Introduction

Heavy equipment inspections are not just a regulatory checkbox; they are essential for ensuring safety, efficiency, and longevity in the construction industry. Regular equipment inspections help identify potential issues before they escalate into costly repairs or accidents, safeguarding both personnel and machinery. In an environment where heavy machinery is constantly in use, a robust heavy equipment inspection process can mean the difference between smooth operations and catastrophic failures.

Understanding compliance requirements is crucial for any organization that operates heavy machinery. Various regulations dictate how often inspections should occur and what specific aspects must be evaluated during each check. Familiarity with these standards not only helps avoid penalties but also promotes a culture of safety within the workplace.

The key inspection steps form the backbone of an effective heavy equipment inspection program. From preparing an equipment inspection checklist to conducting thorough visual examinations and functionality tests, each step plays a vital role in maintaining compliance and operational efficiency. By following a well-structured process, organizations can ensure their heavy equipment remains in optimal condition while adhering to all necessary regulations.

Preparing for a Heavy Equipment Inspection

Preparing for a heavy equipment inspection is crucial to ensure safety, compliance, and operational efficiency. A well-structured approach sets the stage for identifying potential issues before they escalate into costly repairs or accidents. By following a systematic process, teams can confidently conduct thorough equipment inspections that adhere to industry standards.

Importance of an Equipment Inspection Checklist

An equipment inspection checklist is the backbone of any successful heavy equipment inspection. It serves as a comprehensive guide that ensures no critical area is overlooked during the inspection process. With a detailed heavy equipment inspection checklist in hand, inspectors can systematically evaluate each component, making it easier to spot discrepancies and maintain compliance with safety regulations.

Moreover, utilizing an equipment inspection checklist promotes consistency across inspections, allowing different team members to follow the same protocol regardless of experience level. This standardization helps in training new staff and ensures everyone is on the same page when it comes to identifying potential hazards or maintenance needs. Ultimately, relying on a well-crafted construction equipment inspection checklist not only enhances safety but also extends the lifespan of the machinery.

Gathering Necessary Documentation

Before diving into a heavy equipment inspection, gathering necessary documentation is essential for a smooth process. This documentation includes maintenance records, previous inspection reports, and any relevant regulatory guidelines that may impact your assessment. Having these documents on hand provides context and insight into past issues or recurring problems that may need special attention during the current inspection.

Additionally, being well-prepared with documentation allows inspectors to verify compliance with local and state regulations effectively. It also facilitates communication among team members by providing them with background information regarding each piece of equipment being inspected. When everyone has access to this crucial data beforehand, it fosters collaboration and leads to more informed decisions during the actual heavy equipment inspections.

Pre-Inspection Team Briefing

A pre-inspection team briefing is an often-overlooked but vital step in preparing for heavy equipment inspections. This meeting allows team members to discuss their roles and responsibilities while reviewing key areas highlighted in the construction equipment inspection checklist they will be using during the evaluation process. By openly communicating expectations and concerns beforehand, everyone can approach the task with clarity and confidence.

During this briefing, it’s beneficial to address any specific challenges related to individual pieces of machinery or recent changes in regulations that could affect how inspections are conducted. Encouraging questions from team members also helps identify gaps in knowledge or understanding that could lead to oversights later on in the process. Ultimately, investing time in a pre-inspection briefing enhances teamwork and ensures all hands are on deck when conducting thorough inspections.

Conducting Visual Inspections

This process not only ensures the safety of operators and bystanders but also helps maintain the longevity of the machinery. A well-executed visual inspection can save time and money in the long run by preventing costly repairs or accidents.

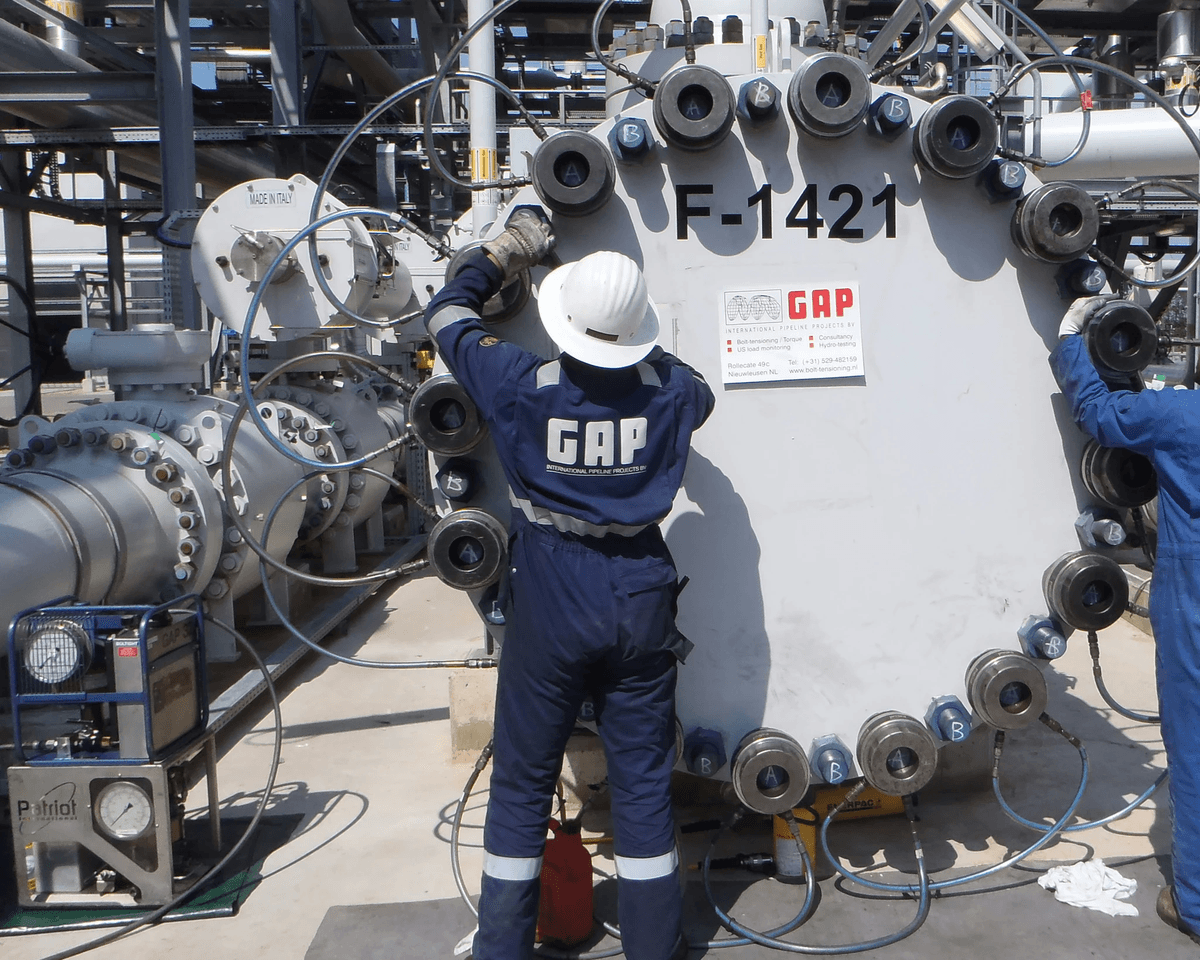

Key Areas to Inspect on Heavy Equipment

During a heavy equipment inspection, certain areas require particular attention to ensure everything is functioning correctly. Start with the undercarriage, checking for signs of wear on tracks or wheels, as these components bear much of the load during operation. Next, inspect hydraulic systems for leaks or damage and examine all electrical connections and wiring for frays or corrosion—these are critical areas where problems often arise.

Don't forget about safety features like lights, alarms, and guards; they play an essential role in maintaining compliance with regulations during equipment inspections. Additionally, pay close attention to fluid levels—oil, coolant, and fuel—as low levels can indicate leaks or other issues that need immediate addressing. Remember that a thorough visual check can prevent minor problems from becoming major headaches down the road.

Identifying Signs of Wear and Tear

Recognizing signs of wear and tear is integral to effective heavy equipment inspections. Look out for cracks in structural components or excessive rust on metal parts that could compromise integrity over time. Additionally, listen for unusual noises during operation; these sounds can be indicators that something isn't functioning as it should.

Pay attention to hoses; if you see bulging or cracking, it's time to replace them before they fail completely. Also watch for any unusual vibrations while operating machinery; this could signal underlying mechanical issues that need further investigation during your construction equipment inspection checklist review. By being proactive about identifying these signs early on, you can significantly reduce downtime and repair costs.

Using the Construction Equipment Inspection Checklist

Utilizing a construction equipment inspection checklist is an excellent way to ensure no detail goes unnoticed during your heavy equipment inspections. This checklist acts as your roadmap through each critical component of the machinery—guiding you step-by-step through every area requiring scrutiny. Not only does this help standardize inspections across different operators, but it also ensures compliance with industry standards.

When using your heavy equipment inspection checklist, make sure to document your findings meticulously—this record will be invaluable when reviewing maintenance history or preparing reports later on. Each item checked off should include notes about any concerns discovered during the process; this documentation serves both as a reference point and as evidence of due diligence in maintaining safety standards. With a comprehensive construction equipment inspection checklist at hand, you'll navigate inspections like a pro!

Testing Equipment Functionality

When it comes to heavy equipment inspections, testing functionality is not just a formality; it's a crucial step that can save lives and prevent costly downtime. Functional tests help ensure that all components of the machinery operate as intended, which is vital for both safety and efficiency on the job site. After all, you wouldn't want to discover that your loader's hydraulics fail during an important lift—better to catch that in advance!

Importance of Functional Tests

Functional tests are at the heart of effective equipment inspections because they assess whether heavy machinery operates according to its specifications. These tests go beyond visual checks, diving into how well the equipment performs under various conditions and loads. By conducting thorough functional tests, operators can identify potential issues before they escalate into major problems or safety hazards.

Moreover, incorporating functional testing into your heavy equipment inspection checklist ensures compliance with industry standards and regulations. It’s not just about ticking boxes; it’s about maintaining operational integrity and protecting your workforce. So next time you pull out your construction equipment inspection checklist, remember that functional tests are non-negotiable!

Checking Safety Features and Alerts

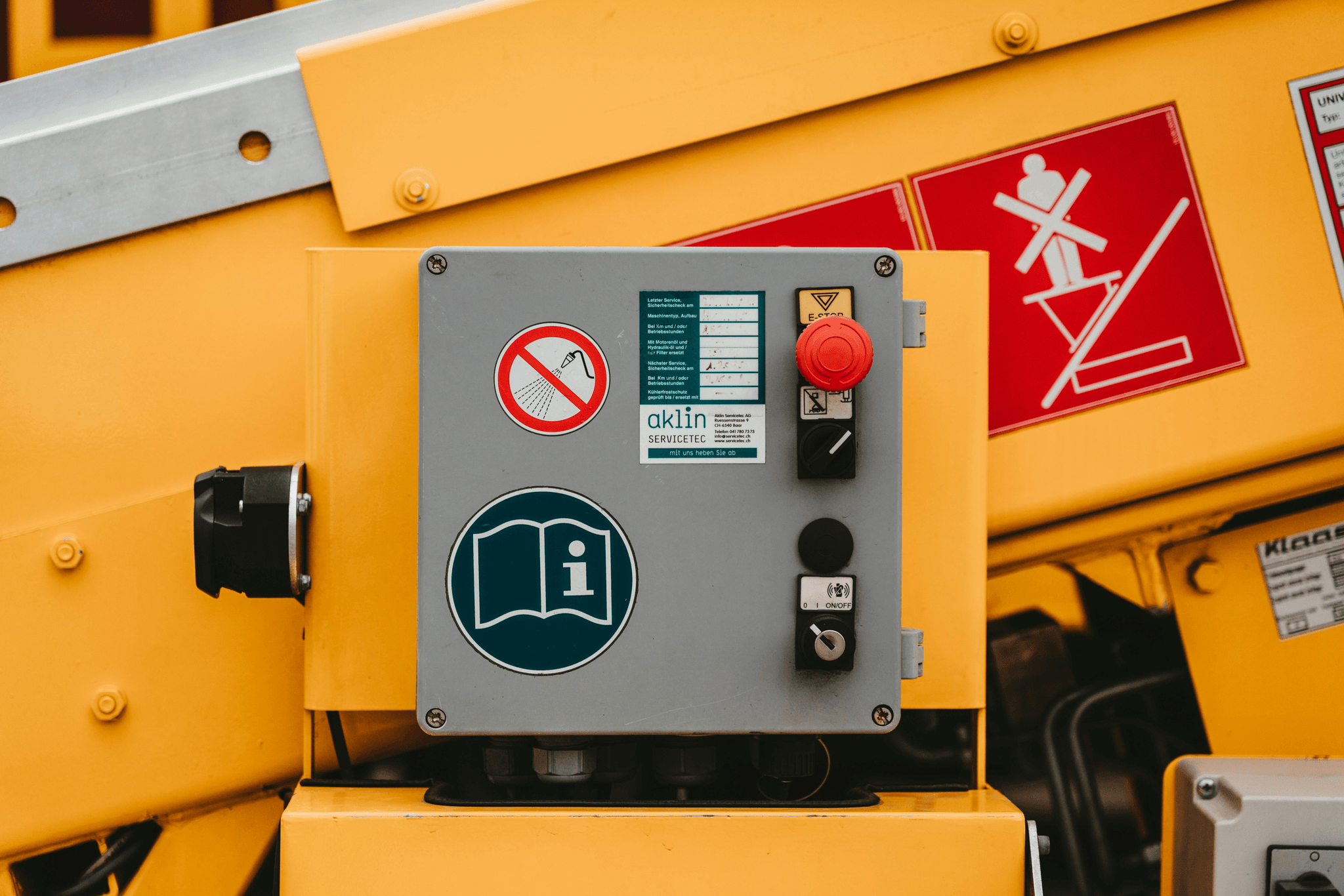

Safety features are like the seatbelt in your car—essential for keeping everyone safe during operation! During a heavy equipment inspection, checking these features should be a top priority; after all, what good is a powerful machine if it can't keep its operators safe? From emergency shut-off switches to warning lights and alarms, each safety feature must be tested for functionality.

A comprehensive inspection includes verifying that all alerts function correctly and provide timely warnings when necessary. This step is crucial not only for compliance but also for cultivating a culture of safety on-site. So don’t overlook this aspect when you're going through your equipment inspection checklist; it could make all the difference in an emergency!

Documenting Test Results

Documenting test results during heavy equipment inspections isn't just busywork—it's an essential part of maintaining accountability and transparency in operations. Each finding should be meticulously recorded on your heavy equipment inspection checklist to ensure no detail is overlooked or forgotten later on. This documentation serves as proof of compliance with regulatory standards while also providing valuable insight into the machine’s performance over time.

Furthermore, clear documentation helps identify recurring issues or trends that may require attention or further investigation down the line. Whether you’re reviewing findings with team members or preparing reports for management, accurate records make communication more effective and actionable. So grab those pens (or tablets) because documenting test results is where theory meets practice!

Compliance with Regulatory Standards

Navigating the landscape of regulatory standards for heavy equipment inspection can feel like a maze, but understanding these requirements is crucial for maintaining safety and efficiency on job sites. Compliance is not just about avoiding penalties; it’s about ensuring that your equipment operates safely and reliably, minimizing risks to operators and bystanders alike. In this section, we will explore OSHA requirements, local regulations, and how companies like China Inspection Pro help ensure compliance.

Understanding OSHA Requirements

The Occupational Safety and Health Administration (OSHA) sets forth specific guidelines regarding heavy equipment inspections that employers must adhere to in order to maintain a safe working environment. These regulations dictate the frequency of inspections, the qualifications of personnel conducting them, and the documentation required to demonstrate compliance. Utilizing an effective equipment inspection checklist that aligns with OSHA standards is essential for ensuring all aspects of the heavy equipment inspection process are met without oversight.

For instance, OSHA mandates regular inspections of cranes, forklifts, and other machinery to identify potential hazards before they escalate into serious incidents. Failure to comply with these guidelines can result in hefty fines or even work stoppages—something no company wants on their record. Therefore, understanding these requirements not only protects workers but also safeguards your company’s reputation.

Local and State Regulations Impacting Inspections

In addition to federal regulations set by OSHA, local and state laws can impose additional requirements on heavy equipment inspections that vary widely across jurisdictions. These regulations may include more stringent inspection frequencies or specific training certifications for inspectors that go beyond federal standards. Keeping abreast of these local nuances is vital for any organization involved in construction or heavy machinery operations.

For example, certain states may require specialized inspections for particular types of construction equipment based on regional safety histories or environmental concerns. This means that relying solely on a generic construction equipment inspection checklist could leave gaps in compliance if tailored documentation isn’t utilized properly. Being proactive about understanding local laws ensures you’re not just compliant at a federal level but also at a state level where it truly counts.

How China Inspection Pro Ensures Compliance

China Inspection Pro takes the guesswork out of regulatory compliance by providing comprehensive services designed specifically for heavy equipment inspections across various jurisdictions. Their team is well-versed in both OSHA requirements and local legislation—ensuring that every piece of machinery undergoes rigorous checks according to applicable standards. By utilizing their expertise alongside an organized heavy equipment inspection checklist tailored for specific regions or types of machinery, companies can rest assured they’re covering all bases.

Moreover, China Inspection Pro offers ongoing support through training programs aimed at keeping your team updated on evolving regulations and best practices in the industry—a crucial element as laws change frequently based on new safety data or technological advancements in construction equipment inspection processes. This commitment not only helps businesses meet current standards but also prepares them for future regulatory changes down the road.

Creating and Using an Inspection Report

When it comes to heavy equipment inspections, creating a thorough inspection report is crucial for maintaining safety and compliance. An effective report not only documents the findings but also serves as a critical tool for future reference and decision-making. By following best practices in report creation, you can ensure that your equipment inspections are both comprehensive and useful.

Features of a Comprehensive Inspection Report

A comprehensive inspection report should include detailed information on all aspects of the heavy equipment inspection conducted. This includes identifying the equipment inspected, noting any deficiencies found, and providing recommendations for repairs or maintenance. Additionally, incorporating visual aids like photographs can enhance clarity, making it easier for stakeholders to understand the condition of the machinery.

Another essential feature is a clear summary section that highlights key findings and actions required. This allows anyone reviewing the report to quickly grasp the overall condition of the equipment without sifting through pages of technical details. Including a timeline for recommended follow-ups or repairs ensures that necessary actions are prioritized effectively.

Lastly, your inspection report should have signatures from both the inspector and a supervisor or manager to validate its authenticity. This adds an extra layer of accountability to your equipment inspections and demonstrates commitment to safety standards.

Best Practices for Documenting Findings

Documenting findings during heavy equipment inspections requires precision and clarity to avoid any miscommunication down the line. Use standardized terminology in your reports so that everyone involved understands what each term means; this helps prevent confusion when discussing issues with team members or regulatory bodies later on.

Be sure to document not just what is wrong but also what is right about the machinery; this balanced approach provides context that can be valuable during future assessments or audits. When using an equipment inspection checklist, make sure each item is addressed thoroughly—this will help ensure nothing gets overlooked.

Lastly, consistency is key! Make it a habit to use similar formats across all your reports so they’re easy to read and compare over time; this practice simplifies tracking trends in wear and tear on various machines in your fleet.

Utilizing the Heavy Equipment Inspection Checklist

The heavy equipment inspection checklist serves as an invaluable tool during both pre-inspection preparations and actual inspections themselves. By using this checklist systematically, you can ensure no critical areas are missed while conducting visual inspections or testing functionality—after all, you wouldn’t want surprises when you least expect them!

Incorporate specific sections into your construction equipment inspection checklist that align with regulatory requirements; this way, compliance becomes part of your regular routine rather than something added at the end as an afterthought. Regularly updating this checklist based on new regulations or insights gained from previous inspections will keep it relevant.

Finally, make sure everyone involved in the inspection process knows how to effectively use this checklist—not just inspectors but also maintenance teams who may need it later on for repairs or ongoing evaluations of machine performance.

Conclusion

In wrapping up our discussion on heavy equipment inspections, it’s clear that a systematic approach is essential for maintaining the safety and efficiency of your machinery. By following the steps outlined in the heavy equipment inspection checklist, you can identify potential issues before they escalate into costly problems. Regularly conducting thorough equipment inspections not only ensures compliance but also extends the lifespan of your valuable assets.

Summarizing Essential Inspection Steps

To summarize, effective heavy equipment inspections involve several key steps that should not be overlooked. Begin with a detailed review of your equipment inspection checklist to ensure all critical areas are covered during visual inspections. Follow this with functional tests to confirm that safety features are working properly and document all findings meticulously in your construction equipment inspection report.

Importance of Regular Equipment Inspections

Regular equipment inspections are not just a regulatory requirement; they are vital for operational efficiency and worker safety on job sites. Consistent use of a comprehensive heavy equipment inspection checklist helps detect wear and tear early, preventing unexpected breakdowns that could lead to project delays or accidents. Ultimately, prioritizing these routine checks fosters a culture of safety and responsibility among operators and management alike.

Resources for Ongoing Compliance Support

For ongoing compliance support, consider leveraging resources offered by industry organizations or consulting firms specializing in heavy equipment inspection protocols. Many provide updated information regarding OSHA requirements and local regulations impacting inspections, ensuring you stay ahead of the curve. Additionally, utilizing online platforms that offer templates for construction equipment inspection checklists can streamline your processes while keeping you compliant with evolving standards.