Introduction

In a world where our furry companions are treated like family, the importance of Pet Product Quality Control cannot be overstated. Pet owners want to ensure that every chew toy, bowl of kibble, and cozy bed is not only enjoyable but also safe for their beloved pets. With a myriad of pet products flooding the market, understanding what goes into quality control can make all the difference in keeping our pets happy and healthy.

Why Quality Control Matters for Pet Products

Quality control is essential in the pet industry because it directly impacts the safety of pets and their owners. Poorly made products can lead to serious health risks or injuries, making rigorous testing a non-negotiable aspect of manufacturing. Furthermore, ensuring high standards fosters trust between brands and consumers, ultimately promoting loyalty among pet owners who prioritize their pets' well-being.

Understanding the Types of Pet Products

The landscape of pet products is vast and varied, ranging from Pet Toys Quality Control to essential nutrition found in Pet Food and Treats. Collars and Leashes must provide strength and reliability to keep our pets secure during walks, while Pet Bedding should prioritize comfort for restful sleep. Each category requires specific attention to detail in quality control processes to guarantee that every item meets safety standards.

Overview of Testing Requirements

To uphold these high-quality standards, various testing requirements must be met across different product categories. For instance, rigorous assessments are necessary for Pet Toys Quality Control to ensure they withstand rough play without posing choking hazards or other dangers. Additionally, nutritional analysis for Pet Food and Treats ensures that our pets receive balanced diets while durability tests on Collars and Leashes confirm their ability to withstand daily wear-and-tear—all integral components of a comprehensive quality control strategy.

The Importance of Pet Product Quality Control

In the pet product industry, quality control is not just a box to check—it's a lifeline for pets and their owners. Ensuring that every item meets rigorous standards can prevent accidents and health issues, making Pet Product Quality Control essential.

Ensuring Safety for Pets and Owners

The primary goal of Pet Product Quality Control is safeguarding the well-being of our furry friends as well as their human companions. For instance, poorly made pet toys can break apart easily, posing choking hazards or causing injuries—definitely not what any pet parent wants! Similarly, when it comes to Pet Food and Treats, quality control ensures that nutritional standards are met so that our pets receive safe and healthy options.

Safety extends beyond just the products themselves; it also encompasses how they interact with pets in everyday life. Collars and Leashes should withstand tugging without snapping or fraying, while Pet Bedding must be free from harmful chemicals that could irritate sensitive skin. By prioritizing safety through rigorous testing and quality checks, brands can provide peace of mind to pet owners everywhere.

Building Brand Reputation and Trust

Quality control isn't just about safety—it's also a vital component in building a brand's reputation in the competitive pet product market. When consumers see consistent quality across products like Pet Toys Quality Control measures or reliable collars and leashes, they’re more likely to trust that brand for future purchases. This trust translates into loyalty; satisfied customers often become repeat buyers who advocate for your brand within their communities.

Moreover, word-of-mouth recommendations can significantly impact sales in this industry. A single negative experience with a subpar product can lead to bad reviews that spread like wildfire on social media platforms—something no brand wants! By investing in thorough quality control processes for all types of pet products—including bedding options—brands solidify their standing as trustworthy providers.

Compliance with Regulations

In addition to enhancing safety and reputation, compliance with regulations is another crucial aspect of Pet Product Quality Control that cannot be overlooked. Regulatory bodies set forth guidelines designed to protect both pets and consumers from hazardous materials or unsafe practices in manufacturing processes. Companies must stay informed about these regulations related to Pet Food and Treats as well as other categories like toys or accessories.

Non-compliance isn't just risky for pets—it can also result in significant financial penalties or even lawsuits against brands found guilty of negligence regarding quality standards. Therefore, adhering strictly to regulatory requirements is essential not only for ethical reasons but also for business sustainability within the competitive landscape of pet products. By maintaining high-quality benchmarks across all offerings—from collars and leashes to bedding manufacturers safeguard their operations against potential pitfalls while promoting overall industry integrity.

Types of Pet Products Requiring Quality Control

Different types of pet products each have unique requirements for testing and quality assurance. From toys that withstand vigorous play to food that meets nutritional standards, understanding these categories can help manufacturers maintain high-quality offerings.

Pet Toys Quality Control: Safety and Durability

Pet toys are not just playthings; they are essential for a pet's mental stimulation and physical health. Therefore, pet toys quality control focuses on ensuring that these items are safe from harmful materials and durable enough to withstand chewing, tugging, and other forms of rough play. Rigorous testing protocols must be established to check for choking hazards, toxic substances, and overall durability to ensure pets can enjoy their toys without worry.

Pet Food and Treats: Nutritional Standards

Nutritional standards must be strictly adhered to in order to provide balanced diets that meet specific dietary needs based on age, size, and breed. Regular testing for contaminants such as bacteria or toxins ensures that every bite is safe and nutritious—because a happy pet starts with healthy food!

Collars and Leashes: Strength and Reliability

Collars and leashes are fundamental tools for any responsible pet owner; they keep pets secure during walks while allowing them some freedom to explore the world around them. The strength of these products is critical—poorly made collars can break or fail at the most inconvenient moments! Quality control measures should focus on testing materials for strength under various conditions, ensuring reliability when it matters most.

Pet Bedding: Comfort and Durability

A good night’s sleep is just as important for pets as it is for humans; hence the role of quality control in pet bedding cannot be overlooked. Comfort should go hand in hand with durability; after all, a cozy bed should last through countless naps without losing its shape or comfort level! Testing materials used in bedding helps ensure they are not only soft but also resistant to wear-and-tear from daily use.

Testing Requirements for Pet Products

From playful pet toys to nutritious food, each category requires specific tests to uphold standards that protect both pets and their owners. This section delves into the essential testing requirements that every responsible manufacturer should prioritize.

Essential Tests for Pet Toys

Pet Toys Quality Control begins with comprehensive safety assessments that identify potential hazards like choking risks or toxic materials. Tests for durability are also critical; after all, no one wants a toy that disintegrates in minutes during a play session! Additionally, assessing the materials used in pet toys ensures they are non-toxic and safe for chewing, which is vital for the health of our furry friends.

Nutritional and Safety Testing for Pet Food

When it comes to Pet Food and Treats, nutritional testing is paramount to confirm that ingredients meet established dietary standards. This involves analyzing nutrient levels to ensure they provide balanced nutrition tailored to different pets' needs—because not every dog can thrive on cat food! Safety testing also plays a crucial role, checking for contaminants like bacteria or harmful additives that could jeopardize pet health.

Durability Tests for Collars and Leashes

Collars and Leashes must undergo stringent durability tests to ensure they can withstand the wear and tear of daily use without breaking or fraying. These tests often simulate extreme conditions—like sudden pulls from an excited pup—to assess strength under stress. Ensuring these products can handle various situations not only enhances safety but also builds trust among pet owners who depend on reliable gear.

Assessing Materials in Pet Bedding

When evaluating Pet Bedding, it's essential to assess materials carefully to guarantee comfort while avoiding allergens or harmful substances. Testing should focus on factors like breathability, ease of cleaning, and resistance to wear over time; no one wants a bed that flattens after a few washes! Additionally, soft yet durable fabrics will keep pets cozy while ensuring longevity—a win-win in any pet owner's book.

Standards and Certifications in the Industry

In the world of pet products, adhering to established standards and obtaining relevant certifications is crucial for ensuring quality control. These benchmarks not only safeguard the welfare of our furry friends but also enhance brand credibility in a competitive market. Understanding these standards helps manufacturers navigate the complex landscape of pet product quality control effectively.

ASTM and ISO Standards Explained

The American Society for Testing and Materials (ASTM) and International Organization for Standardization (ISO) provide essential guidelines that shape pet product quality control practices. ASTM sets specific safety and performance criteria, particularly relevant for pet toys quality control, while ISO focuses on broader organizational standards that ensure consistent product quality across various categories, including pet food and treats. By complying with these standards, manufacturers can assure customers that their products meet rigorous safety requirements.

For instance, ASTM standards dictate how to evaluate the durability of materials used in collars and leashes or assess potential choking hazards in pet toys. Similarly, ISO certification can indicate a company’s commitment to ongoing improvement in processes related to pet bedding production or food safety protocols for treats. Ultimately, these standards serve as a foundation upon which brands can build trust with consumers who prioritize safety.

Importance of Certifications like APPA

Certifications such as those offered by the American Pet Products Association (APPA) play an integral role in enhancing pet product quality control across various segments. APPA certification signifies that a product has undergone thorough testing and meets specific industry benchmarks regarding safety and reliability—especially important for items like collars and leashes or nutritional content in pet food and treats. For consumers, this certification acts as a badge of honor indicating that they are purchasing from reputable brands committed to excellence.

Moreover, having an APPA certification can elevate a brand's visibility within an increasingly crowded marketplace where discerning customers seek assurance about their purchases' safety. It also encourages manufacturers to maintain high-quality standards throughout their production processes—from initial design concepts through final inspections—ensuring every aspect aligns with best practices in pet product quality control. In essence, certifications foster consumer confidence while incentivizing companies to strive for continuous improvement.

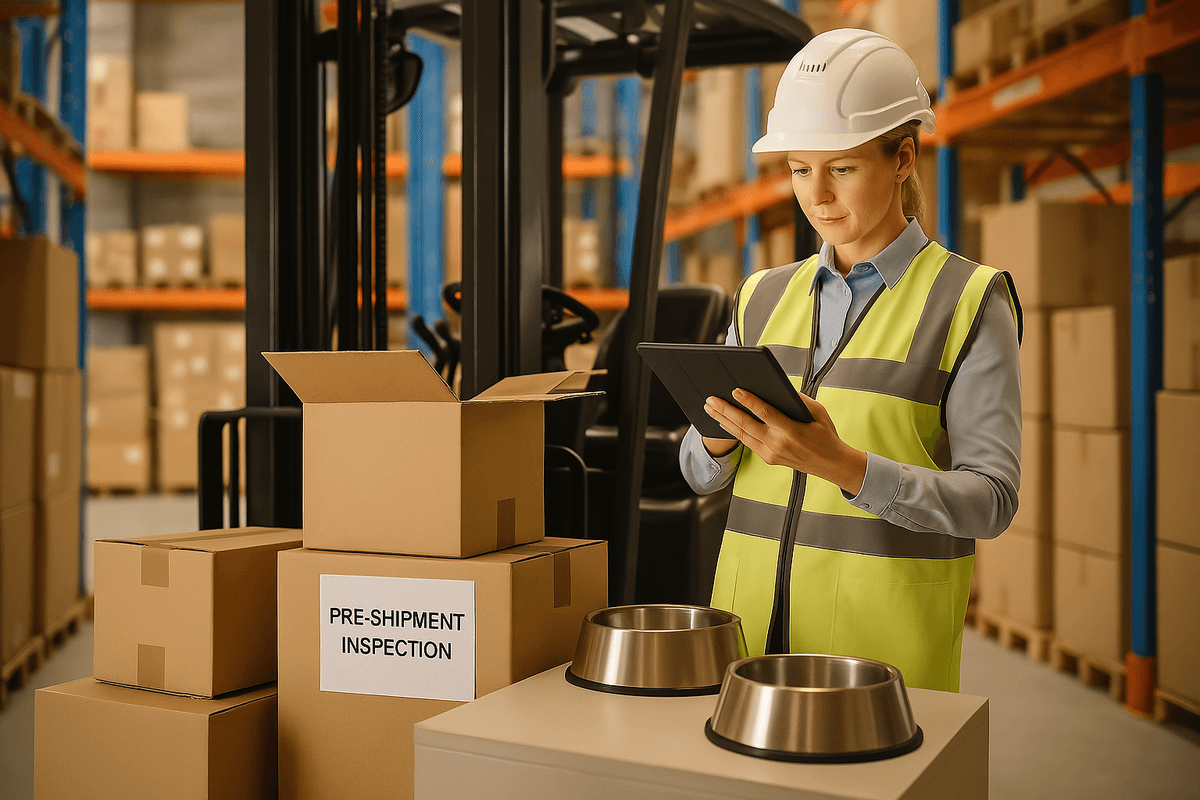

Role of China Inspection Pro in Ensuring Quality

As global supply chains become more intricate, organizations like China Inspection Pro have emerged as vital players in ensuring robust quality control measures for pet products manufactured overseas. They specialize in conducting comprehensive inspections that cover everything from raw materials used in manufacturing collars and leashes to final assessments of packaging integrity for pet food and treats before they hit store shelves. By leveraging their expertise, businesses can mitigate risks associated with subpar products entering the market.

China Inspection Pro's services include verifying compliance with international standards such as ASTM or ISO while also focusing on specific requirements unique to different types of products—like durability tests for pet toys or comfort assessments for bedding materials. Their involvement not only streamlines the production process but also reinforces trust between manufacturers and retailers by ensuring all parties are aligned on quality expectations throughout the supply chain journey. Ultimately, partnering with inspection agencies enhances overall confidence surrounding pet product quality control efforts.

The Role of Quality Control in Product Development

Quality control is not just a final step; it’s a crucial element woven into the fabric of product development for pet products. By integrating Pet Product Quality Control early in the design process, companies can identify potential issues before they become costly problems. This proactive approach ensures that products like pet toys, food, collars, and bedding meet safety and durability standards from the get-go.

Integrating Quality Control Early in the Process

When developing pet products, incorporating Pet Toys Quality Control at the initial stages can save time and resources down the line. Early testing allows manufacturers to tweak designs based on feedback regarding safety and durability before hitting the market. Similarly, for items such as Pet Food and Treats, establishing nutritional benchmarks early on guarantees that pets receive high-quality sustenance right from launch.

Moreover, applying quality control measures to Collars and Leashes during design helps ensure their strength and reliability under various conditions. This foresight not only enhances product performance but also elevates customer satisfaction by reducing returns due to defects or failures. In essence, integrating quality control early fosters a culture of excellence that resonates throughout a brand's offerings.

Continuous Improvement Through Feedback Loops

Once products are on shelves, maintaining high standards through continuous improvement is vital for long-term success in Pet Product Quality Control. Establishing feedback loops with customers allows brands to gather insights about their pet toys or bedding after real-world usage. This information feeds back into development cycles, enabling companies to refine existing products or innovate new ones based on actual consumer experiences.

For instance, if customers report that certain collars are prone to wear-and-tear faster than expected, manufacturers can investigate materials used and make necessary adjustments for future batches. This commitment to improvement not only enhances product quality but also builds trust with consumers who see that brands listen and respond effectively to their needs. Ultimately, creating an environment where feedback drives innovation leads to better quality across all categories—be it Pet Food and Treats or durable pet toys.

Case Studies of Brands Excelling in Quality Control

Several brands have set benchmarks in Pet Product Quality Control by prioritizing safety and durability throughout their development processes. For example, a leading manufacturer of pet toys has implemented rigorous testing protocols that assess both material integrity and playability—ensuring pets enjoy safe fun without risk of choking hazards or breakage over time. Their commitment has earned them loyal customers who appreciate transparency regarding safety standards.

Similarly, another company specializing in Pet Bedding has adopted an eco-friendly approach while maintaining strict quality checks on comfort levels and durability against wear over time. By showcasing their adherence to high-quality standards through certifications like APPA (American Pet Products Association), they’ve cultivated trust among environmentally-conscious consumers seeking reliable options for their furry friends’ comfort needs.

In conclusion, these case studies illustrate how effective integration of quality control not only enhances product offerings but also strengthens brand loyalty within competitive markets saturated with choices for discerning pet owners.

Conclusion

In the ever-evolving landscape of pet products, the importance of Pet Product Quality Control cannot be overstated. As pet owners become more discerning about what they buy, ensuring that products are safe and reliable is essential for both pets and their humans. By prioritizing quality control, brands not only protect their furry customers but also enhance their overall market reputation.

Enhancing Pet Safety Through Quality Control

Pet safety is paramount in every aspect of product development, from Pet Toys Quality Control to the manufacturing of Pet Food and Treats. Rigorous testing ensures that toys are free from harmful materials and that food meets nutritional standards, keeping pets healthy and happy. When companies invest in quality control measures, they significantly reduce the risk of recalls or safety incidents, fostering a safer environment for our four-legged friends.

Building Loyalty with Quality Assurance

Quality assurance is more than just a buzzword; it’s a commitment to excellence that resonates with consumers. When brands demonstrate unwavering dedication to Pet Product Quality Control—be it through durable Collars and Leashes or cozy Pet Bedding—they cultivate trust among pet owners. This loyalty translates into repeat purchases and positive word-of-mouth recommendations, which are invaluable in today’s competitive marketplace.

Future Trends in Pet Product Quality Control

As technology advances, so do the methods used for ensuring quality in pet products. Emerging trends include enhanced tracking systems for supply chain transparency and innovative testing methods for both safety and sustainability in materials used across all categories—from toys to bedding. The future of Pet Product Quality Control will likely see an increased focus on eco-friendly practices alongside rigorous safety standards, appealing to conscientious consumers who care about both their pets' welfare and the planet.