Introduction

In today's competitive landscape, the significance of quality checks cannot be overstated. Businesses that prioritize quality inspections not only enhance their product reliability but also foster customer trust and loyalty. As we delve into innovative methods for quality assurance, it becomes clear that embracing comprehensive strategies is essential for long-term success.

Understand the Importance of Quality Checks

Quality checks serve as the backbone of any production process, ensuring that products meet established standards before they reach consumers. By systematically implementing quality inspections, companies can identify defects early in the manufacturing cycle, preventing costly recalls and damage to their reputation. This proactive approach not only saves money but also enhances operational efficiency and customer satisfaction.

The Impact of Quality Inspections on Business

The impact of rigorous quality inspections on business outcomes is profound; it directly correlates with profitability and brand integrity. When customers receive high-quality products consistently, they are more likely to become repeat buyers and advocates for the brand. Furthermore, effective production inspection processes can streamline operations and reduce waste, ultimately contributing to a healthier bottom line.

Explore Innovative Methods for Quality Assurance

As industries evolve, so do the methods employed for quality assurance; innovative techniques like factory witness tests are gaining traction among manufacturers seeking excellence. These cutting-edge approaches not only refine existing practices but also integrate modern technology to enhance accuracy in quality checks. By exploring these new avenues, businesses can stay ahead of the curve while ensuring their products meet or exceed market expectations.

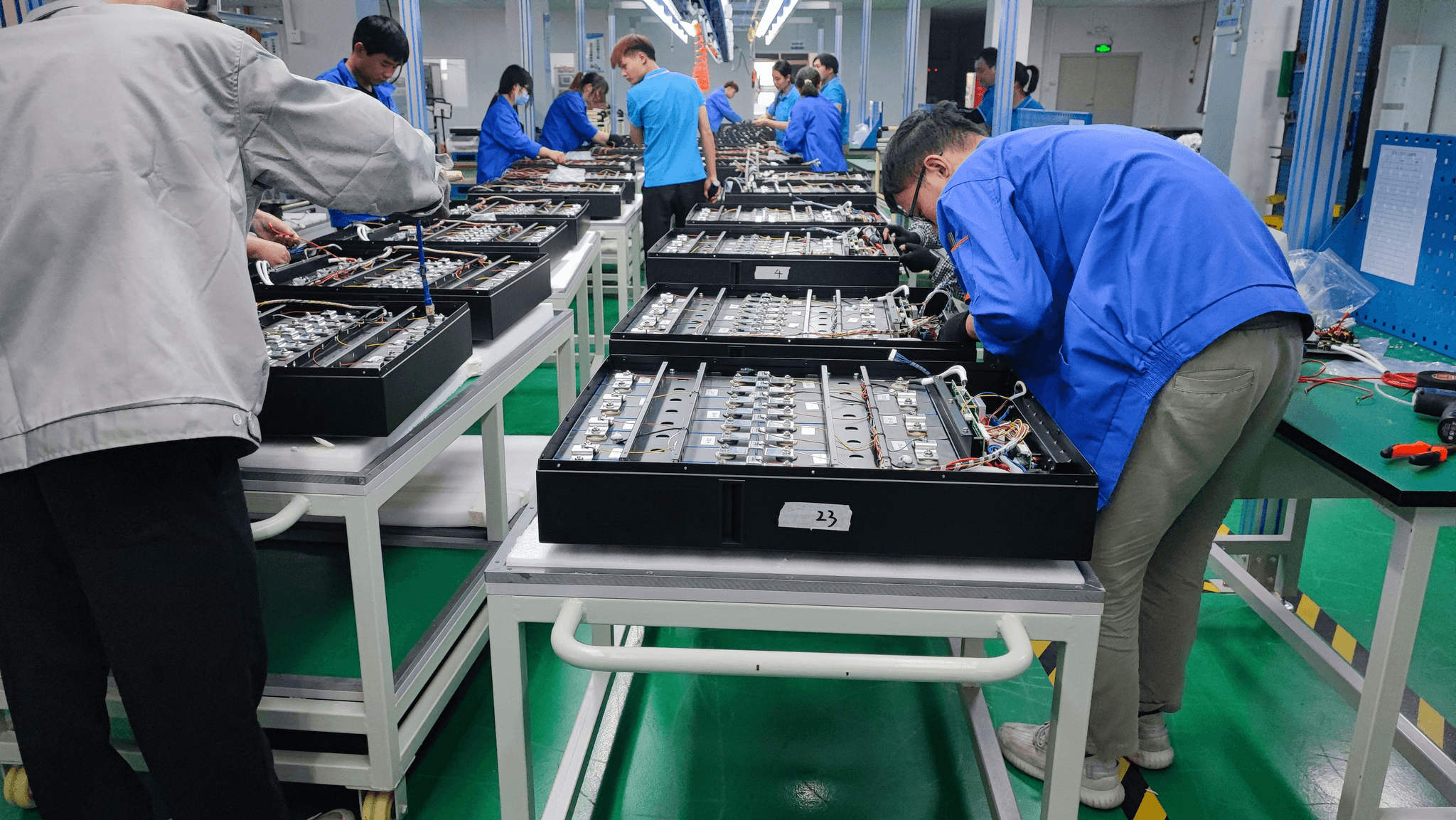

Embracing Factory Witness Tests

In the realm of quality inspections, factory witness tests stand out as a proactive approach to ensuring product excellence. These tests allow stakeholders, such as clients and quality assurance teams, to observe the production process firsthand, verifying that every aspect aligns with predefined standards. By embracing factory witness tests, businesses can enhance their quality checks and foster greater transparency throughout their operations.

What is a Factory Witness Test?

A factory witness test is essentially an on-site evaluation where designated representatives observe the manufacturing process in real-time. This type of quality inspection allows for immediate feedback and adjustments if any discrepancies arise during production. Unlike traditional inspections that occur post-production, factory witness tests provide a dynamic way to ensure compliance with specifications while products are still being made.

Benefits of Involving Witness Tests

Incorporating factory witness tests into your quality checks offers multiple benefits that can significantly impact overall production outcomes. Firstly, it fosters collaboration between manufacturers and clients, creating a sense of shared responsibility for quality assurance. Secondly, these tests help identify potential issues early in the production cycle—saving time and resources—and ultimately enhancing customer satisfaction by delivering products that meet expectations.

Real-World Examples of Success

Numerous companies have successfully integrated factory witness tests into their production inspection processes with remarkable results. For instance, a leading electronics manufacturer implemented these tests to ensure compliance with international safety standards; they reported a 30% reduction in product recalls within just one year! Another example includes an automotive supplier who utilized factory witness testing to streamline their assembly line processes; they not only improved efficiency but also bolstered client trust through transparent operations.

A Deep Dive into Production Inspections

When it comes to ensuring the integrity of products, production inspections are a cornerstone of quality checks. These inspections serve as a critical checkpoint during the manufacturing process, allowing businesses to catch potential defects before they become costly issues. By implementing various types of quality inspections throughout production, companies can enhance their overall output and safeguard their reputation.

Types of Production Inspections Explained

Production inspections come in several flavors, each tailored to specific stages of the manufacturing process. The most common types include pre-production inspections, in-line inspections, and final random inspections. Pre-production checks focus on raw materials and components before assembly; in-line inspections monitor processes as they happen; and final random inspections assess finished goods just before they reach customers.

Each type of quality inspection plays a vital role in maintaining standards throughout production. For instance, pre-production checks ensure that materials meet specifications and reduce risks later on. In contrast, in-line checks help identify issues immediately during manufacturing, while final random inspections act as a last line of defense before products hit the market.

How Production Inspections Improve Outcomes

Production inspections significantly improve outcomes by minimizing waste and reducing rework costs associated with defective products. By catching issues early through various types of quality checks, businesses can save time and money while enhancing customer satisfaction. Moreover, consistent quality inspections foster a culture of accountability among team members who recognize the importance of producing high-quality goods.

Incorporating production inspection protocols also leads to better compliance with industry standards and regulations—something that can save companies from hefty fines or legal troubles down the line. Additionally, these practices help build trust with customers who expect reliable products delivered on time without surprises. Ultimately, investing in robust inspection processes pays off through improved efficiency and enhanced brand loyalty.

Case Studies Showcasing Benefits

Consider Company A, which implemented rigorous production inspection protocols after experiencing significant returns due to defective items. By adopting multiple types of quality checks across its manufacturing lines—including factory witness tests—they reduced defects by 40% within six months. This not only saved them money but also improved their reputation among consumers seeking dependable products.

Another example is Company B's use of continuous feedback loops tied to their production inspection processes; this led them to discover recurring issues with one supplier's materials through systematic evaluations over time. Armed with this knowledge, they switched suppliers and subsequently saw an impressive drop in defects—proving that effective quality inspections can drive meaningful change across an organization’s supply chain.

These case studies illustrate how comprehensive production inspection strategies yield tangible benefits for companies committed to maintaining high standards through proactive quality assurance measures.

Implementing the 5 Whys Technique

When it comes to quality checks, the 5 Whys technique is a powerful tool for problem-solving. This method involves asking why multiple times—typically five—to drill down to the root cause of an issue. By systematically exploring the layers of a problem, organizations can identify underlying issues that may affect production inspections and overall quality inspections.

Understanding the 5 Whys Method

The 5 Whys method is deceptively simple yet highly effective in uncovering the core reasons behind problems in production and quality checks. Originating from Toyota's production system, it encourages teams to look beyond surface-level symptoms and understand what’s truly causing defects or failures. By continuously asking why, teams can trace back through processes until they arrive at actionable solutions that improve quality.

How It Uncovers Root Causes

Uncovering root causes is crucial for effective quality inspections, and that's where the 5 Whys shines brightly. For instance, if a factory witness test reveals a defect in a product, applying this technique can help identify whether it’s due to faulty machinery, inadequate training, or subpar materials used during production inspection. This deep dive not only addresses immediate concerns but also leads to long-term improvements in processes and products.

Success Stories from Various Industries

Numerous industries have successfully implemented the 5 Whys technique to elevate their standards of quality checks and enhance operational efficiency. For example, in manufacturing, one company discovered that repeated defects were traced back to insufficient employee training—a revelation that led them to revamp their onboarding process entirely. Similarly, in healthcare settings, teams have used this method to improve patient safety protocols by identifying systemic issues rather than just addressing isolated incidents.

The Role of Statistical Process Control

In the ever-evolving landscape of quality assurance, Statistical Process Control (SPC) stands out as a vital tool for ensuring that quality checks are not just routine tasks but integral components of a robust production process. By utilizing statistical methods to monitor and control production processes, businesses can identify variations and trends that may indicate potential issues before they escalate. This proactive approach to quality inspections not only saves time and resources but also enhances overall product quality.

Basics of Statistical Process Control

At its core, Statistical Process Control involves the use of statistical techniques to analyze and improve manufacturing processes. It helps in measuring the stability of a process by monitoring data points over time, allowing teams to determine whether variations are due to common causes or special causes. Understanding these distinctions is crucial for effective production inspection, as it enables teams to implement corrective actions swiftly when deviations from expected performance occur.

SPC employs various tools such as control charts, histograms, and Pareto charts to visualize data trends and variations. These tools help teams identify patterns that may not be immediately evident through traditional inspection methods alone. By integrating SPC into their quality checks, organizations can enhance their decision-making capabilities and ensure more consistent outcomes.

Applications in Quality Checks

The applications of Statistical Process Control in quality checks are extensive and impactful across multiple industries. For instance, in manufacturing environments where precision is critical, SPC can be used to monitor dimensions or tolerances during production runs. This ensures that any deviations from specifications are caught early through systematic factory witness tests or other forms of real-time monitoring.

Additionally, SPC can aid in identifying areas for improvement within existing processes by analyzing historical data trends over time. This allows companies to refine their operations continually while reducing waste and increasing efficiency—key elements in maintaining high standards during quality inspections. As organizations embrace these applications, they position themselves favorably against competitors who may still rely on outdated methods.

Real-Life Applications and Results

Numerous companies have successfully implemented Statistical Process Control with remarkable results that underscore its importance in modern manufacturing practices. For example, a well-known automotive manufacturer adopted SPC techniques for their assembly lines and reported a significant reduction in defects—by over 30%—within just six months of implementation. This success was largely attributed to enhanced visibility into their production processes through regular statistical analysis.

Another case involves a food processing company that integrated SPC into its quality checks system to monitor critical control points during production cycles closely. As a result, they achieved compliance with stringent industry regulations while simultaneously improving product consistency—a win-win scenario made possible by effective use of statistical methods within their production inspection framework.

In conclusion, the role of Statistical Process Control is paramount when it comes to elevating the standard of quality checks within any organization striving for excellence in product delivery. By leveraging this powerful tool alongside innovative practices like factory witness tests or various types of production inspections, businesses can foster an environment conducive to continuous improvement.

Leveraging Technology for Quality Control

In today's fast-paced manufacturing landscape, technology is not just a luxury; it's a necessity for effective quality checks. The integration of advanced tech tools can significantly enhance the precision and efficiency of quality inspections, ensuring that products meet the highest standards. By adopting these innovations, businesses can streamline processes and reduce the risk of errors during production inspection.

Tech Tools Revolutionizing Quality Inspections

The emergence of sophisticated tech tools has transformed how companies approach quality inspections. From AI-driven cameras that detect defects to software that analyzes data in real-time, these innovations are making it easier to conduct thorough quality checks. For instance, using drones for factory witness tests allows inspectors to cover large areas quickly and efficiently while capturing high-resolution images for detailed analysis.

Moreover, mobile apps designed specifically for quality control enable inspectors to log findings instantly and generate reports on-the-go. This immediacy ensures that any issues are flagged right away, allowing teams to address problems before they escalate into significant setbacks. With these tech advancements at their disposal, businesses can maintain rigorous standards throughout their production processes.

Benefits of Automation in Quality Checks

Automation plays a pivotal role in enhancing the reliability and speed of quality checks across various industries. By automating repetitive tasks involved in production inspection, companies can free up human resources for more complex problem-solving activities that require critical thinking and creativity. This shift not only increases efficiency but also minimizes the likelihood of human error during inspections.

Additionally, automated systems provide consistent results by adhering strictly to predefined criteria during each inspection cycle. This consistency is crucial when dealing with multiple types of quality checks across different product lines or factories. Ultimately, automation leads to faster turnaround times without sacrificing accuracy—an essential factor in maintaining competitive advantage.

Notable Innovations in the Field

Innovations such as machine learning algorithms are revolutionizing how businesses conduct their quality inspections by predicting potential defects before they occur based on historical data patterns. These predictive analytics tools empower manufacturers to proactively address issues rather than reactively managing them after they’ve impacted production outcomes or customer satisfaction levels.

Another noteworthy innovation is the use of blockchain technology for traceability within supply chains—ensuring transparency at every stage from raw materials through factory witness tests to final delivery. This level of visibility enhances trust between partners and clients alike while reinforcing accountability throughout the entire process of ensuring product integrity during quality checks.

As we look ahead into an increasingly digital future, it’s clear that leveraging technology will be paramount for organizations striving to uphold exceptional standards in their products through effective quality inspections.

Continuous Improvement Through Feedback Loops

In the realm of quality checks, feedback loops are essential for fostering a culture of continuous improvement. They create a structured way to gather insights from various stages of production inspections and quality inspections, allowing businesses to refine their processes consistently. By integrating feedback into their operations, companies can identify areas for enhancement, ensuring that quality remains at the forefront of their manufacturing or service delivery.

The Importance of Feedback in Quality Checks

Feedback serves as a vital component in the quality checks process because it provides real-time insights into performance and issues that may arise during production inspection. Without this critical input, organizations risk making decisions based on outdated or incomplete information, which can lead to costly mistakes and compromised product quality. Moreover, constructive feedback encourages collaboration among teams, fostering an environment where employees feel empowered to contribute to ongoing improvements in quality inspections.

Strategies for Effective Feedback Loops

To establish effective feedback loops within quality checks, companies should implement regular review meetings that bring together stakeholders from all relevant departments. These sessions should focus on discussing findings from factory witness tests and other types of quality inspections while encouraging open dialogue about potential improvements. Additionally, utilizing technology such as automated surveys or real-time dashboards can streamline the collection of feedback data and ensure timely responses to any identified issues.

Examples of Companies Adopting This Approach

Several successful companies have embraced continuous improvement through structured feedback loops in their quality checks processes. For instance, a leading automotive manufacturer implemented regular cross-departmental meetings after production inspections revealed recurring defects in specific components; this led to significant reductions in error rates and improved overall product reliability. Similarly, a global electronics firm adopted customer feedback mechanisms following factory witness tests which helped them enhance product features based on user experiences—ultimately boosting customer satisfaction and loyalty.

The Power of Third-Party Quality Inspections

In the ever-evolving world of manufacturing, third-party quality inspections have emerged as a vital component in ensuring that products meet the highest standards. By enlisting external inspectors, businesses can gain an unbiased view of their quality checks, which is crucial for maintaining credibility and trust with consumers. This approach not only enhances the reliability of quality inspections but also fosters a culture of transparency within organizations.

Why Choose Third-Party Inspections?

Choosing third-party inspections can significantly elevate the integrity of your production processes. These independent evaluators bring expertise that may not be available internally, allowing for thorough factory witness tests and detailed production inspections that highlight areas needing improvement. Moreover, third-party inspectors provide an objective perspective on the type of quality being produced, ensuring that companies adhere to industry standards and regulations.

The advantages extend beyond mere compliance; they include reduced risks associated with product defects and recalls. When businesses prioritize quality checks through independent assessments, they often see enhanced customer satisfaction and loyalty. Ultimately, this investment translates into higher profitability as companies avoid costly errors down the line.

How China Inspection Pro Elevates Quality Checks

China Inspection Pro stands out in the realm of third-party inspections by offering tailored solutions designed to meet diverse business needs. With a focus on comprehensive quality checks and factory witness tests, they ensure that every aspect of production is meticulously examined before goods leave the factory floor. Their experienced team conducts rigorous production inspections to identify potential issues early on, helping clients mitigate risks effectively.

Moreover, China Inspection Pro employs state-of-the-art technology to enhance their inspection processes further. This integration allows for real-time data collection and analysis, providing clients with immediate feedback on their products' quality status. As a result, companies are empowered to make swift decisions based on accurate information rather than relying solely on internal assessments.

Success Stories from Partnering with Inspectors

Numerous companies have reaped significant benefits from partnering with third-party inspectors like China Inspection Pro in their quest for improved quality assurance. For instance, a well-known electronics manufacturer faced challenges with defective components leading to costly returns and damaged reputation. By implementing rigorous factory witness tests through an independent inspector, they identified critical flaws in their supply chain management process and made necessary adjustments.

Another success story involves a clothing brand that struggled with inconsistent fabric quality across its production lines in Asia. After engaging third-party inspectors for regular production inspections, they were able to standardize materials used across all factories while enhancing overall product consistency—leading directly to increased customer satisfaction ratings and sales growth.

In conclusion, leveraging third-party quality inspections offers substantial advantages for businesses aiming to improve their product offerings while minimizing risks associated with poor-quality outputs. By integrating these services into your operational framework—alongside effective feedback loops—you can maximize success with robust quality assurance strategies.

Conclusion

In the ever-evolving landscape of quality inspections, businesses must stay ahead of the curve by embracing innovative practices that enhance their quality checks. The future will likely see a greater integration of technology and data analysis in production inspection processes, ensuring that companies can quickly adapt to changing market demands. Moreover, as consumer expectations rise, the importance of thorough quality checks will only intensify, leading to more stringent regulations and standards across various industries.

Future Trends in Quality Inspections

Looking ahead, one can expect a surge in automated solutions for quality inspections that leverage artificial intelligence and machine learning. These advancements will not only streamline factory witness tests but also improve accuracy by reducing human error during production inspections. Additionally, predictive analytics will play a vital role in anticipating potential failures before they occur, allowing businesses to implement proactive measures for maintaining high-quality standards.

Integrating Innovative Quality Checks

To remain competitive, organizations need to integrate innovative quality checks into their existing frameworks seamlessly. This could involve adopting hybrid models that combine traditional methods with cutting-edge technologies like IoT devices for real-time monitoring during production inspection phases. By fostering a culture of continuous improvement and adaptability, companies can ensure that their type of quality meets or exceeds customer expectations while minimizing waste and inefficiencies.

Maximizing Success with Quality Assurance

Ultimately, maximizing success with quality assurance requires a holistic approach that encompasses all aspects of production—from initial design through final delivery. By prioritizing comprehensive training on factory witness tests and other critical inspections for employees at all levels, organizations can cultivate an environment where quality is everyone's responsibility. As businesses commit to ongoing education and technological integration in their quality checks process, they set themselves up not just for survival but for thriving in an increasingly competitive marketplace.