Introduction

In the fast-paced world of manufacturing and production, visual inspections play a critical role in ensuring quality and safety. These inspections are not just routine checks; they are essential for maintaining compliance with safety standards and improving overall product quality. By understanding the nuances of visual inspections, organizations can better navigate compliance issues and enhance their quality assurance processes.

The Importance of Visual Inspections

Visual inspections serve as the first line of defense against defects in various types of quality assurance practices. They help identify potential hazards before they escalate into serious problems, ensuring that products meet acceptable quality limits. In industries where precision is paramount, neglecting visual inspections can lead to costly errors, making their importance undeniable.

Understanding Safety Standards

Safety standards set the benchmark for operational excellence across industries, guiding how visual inspections should be conducted. Familiarity with these standards equips teams to perform thorough checks that comply with regulations while also addressing any compliance issues that may arise during factory audits. Understanding these standards ensures that organizations not only meet legal requirements but also foster a culture of safety and accountability.

How Visual Inspections Impact Quality

The impact of visual inspections on quality cannot be overstated; they directly influence both product reliability and customer satisfaction. By employing various types of visual inspection techniques, companies can detect flaws early in the production process, preventing defective products from reaching consumers. Ultimately, effective visual inspections contribute to improved quality by bridging the gap between quality assurance vs compliance efforts within an organization.

What are Visual Inspections?

Visual inspections are a critical element in maintaining quality and safety standards across various industries. They involve the careful observation of products, processes, or environments to identify any potential issues that could impact safety or quality. The primary purpose of visual inspections is to ensure compliance with established standards while enhancing overall product integrity.

Definition and Purpose

At its core, a visual inspection is a systematic examination conducted by trained personnel to assess the condition of an object or environment based on visual criteria. This process serves multiple purposes: it helps detect defects, ensures adherence to safety regulations, and supports quality assurance efforts. By identifying issues early on, companies can avoid costly mistakes and maintain an acceptable quality limit that satisfies both regulatory requirements and customer expectations.

Types of Visual Inspections

Visual inspections can be categorized into several types depending on the context and objectives involved. Common types include surface inspections, where inspectors examine the exterior for signs of wear or damage; dimensional checks that verify measurements against specifications; and functional tests that assess operational performance. Each type plays a vital role in ensuring compliance issues are addressed effectively while contributing to improved quality across production lines.

Role in Safety Standards

Visual inspections are integral to upholding safety standards across industries by proactively identifying potential hazards before they escalate into serious problems. They provide a first line of defense against non-compliance with regulations which can lead to severe penalties or operational shutdowns during factory audits. Ultimately, the role of visual inspections transcends mere compliance; they foster a culture of continuous improvement in quality assurance versus compliance by promoting proactive risk management strategies within organizations.

Types of Visual Inspection Techniques

Visual inspections are an essential aspect of maintaining quality across various industries. Understanding the different types of visual inspection techniques can significantly enhance compliance issues and quality assurance, ultimately leading to improved quality in products and processes. By categorizing these methods, we can better appreciate their roles in factory audits and how they relate to acceptable quality limits.

Surface Inspection Methods

Surface inspection methods are a foundational element in the realm of visual inspections, focusing on evaluating the external characteristics of a product. These techniques involve examining surfaces for defects such as scratches, dents, or discoloration that could affect the overall quality perception. By implementing robust surface inspection protocols, businesses can ensure they meet compliance issues while adhering to safety standards.

There are various types of surface inspection methods ranging from manual checks to automated systems utilizing high-resolution cameras. Each method has its strengths and weaknesses; thus, selecting the appropriate technique is crucial for achieving acceptable quality limits within production processes. Ultimately, effective surface inspections contribute significantly to maintaining high-quality standards and reducing non-compliance risks.

Dimensional Checks and Measurements

Dimensional checks and measurements form another vital category within visual inspections that focuses on verifying product specifications against predetermined criteria. This process ensures that products not only look right but also meet essential functional requirements by confirming their dimensions align with industry standards or customer expectations. Such checks help identify potential compliance issues early on, streamlining factory audit processes.

Incorporating dimensional inspections into your quality assurance strategy allows for a more comprehensive understanding of product integrity across various types of quality metrics. This method often involves tools like calipers or gauges alongside visual assessments to provide accurate results swiftly. By emphasizing dimensional checks as part of your overall approach to visual inspections, you enhance both compliance adherence and customer satisfaction.

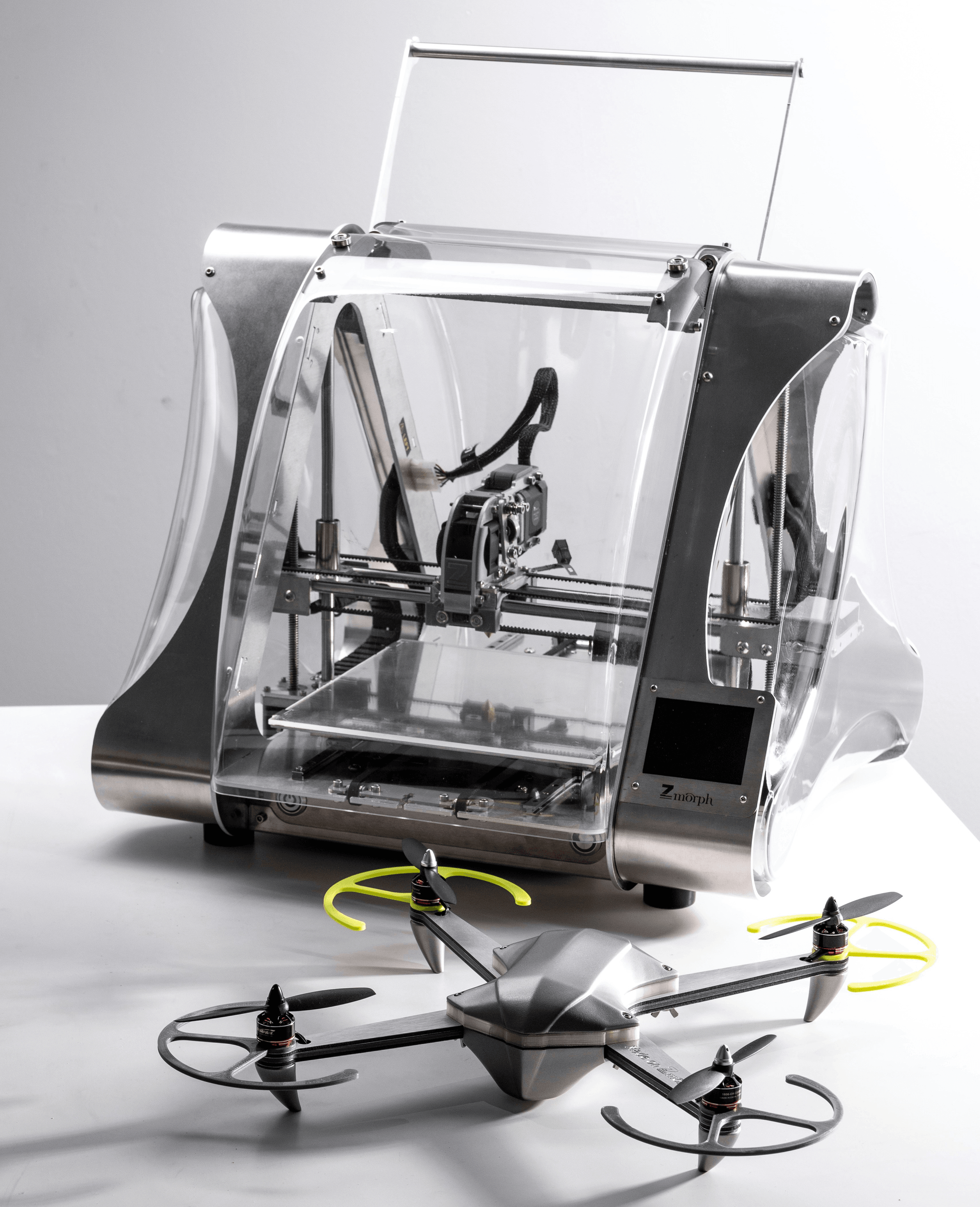

Use of Technology in Visual Inspections

The integration of technology into visual inspections has revolutionized how industries approach quality control measures today. Utilizing advanced tools such as drones for aerial views or AI-driven software for defect detection enhances accuracy while minimizing human error during assessments. As businesses face increasing compliance issues related to safety standards, leveraging technology in visual inspections becomes an indispensable asset toward achieving improved quality outcomes.

From 3D imaging systems that provide detailed insights into product conditions to augmented reality applications that assist inspectors in real-time evaluations—technology offers innovative solutions tailored for various types of visual inspection needs. Embracing these advancements not only helps organizations navigate complex regulatory landscapes but also contributes positively toward establishing acceptable quality limits across production lines effectively. In summary, technology's role is pivotal in elevating the standard practices surrounding visual inspections while ensuring ongoing compliance with industry regulations.

Compliance Issues and Quality Assurance

Navigating the complex landscape of compliance issues and quality assurance can feel like trying to solve a Rubik's Cube blindfolded. Organizations often face challenges in adhering to various safety standards while also ensuring that their products meet the required types of quality. Visual inspections play a crucial role here, serving as both a checkpoint for compliance and a tool for enhancing overall product quality.

Navigating Compliance Challenges

Compliance challenges are ubiquitous in industries where safety is paramount. Companies must stay updated on ever-evolving regulations while also managing their internal quality assurance processes. This dual responsibility can lead to confusion, especially when visual inspections aren't integrated effectively into both compliance frameworks and quality assurance systems.

Understanding the nuances of different types of visual inspection becomes essential for navigating these compliance hurdles. For instance, surface inspection methods may be more relevant in certain scenarios than dimensional checks when assessing compliance with specific safety standards. By aligning visual inspection techniques with regulatory requirements, organizations can streamline their approach to both compliance issues and quality assurance.

Acceptable Quality Limit Explained

The concept of an Acceptable Quality Limit (AQL) is vital for any organization striving to maintain high-quality standards while meeting regulatory demands. AQL defines the maximum number of defective items considered acceptable during random sampling inspections—essentially setting the bar for what constitutes good enough. In this context, visual inspections serve as an effective means to assess whether products fall within these acceptable limits.

When implementing visual inspections, companies need to clearly understand how AQL applies across different types of quality metrics. For example, if a factory audit reveals that defects exceed the established AQL threshold due to insufficient surface inspection techniques, corrective actions must be taken immediately. Thus, integrating AQL into visual inspections not only aids in identifying potential issues but also reinforces overall adherence to safety standards.

Visual Inspections in Quality Assurance vs Compliance

While both quality assurance and compliance aim for excellence, they are not always synonymous; understanding their distinctions is key when employing visual inspections effectively. Quality assurance focuses on improving processes and product attributes over time—essentially striving for improved quality through continuous monitoring and refinement. Conversely, compliance emphasizes adherence to predefined regulations; it’s about checking boxes rather than fostering innovation.

Visual inspections play a pivotal role in bridging these two realms by ensuring that products meet safety standards while also allowing room for improvement over time. By using various types of visual inspection techniques—such as surface checks or dimensional measurements—organizations can gather data that informs both their compliance status and ongoing efforts toward enhanced product quality. Balancing these aspects helps companies navigate factory audits more smoothly while fostering an environment conducive to continuous improvement.

Enhancing Safety Standards through Visual Inspections

Visual inspections are a crucial component in enhancing safety standards across various industries. They serve as the first line of defense against potential hazards that could compromise quality and safety. By systematically identifying issues during these inspections, companies can mitigate risks before they escalate into compliance issues or costly defects.

Identifying Potential Hazards

Identifying potential hazards is one of the primary functions of visual inspections, which can be both straightforward and complex. Inspectors utilize various types of visual inspection techniques to spot irregularities that may indicate safety risks or quality concerns. These inspections not only help in recognizing immediate dangers but also play a pivotal role in establishing acceptable quality limits for products and processes.

For instance, during surface inspections, inspectors look for signs of wear, corrosion, or other defects that might compromise safety standards. Additionally, dimensional checks ensure that components meet specified tolerances; deviations can signal underlying problems that could lead to failure if left unchecked. Thus, regular visual inspections contribute significantly to proactive hazard identification and management.

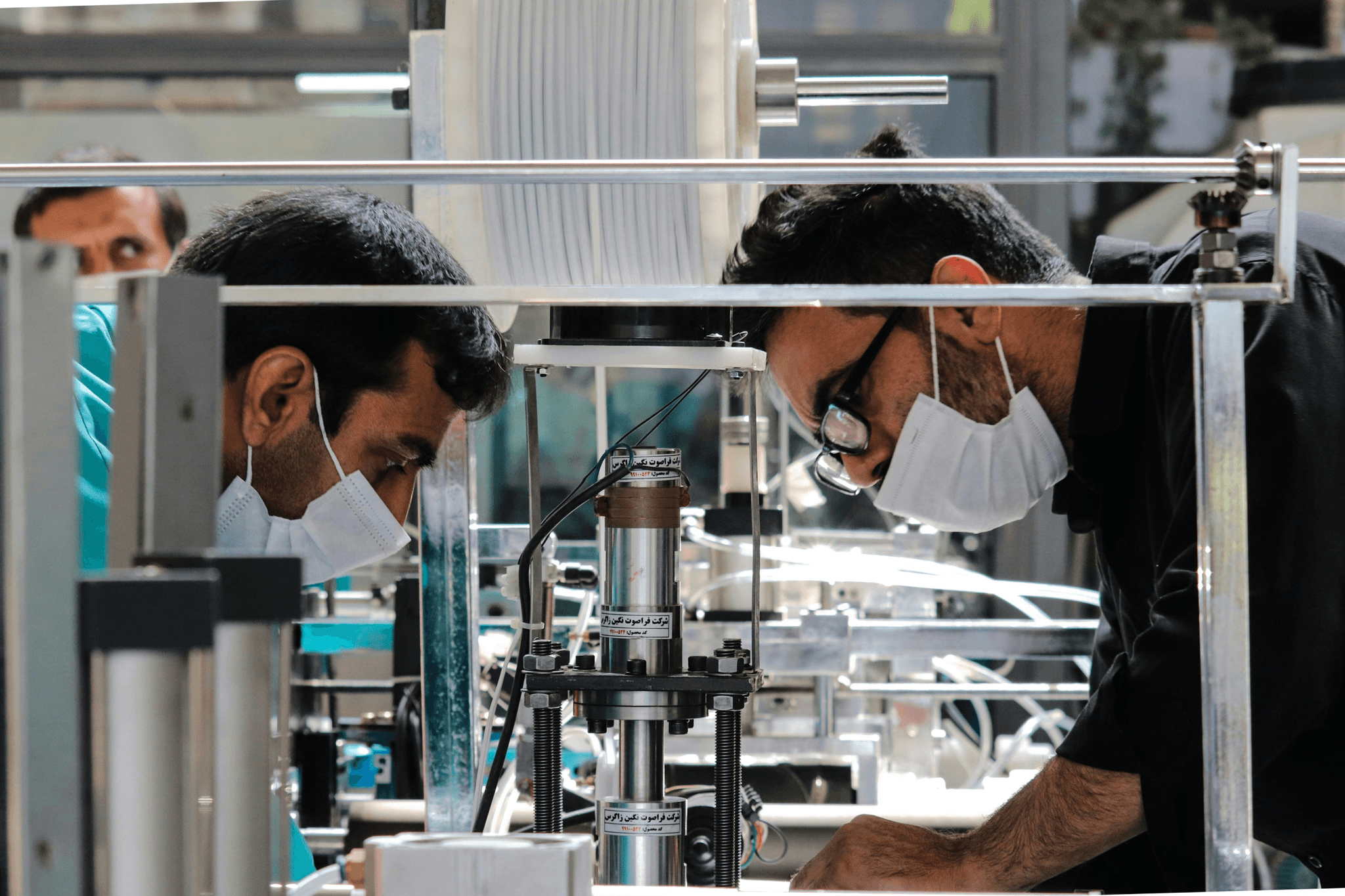

Impact on Factory Audit Processes

The impact of visual inspections on factory audit processes cannot be overstated; they are integral to ensuring compliance with established safety standards and regulations. During audits, a thorough review of visual inspection records can reveal patterns indicative of recurring compliance issues or lapses in quality assurance practices. This data is invaluable for auditors who assess whether the factory meets acceptable quality limits and adheres to safety protocols.

Moreover, effective visual inspections streamline the audit process by providing clear documentation and evidence of compliance efforts over time. Auditors often rely on these findings to determine if further action is needed or if the facility has successfully addressed prior deficiencies. Ultimately, robust visual inspection practices enhance transparency during audits, fostering an environment where improved quality becomes a shared goal.

Case Studies of Successful Implementation

Numerous case studies illustrate how organizations have successfully enhanced their safety standards through diligent visual inspections. For example, a manufacturing company implemented regular surface inspection routines that led to a 30% reduction in workplace accidents related to equipment failure within just one year. By aligning their inspection strategies with industry best practices for compliance issues and quality assurance, they not only improved workplace safety but also boosted overall product quality.

Another compelling case involved an electronics manufacturer that integrated advanced technology into its types of visual inspection processes—such as automated cameras equipped with AI capabilities—to identify defects more accurately than human inspectors alone could achieve. This innovation resulted in significantly fewer errors and higher customer satisfaction ratings due to consistently meeting acceptable quality limits on all products shipped out the door. These examples underscore how embracing comprehensive visual inspection methodologies can yield substantial benefits for both safety standards and overall operational excellence.

The Role of China Inspection Pro in Quality Improvement

In the realm of quality improvement, China Inspection Pro stands out as a pivotal player, expertly navigating the intricacies of visual inspections and their role in enhancing product quality. Their comprehensive quality inspection services cater to various industries, ensuring that every facet of production meets stringent standards. By focusing on different types of quality and compliance issues, they help businesses maintain a competitive edge while adhering to safety norms.

Comprehensive Quality Inspection Services

China Inspection Pro offers a wide array of comprehensive quality inspection services that encompass all types of visual inspections necessary for effective production oversight. These services not only identify defects but also ensure adherence to acceptable quality limits (AQL), which is crucial for maintaining high-quality standards. From pre-production checks to final shipments, their inspections provide businesses with peace of mind that their products meet both compliance requirements and customer expectations.

How Specialists Ensure Compliance

The specialists at China Inspection Pro are well-versed in navigating compliance issues and quality assurance challenges faced by manufacturers today. They employ various types of visual inspection techniques to ensure that products meet regulatory standards while also aligning with industry best practices. By meticulously evaluating each stage of production through factory audits and detailed assessments, they help companies avoid costly penalties associated with non-compliance.

Turning Findings into Actionable Recommendations

One of the standout features of China Inspection Pro's services is their ability to turn findings from visual inspections into actionable recommendations for improved quality management systems. After conducting thorough assessments, they provide clients with tailored strategies that can enhance operational efficiency and product reliability. This proactive approach not only addresses immediate compliance issues but also fosters long-term improvements in overall product quality.

Conclusion

In wrapping up our exploration of visual inspections, it’s crucial to recognize their role as a safety backbone in various industries. These inspections are not just a procedural formality; they are essential for maintaining high standards of safety and quality. By effectively identifying potential issues before they escalate, visual inspections help ensure that products meet both compliance requirements and customer expectations.

Visual Inspections as a Safety Backbone

Visual inspections serve as the first line of defense against defects and hazards in manufacturing processes. They play an integral role in establishing acceptable quality limits, which dictate what is deemed acceptable in terms of product quality and safety standards. By employing various types of visual inspection techniques, companies can safeguard their operations while also promoting a culture of quality assurance over mere compliance.

The Path to Improved Quality

The journey toward improved quality is paved with diligent attention to detail through consistent visual inspections. By understanding the difference between quality assurance vs compliance, organizations can focus on enhancing their processes rather than simply meeting minimum regulatory requirements. This proactive approach not only elevates product integrity but also fosters consumer trust and satisfaction.

Future of Visual Inspections in Industry

As industries evolve, so too will the methods employed for visual inspections, integrating advanced technologies to enhance efficiency and accuracy. The future may see more automated systems that utilize AI for real-time analysis alongside traditional inspection methods, ensuring compliance issues are addressed promptly while maintaining high-quality standards. With ongoing advancements, the types of visual inspection techniques will likely expand, making it easier to navigate the complexities of factory audits and overall quality assurance.