Introduction

In the intricate world of business, understanding quality costs is pivotal to maintaining competitiveness and ensuring customer satisfaction. Quality costs encompass various aspects, including inspection and testing, which are what kind of quality cost that can significantly influence a company's bottom line. By grasping the nuances of these costs, businesses can implement better strategies to enhance product quality while minimizing expenses.

Understanding Quality Costs in Business

Quality costs can be categorized into four primary types: prevention, appraisal, internal failure, and external failure. Inspection and testing play a crucial role in the appraisal category, helping organizations assess whether products meet established standards before they reach customers. By investing wisely in quality inspections—like Incoming Inspection or Final Inspection—businesses can effectively reduce overall quality costs while improving their reputation.

The Importance of Inspection and Testing

Inspection and testing are fundamental practices that ensure products conform to specified requirements throughout the production process. Without thorough inspections—such as In-Process Inspection or First Article Inspection (FAI)—companies risk delivering subpar products that could lead to costly recalls or reputational damage. Therefore, implementing robust inspection strategies is essential for maintaining high-quality standards while managing associated costs effectively.

Exploring Different Types of Inspections

There are several types of inspections that businesses utilize to safeguard product quality at various stages of production. Incoming Inspection verifies raw materials upon arrival; In-Process Inspection monitors ongoing production; First Article Inspection (FAI) assesses initial production runs; Final Inspection ensures end-product compliance; and Specialized Inspections cater to unique industry needs. Each type serves a distinct purpose in the overall quality management framework, contributing significantly to controlling quality costs.

What Are Quality Costs?

Quality costs are a critical component of any business strategy, impacting both the bottom line and customer satisfaction. These costs encompass all expenses associated with ensuring that products or services meet quality standards. Understanding these costs helps organizations optimize their processes and enhance overall quality.

Defining Quality Costs

At its core, quality costs refer to the expenses incurred to prevent poor quality, appraise products for defects, and address failures when they occur. They can be categorized into four main types: prevention costs, appraisal costs, internal failure costs, and external failure costs. When discussing inspection and testing are what kind of quality cost, they primarily fall under appraisal costs since these activities help assess whether products meet established standards.

Direct and Indirect Costs Explained

Direct costs are those that can be directly attributed to a specific product or service, such as materials used in Incoming Inspection or labor involved in Final Inspection processes. On the other hand, indirect costs are more challenging to trace back to a single product; they include overheads like utilities or management salaries that support overall operations including In-Process Inspection efforts. Both types of quality costs play a significant role in determining how effectively an organization manages its resources while maintaining high-quality standards.

The Role of Inspection and Testing

Inspection and testing are what kind of quality cost? They serve as essential functions within the broader framework of quality management by identifying defects early on in production stages such as First Article Inspection (FAI) or during specialized inspections tailored for unique product requirements. By implementing rigorous inspection protocols—like those seen in Boeing’s In-Process Inspection—the likelihood of costly failures decreases significantly over time. Ultimately, effective inspection strategies not only reduce overall quality costs but also foster consumer trust through consistent delivery of superior products.

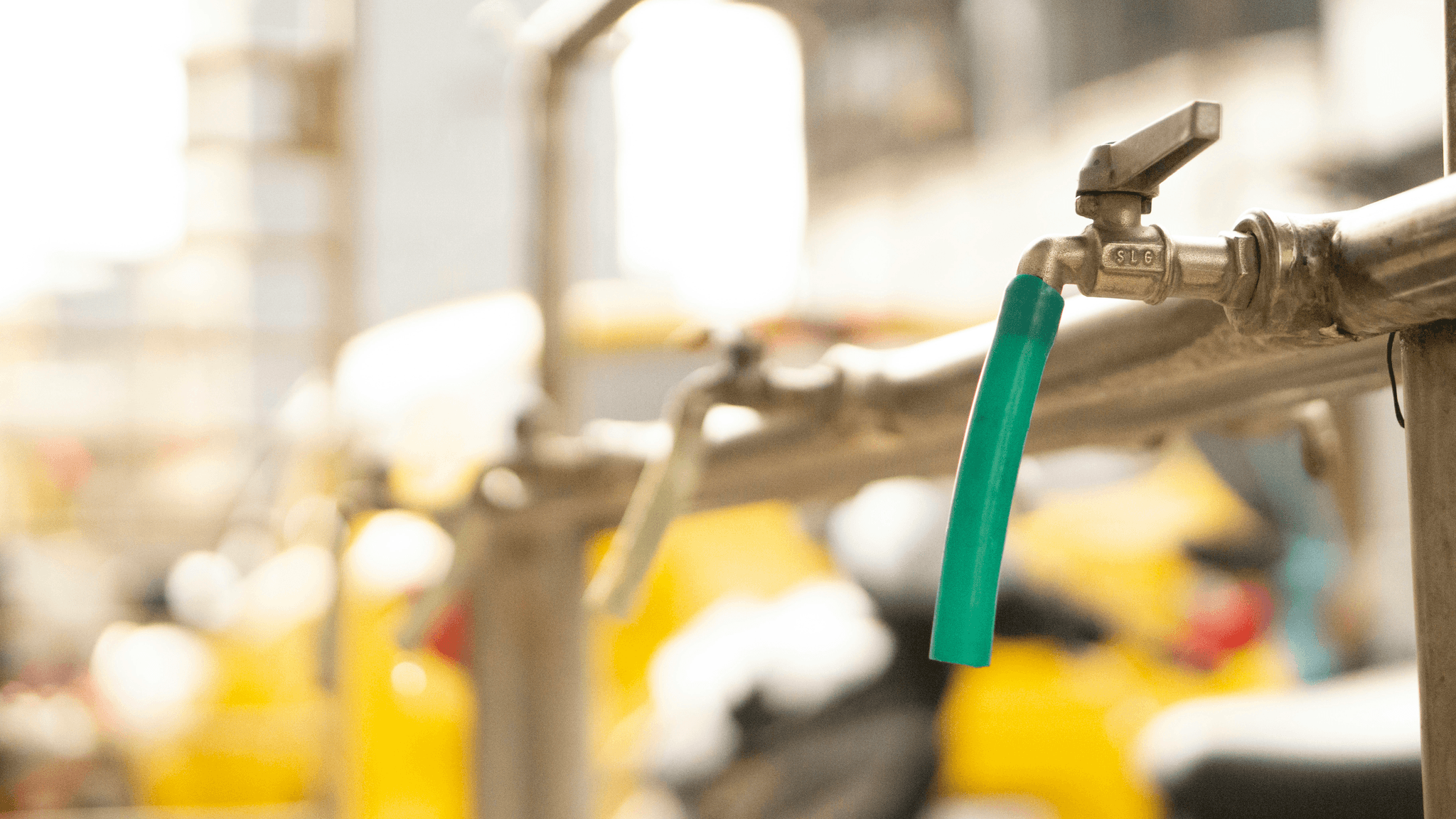

The Role of Incoming Inspection

Incoming inspection is a critical step in ensuring that raw materials meet specified standards before they enter the production process. This proactive approach to quality management helps identify defects early, preventing costly issues down the line. By focusing on incoming inspection, businesses can minimize risks associated with subpar materials, ultimately enhancing product quality and customer satisfaction.

Ensuring Raw Material Compliance

Ensuring raw material compliance is paramount for any manufacturing operation aiming for excellence. Incoming inspection allows companies to verify that suppliers adhere to predefined specifications, which directly impacts the overall quality of the final product. When businesses prioritize this type of inspection and testing, they can avoid costly rework or recalls that stem from using non-compliant materials.

Impact on Overall Quality Cost

The impact of incoming inspection on overall quality cost cannot be overstated. By catching defects early through rigorous inspections, companies can save significantly on costs associated with rework and warranty claims later in the production cycle. Thus, investing in effective incoming inspections becomes a strategic move that pays dividends by reducing long-term expenses related to poor-quality inputs.

Case Study: Toyota’s Incoming Inspection Strategy

Toyota’s incoming inspection strategy exemplifies how effective quality control can enhance operational efficiency and reduce costs. The automaker employs stringent incoming inspections to ensure that every component meets their high standards before assembly begins—this includes both visual checks and functional tests of parts received from suppliers. By integrating these inspections into their supply chain management, Toyota has managed to maintain its reputation for quality while keeping production costs low; a perfect example of how smart investment in inspection and testing are what kind of quality cost savings can yield.

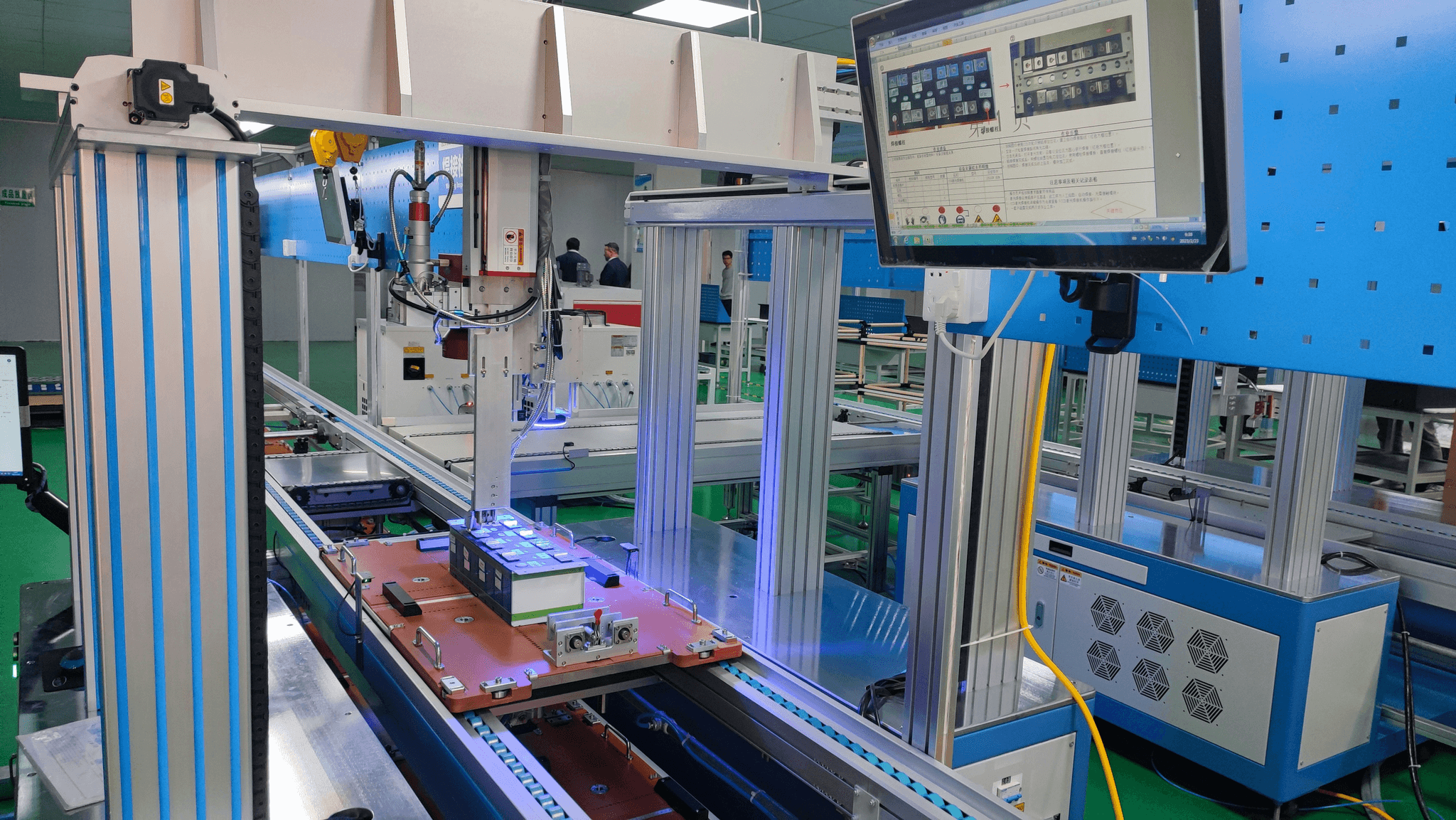

The Significance of In-Process Inspection

In-process inspection plays a pivotal role in maintaining production quality throughout the manufacturing process. By continuously monitoring production, businesses can identify defects or deviations from standards before they escalate into larger issues. This proactive approach not only enhances product reliability but also ensures that the costs associated with quality—such as inspection and testing—are kept in check.

Monitoring Production Quality

Monitoring production quality through in-process inspections is essential for preventing defects from reaching the final stages of manufacturing. This type of inspection allows for real-time feedback, enabling teams to make immediate adjustments when necessary. As a result, companies can maintain high standards and reduce the likelihood of costly rework or recalls later on.

Cost Savings Through Early Detection

One of the most significant advantages of in-process inspections is the cost savings realized through early detection of potential problems. When issues are identified during production rather than after completion, businesses can save on both labor and material costs associated with fixing defects post-production. Thus, investing in effective inspection and testing strategies during this phase can significantly lower overall quality costs.

Example: Boeing’s In-Process Testing

Boeing exemplifies how effective in-process testing can lead to superior product quality and reduced costs. Their rigorous in-process inspection protocols ensure that each component meets strict specifications before moving forward in the assembly line. By implementing such thorough checks, Boeing minimizes errors and reinforces their commitment to safety and reliability—key factors that contribute to their reputation within the aerospace industry.

Exploring First Article Inspection (FAI)

First Article Inspection (FAI) is a critical process that serves as the foundation for ensuring product quality right from the start of production. It involves a comprehensive evaluation of the first produced item against specified design requirements, ensuring that manufacturing processes are capable of producing parts that meet quality standards consistently. FAI acts as a safeguard, allowing manufacturers to identify potential issues before mass production begins, thereby reducing waste and enhancing overall efficiency.

What Is FAI, and Why Is It Essential?

FAI is essentially a detailed inspection and testing process applied to the initial sample of a product before it enters full-scale production. This step is essential because it confirms that all specifications are met and that the manufacturing processes are in control, which ultimately contributes to minimizing quality costs associated with defects later on. By conducting thorough inspections during FAI, companies can prevent costly rework or recalls caused by non-compliance with standards.

The significance of FAI cannot be overstated; it sets the stage for subsequent inspections, including Incoming Inspection and In-Process Inspection. When companies invest in robust FAI procedures, they not only enhance their product reliability but also build trust with customers who expect high-quality outcomes from their purchases. In this way, First Article Inspection becomes an indispensable part of any effective quality management strategy.

Reducing Risks in Production

Incorporating FAI into the manufacturing process significantly reduces risks associated with production errors and defects. By verifying that initial samples meet specifications through rigorous inspection and testing, manufacturers can identify deviations early on—before they escalate into larger problems during mass production runs. This proactive approach minimizes quality costs by addressing potential issues at their source rather than dealing with them after they have affected multiple units.

Additionally, implementing effective First Article Inspections allows organizations to streamline their operations by ensuring that all subsequent components adhere to established standards set during this initial phase. This means fewer disruptions in production flow due to rework or redesigns—ultimately saving time and resources while maintaining high-quality output levels across various stages such as Final Inspection or Specialized Inspections later on.

By embracing FAI as part of their quality assurance protocols, companies can foster an environment where continuous improvement thrives—leading not just to reduced risks but also enhanced customer satisfaction over time.

Lessons from General Motors on FAI

General Motors (GM) has long recognized the importance of First Article Inspection (FAI) in its manufacturing processes as a means to maintain its reputation for quality vehicles while minimizing inspection and testing costs throughout its supply chain. GM's approach emphasizes thorough documentation and standardized procedures during FAI—ensuring consistency across different plants worldwide while keeping an eye on Incoming Inspection practices for raw materials used in vehicle assembly.

One key lesson learned from GM's experience is the value of collaboration between engineering teams and suppliers during the FAI process; this partnership helps clarify expectations upfront and fosters accountability throughout production cycles involving In-Process Inspections as well as Final Inspections before products reach consumers' hands. Additionally, GM’s commitment to continuous training ensures that all personnel involved understand both the technical aspects of inspections as well as broader organizational goals related to reducing overall quality costs through efficient practices.

Ultimately, GM demonstrates how investing time upfront in thorough First Article Inspections pays dividends down the line—not only safeguarding against costly errors but also reinforcing brand loyalty among customers who appreciate consistent performance backed by rigorous inspection protocols.

The Necessity of Final Inspection

Final inspection is the last line of defense in the manufacturing process, ensuring that products meet predefined standards before they reach customers. It serves as a critical checkpoint to verify product conformance, which directly impacts customer satisfaction and brand reputation. When done effectively, final inspection can significantly reduce the costs associated with defects and returns, making it an essential component in managing quality costs.

Verifying Product Conformance

Verifying product conformance during final inspection is crucial for maintaining quality standards across various industries. This step ensures that every item produced aligns with specifications and regulatory requirements, thereby minimizing the risk of subpar products reaching consumers. Without thorough final inspections, companies may face costly recalls or damage to their reputation due to non-compliance issues.

Final Inspection as a Quality Cost Strategy

Incorporating final inspection into a company's quality cost strategy can lead to substantial long-term savings. By identifying defects before products leave the facility, businesses can avoid higher costs associated with returns and repairs after sale. Essentially, investing in robust final inspection processes helps mitigate risks and ultimately reduces overall quality costs by enhancing customer trust and loyalty.

Insights from Apple’s Final Inspection Process

Apple's approach to final inspection exemplifies how meticulous attention to detail can yield significant benefits in terms of quality assurance. The company employs rigorous testing protocols that include both visual inspections and functional tests on each device before it reaches consumers' hands. This commitment not only ensures product excellence but also reinforces Apple's brand image as a leader in innovation—demonstrating that effective inspection and testing are what kind of quality cost matters most for success.

Specialized Inspections and Their Value

In the realm of quality assurance, specialized inspections play a pivotal role in ensuring that products meet stringent standards. These inspections go beyond general checks, targeting specific aspects of a product that are crucial for its performance and safety. By incorporating various forms of inspection and testing, businesses can mitigate risks associated with quality costs while enhancing customer satisfaction.

Types of Specialized Inspections

Specialized inspections encompass a variety of methods tailored to specific industries or product types. For instance, non-destructive testing (NDT) is widely used in aerospace and manufacturing to evaluate materials without causing damage. Similarly, environmental testing assesses how products perform under various conditions—think extreme temperatures or humidity levels—ensuring they can withstand real-world challenges.

When considering inspection and testing are what kind of quality cost, it becomes clear that specialized inspections are essential for high-stakes industries like pharmaceuticals and electronics. These sectors often require rigorous validation processes to comply with regulatory standards, which can involve First Article Inspection (FAI) or Final Inspection protocols. By investing in these specialized inspections, companies not only adhere to compliance but also safeguard their reputation against potential failures.

Quality Costs Associated with Specialized Testing

The financial implications of specialized inspections cannot be overlooked; they represent both direct and indirect quality costs that affect the bottom line. While the initial investment in sophisticated inspection technologies may seem steep, the long-term savings from preventing defects far outweigh these costs. In fact, organizations that prioritize thorough Incoming Inspection processes often find themselves reducing overall expenses related to warranty claims and product recalls.

Moreover, when businesses incorporate In-Process Inspection strategies alongside specialized tests, they create a comprehensive safety net throughout production cycles. This proactive approach minimizes waste by identifying discrepancies early on—essentially catching issues before they escalate into more significant problems down the line. Ultimately, understanding how inspection and testing are what kind of quality cost emphasizes the necessity for organizations to adopt robust quality assurance measures.

Real-World Application: China Inspection Pro’s Expertise

China Inspection Pro exemplifies how specialized inspections can be effectively implemented across diverse industries to enhance product integrity. With services ranging from Final Inspections to detailed FAI procedures, this company has established itself as a leader in ensuring compliance with international standards while minimizing quality costs for its clients. Their expertise highlights how strategic investments in specialized inspections lead not only to improved product reliability but also foster trust among consumers.

By leveraging advanced technologies and methodologies in their inspection processes, China Inspection Pro demonstrates that thoroughness pays off—literally! Companies partnering with them benefit from reduced risk exposure due to comprehensive assessments at every stage—from Incoming Inspection through Final Inspection stages—ultimately leading to better market performance and customer loyalty. As such examples illustrate the value added by specialized inspections within broader quality cost frameworks.

Conclusion

In the intricate dance of business operations, understanding quality costs is paramount. Inspection and testing are what kind of quality cost? They represent a pivotal investment in ensuring product excellence, safeguarding brand reputation, and minimizing costly defects. By recognizing the various types of inspections—Incoming Inspection, In-Process Inspection, First Article Inspection (FAI), Final Inspection, and Specialized Inspections—companies can strategically allocate resources to enhance overall quality.

Key Takeaways on Quality Costs

Quality costs encapsulate the expenses associated with preventing poor quality as well as those incurred when defects occur. Each type of inspection plays a vital role in this ecosystem; for instance, Incoming Inspection ensures raw materials meet required standards before production begins. Meanwhile, In-Process Inspection allows businesses to catch potential issues early on, ultimately reducing waste and saving money in the long run.

Understanding that inspection and testing are what kind of quality cost can help organizations prioritize their efforts effectively. First Article Inspection (FAI) serves as a crucial checkpoint to validate manufacturing processes before full-scale production kicks off. Final Inspections confirm that products meet specifications before they reach customers' hands, reinforcing customer satisfaction and loyalty.

The Impact of Effective Inspections

Effective inspections have a profound impact on both product quality and financial health. By implementing thorough Incoming Inspections, companies can avoid costly recalls or rework later down the line. Similarly, In-Process Inspections contribute significantly by identifying defects during production rather than after completion.

The role of Specialized Inspections cannot be overstated; these tailored assessments ensure compliance with industry-specific standards that might otherwise go unnoticed. The cumulative effect of these inspections translates into lower overall quality costs while enhancing brand reputation through consistent delivery of high-quality products. Ultimately, effective inspection strategies empower businesses to foster trust among consumers while minimizing operational disruptions.

Future Trends in Quality Testing and Inspections

Looking ahead, the landscape of quality testing and inspections is poised for transformation driven by technology advancements. Automation and artificial intelligence will increasingly play roles in Incoming Inspection processes by streamlining data analysis for quicker decision-making. Moreover, real-time monitoring during In-Process Inspections will facilitate immediate corrective actions without halting production lines.

First Article Inspection (FAI) will evolve with digital tools enabling faster feedback loops between design teams and manufacturers—enhancing agility in addressing potential issues before they escalate into larger problems. As industries continue embracing specialized inspections tailored to unique needs—such as sustainability certifications—the importance placed on comprehensive inspection strategies will only grow stronger.

In conclusion, recognizing that inspection and testing are what kind of quality cost not only reinforces their significance but also paves the way for innovative approaches in maintaining high-quality standards across sectors.