Introduction

In the world of jewelry, quality is not just a luxury; it's a necessity. Jewelry Quality Control ensures that every piece meets the highest standards before it reaches the consumer, safeguarding both reputation and revenue. With increasing competition and discerning customers, mastering the Jewelry Quality Control Process has never been more critical.

Importance of Jewelry Quality Control

Jewelry Quality Control serves as the backbone of any successful jewelry business. It not only helps in maintaining brand integrity but also builds trust with customers who expect flawless products. By implementing robust quality control measures, businesses can minimize returns and enhance customer satisfaction, ultimately driving sales.

Understanding the Jewelry Quality Control Process

The Jewelry Quality Control Process involves several stages that ensure each item is meticulously inspected from production to delivery. This process includes setting clear standards for craftsmanship and materials, which are crucial for compliance with industry norms. A thorough understanding of this process allows businesses to identify potential issues early and maintain high-quality output consistently.

Why Inspect Jewelry Before Shipping

Inspecting jewelry before shipping is an essential step in maintaining quality assurance throughout the supply chain. Pre-Shipment Inspection (PSI) for Jewelry Products acts as a final checkpoint to catch any defects or discrepancies that may have slipped through earlier stages of production. By prioritizing this inspection phase, companies can significantly reduce costly errors and uphold their commitment to excellence in every piece they deliver.

Defining Jewelry Quality Control

Jewelry Quality Control is a crucial component of the jewelry manufacturing process, ensuring that each piece meets the highest standards before reaching consumers. The Jewelry Quality Control Process encompasses various stages, from design to production, and ultimately pre-shipment inspections. By adhering to a robust quality control framework, manufacturers can significantly enhance their reputation and customer satisfaction.

Key Elements of Quality Control

The key elements of Jewelry Quality Control include inspection, testing, and compliance with established standards. Each stage in the production schedule adherence must be meticulously monitored to identify any discrepancies early on. Effective quality control not only safeguards against defects but also reinforces brand integrity through consistent delivery of high-quality products.

Role of Standards in Quality Assessment

Standards play an integral role in the Jewelry Quality Control Process by providing benchmarks for evaluating quality across various parameters such as materials, craftsmanship, and durability. Compliance with these standards ensures that manufacturers meet customer expectations while maintaining industry credibility. By aligning with recognized quality assessment frameworks, businesses can streamline their processes and enhance overall product reliability.

Importance of Compliance with International Norms

Adhering to international norms is essential for successful Jewelry Quality Control as it facilitates market access and consumer trust worldwide. Compliance demonstrates a commitment to safety, ethical sourcing, and environmental responsibility—factors increasingly important to modern consumers. Moreover, ensuring alignment with international regulations can prevent costly recalls or reputational damage due to subpar products.

Setting Up Your Production Schedule Adherence

Establishing a robust production schedule adherence is crucial for maintaining the integrity of the Jewelry Quality Control process. A well-structured timeline not only ensures that each piece meets quality standards but also aligns with customer expectations and delivery deadlines. By incorporating flexibility into your production schedule, you can better respond to unforeseen challenges while still adhering to quality control measures.

Creating a Flexible Production Timeline

A flexible production timeline is essential for navigating the dynamic landscape of jewelry manufacturing. This adaptability allows for adjustments in response to delays or changes in demand, ensuring that the Jewelry Quality Control process remains uninterrupted. To create this timeline, consider using project management tools that allow for real-time updates and collaboration among team members.

Incorporating buffer periods into your schedule can also help accommodate unexpected issues without derailing the entire operation. This way, even if a hiccup occurs during Pre-Shipment Inspection (PSI) for Jewelry Products, you have room to rectify any problems without compromising on quality or delivery times. Ultimately, flexibility in your production timeline fosters resilience and enhances overall efficiency.

Key Factors Affecting Production Schedule

Several key factors can significantly impact your production schedule adherence in jewelry manufacturing. These include supply chain reliability, workforce availability, and equipment efficiency—each playing a pivotal role in maintaining consistent output levels while upholding Jewelry Quality Control standards. Additionally, fluctuations in material costs or unexpected regulatory changes may necessitate rapid adjustments to your planned timeline.

Communication is another critical factor; keeping all stakeholders informed about potential delays or changes helps mitigate risks associated with inconsistent schedules. When everyone is on the same page regarding expectations and timelines, it becomes easier to maintain high-quality standards throughout every phase of production—from design through comprehensive visual inspection to packaging and labeling.

Lastly, integrating technology into your scheduling processes can enhance accuracy and provide valuable data insights that inform future planning decisions—ensuring that quantity and quality verification remain at the forefront of your operations.

Ensuring Consistency in Production

Consistency is key when it comes to delivering high-quality jewelry products that meet customer expectations and adhere to industry standards. To achieve this consistency within your production schedule adherence framework, it's vital to establish clear protocols for each stage of manufacturing aligned with Jewelry Quality Control principles. This includes regular training sessions for employees focused on quality assurance techniques such as comprehensive visual inspection methods.

Implementing standardized operating procedures (SOPs) will also help streamline processes across different teams while minimizing variations in product output—ensuring each piece undergoes rigorous checks before moving onto packaging and labeling stages. Moreover, regular audits of both equipment functionality and staff performance can identify areas needing improvement while reinforcing commitment toward maintaining exceptional quality levels throughout all aspects of production.

By prioritizing consistency as part of your overall strategy for managing production schedules effectively, you not only enhance operational efficiency but also build trust with consumers who rely on high-quality craftsmanship delivered consistently over time.

Conducting Pre-Shipment Inspection (PSI) for Jewelry Products

In the realm of Jewelry Quality Control, Pre-Shipment Inspection (PSI) serves as a pivotal checkpoint. This process ensures that every piece meets the established standards before it leaves the production facility. By implementing PSI, businesses can significantly reduce the risk of shipping defective or subpar products to customers.

What is Pre-Shipment Inspection?

Pre-Shipment Inspection (PSI) is a comprehensive evaluation conducted on jewelry products just before they are dispatched to retailers or consumers. This inspection aims to verify that the items conform to quality specifications and contractual obligations, ensuring adherence to the Jewelry Quality Control Process. By identifying potential issues at this stage, companies can avoid costly returns and maintain customer satisfaction.

Steps to Execute Effective PSI

Executing effective PSI involves several critical steps that ensure thorough evaluation of jewelry products. First, establish clear criteria based on quality standards and specifications outlined in your production schedule adherence documentation. Next, conduct a comprehensive visual inspection, assessing each item for defects such as scratches or missing stones while also verifying quantity against orders in your inventory system.

Following this initial assessment, it's vital to document findings meticulously—this includes capturing photographs and noting any discrepancies found during inspection. After addressing any issues identified during PSI, finalize packaging and labeling according to industry best practices before shipment occurs. This structured approach enhances overall quality assurance within your Jewelry Quality Control framework.

The Role of China Inspection Pro in PSI

China Inspection Pro plays an integral role in executing efficient Pre-Shipment Inspections for jewelry products, particularly for businesses sourcing from China. Their expertise ensures compliance with international norms while adhering strictly to the Jewelry Quality Control Process throughout each inspection phase. With experienced inspectors trained specifically in jewelry evaluation techniques like comprehensive visual inspection, they help businesses maintain high-quality standards consistently.

Moreover, utilizing services like China Inspection Pro allows companies to focus on their core operations while guaranteeing quantity and quality verification through reliable third-party assessments. This partnership not only streamlines logistics but also reinforces confidence among buyers regarding product integrity before reaching retail outlets or end consumers.

Implementing Comprehensive Visual Inspection

When it comes to Jewelry Quality Control, implementing a thorough visual inspection is non-negotiable. This process ensures that every piece of jewelry meets the highest standards before it reaches the customer. By focusing on a comprehensive visual inspection, businesses can significantly minimize returns and enhance customer satisfaction.

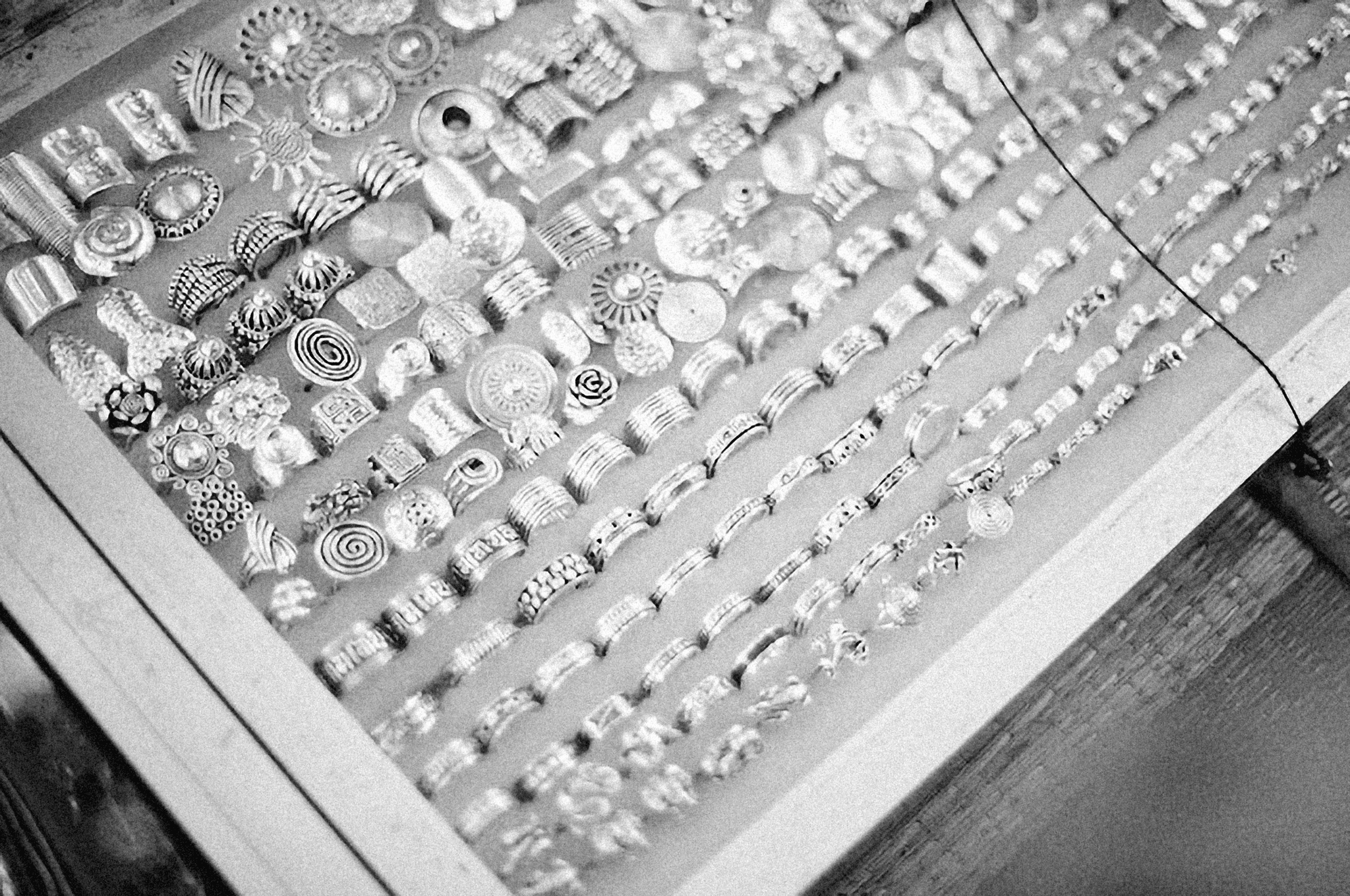

Techniques for Visual Inspection

Visual inspection techniques are crucial in the Jewelry Quality Control Process. Inspectors should be equipped with tools like magnifying glasses and light sources to scrutinize intricate details that may otherwise go unnoticed. Additionally, using standardized checklists can help ensure that each piece is evaluated consistently against established criteria.

Identifying Flaws and Defects

Identifying flaws and defects is an essential part of the visual inspection process in Jewelry Quality Control. Common issues include scratches, discoloration, or misalignment of stones, which can detract from the overall appeal of a piece. By training inspectors to recognize these imperfections promptly, businesses can uphold their production schedule adherence without compromising quality.

Best Practices for Comprehensive Assessment

To achieve an effective comprehensive assessment during visual inspections, several best practices should be followed within the Jewelry Quality Control framework. First, conducting inspections in a well-lit environment helps reveal subtle defects that might otherwise remain hidden. Second, involving multiple inspectors can provide varied perspectives on quality issues and reduce bias during evaluations.

Incorporating these best practices will not only streamline your Pre-Shipment Inspection (PSI) for Jewelry Products but also ensure that packaging and labeling are aligned with quality expectations before shipping out products to customers.

Ensuring Proper Packaging and Labeling

In the jewelry industry, packaging and labeling aren't just afterthoughts; they are crucial components of the Jewelry Quality Control process. Proper packaging protects delicate pieces from damage during transit, while effective labeling ensures that customers receive exactly what they ordered. When done right, these elements can enhance customer satisfaction and reflect the overall quality of your brand.

Importance of Packaging in Jewelry Quality

Packaging plays a vital role in Jewelry Quality Control by safeguarding items from environmental factors and physical damage during shipping. High-quality packaging not only prevents scratches or breakage but also elevates the perceived value of the jewelry piece itself—think luxurious boxes or elegant pouches that entice customers upon unboxing. Additionally, good packaging can serve as a marketing tool, reinforcing brand identity and encouraging repeat business.

Key Labeling Requirements for Jewelry

Labeling is equally important in ensuring compliance with regulations and enhancing customer trust. Key labeling requirements for jewelry include clear identification of materials used, care instructions, country of origin, and any relevant certifications (like conflict-free sourcing). Adhering to these requirements not only meets legal standards but also aligns with best practices in the Jewelry Quality Control process.

Tips for Effective Packaging Solutions

To achieve effective packaging solutions for your jewelry products, consider using materials that balance aesthetics with protection—such as padded boxes or biodegradable fillers. Always ensure that labels are easy to read and securely attached to avoid any mix-ups during Pre-Shipment Inspection (PSI) for Jewelry Products. Finally, remember to incorporate branding elements into your packaging design; this will not only make your product stand out but also reinforce your commitment to quality throughout the entire production schedule adherence.

Performing Quantity and Quality Verification

In the realm of Jewelry Quality Control, verifying both quantity and quality is paramount to maintaining customer satisfaction and brand integrity. This dual verification process ensures that each shipment meets the required standards before it leaves the production floor. By implementing effective strategies, businesses can enhance their overall Jewelry Quality Control Process.

Methods for Accurate Quantity Verification

Accurate quantity verification starts with meticulous inventory management practices. Utilizing barcode scanning systems or RFID technology can streamline this process, allowing for quick and precise tracking of jewelry items throughout production and shipping stages. Additionally, conducting regular cycle counts helps ensure that discrepancies are identified and addressed promptly, thus maintaining adherence to the Production Schedule Adherence.

Another effective method involves cross-referencing packing lists with actual inventory before shipment. This step not only confirms that the correct quantities are being sent but also serves as a final checkpoint in your Pre-Shipment Inspection (PSI) for Jewelry Products process. Employing these methods minimizes errors and fosters trust between suppliers and retailers.

Balancing Quantity with Quality Expectations

While meeting quantity demands is crucial, it should never come at the cost of quality expectations in jewelry production. Striking a balance requires clear communication of quality standards across all departments involved in the Jewelry Quality Control Process. Regular training sessions can ensure that all team members understand how to maintain this equilibrium without compromising either aspect.

Moreover, setting realistic production goals based on past performance data can help manage expectations while ensuring that quality remains a priority during high-demand periods. Implementing robust checks during Comprehensive Visual Inspection will catch any potential issues early on, thereby preventing subpar products from reaching customers despite meeting quantity targets.

Ultimately, fostering a culture where quality is valued alongside quantity can lead to long-term success in jewelry manufacturing and sales.

Tools for Ensuring Consistent Quality

To achieve consistent quality across every piece of jewelry produced, investing in specialized tools is essential. Advanced inspection equipment such as digital calipers or magnifying lenses allows teams to detect minute details that could affect overall product integrity during Comprehensive Visual Inspection phases. These tools not only enhance accuracy but also provide valuable data for continuous improvement within the Jewelry Quality Control Process.

Additionally, utilizing software solutions tailored for inventory management can assist in tracking both quantity and quality metrics effectively over time. These systems often include reporting features that highlight trends or recurring issues related to specific products or batches—information vital for refining production schedules while adhering to quality standards.

Lastly, collaboration with professional inspection services can provide an extra layer of assurance regarding both quantity verification and overall product excellence before items are packaged and labeled for shipment.

Conclusion

In the world of jewelry, quality control is not just a checkbox on a to-do list; it’s the backbone of customer satisfaction and brand integrity. The Jewelry Quality Control Process encompasses various steps, from production schedule adherence to comprehensive visual inspections, ensuring that every piece meets high standards before it reaches the consumer's hands. By prioritizing these elements, jewelers can minimize defects and enhance their reputation in a competitive market.

Key Takeaways on Jewelry Quality Control

Understanding the key components of Jewelry Quality Control is essential for any jewelry business aiming for success. Emphasizing production schedule adherence allows manufacturers to maintain consistency while managing time effectively, ensuring products are ready for timely delivery. Moreover, implementing rigorous Pre-Shipment Inspection (PSI) for jewelry products helps catch potential issues before they reach customers, ultimately safeguarding both quality and brand reputation.

The Role of Professional Inspection Services

Professional inspection services play an indispensable role in the Jewelry Quality Control process by providing expertise that many businesses may lack in-house. These services specialize in conducting comprehensive visual inspections and thorough quantity and quality verification, offering an objective perspective that enhances overall product integrity. By leveraging such professional support, jewelers can ensure their packaging and labeling meet industry standards while also adhering to international compliance norms.

Final Thoughts on Quality Assurance in Jewelry

Quality assurance in jewelry isn't merely about meeting expectations; it's about exceeding them at every turn. As we’ve explored through various stages—from production schedule adherence to effective packaging solutions—the importance of maintaining high-quality standards cannot be overstated. Investing in robust Jewelry Quality Control practices not only elevates your brand but also fosters trust with your customers, paving the way for long-term success.