Introduction

In the fast-paced world of manufacturing, the significance of inspection points cannot be overstated. These critical checkpoints throughout the production process ensure that products meet quality standards and specifications before reaching consumers. By systematically integrating inspection points in manufacturing, companies can not only enhance product reliability but also foster trust with their customers.

Importance of Manufacturing Inspection Points

Manufacturing inspection points serve as essential safeguards against defects and inconsistencies in products. From incoming materials/components inspection to final random inspections, these checkpoints allow manufacturers to identify potential issues early on, reducing waste and rework costs significantly. The proactive approach of incorporating multiple inspection stages ensures that quality is built into the product from start to finish.

Key Benefits of Effective Inspections

Effective inspections provide a multitude of benefits that extend beyond mere compliance with regulations. They help streamline operations by minimizing delays caused by defective materials or processes, ultimately leading to increased productivity and profitability. Furthermore, thorough inspections cultivate a culture of quality within organizations, encouraging employees to take pride in their work and strive for excellence at every stage.

How Inspections Drive Quality Control

Inspections are the backbone of quality control in any manufacturing environment; they are not merely a box-ticking exercise but rather a vital part of an integrated system aimed at continuous improvement. Through techniques like in-line/in-process inspections and post-delivery inspections, manufacturers can ensure that every aspect of production adheres to established standards and customer expectations. This relentless focus on quality not only enhances product performance but also fortifies brand reputation in an increasingly competitive market.

Understanding Incoming Materials Components Inspection

In the world of manufacturing, the journey to quality begins long before products hit the assembly line. Incoming materials/components inspection is a critical process that ensures only the best materials make it into production. By focusing on inspection points in manufacturing at this stage, companies can prevent costly errors and uphold their standards.

Importance of Pre-production Checks

Pre-production checks are like the first line of defense in quality control; they set the tone for everything that follows. By thoroughly inspecting incoming materials, manufacturers can identify defects or discrepancies early on, saving time and resources down the line. This proactive approach not only minimizes waste but also reinforces confidence in product quality and compliance with industry standards.

Methods for Evaluating Suppliers

Evaluating suppliers involves more than just a handshake; it requires systematic methods to ensure they meet your quality expectations. Techniques such as audits, performance reviews, and sample testing are essential to gauge reliability and consistency. By establishing clear criteria for supplier evaluation, manufacturers can create robust inspection points in manufacturing that help maintain high-quality incoming materials/components inspection.

Role of China Inspection Pro in Quality Assurance

Enter China Inspection Pro: a game-changer for businesses looking to streamline their incoming materials/components inspection process. This organization specializes in providing comprehensive inspections that cover every aspect of material quality before it reaches your factory floor. With their expertise, companies can effectively leverage inspection points in manufacturing to ensure that all components meet strict quality assurance standards—keeping production smooth and efficient.

Implementing In-line / In-process Inspections

In-line or in-process inspections are pivotal in maintaining quality throughout the manufacturing journey. These inspection points in manufacturing allow for immediate feedback and corrective actions, ensuring that any deviations from standards are addressed promptly. By integrating these inspections into the production workflow, manufacturers can significantly reduce waste and enhance product reliability.

Continuous Monitoring During Production

Continuous monitoring during production is essential to uphold quality standards. This approach involves regularly checking products at various stages of the manufacturing process, providing a real-time view of compliance with specifications. By establishing specific inspection points in manufacturing, teams can identify potential issues before they escalate, promoting a culture of proactive quality management.

Moreover, continuous monitoring allows for immediate adjustments to be made in response to any anomalies detected during production. This not only helps maintain consistency but also fosters greater accountability among team members who are responsible for upholding product integrity. Ultimately, this strategy leads to higher customer satisfaction and fewer returns due to defects.

Techniques to Ensure Process Compliance

Ensuring process compliance requires a combination of well-defined techniques and robust training for staff involved in the manufacturing process. Techniques such as standardized work instructions, visual aids at inspection points in manufacturing, and regular audits can significantly enhance adherence to established protocols. These practices help create an environment where quality is everyone's responsibility.

Additionally, implementing checklists tailored for each stage of production can serve as effective tools for maintaining consistency and compliance with quality standards during in-line inspections. Regular training sessions reinforce the importance of these techniques and empower employees to take ownership of their roles within the production line. When everyone is aligned on best practices, the likelihood of defects diminishes considerably.

Leveraging Technology for Real-time Analysis

In today's fast-paced manufacturing landscape, leveraging technology for real-time analysis has become non-negotiable. Advanced software solutions equipped with machine learning capabilities can analyze data collected at various inspection points in manufacturing instantly—allowing teams to spot trends or emerging issues without delay. This level of insight enables manufacturers to make informed decisions that enhance overall efficiency.

Moreover, utilizing IoT devices facilitates seamless data collection from machines directly on the shop floor during in-process inspections. With this technology at their fingertips, manufacturers can track performance metrics continuously and adjust processes dynamically based on real-time findings—leading to improved outcomes across all stages of production including final random inspections and post-delivery evaluations.

As we embrace these technological advancements, it’s crucial not only to implement them but also ensure that all team members are trained adequately on how to utilize these tools effectively within their workflows—creating a cohesive system where technology complements human oversight rather than replaces it entirely.

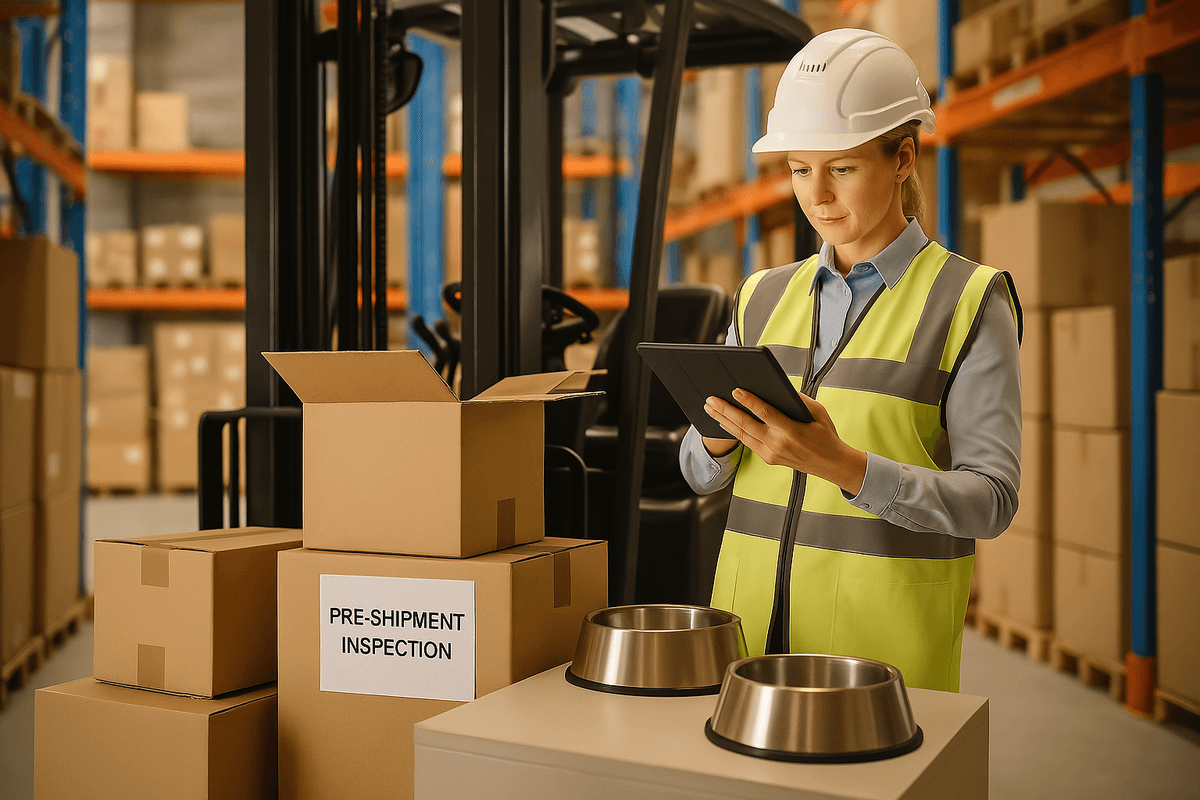

The Necessity of Final Random Inspection

Final random inspection (FRI) serves as the last line of defense in ensuring product quality before shipment. This critical step helps catch defects that may have slipped through earlier inspection points in manufacturing, including incoming materials/components inspection and in-line/in-process inspections. By implementing thorough final checks, manufacturers can significantly reduce the risk of delivering faulty products to customers.

Why Final Checks Are Crucial

Final checks are crucial because they provide an opportunity to identify any discrepancies that may have occurred during production. While incoming materials/components inspection and in-line/in-process inspections are essential for maintaining quality throughout the manufacturing process, they cannot guarantee that every item meets specifications at the end. A robust final random inspection ensures that products align with customer expectations and industry standards, ultimately enhancing brand reputation and customer satisfaction.

Sampling Methods and Best Practices

When it comes to final random inspection, selecting appropriate sampling methods is paramount for effective quality control. Common practices include systematic sampling, where items are chosen at regular intervals, or random sampling, which provides a more varied representation of the batch. Best practices also emphasize defining clear acceptance criteria and documenting findings meticulously to facilitate continuous improvement based on data collected during these inspections.

Case Studies of Successful Final Inspections

Several companies have successfully integrated final random inspection into their quality assurance processes with impressive results. For instance, a prominent electronics manufacturer implemented rigorous FRI protocols after experiencing high return rates due to undetected defects during production stages like incoming materials/components inspection and in-line/in-process inspections. By refining their final checks using advanced statistical methods and technology-driven analysis, they drastically reduced returns by 30%, demonstrating how effective FRI can be when executed properly.

Importance of Post-delivery Inspection

In the world of manufacturing, post-delivery inspections are pivotal in ensuring that products meet quality standards even after they leave the production floor. These inspection points in manufacturing serve as a final checkpoint to verify that the items shipped are free from defects and meet customer expectations. By implementing thorough post-delivery inspections, manufacturers can significantly reduce the risk of returns and enhance customer satisfaction.

Ensuring Quality After Shipment

Quality assurance doesn't stop at shipment; it continues with post-delivery inspections that help ensure products maintain their integrity during transit. By examining items after they arrive at their destination, manufacturers can identify any issues that may have occurred en route or during handling. This step is crucial not only for maintaining brand reputation but also for reinforcing trust with customers who expect high-quality goods.

Addressing Customer Feedback and Returns

Customer feedback is an invaluable resource for improving product quality and service delivery. Post-delivery inspections allow manufacturers to analyze returns systematically, identifying trends or recurring issues related to specific products or suppliers. Addressing these concerns promptly can lead to better relationships with customers and provide insights that inform future incoming materials/components inspection processes.

Strategies for Continuous Improvement

Continuous improvement should be at the heart of any manufacturing operation, especially when it comes to quality control through inspection points in manufacturing. Implementing a robust feedback loop from post-delivery inspections helps refine processes such as in-line / in-process inspections and final random inspection methods. By leveraging data collected from these inspections, manufacturers can fine-tune their practices, ensuring they adapt to changing market demands while consistently delivering top-notch products.

Leveraging Inspection Points for Compliance

In today's manufacturing landscape, leveraging inspection points for compliance is not just a best practice; it's a necessity. Meeting industry standards and regulations ensures that products are safe, reliable, and of high quality. By systematically integrating inspection points throughout the manufacturing process—from incoming materials/components inspection to post-delivery inspection—companies can create a robust framework for compliance that protects both consumers and manufacturers.

Meeting Industry Standards and Regulations

Manufacturers face an array of industry standards and regulations that govern everything from safety to environmental impact. By implementing thorough inspection points in manufacturing, businesses can ensure they meet these requirements at every stage of production. Whether it's through rigorous incoming materials/components inspection or final random inspections, maintaining compliance helps avoid costly penalties and enhances overall product integrity.

Moreover, staying compliant fosters trust with customers who increasingly prioritize quality assurance in their purchasing decisions. Companies that excel in meeting these standards often find themselves ahead of the competition, as well-regarded certifications become valuable marketing tools. This commitment to compliance not only safeguards the brand but also reinforces a culture of quality across the organization.

Role of Third-party Inspectors

Third-party inspectors play a crucial role in enhancing the credibility of manufacturing processes by providing an objective assessment of quality control measures. These professionals bring expertise that can elevate the effectiveness of various inspection points in manufacturing—be it during incoming materials/components inspections or in-line/in-process inspections. Their independent evaluations help identify areas for improvement while ensuring adherence to industry standards.

Engaging third-party inspectors also mitigates potential biases within internal teams, leading to more accurate assessments during final random inspections and beyond. This external validation can be particularly beneficial when entering new markets or working with unfamiliar suppliers, as it builds confidence among stakeholders regarding product quality and compliance levels. In essence, third-party inspectors serve as both watchdogs and advisors on the path toward excellence.

Enhancing Reputation Through Quality Assurance

A strong reputation hinges on consistent quality assurance practices throughout the manufacturing process—starting from incoming materials/components inspections all the way through to post-delivery inspections. When companies prioritize effective inspection points in manufacturing, they not only enhance product reliability but also cultivate customer loyalty over time. Satisfied customers are likely to share their positive experiences, turning them into brand advocates who contribute to organic growth.

Furthermore, businesses known for their rigorous adherence to quality often enjoy competitive advantages such as better pricing strategies and increased market share. By showcasing successful outcomes from various inspections—including final random inspections—companies can differentiate themselves within crowded markets while reinforcing their commitment to excellence. Ultimately, investing in robust quality assurance frameworks pays dividends by establishing lasting relationships with customers built on trust.

Conclusion

In the ever-evolving landscape of manufacturing, inspection points play a pivotal role in ensuring product quality and compliance. From incoming materials/components inspection to post-delivery checks, each stage of the inspection process contributes significantly to overall quality assurance. By understanding and implementing effective inspections, manufacturers can enhance their reputation and drive customer satisfaction.

Key Takeaways on Manufacturing Inspection Points

Manufacturing inspection points are critical checkpoints that help maintain product integrity throughout the production cycle. The importance of incoming materials/components inspection cannot be overstated; it sets the foundation for quality by ensuring that only compliant materials enter the production line. Similarly, in-line/in-process inspections guarantee that products meet specifications during manufacturing, while final random inspections serve as a last line of defense before shipment.

Moreover, post-delivery inspections are essential for capturing feedback and addressing any potential issues after products reach customers. These multifaceted approaches not only safeguard against defects but also foster a culture of continuous improvement within organizations. Ultimately, effective utilization of these inspection points in manufacturing can lead to significant cost savings and enhanced operational efficiency.

Steps for Effective Implementation of Inspections

To effectively implement inspections in manufacturing, companies should start by defining clear objectives for each type of inspection point. Establishing a robust incoming materials/components inspection protocol is crucial; this includes evaluating suppliers meticulously and setting criteria that align with industry standards. Following this, integrating in-line/in-process inspections into daily practice ensures continuous monitoring and compliance with established processes.

Additionally, leveraging technology can streamline these efforts—think real-time data analysis tools that provide instant feedback during production phases. Final random inspections should be strategically planned based on historical data to maximize their effectiveness while minimizing disruption to workflows. Finally, incorporating systematic post-delivery inspections allows businesses to learn from customer feedback and refine processes over time.

Future Trends in Manufacturing Quality Control

As we look ahead, several trends are poised to reshape how we approach quality control through inspection points in manufacturing. The rise of automation and artificial intelligence will likely enhance both efficiency and accuracy across all types of inspections—from incoming materials/components inspection right through to final random checks. Furthermore, an increased focus on sustainability will drive manufacturers to adopt greener practices within their inspection processes.

The integration of advanced analytics will also play a significant role; predictive analytics could help foresee potential quality issues before they arise during production or after delivery. Additionally, collaboration with third-party inspectors may become more common as businesses seek objective assessments that bolster confidence among stakeholders. Embracing these trends will not only improve compliance but also elevate the overall standard of quality assurance across industries.