providing a robust framework for quality control that aligns with industry standards. By implementing rigorous welding inspections, companies can significantly enhance their welding productivity while adhering to regulatory requirements.

Ensuring Compliance with Industry Standards

Compliance with industry standards is not just a checkbox; it’s a commitment to excellence in every weld made. China Inspection Pro helps organizations navigate the complex landscape of regulations by offering comprehensive welding inspections that ensure all processes meet required benchmarks. This adherence not only protects workers but also enhances overall welding productivity by reducing rework and minimizing defects.

Delivering Actionable Recommendations

After thorough inspections, it’s crucial to translate findings into actionable recommendations that can drive improvement. China Inspection Pro excels in providing clear and concise feedback that welders and supervisors can implement immediately on-site. These recommendations are tailored to specific challenges identified during inspections, thereby fostering an environment where continuous improvement becomes part of the daily workflow—boosting both morale and welding productivity.

Raising Overall Welding Quality

The ultimate goal of any quality control system is to elevate the standard of work produced, and this is precisely what China Inspection Pro aims to achieve. By focusing on consistent monitoring through on-site reviews, teams can identify weaknesses in their processes before they lead to larger issues down the line. As overall welding quality improves, so does productivity; satisfied customers are more likely to return for future projects when they know they can rely on top-notch results every time.

Measuring Productivity Metrics

In the world of welding, productivity metrics are the unsung heroes that drive improvements and ensure projects stay on track. By harnessing data from various sources, including on-site reviews and welding inspections, teams can identify bottlenecks and optimize processes effectively. Ultimately, a data-driven approach empowers welders to enhance their skills while boosting overall welding productivity.

Utilizing Data to Drive Improvements

Data is more than just numbers; it tells a story about performance and potential. By analyzing metrics gathered during on-site reviews, organizations can pinpoint areas where welding productivity can be enhanced. Whether it's adjusting techniques or reallocating resources based on inspection findings, leveraging data transforms insights into actionable strategies that lead to tangible improvements in output.

Tracking Performance Over Time

Tracking performance over time is crucial for understanding trends in welding productivity. Regular assessments through on-site reviews allow teams to compare current results with historical data, providing a clear picture of progress or decline. This ongoing analysis not only helps identify persistent issues but also sheds light on successful practices that should be celebrated and emulated across the board.

Celebrating Achievements and Milestones

Recognizing achievements in welding productivity is essential for maintaining morale and motivation among team members. Celebrating milestones—whether it’s hitting production targets or successfully implementing feedback from inspections—creates a culture of excellence within the workplace. When welders see their hard work acknowledged through formal recognition or informal shout-outs, it fosters an environment where continuous improvement thrives.

Conclusion

In the dynamic world of welding, performance reviews are not just a box to tick; they are a vital tool for enhancing welding productivity. By leveraging on-site reviews, organizations can gain immediate insights into the strengths and weaknesses of their teams, ensuring that welders are not only meeting expectations but also exceeding them. The continuous cycle of feedback and improvement fosters an environment where everyone is motivated to elevate their skills and contribute to the overall success of the project.

Maximizing the Value of Performance Reviews

To truly maximize the value of performance reviews in welding, it's essential to focus on actionable insights rather than generic assessments. On-site reviews provide a unique opportunity for supervisors to observe welders in action, identifying specific areas where productivity can be boosted through targeted training or technique adjustments. This tailored approach ensures that each welder receives personalized feedback that aligns with their individual skill sets and job roles, ultimately leading to improved performance and higher quality results.

Future Trends in Welding Productivity

As technology continues to evolve, so too will the methods we use to enhance welding productivity. One significant trend is the integration of advanced inspection technologies that allow for real-time monitoring during on-site reviews and welding inspections. These innovations not only streamline workflows but also provide data-driven insights that can help predict potential issues before they become costly problems, paving the way for a more efficient future in welding practices.

Enhancing Skills through Continuous Feedback

Continuous feedback is crucial for fostering an environment where welders feel empowered to improve their skills consistently. Regular on-site reviews create opportunities for constructive dialogue between supervisors and team members, allowing for immediate corrections and encouragement alike. By prioritizing ongoing skill enhancement through frequent feedback loops, companies can ensure that their workforce remains agile and adaptable in an ever-changing industry landscape.