Introduction

In the fast-paced world of food production, quality control (QC) stands as a cornerstone of success. The food industry is unique, requiring stringent quality assurance measures to ensure that products are safe, nutritious, and appealing to consumers. Understanding the nuances of QC in the food industry is essential for maintaining high standards and fostering customer trust.

Understanding QC in the Food Industry

Quality control in the food industry encompasses various processes designed to monitor and maintain product integrity throughout production. This involves not only routine checks but also a comprehensive understanding of how ingredients interact and how final products are handled. By implementing effective quality management systems, organizations can better safeguard against contamination and ensure compliance with health regulations.

The Importance of Quality Assurance

Quality assurance plays a pivotal role in the food sector by establishing protocols that guarantee product safety and quality from farm to table. It’s not just about meeting regulatory requirements; it’s about building a reputation for excellence that keeps customers coming back for more. A well-trained quality assurance specialist can make all the difference in identifying potential issues before they escalate into costly recalls or safety crises.

Common Pitfalls in Quality Management

Despite its importance, many organizations fall prey to common pitfalls in quality management that undermine their efforts. These include inadequate training for staff, insufficient process control measures, and neglecting regular inspections—all of which can lead to significant lapses in product quality. Recognizing these challenges is the first step toward implementing effective solutions that enhance overall quality improvement initiatives within the food industry.

Lack of Education and Training

In the food industry, the importance of education and training cannot be overstated. Quality control (QC) processes hinge on a well-informed workforce capable of implementing effective quality management strategies. Without proper training, even the best quality assurance systems can falter, leading to detrimental outcomes for both products and consumers.

The Role of a Quality Assurance Specialist

A quality assurance specialist is the backbone of any successful QC in the food industry. This role involves monitoring production processes, ensuring compliance with safety standards, and driving continuous improvement initiatives. By understanding their responsibilities, these specialists can effectively manage quality issues before they escalate into major problems.

Importance of Continuous Learning

In an ever-evolving landscape like food production, continuous learning is essential for maintaining high-quality standards. The field of quality assurance is dynamic; new regulations and technologies emerge frequently that require professionals to stay updated. Investing in ongoing education not only enhances individual skill sets but also strengthens overall process control within organizations.

Implementing Effective Training Programs

To combat the pitfalls associated with inadequate training, organizations must develop robust training programs tailored to their specific needs in quality management. These programs should encompass both theoretical knowledge and practical applications relevant to quality assurance inspectors' daily tasks. By fostering a culture of learning and adaptation, companies can significantly enhance their quality improvement efforts while ensuring compliance with industry standards.

Inadequate Process Control

In the realm of the food industry, inadequate process control can lead to a cascade of quality issues that compromise both safety and consumer trust. Effective process control is essential for maintaining high standards in quality assurance, ensuring that every stage of food production meets stringent quality management criteria. Without robust systems in place, even the best intentions can fall flat, resulting in subpar products and potential regulatory repercussions.

Defining Process Control in Food Production

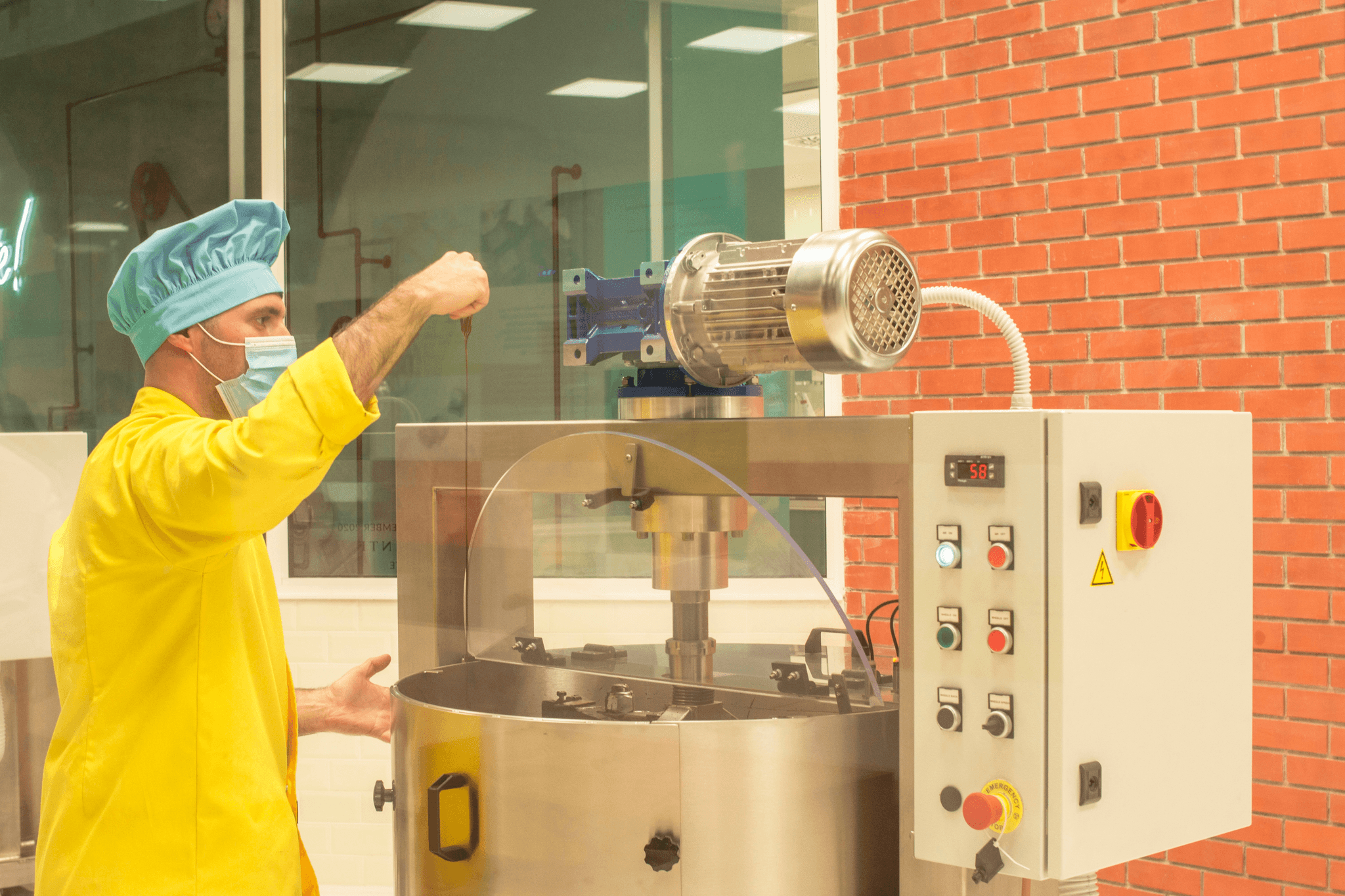

Process control in food production refers to the systematic approach of managing and monitoring various stages of manufacturing to ensure consistent product quality. This involves defining critical parameters such as temperature, humidity, and time, which are vital for maintaining safety and quality assurance throughout the production cycle. By establishing clear standards within these parameters, a quality assurance specialist can help mitigate risks associated with food safety and enhance overall product integrity.

Tools for Monitoring Quality

To effectively monitor quality in food production, several tools are at a quality assurance inspector’s disposal. These include statistical process control (SPC) charts, which track variations over time and help identify trends that could indicate potential issues before they escalate. Additionally, real-time monitoring technologies such as sensors and automated systems provide immediate feedback on critical parameters, ensuring that any deviations from established norms are swiftly addressed to uphold standards in quality management.

Strategies to Improve Process Control

Improving process control requires a multifaceted approach that incorporates both technology and human expertise into daily operations. One strategy is implementing regular training sessions for staff members focused on understanding their roles within the framework of QC in the food industry; this fosters a culture of accountability and continuous improvement among team members. Furthermore, conducting routine audits will not only highlight areas needing attention but also reinforce best practices among employees dedicated to upholding high standards in quality assurance.

Ignoring the Importance of Inspections

In the realm of quality control in the food industry, inspections play a pivotal role that is often overlooked. Quality assurance inspectors are at the forefront of ensuring that products meet established standards, safeguarding not just consumer health but also brand integrity. By integrating regular inspections into quality management practices, companies can foster a culture of continuous improvement and accountability.

The Function of a Quality Assurance Inspector

A quality assurance inspector serves as the eyes and ears of an organization’s quality control efforts. Their primary function is to evaluate processes and products, identifying any deviations from set standards in real-time. This proactive approach not only helps in maintaining compliance with regulations but also ensures that potential issues are addressed before they escalate into larger problems.

Benefits of Regular Quality Inspections

Regular quality inspections provide numerous benefits that extend beyond mere compliance checks. They serve as a critical component in maintaining high-quality standards, ultimately leading to enhanced customer satisfaction and trust. Moreover, consistent inspections contribute to process control by identifying inefficiencies and fostering an environment where quality improvement is prioritized across all levels of production.

Integrating Inspections into Daily Operations

Integrating inspections into daily operations requires a strategic approach that emphasizes their importance within the overall framework of quality management. By embedding inspection routines into everyday practices, organizations can ensure that every team member understands their role in upholding product excellence. Utilizing technology and data analytics can further streamline this integration, making it easier for quality assurance specialists to monitor compliance continuously and adapt quickly to any regulatory changes.

Poor Documentation Practices

In the realm of quality control (QC) in the food industry, documentation is often underestimated, yet it serves as the backbone of effective quality management. Detailed quality records not only provide a historical account of processes but also facilitate compliance with regulatory standards and internal policies. Without proper documentation, even the most diligent quality assurance specialists may find themselves navigating a maze without a map, leading to potential pitfalls in product safety and quality.

Importance of Detailed Quality Records

Detailed quality records are crucial for maintaining high standards in food production and ensuring that all processes adhere to established guidelines. These records serve as tangible evidence of compliance with both internal protocols and external regulations, providing peace of mind for consumers and stakeholders alike. Furthermore, accurate documentation aids in identifying trends over time, allowing for proactive adjustments that enhance overall quality improvement efforts.

Best Practices for Document Management

Effective document management is essential for any organization aiming to excel in QC in the food industry. Best practices include establishing a centralized digital repository where all documents can be easily accessed and updated by relevant personnel, including quality assurance inspectors. Regular audits should be conducted to ensure that records are complete, accurate, and up-to-date; this not only fosters accountability but also streamlines communication across teams involved in process control.

How Documentation Supports Quality Improvement

Documentation plays a pivotal role in driving continuous improvement within an organization's quality management framework. By analyzing documented data from past inspections and operational processes, companies can identify areas needing enhancement or adjustment—ultimately leading to better product outcomes. Moreover, fostering a culture that values thorough documentation empowers every team member to contribute to ongoing quality improvement initiatives effectively.

Failure to Adapt to Regulatory Changes

In the ever-evolving landscape of the food industry, failure to adapt to regulatory changes can spell disaster for quality control and assurance. Regulations are not static; they shift based on new research, consumer demands, and global standards. Companies that neglect to stay informed about these changes risk compromising their quality management strategies and ultimately their reputation.

Staying Informed About Industry Regulations

The first step in maintaining robust quality assurance practices is staying informed about industry regulations. This involves regularly monitoring updates from regulatory bodies such as the FDA or EFSA, as well as understanding local guidelines that may impact food safety and quality control. Quality assurance specialists play a crucial role in this process by ensuring that all team members are aware of current regulations and their implications for product safety.

Additionally, subscribing to industry newsletters or attending relevant conferences can provide invaluable insights into upcoming regulatory changes. By fostering a culture of continuous learning within your organization, you empower your team to proactively adapt to these shifts instead of reacting after the fact. Ultimately, staying informed helps ensure compliance while enhancing overall quality improvement efforts in your operations.

Adapting Quality Standards to Global Norms

As globalization continues to shape the food industry, adapting quality standards to align with global norms becomes essential for competitive advantage. Different countries have varying requirements regarding food safety and quality control processes; therefore, understanding these differences is vital for any organization looking to expand internationally. A well-rounded approach involves not just complying with local laws but also aligning with international best practices.

Quality management systems must be flexible enough to incorporate these diverse standards without sacrificing product integrity or consumer trust. This adaptability not only enhances your company's reputation but also fosters better relationships with international partners and customers alike. By focusing on harmonizing your processes with global norms, you can elevate your brand's standing in an increasingly interconnected market.

How China Inspection Pro Can Help You

Navigating the complex landscape of regulatory compliance can be daunting; that's where China Inspection Pro steps in as a game-changer for businesses focused on qc in the food industry. With specialized services designed for quality assurance and inspection, they provide tailored solutions that help companies stay compliant with both local and international regulations effectively. Their team of experienced quality assurance inspectors brings deep expertise in understanding diverse regulatory frameworks across various markets.

China Inspection Pro offers comprehensive training programs aimed at enhancing your internal capabilities related to process control and documentation practices—crucial components for successful quality management strategies. Furthermore, leveraging their resources ensures you're not just meeting minimum standards but striving for continuous improvement across all facets of your operations. With their support, you can confidently navigate regulatory changes while maintaining high-quality products that meet consumer expectations.

Conclusion

In the ever-evolving landscape of the food industry, elevating your quality control practices is not just a good idea—it's essential. Quality management is the backbone of any successful food production operation, ensuring that products meet safety standards and consumer expectations. By focusing on quality assurance, businesses can build a reputation for excellence that resonates with customers and regulatory bodies alike.

Elevating Your Quality Control Practices

To truly elevate your quality control, it's crucial to understand the roles of both quality assurance specialists and inspectors within your organization. These professionals are not just gatekeepers; they are vital players in creating a culture of continuous improvement. By fostering communication between teams and encouraging proactive problem-solving, you can create an environment where quality is everyone's responsibility.

Moreover, adopting modern tools for process control can significantly enhance your QC in the food industry. From real-time monitoring systems to data analytics software, these technologies help identify issues before they escalate into costly problems. The more you invest in elevating your quality control practices, the more resilient your operations will become.

Investing in Quality Improvement Strategies

Investing in quality improvement strategies goes beyond implementing new technologies; it involves cultivating a mindset geared towards excellence at every level of production. Continuous learning opportunities for team members—from workshops to online courses—empower employees to stay updated on best practices in quality management. When everyone understands their role in maintaining high standards, it fosters accountability and engagement.

Furthermore, regular assessments of existing processes can reveal areas ripe for enhancement. This could mean refining inspection protocols or introducing innovative approaches to training programs for quality assurance specialists. Ultimately, when organizations prioritize investment in their people and processes, they lay down a solid foundation for long-term success.

Ensuring Compliance and Product Excellence

Ensuring compliance with regulatory standards is non-negotiable in the food industry; it's how we protect consumers while maintaining product excellence. Regular inspections carried out by qualified quality assurance inspectors play an integral role here—they catch potential compliance issues before they become liabilities. By integrating inspections seamlessly into daily operations, companies can build trust with consumers while safeguarding their brand's integrity.

Moreover, staying informed about changes in regulations is crucial for adapting your quality standards accordingly. In today’s global market, aligning with international norms not only enhances credibility but also opens doors to new opportunities for growth and expansion within various markets like China or Europe. With proactive measures taken towards compliance and product excellence through effective QC strategies, businesses set themselves apart as leaders in their field.