Introduction

In the intricate world of manufacturing, the role of a quality inspector is pivotal. But what is a quality inspector, exactly? This professional ensures that products meet specific standards and specifications, playing a crucial part in maintaining the integrity of the manufacturing process. Their keen eye for detail helps catch potential defects before they reach consumers, safeguarding both company reputation and customer satisfaction.

Understanding the Quality Inspector's Role

Quality inspectors are responsible for verifying that products are manufactured to meet predetermined quality standards. They conduct inspections at various stages of production, meticulously examining materials and finished goods to ensure compliance with specifications. By understanding what is a quality inspector's role, we can appreciate how vital they are in reducing waste and enhancing efficiency within manufacturing environments.

Importance of Quality Assurance in Manufacturing

Quality assurance (QA) is essential in manufacturing as it establishes protocols to prevent defects and ensure product reliability. A robust QA program not only enhances product quality but also boosts consumer confidence, ultimately leading to increased sales and market share. The significance of quality assurance certification cannot be overstated; it demonstrates a commitment to high standards and continuous improvement within an organization.

Certifications Every Quality Inspector Should Have

To excel as a quality inspector, obtaining relevant certifications is crucial for career advancement and credibility in the field. Quality certification programs provide essential training on industry standards and best practices while also validating an inspector’s skills and knowledge base. Pursuing an inspector certification can open doors to new opportunities, making it an invaluable asset for anyone looking to thrive in this dynamic industry.

What is a Quality Inspector?

Quality inspectors play a pivotal role in the manufacturing landscape, ensuring that products meet specific standards and regulations. So, what is a quality inspector? In essence, they are the gatekeepers of quality assurance, tasked with examining materials and finished goods to identify defects or deviations from established specifications. This position not only demands technical knowledge but also a keen eye for detail and a commitment to excellence.

Definition and Key Responsibilities

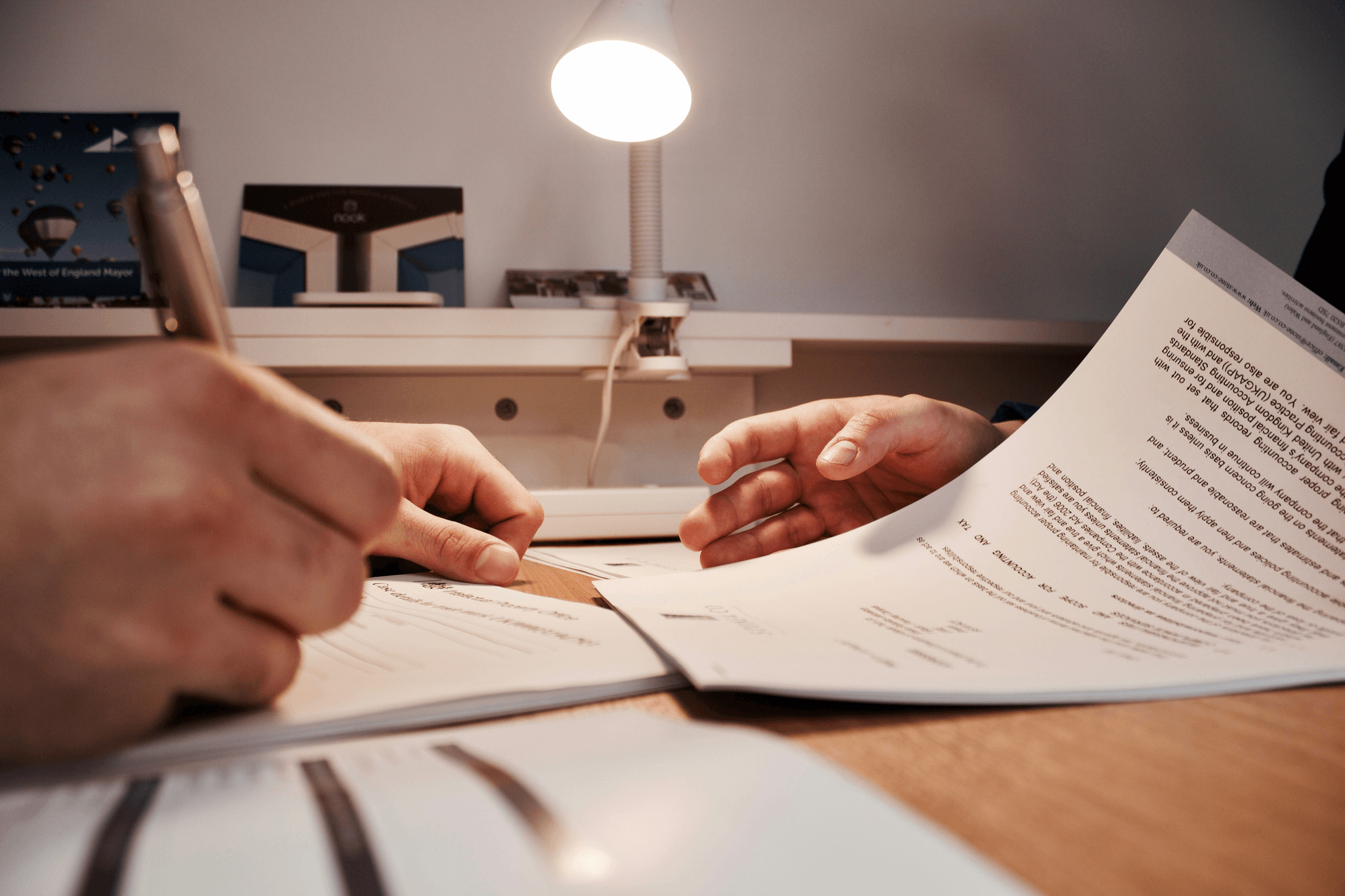

A quality inspector is responsible for evaluating products at various stages of production to ensure compliance with quality standards. Their key responsibilities include conducting inspections, documenting findings, and collaborating with production teams to resolve issues promptly. An essential part of their role is to uphold quality assurance certification requirements, which helps maintain industry standards and customer satisfaction.

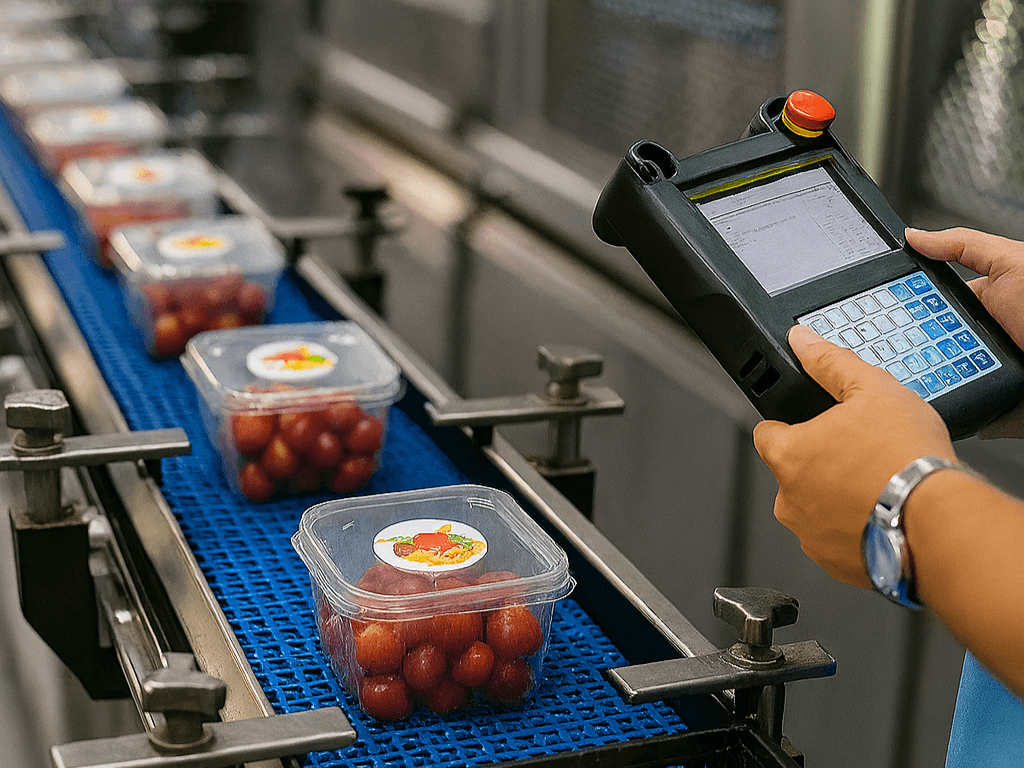

Daily Tasks in Manufacturing Environments

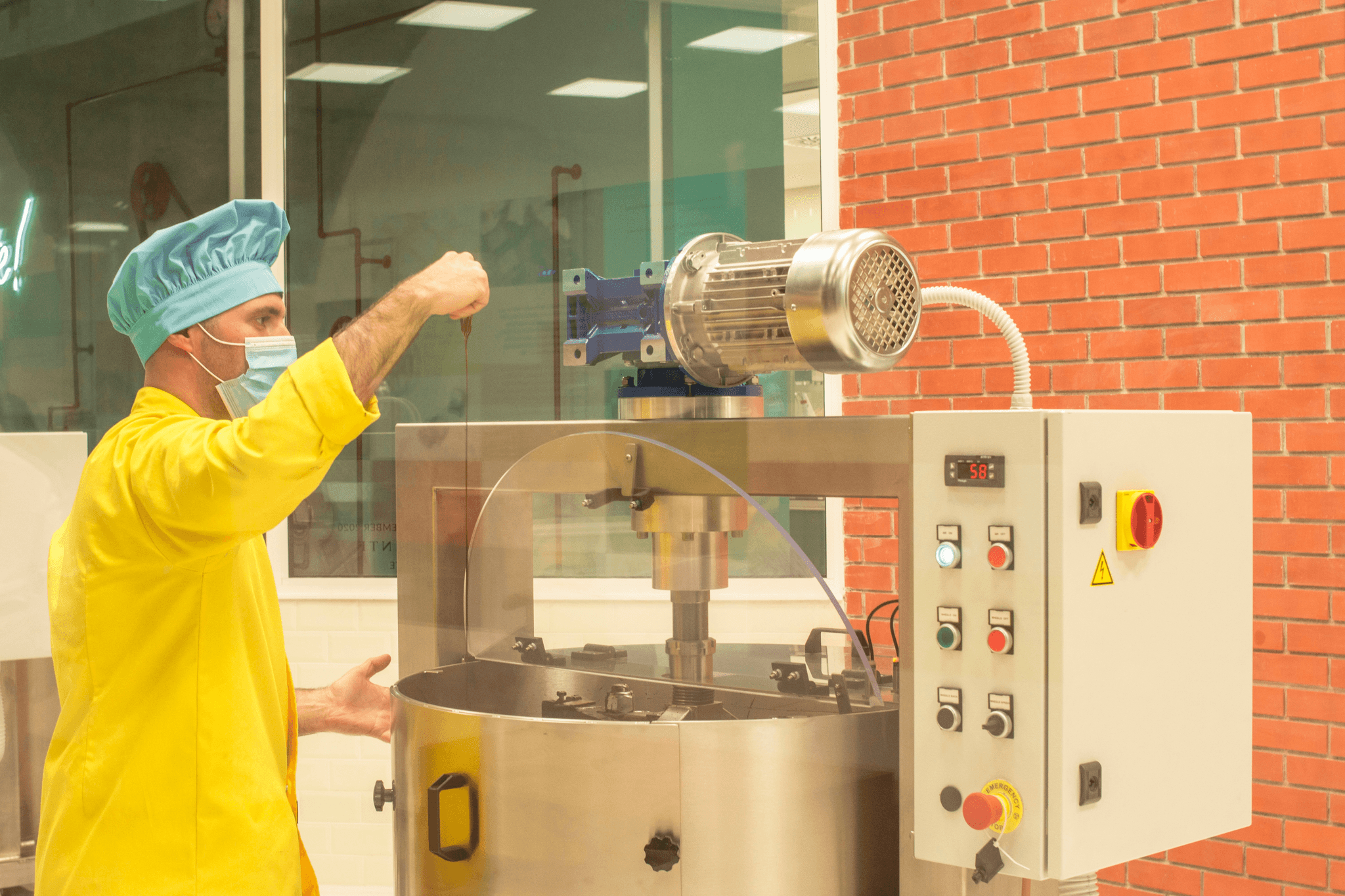

In manufacturing environments, daily tasks for a quality inspector can vary widely but often include visual inspections, measurements using precision tools, and performing tests on samples. They may also be involved in analyzing data collected during inspections to identify trends or recurring issues that need addressing. Each day presents new challenges as inspectors strive to ensure that every product meets the rigorous criteria set forth by industry regulations and internal policies related to inspector certification.

The Importance of Attention to Detail

Attention to detail is paramount for any quality inspector; it’s the difference between a flawless product and one that fails inspection. Small oversights can lead to significant consequences in manufacturing—think costly recalls or safety hazards! By honing their skills in meticulous observation and thorough documentation, inspectors not only enhance product quality but also contribute significantly toward achieving overall quality certification within their organizations.

Quality Assurance vs. Quality Control

In the world of manufacturing, understanding the distinction between quality assurance (QA) and quality control (QC) is crucial for any quality inspector. While these terms are often used interchangeably, they represent two distinct processes that play vital roles in ensuring product excellence. Quality assurance focuses on preventing defects through systematic processes, whereas quality control emphasizes identifying and correcting defects in finished products.

Differences Explained

To grasp what is a quality inspector's role, it's essential to delineate QA from QC clearly. Quality assurance is proactive; it involves establishing standards and procedures to ensure that products are developed correctly from the outset. On the other hand, quality control is reactive; it inspects final products to catch any errors before they reach consumers, ensuring compliance with established standards.

This difference highlights why both QA and QC are necessary in manufacturing environments. Without effective QA practices, defects may go unnoticed until they manifest in the final product, leading to costly recalls or customer dissatisfaction. Conversely, relying solely on QC can result in wasted resources as problems are only addressed after production rather than preventing them from occurring initially.

How Each Role Contributes to Manufacturing

Each role contributes uniquely to manufacturing efficiency and product integrity. A quality inspector engaged in QA will implement procedures that reduce variability and improve consistency across production lines—essentially setting the stage for success before items roll off the assembly line. This proactive approach not only saves time but also enhances customer trust by delivering high-quality products consistently.

On the flip side, those involved in QC focus on inspecting finished goods against predefined criteria—this ensures that only items meeting specific standards reach consumers’ hands. By identifying flaws during this stage, inspectors help prevent defective products from tarnishing a company’s reputation or leading to safety issues down the line. Together, these functions create a robust framework for maintaining high-quality output throughout every phase of production.

The Synergy Between QA and QC

The synergy between QA and QC lies at the heart of effective manufacturing practices—each supports and enhances the other’s effectiveness significantly. When a quality inspector adopts both perspectives within their role, they can foster an environment where continuous improvement thrives; this means not just fixing problems but also understanding their root causes to prevent future occurrences through better processes or training initiatives.

Moreover, implementing strong quality assurance certification programs can elevate both functions by providing standardized guidelines for performance evaluation within organizations. Similarly, obtaining an inspector certification demonstrates commitment not just to personal growth but also contributes positively toward overall company objectives regarding product reliability and consumer satisfaction.

Ultimately, recognizing how QA complements QC—and vice versa—can lead organizations toward achieving higher levels of operational excellence while minimizing wasteful practices associated with unchecked errors or inconsistencies throughout production cycles.

Essential Skills for Quality Inspectors

Quality inspectors play a crucial role in maintaining the standards of manufacturing processes, and possessing essential skills is key to their success. From analytical prowess to effective communication, these abilities ensure that quality assurance practices are upheld. This section delves into the core competencies that every quality inspector should cultivate for optimal performance.

Analytical and Problem-Solving Skills

At the heart of what is a quality inspector lies the ability to analyze data and identify potential issues before they escalate. Quality inspectors must possess strong analytical skills to dissect manufacturing processes and pinpoint areas that require improvement or correction. By honing their problem-solving abilities, inspectors can devise practical solutions that enhance product quality, ensuring compliance with industry standards.

Furthermore, these skills are not just about crunching numbers; they involve critical thinking and an understanding of complex systems. A quality inspector who can navigate through data trends will be invaluable in spotting anomalies and proposing corrective actions swiftly. In essence, analytical and problem-solving skills allow inspectors to maintain high levels of quality assurance certification throughout their careers.

Communication and Reporting Skills

Effective communication is vital for any role within manufacturing, but it takes on special significance when discussing what is a quality inspector’s duties. Quality inspectors need to relay findings clearly and concisely to various stakeholders, from production teams to upper management. Strong reporting skills ensure that all parties understand inspection results and any necessary actions required—after all, what's the point of identifying issues if no one knows about them?

Moreover, written reports must be thorough yet straightforward enough for non-technical personnel to grasp easily. Inspectors also benefit from active listening during discussions with team members regarding potential improvements or concerns in processes. Ultimately, robust communication skills facilitate collaboration across departments while reinforcing the importance of maintaining high standards through effective quality certification practices.

Technical Proficiency and Tools Used

In today's tech-driven world, being technically proficient is non-negotiable for anyone asking what is a quality inspector's job description encompasses fully. Familiarity with inspection tools such as calipers, micrometers, gauges, and software programs designed for quality management systems (QMS) is essential for modern-day inspectors. These tools not only aid in accurate measurements but also streamline reporting processes—making it easier than ever to uphold rigorous standards associated with inspector certification.

Additionally, understanding how these tools integrate into broader manufacturing technology can set an inspector apart from their peers in terms of efficiency and effectiveness on the job site. As industries evolve towards automation and digitization, continuous learning becomes imperative; staying updated on new technologies ensures relevance within an ever-changing landscape of quality assurance certification requirements. Thus, technical proficiency equips inspectors with the capabilities needed to excel while fostering confidence among team members regarding product integrity.

Certifications That Enhance Your Career

In the world of manufacturing, certifications can be the golden ticket that elevates your career as a quality inspector. With the right credentials, you not only gain knowledge but also enhance your credibility in a field that demands precision and reliability. Quality assurance certification is essential for anyone looking to solidify their role and make a significant impact on product quality.

Overview of Quality Assurance Certification

Quality assurance certification serves as an official recognition of an individual's expertise in maintaining high standards within manufacturing processes. This certification typically covers various aspects of quality management systems, methodologies, and best practices that are crucial for effective quality inspection. Understanding what is a quality inspector becomes clearer through this lens, as certified professionals are equipped with the tools to identify defects and ensure compliance with industry standards.

The process to obtain a quality assurance certification often involves rigorous training and examinations designed to test one’s knowledge comprehensively. Many organizations offer these certifications, each with its own focus areas such as ISO standards or Six Sigma methodologies. By pursuing such credentials, you demonstrate commitment to excellence in your role as a quality inspector.

Importance of Inspector Certification

Inspector certification is not just about adding letters after your name; it’s about showcasing your dedication to maintaining high-quality standards in manufacturing environments. Having this certification can significantly boost your employability since many employers prefer candidates who have proven their skills through formal training and assessment. It acts as a seal of approval that tells potential employers: “I know what I’m doing when it comes to ensuring product quality.”

Moreover, certified inspectors often have access to exclusive resources and networks that can further enhance their professional growth. This community aspect encourages sharing best practices and staying updated on the latest trends in quality inspection methodologies. In essence, obtaining inspector certification is an investment in both personal development and career advancement.

Benefits of Quality Certification in the Industry

The benefits of quality certification extend beyond individual inspectors; they positively impact entire organizations by fostering a culture focused on continuous improvement and excellence. Companies with certified inspectors are more likely to produce high-quality products consistently, which can lead to increased customer satisfaction and loyalty—an invaluable asset in today’s competitive market landscape. Additionally, having qualified personnel helps organizations comply with regulatory requirements more efficiently.

Quality certifications also open doors for networking opportunities within industry circles where knowledge sharing thrives among peers who understand the nuances of what is a quality inspector's role in various sectors. Furthermore, these certifications often come with ongoing education requirements that keep professionals abreast of new technologies and methods—ensuring they remain relevant in an ever-evolving field like manufacturing.

In summary, pursuing quality assurance certification or inspector certification offers numerous advantages for both individuals seeking growth within their careers and companies striving for excellence in product delivery.

Real-World Applications of Quality Inspection

Quality inspection plays a pivotal role in ensuring that products meet the required standards and specifications before they reach consumers. This section delves into real-world applications, showcasing the significance of quality inspectors and their contributions to manufacturing excellence. Through case studies, insights into industry leaders, and the impact on product quality, we can appreciate how vital this role is in today’s marketplace.

Case Studies of Successful Inspections

Consider a leading automotive manufacturer that faced significant challenges with defective parts entering the assembly line. By employing rigorous quality inspections and implementing a comprehensive quality assurance certification program, they reduced defects by over 30%. This success story illustrates not only what is a quality inspector's role but also highlights how effective inspections can lead to substantial cost savings and improved customer satisfaction.

Another notable example involves a consumer electronics company that integrated advanced inspection technologies into its production process. By training their staff in inspector certification programs, they enhanced their team's ability to identify flaws early on, resulting in fewer returns and higher customer loyalty. These case studies underscore the importance of having well-trained quality inspectors who are equipped with the right skills and certifications to excel in their roles.

How China Inspection Pro Leads in Quality Assurance

China Inspection Pro has emerged as a leader in quality assurance by leveraging cutting-edge technology and skilled professionals dedicated to maintaining high standards across various industries. Their approach combines traditional inspection methods with modern techniques, ensuring that every product undergoes thorough scrutiny before reaching consumers. With an emphasis on continuous improvement, they provide extensive training for their inspectors through recognized quality certification programs.

By focusing on inspector certification, China Inspection Pro ensures that its team possesses the necessary qualifications to perform detailed evaluations effectively. This commitment not only enhances their reputation but also instills confidence among clients seeking reliable inspection services. Their leadership in this space demonstrates how investing in quality assurance can significantly elevate industry standards.

Impact on Product Quality and Compliance

The impact of effective quality inspections extends beyond mere compliance; it influences brand reputation and consumer trust as well. When companies prioritize what is a quality inspector's role within their operations, they often see improvements not just in defect rates but also in overall product performance metrics. The benefits of obtaining relevant certifications are clear: businesses experience enhanced credibility while fostering positive relationships with customers who value high-quality products.

Moreover, adherence to strict compliance regulations becomes more manageable when organizations have robust inspection processes backed by qualified personnel holding relevant certifications like ISO or Six Sigma credentials. As industries continue evolving towards higher standards, understanding the nuances of inspector certification will be essential for companies aiming for long-term success amidst growing competition.

Conclusion

In the ever-evolving landscape of manufacturing, the role of quality inspectors cannot be overstated. They serve as the guardians of product integrity, ensuring that every item meets stringent standards before it reaches consumers. This not only safeguards a company's reputation but also fosters trust in the marketplace, making quality inspectors invaluable assets.

The Value of Quality Inspectors in Manufacturing

What is a quality inspector? At their core, these professionals are responsible for evaluating products and processes to ensure compliance with industry standards and specifications. Their meticulous attention to detail helps prevent defects and enhances overall product quality, ultimately contributing to customer satisfaction and loyalty.

The importance of inspector certification cannot be overlooked; it equips quality inspectors with essential skills and knowledge that enhance their effectiveness. Certified inspectors bring credibility to their roles, demonstrating a commitment to excellence in quality assurance practices. In a competitive market, businesses that prioritize hiring certified professionals often see improved performance metrics and reduced costs associated with defects.

Future Trends in Quality Inspection Practices

As technology advances, so too does the field of quality inspection. Future trends indicate an increasing reliance on automation and artificial intelligence (AI) to assist inspectors in their duties, streamlining processes while maintaining high standards of accuracy. Additionally, embracing data analytics will enable inspectors to identify patterns and potential issues more efficiently than ever before.

Quality assurance certification programs are evolving alongside these advancements, incorporating new technologies into training modules so that inspectors remain at the forefront of industry practices. This shift not only enhances skill sets but also prepares professionals for emerging challenges in manufacturing environments. As industries adapt to changing consumer demands and regulatory requirements, certified inspectors will play a crucial role in navigating these complexities.

How to Become a Certified Quality Inspector

Becoming a certified quality inspector involves several key steps that can set you on the path toward success in this rewarding career field. First and foremost, obtaining relevant education—often through technical programs or degrees—provides foundational knowledge about what is a quality inspector's responsibilities and best practices within manufacturing settings.

Next comes pursuing specific certifications such as those offered by recognized organizations like ASQ (American Society for Quality). These certifications validate your expertise while enhancing your resume; they demonstrate your commitment to professional development in areas such as quality assurance certification or inspector certification specifically tailored for various industries.

In conclusion, investing time into achieving quality certification not only boosts your career prospects but also contributes significantly to improving product standards within manufacturing sectors worldwide. By understanding what is a quality inspector’s role today—and preparing for tomorrow—you position yourself as an essential player in ensuring excellence across industries.