Introduction

In today’s fast-paced market, the significance of Packaging Inspection cannot be overstated. It serves as a critical checkpoint to ensure that products reach consumers in optimal condition, safeguarding both quality and brand reputation. As we delve into the nuances of Packaging Inspection, it becomes clear that understanding Product Type and Characteristics is essential for tailoring effective inspection processes.

Understanding the Importance of Packaging Inspection

Packaging Inspection is pivotal in maintaining product integrity throughout its lifecycle, from production to consumption. By systematically evaluating packaging materials and their performance, companies can identify potential flaws that could compromise product quality. This proactive approach not only minimizes waste but also enhances customer satisfaction by ensuring that products are delivered as intended.

Why Product Type Matters in Packaging

Different Product Types demand unique packaging strategies to address their specific characteristics and vulnerabilities. For instance, fragile items may require additional cushioning or specialized materials to prevent damage during shipping and handling. Understanding these distinctions allows businesses to implement targeted inspection protocols that enhance the overall effectiveness of the Packaging Inspection Process.

The Role of Regulatory Requirements

Regulatory Requirements play a crucial role in shaping packaging standards across various industries. Compliance with these regulations ensures not only legal adherence but also fosters consumer trust by guaranteeing safety and quality in packaging practices. Neglecting these requirements can lead to significant risks, including financial penalties and damage to brand reputation, making it imperative for companies to prioritize compliance within their Packaging Inspection strategies.

What is Packaging Inspection?

Packaging inspection is a critical process that ensures products are securely and correctly packaged before they reach consumers. This process involves evaluating various aspects of packaging, from the materials used to the design and compliance with regulatory requirements. Ultimately, effective packaging inspection safeguards product integrity and enhances customer satisfaction.

Defining the Packaging Inspection Process

The packaging inspection process entails a systematic evaluation of packaging materials, design, and functionality to ensure they meet predetermined standards. This includes checking for defects, verifying compliance with regulatory requirements, and assessing the suitability of packaging based on product type and characteristics. By implementing a thorough inspection process, businesses can identify potential issues before products hit the market.

Key Objectives of Packaging Inspection

The primary objectives of packaging inspection are to ensure product safety, maintain quality during shipping and handling, and comply with relevant regulations. By focusing on these objectives, companies can mitigate risks associated with damaged goods or non-compliance penalties. Additionally, effective inspections help tailor packaging materials to specific products while considering environmental conditions that may affect performance.

How It Affects Product Quality

Packaging inspection directly impacts product quality by ensuring that items are protected from external factors such as moisture or temperature fluctuations during transportation. Well-executed inspections help identify any weaknesses in packaging that could lead to product damage or spoilage over time. Furthermore, adhering to regulatory requirements through diligent inspections fosters consumer trust in brands by guaranteeing that products arrive in optimal condition.

Importance of Product Type and Characteristics

Understanding the importance of product type and characteristics is crucial in the realm of Packaging Inspection. Each product comes with its own unique set of requirements, which must be carefully considered during the inspection process to ensure compliance with regulatory requirements and maintain product integrity. By tailoring the Packaging Inspection process to specific products, companies can enhance their overall quality control and customer satisfaction.

Tailoring Inspection to Different Products

Tailoring Packaging Inspection to different products is essential for identifying specific risks associated with each item. For instance, a delicate glass vase will require a different inspection approach than a robust electronic device; hence, understanding the nuances of various Product Types and Characteristics is vital. This customization not only ensures compliance with regulatory requirements but also helps in selecting appropriate Packaging Materials that safeguard the product during shipping and handling.

Moreover, by adapting inspection processes based on product characteristics, businesses can proactively address potential weaknesses in packaging design or materials. This foresight minimizes damage during transportation while enhancing the overall user experience once products reach their final destination. Ultimately, effective tailoring leads to reduced returns and improved brand loyalty.

Special Considerations for Fragile Items

Fragile items present unique challenges in Packaging Inspection that demand extra attention during both design and testing phases. These items often require specialized packaging solutions to withstand environmental conditions such as temperature fluctuations or humidity variations that could compromise their integrity. Consequently, incorporating rigorous inspection criteria tailored specifically for fragile products is paramount in ensuring they arrive at their destination unscathed.

One key consideration involves using cushioning materials that absorb shocks effectively while maintaining lightweight properties—this balance is crucial for minimizing shipping costs without sacrificing protection. Additionally, clear labeling indicating fragility can aid handlers in exercising caution during shipping and handling processes, further reducing risk factors associated with damage.

By prioritizing these special considerations within the Packaging Inspection framework, companies not only protect their investments but also enhance customer satisfaction through reliable delivery experiences—after all, no one wants a shattered surprise!

Impact on Packaging Design and Strategy

The impact of product type on packaging design cannot be overstated; it fundamentally shapes how packaging strategies are developed across industries. Effective packaging must cater not only to physical protection but also align with regulatory requirements regarding safety standards—this alignment ensures that businesses remain compliant while providing an appealing presentation for consumers.

Moreover, understanding Product Type and Characteristics allows companies to innovate when it comes to sustainable practices in packaging design—an increasingly important aspect as consumers grow more environmentally conscious about their purchases. By choosing eco-friendly materials or designing reusable packages tailored specifically around certain products’ needs (like perishables), brands can attract a more conscientious consumer base while still adhering to essential shipping standards.

In conclusion, integrating insights from both product characteristics and strategic considerations into the Packaging Inspection process ultimately leads to better outcomes: fewer damages during transit, higher customer satisfaction rates, and increased brand loyalty—all contributing factors toward long-term business success.

Navigating Regulatory Requirements

Navigating the maze of regulatory requirements can feel like trying to solve a Rubik's Cube blindfolded, especially when it comes to packaging inspection. Each product type and its characteristics come with their own set of standards that must be met, ensuring safety and compliance in the marketplace. Understanding these regulations is crucial not only for legal reasons but also for maintaining product integrity throughout its lifecycle.

Key Standards and Compliance Issues

Packaging inspection is heavily influenced by various key standards that vary by industry and region. For instance, food packaging must adhere to stringent health regulations, while electronics require compliance with safety standards to prevent hazards. These compliance issues are not just bureaucratic hurdles; they directly impact how packaging materials are chosen and how products are shipped and handled.

How China Inspection Pro Ensures Compliance

China Inspection Pro has carved a niche in helping businesses navigate these complex regulatory waters with ease. Their expertise in the packaging inspection process ensures that companies meet both local and international standards without breaking a sweat. By offering tailored solutions based on specific product types and characteristics, they help clients avoid costly delays or penalties associated with non-compliance.

Risks of Ignoring Regulations

Ignoring regulatory requirements can lead to disastrous consequences—think fines, recalls, or worse yet, damage to your brand’s reputation! A failure in the packaging inspection process can result in products being deemed unsafe or unsuitable for sale, leading to significant financial losses. Moreover, overlooking compliance can create long-term issues that affect everything from shipping and handling logistics to customer trust.

Selecting Suitable Packaging Materials

Choosing the right packaging materials is crucial in ensuring product safety and compliance with regulatory requirements. The selection process must take into account the product type and characteristics, as different items require different protective measures. Ultimately, the right packaging materials can enhance the effectiveness of the packaging inspection process, safeguarding products from environmental conditions and shipping and handling challenges.

Types of Materials and Their Properties

When it comes to packaging materials, there are several options available, each with unique properties that cater to various product types. Common materials include cardboard, plastic, glass, and metal—each offering distinct benefits such as durability, weight reduction, or barrier protection against moisture and UV light. Understanding these properties allows businesses to tailor their packaging strategies effectively while ensuring compliance with relevant regulatory requirements.

For instance, cardboard is lightweight and recyclable but may not provide adequate protection for fragile items during shipping and handling. On the other hand, glass offers excellent barrier properties but can be heavy and prone to breakage if not properly inspected before use. By considering these factors in conjunction with the packaging inspection process, companies can optimize their choices for both functionality and sustainability.

Environmental Impact of Packaging Choices

The environmental impact of packaging choices has become a pressing concern for consumers and manufacturers alike. Many traditional packaging materials contribute significantly to landfill waste due to their non-biodegradable nature or difficulty in recycling processes. As a result, businesses must now evaluate not only how well their chosen materials protect products but also how they align with sustainability goals while meeting regulatory requirements.

Moreover, understanding the carbon footprint associated with various types of packaging materials is essential for making informed decisions that minimize environmental harm. The shift towards eco-friendly alternatives can lead to enhanced brand reputation among environmentally conscious consumers who prioritize sustainable practices in their purchasing decisions. Therefore, integrating environmental considerations into the overall packaging inspection process becomes vital for long-term success.

Innovations in Sustainable Packaging

Innovations in sustainable packaging are reshaping how companies approach their material selections while maintaining compliance with regulatory requirements. From biodegradable plastics made from plant-based sources to reusable containers designed for multiple uses, there’s no shortage of creative solutions aimed at reducing waste without compromising product integrity during shipping and handling processes. These advancements not only help mitigate environmental impact but also align businesses with evolving consumer preferences toward sustainability.

Additionally, many companies are exploring smart packaging technologies that provide real-time data on product conditions throughout its lifecycle—offering insights into temperature fluctuations or potential contamination risks during transportation or storage environments affected by adverse climate conditions. This level of monitoring enhances the overall effectiveness of the packaging inspection process by ensuring products remain safe until they reach consumers' hands.

In conclusion, selecting suitable packaging materials involves a careful balance between functionality, sustainability, and compliance with regulatory requirements—all while taking into account product type characteristics that dictate specific needs during shipping and handling phases.

Adapting to Environmental Conditions

In the world of packaging, environmental conditions can be a game-changer. Whether it’s extreme heat, humidity, or cold temperatures, these factors can significantly impact the effectiveness of your packaging inspection process. Understanding and adapting to these conditions ensures that your product type and characteristics are well protected throughout its journey.

Importance of Climate Considerations

Climate considerations are paramount when designing packaging materials for various products. For instance, food items may require moisture-resistant packaging to maintain freshness in humid climates, while electronics might need anti-static materials in dry environments. By tailoring the packaging inspection process to account for these climate-related factors, businesses can avoid costly damage and ensure compliance with regulatory requirements.

Testing Packaging Performance in Various Conditions

Testing is where the magic happens—it's not just about slapping a box together and calling it a day! Rigorous testing under different environmental conditions helps identify weaknesses in packaging materials before they hit the market. This proactive approach not only fortifies your product's integrity but also aligns with essential regulatory requirements that mandate comprehensive performance evaluations.

Long-term Effects on Product Integrity

Ignoring environmental conditions during the packaging inspection process can have long-lasting repercussions on product integrity. Over time, exposure to adverse climates can lead to degradation of both the product and its packaging materials, resulting in customer dissatisfaction or even recalls. Therefore, investing time in understanding how various environmental factors affect different products is crucial for maintaining quality and compliance over time.

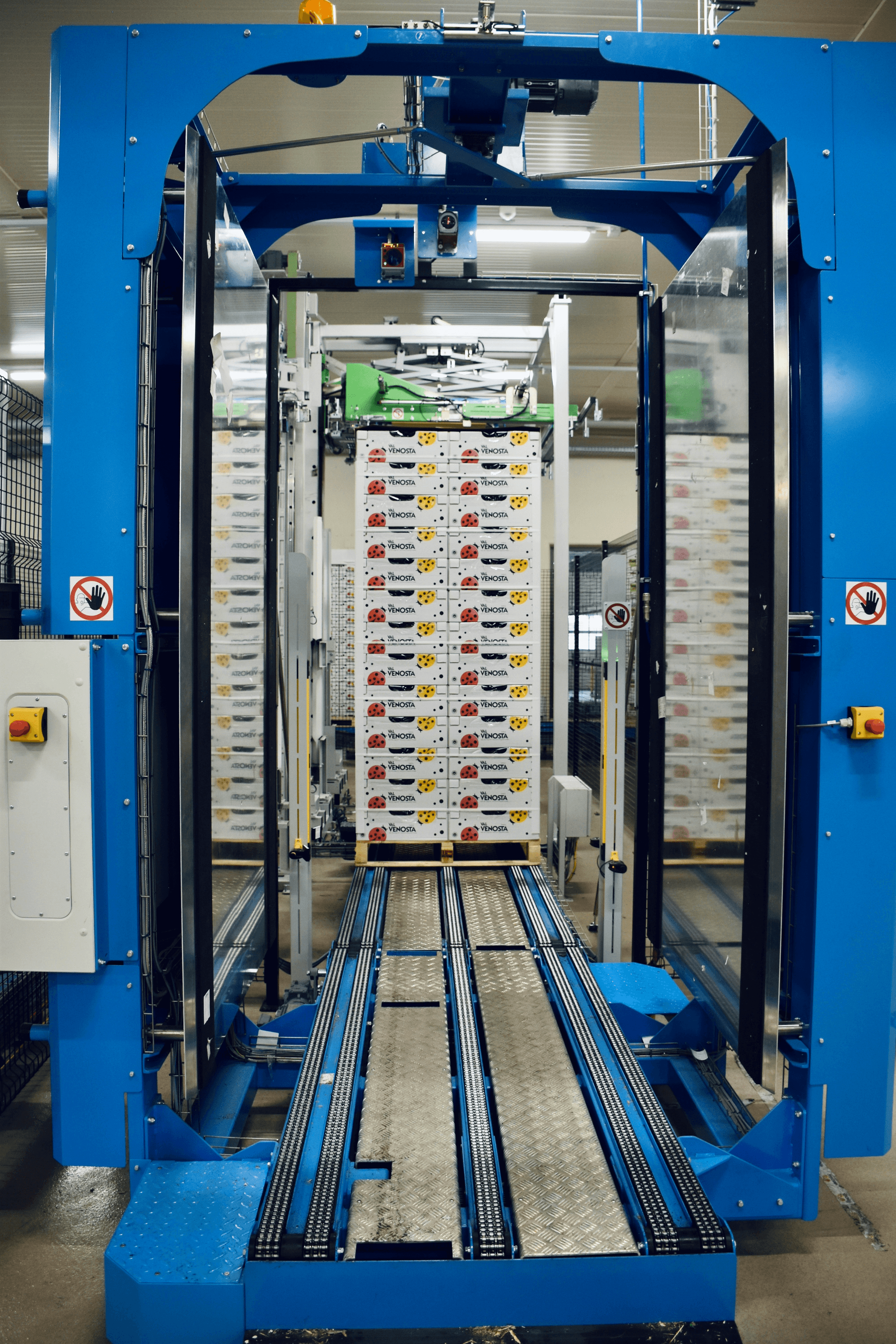

Understanding Shipping and Handling Factors

Shipping and handling are crucial stages in the lifecycle of a product, often determining its final quality upon arrival. The integrity of packaging can be significantly compromised during transportation due to various external forces, including impact, vibration, and environmental conditions. Therefore, understanding these factors is essential for effective packaging inspection and ensuring compliance with regulatory requirements.

Impacts of Transportation on Packaging Integrity

Transportation can expose products to a myriad of challenges that directly affect packaging integrity. For instance, sudden stops or rough handling can lead to physical damage, while temperature fluctuations may compromise sensitive materials—especially for fragile items or those requiring specific environmental conditions. Consequently, the packaging inspection process must account for these potential risks to ensure that products remain safe and intact until they reach their destination.

Best Practices for Robust Packaging

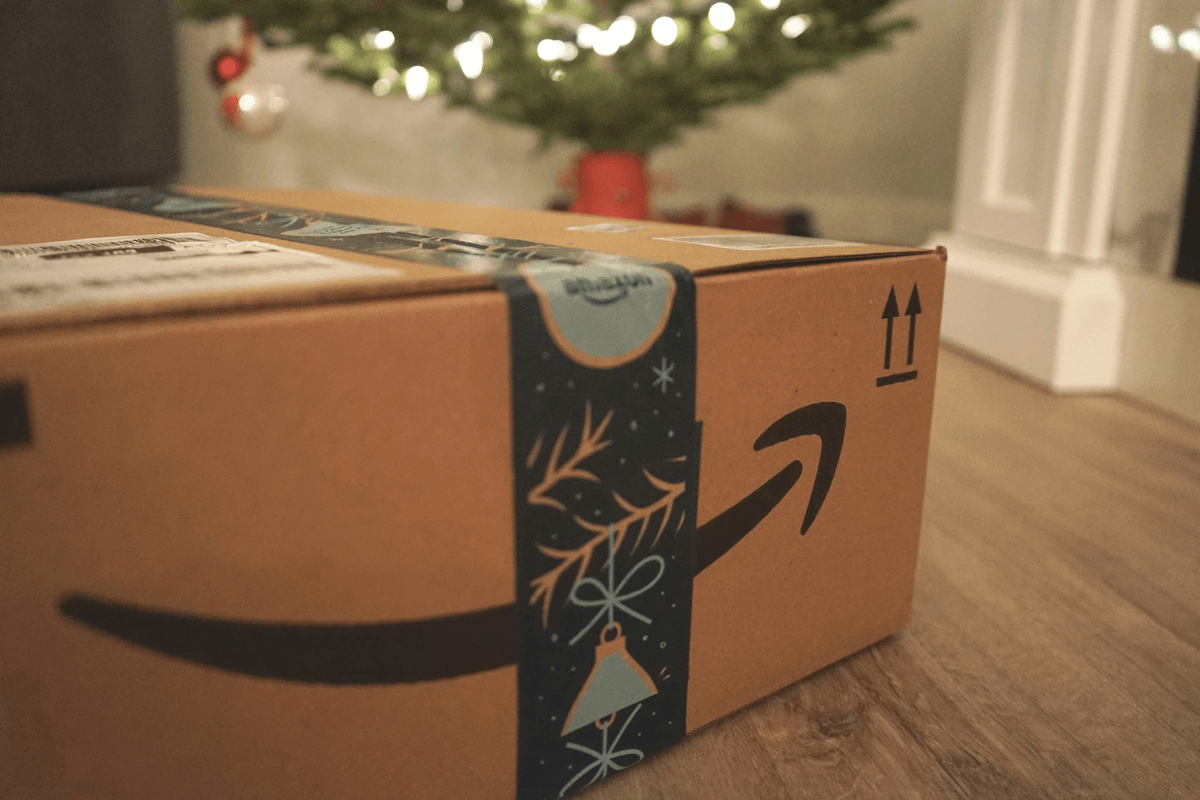

To mitigate risks associated with shipping and handling, adopting best practices in packaging design is paramount. Utilizing high-quality packaging materials tailored to the product type and characteristics can enhance durability and protection against external stresses. Additionally, incorporating cushioning elements like bubble wrap or foam inserts can provide extra security during transit while ensuring compliance with relevant regulatory requirements.

Case Studies of Failures and Lessons Learned

Examining real-world case studies provides valuable insights into the importance of robust shipping practices in maintaining packaging integrity. One notable incident involved a shipment of glassware that arrived shattered due to insufficient cushioning—a failure attributed to ignoring shipping impacts during the packaging inspection process. Such cases underscore the necessity for businesses to prioritize both innovative packaging materials and strategic designs that align with environmental conditions encountered during transport.

Conclusion

In the fast-paced world of commerce, the significance of effective packaging inspection cannot be overstated. From ensuring compliance with regulatory requirements to considering product type and characteristics, a thorough understanding of the packaging inspection process is essential for maintaining product quality. As we wrap up this discussion, it’s clear that each element—from the choice of packaging materials to the environmental conditions during shipping and handling—plays a pivotal role in safeguarding products.

Recap of Key Packaging Inspection Insights

Throughout our exploration, we highlighted how packaging inspection serves as a critical checkpoint in the supply chain. We learned that tailoring inspections based on product type and characteristics allows companies to address specific vulnerabilities, particularly for fragile items or those with unique requirements. Additionally, adhering to regulatory requirements ensures that businesses not only meet legal standards but also build consumer trust in their products.

Enhancing Product Quality Through Effective Inspection

Effective packaging inspection directly correlates with enhanced product quality and customer satisfaction. By implementing robust inspection processes, businesses can identify potential weaknesses in their packaging materials and strategies before they lead to costly failures or returns. Moreover, understanding how environmental conditions affect packaging integrity helps companies adapt their approaches, ensuring that products arrive safely at their destinations.

Future Trends in Packaging Inspection and Compliance

Looking ahead, trends indicate a growing emphasis on sustainability within the realm of packaging materials and practices. Innovations aimed at reducing environmental impact will likely drive changes in regulatory requirements as consumers demand greener options without sacrificing quality or safety. Furthermore, advancements in technology will enhance the efficiency of the packaging inspection process itself—think smart sensors and AI-driven analytics—enabling businesses to stay ahead of compliance challenges while continuously improving their offerings.