Introduction

In the fast-paced world of manufacturing, visual inspection plays a crucial role in ensuring that products meet quality standards. This process involves examining items for defects or irregularities before they reach the consumer, making it a vital component of quality control systems. As industries strive for excellence, understanding the nuances of visual inspection in manufacturing becomes essential to maintain high standards of quality assurance.

Understanding Visual Inspection in Manufacturing

Visual inspection in manufacturing is not just about looking; it's about discerning subtle differences that could impact product performance and safety. Whether it’s a tiny scratch on a surface or an improper assembly, these inspections can save companies from costly recalls and reputation damage. By integrating effective quality inspection techniques into their processes, manufacturers can enhance their overall output and customer satisfaction.

The Role of Quality Control

Quality control serves as the backbone of any successful manufacturing operation, ensuring that products are consistently produced to meet predefined standards. It encompasses various methods, including visual inspection, to monitor production processes and identify areas for improvement. By prioritizing quality and control throughout the production line, companies can foster a culture of excellence that resonates with consumers.

Why Precision Matters in Production

Precision is paramount in production because even the smallest deviation from specifications can lead to significant consequences down the line. In industries where safety is non-negotiable—like automotive or aerospace—ensuring precision through rigorous quality assurance practices is essential to prevent catastrophic failures. Therefore, investing time and resources into robust visual inspection methods not only enhances product reliability but also builds trust with customers.

The Basics of Visual Inspection

Visual inspection in manufacturing is a critical component of quality control that ensures products meet established standards before they reach consumers. This process involves examining products for defects, inconsistencies, or deviations from specifications, thereby safeguarding quality assurance throughout the production cycle. With its ability to identify issues early, visual inspection plays a vital role in maintaining the integrity of manufacturing processes.

Definition and Importance in Manufacturing

At its core, visual inspection is the practice of assessing the physical attributes of manufactured goods using human observation or technology. It serves as an essential checkpoint in quality and control systems, allowing manufacturers to catch flaws that could compromise product safety or performance. The importance of this practice cannot be overstated; it not only enhances customer satisfaction but also reduces costs associated with rework and returns.

Key Techniques Used in Quality Inspection

Quality inspection employs several key techniques to ensure thorough evaluation of products. Common methods include direct observation, where inspectors visually assess items against predetermined criteria, and comparative analysis, which involves measuring against samples or benchmarks. Additionally, advanced techniques like color matching and dimensional checks are utilized to enhance accuracy in identifying defects during the quality assurance process.

Tools and Technologies for Effective Inspection

To facilitate effective visual inspection in manufacturing, a variety of tools and technologies are employed. Traditional tools such as magnifying glasses and calipers remain popular for manual inspections; however, modern advancements have introduced high-tech solutions like cameras equipped with image processing software that can detect anomalies at lightning speed. These innovations not only streamline the quality control process but also significantly improve accuracy by minimizing human error during quality inspection.

Quality Control Systems in Manufacturing

Quality control systems are the backbone of any successful manufacturing operation. They not only ensure that products meet established standards but also foster a culture of continuous improvement. By implementing robust frameworks for quality and control, businesses can enhance their reputation and customer satisfaction while minimizing costs associated with defects.

Frameworks for Ensuring Quality and Control

In the realm of quality control, frameworks like Total Quality Management (TQM) and Six Sigma have emerged as popular methodologies. These systems emphasize process improvement, employee involvement, and data-driven decision-making to achieve high-quality outcomes. By adopting such frameworks, manufacturers can systematically address issues in their visual inspection processes, ensuring that every product meets stringent quality assurance standards.

Furthermore, these frameworks provide a structured approach to integrating visual inspection into the broader quality ecosystem of an organization. This integration is crucial because it allows for real-time feedback loops that can identify defects before they escalate into larger problems. Ultimately, effective quality control frameworks lead to reduced waste and improved efficiency in production.

Integrating Visual Inspection into Quality Processes

Integrating visual inspection into existing quality processes is essential for maintaining high standards in manufacturing. This integration involves training staff on best practices for quality inspection while leveraging advanced tools and technologies that enhance accuracy. When visual inspection is seamlessly woven into the fabric of quality assurance protocols, it becomes a powerful ally in identifying defects early on.

Moreover, this integration helps create a culture where everyone feels responsible for upholding quality standards—employees become vigilant inspectors who take pride in their work. The use of checklists or digital platforms can facilitate this process by standardizing inspections across various teams or shifts, ensuring consistency in how products are evaluated. When visual inspection is prioritized within the framework of quality control, manufacturers are better equipped to deliver exceptional products consistently.

Case Studies Highlighting Success Stories

Several companies have successfully implemented comprehensive quality control systems that emphasize visual inspection in manufacturing with remarkable results. For instance, an automotive manufacturer revamped its production line by incorporating automated visual inspection techniques alongside traditional manual methods; this shift led to a 30% reduction in defect rates within just six months! Such success stories underscore the importance of blending human expertise with technological advancements to optimize overall performance.

Another example comes from a consumer electronics company that integrated machine learning algorithms with its visual inspection processes to analyze product images more effectively than ever before. By doing so, they not only increased detection rates but also reduced reliance on manual labor—freeing up employees to focus on more complex tasks related to product development and innovation. These case studies highlight how effective integration of visual inspections within robust quality control systems can lead businesses toward unprecedented levels of efficiency and excellence.

Common Challenges in Visual Inspection

Visual inspection in manufacturing plays a crucial role in maintaining quality control; however, it is not without its challenges. Companies often face difficulties that can compromise the effectiveness of their quality assurance processes. Understanding these common hurdles is essential for improving overall quality and control.

Identifying the Limitations of Manual Inspection

Manual inspection relies heavily on human judgment, which can introduce inconsistencies in quality inspection results. Factors such as fatigue, distraction, and varying levels of skill among inspectors can lead to oversight or errors during critical assessments. Furthermore, the sheer volume of products requiring inspection can overwhelm even the most diligent workers, making it challenging to maintain consistent quality assurance.

Overcoming Human Error in Quality Control

Human error remains a significant challenge in any quality control system, including visual inspection in manufacturing. Mistakes can arise from misinterpretation of standards or simply overlooking defects due to repetitive tasks leading to complacency. To combat this issue, organizations must implement robust training programs and establish clear guidelines that help reduce variability and enhance accuracy within their quality assurance processes.

Strategies to Enhance Accuracy and Efficiency

Enhancing accuracy and efficiency in visual inspection requires a multi-faceted approach that combines technology with human expertise. Integrating automated solutions such as machine vision systems can significantly reduce the reliance on manual inspections while increasing precision in identifying defects during production cycles. Additionally, fostering a culture of continuous improvement through regular feedback loops and performance evaluations helps ensure that both human inspectors and technology work harmoniously toward achieving optimal quality control outcomes.

The Impact of Automation on Visual Inspection

The rise of automation has significantly reshaped the landscape of visual inspection in manufacturing, enhancing both efficiency and accuracy. As industries strive for higher standards in quality control, the integration of advanced technologies such as robotics and artificial intelligence has become paramount. These innovations not only streamline processes but also improve the consistency and reliability of quality inspection outcomes.

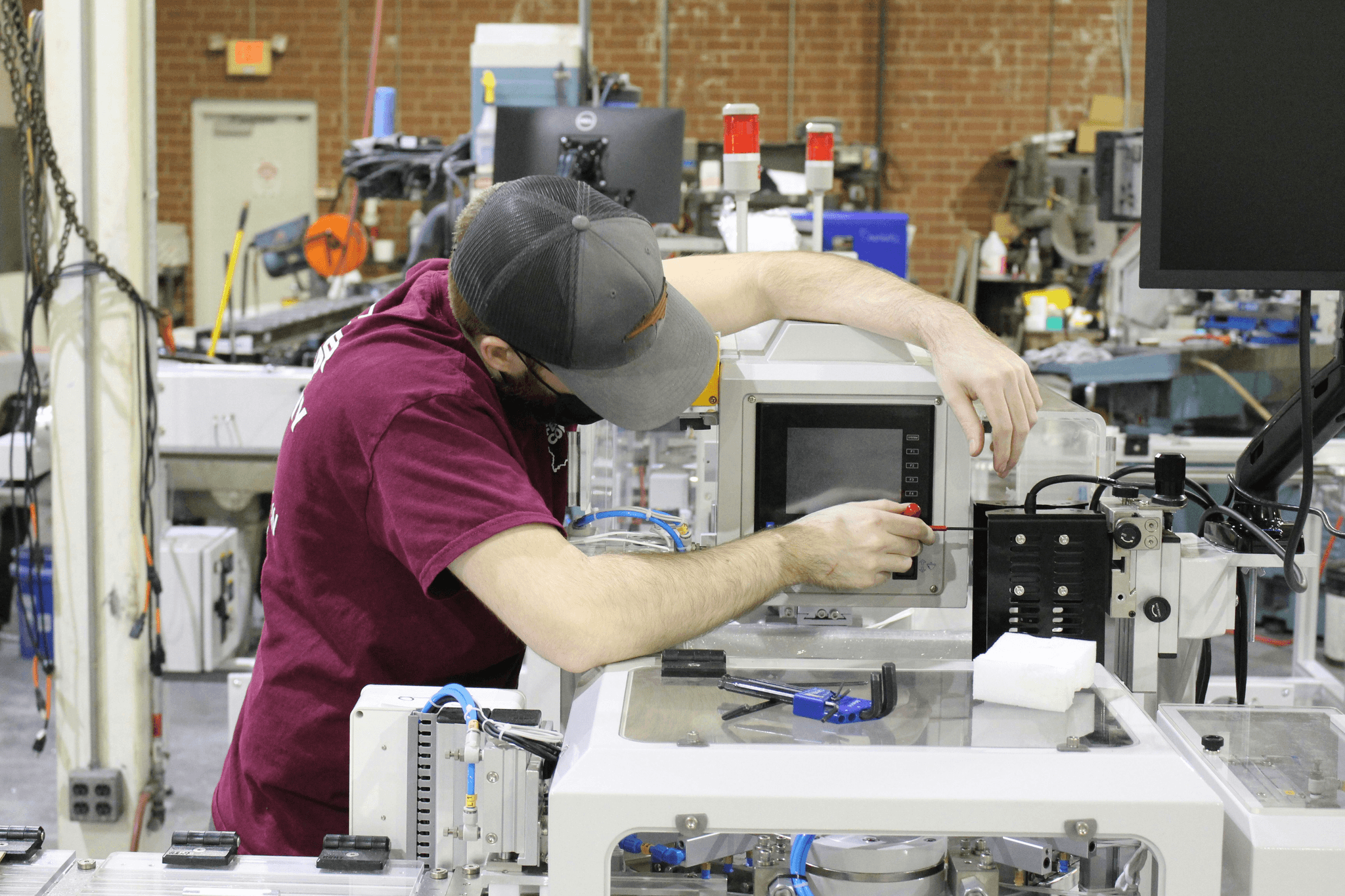

How Robotics are Transforming Quality Assurance

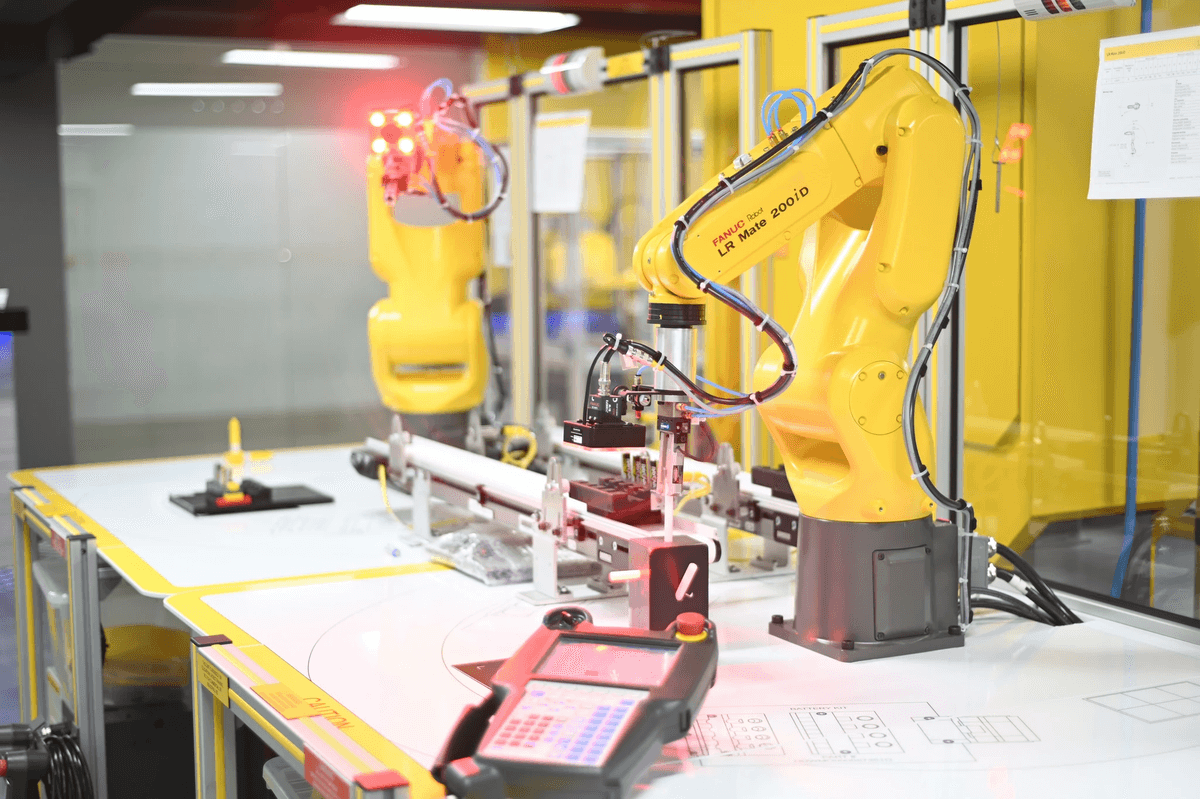

Robotics have revolutionized quality assurance by introducing precision that human inspectors may struggle to achieve consistently. Automated systems can perform repetitive tasks at a speed and accuracy level that far surpasses manual efforts, reducing the risk of errors inherent in human inspections. Moreover, these robotic systems can be programmed to adapt to various inspection criteria, ensuring that every product meets stringent quality control standards.

The implementation of robotic visual inspection systems allows for real-time monitoring and analysis, which is crucial for maintaining high-quality production lines. With capabilities such as image recognition and data processing, robots can identify defects or deviations from specifications almost instantaneously. This transformation not only enhances product quality but also optimizes operational efficiency by minimizing downtime associated with manual inspections.

Benefits of AI and Machine Learning in Inspection

AI and machine learning have taken visual inspection in manufacturing to new heights by enabling systems to learn from past data and improve over time. These technologies analyze vast amounts of visual information quickly, identifying patterns that may escape human inspectors' notice. Consequently, AI-driven solutions enhance the overall effectiveness of quality control measures while reducing costs associated with rework or scrap due to undetected flaws.

One significant advantage is predictive maintenance; machine learning algorithms can predict potential failures based on historical data trends, allowing manufacturers to address issues proactively before they escalate into costly problems. Additionally, AI enhances decision-making processes by providing insights derived from comprehensive analyses of inspection results over time. This data-driven approach fosters a culture of continuous improvement within organizations striving for excellence in their quality assurance practices.

Examples from Industry Leaders like China Inspection Pro

Industry leaders like China Inspection Pro exemplify how automation can elevate the standards of visual inspection in manufacturing through innovative solutions tailored for diverse sectors. Their cutting-edge technology combines robotics with advanced imaging techniques to deliver precise quality control results across various applications—from electronics to automotive components. By leveraging these automated systems, companies can ensure compliance with international standards while boosting their competitiveness in global markets.

China Inspection Pro's commitment to integrating AI into their inspection processes showcases the potential benefits that come with embracing technological advancements in quality assurance practices. Their ability to provide real-time feedback on product integrity empowers manufacturers to make informed decisions swiftly—ultimately leading to improved customer satisfaction rates due to consistently high-quality outputs. As more organizations adopt similar strategies, we will likely see a paradigm shift toward fully automated environments where visual inspection becomes synonymous with reliability and excellence.

Future Trends in Quality Inspection

As we look ahead, the landscape of visual inspection in manufacturing is evolving rapidly, driven by technological advancements and shifting industry needs. Innovations are not only enhancing the efficiency of quality control processes but also redefining how we perceive quality assurance in production environments. The integration of cutting-edge tools and techniques promises to elevate quality inspection practices to new heights.

Innovations Shaping Visual Inspection Practices

The advent of advanced imaging technologies is revolutionizing visual inspection in manufacturing. High-resolution cameras, 3D scanning, and thermal imaging are now commonplace, enabling inspectors to detect defects that were previously invisible to the naked eye. Moreover, augmented reality (AR) is making its way into quality control, allowing operators to visualize data overlays on real-time inspections, thus improving accuracy and decision-making.

In addition to hardware innovations, software solutions are becoming increasingly sophisticated. Machine learning algorithms can analyze vast amounts of data from quality inspections to identify patterns and predict potential failures before they occur. This proactive approach not only enhances quality assurance but also streamlines production processes by reducing downtime associated with unexpected defects.

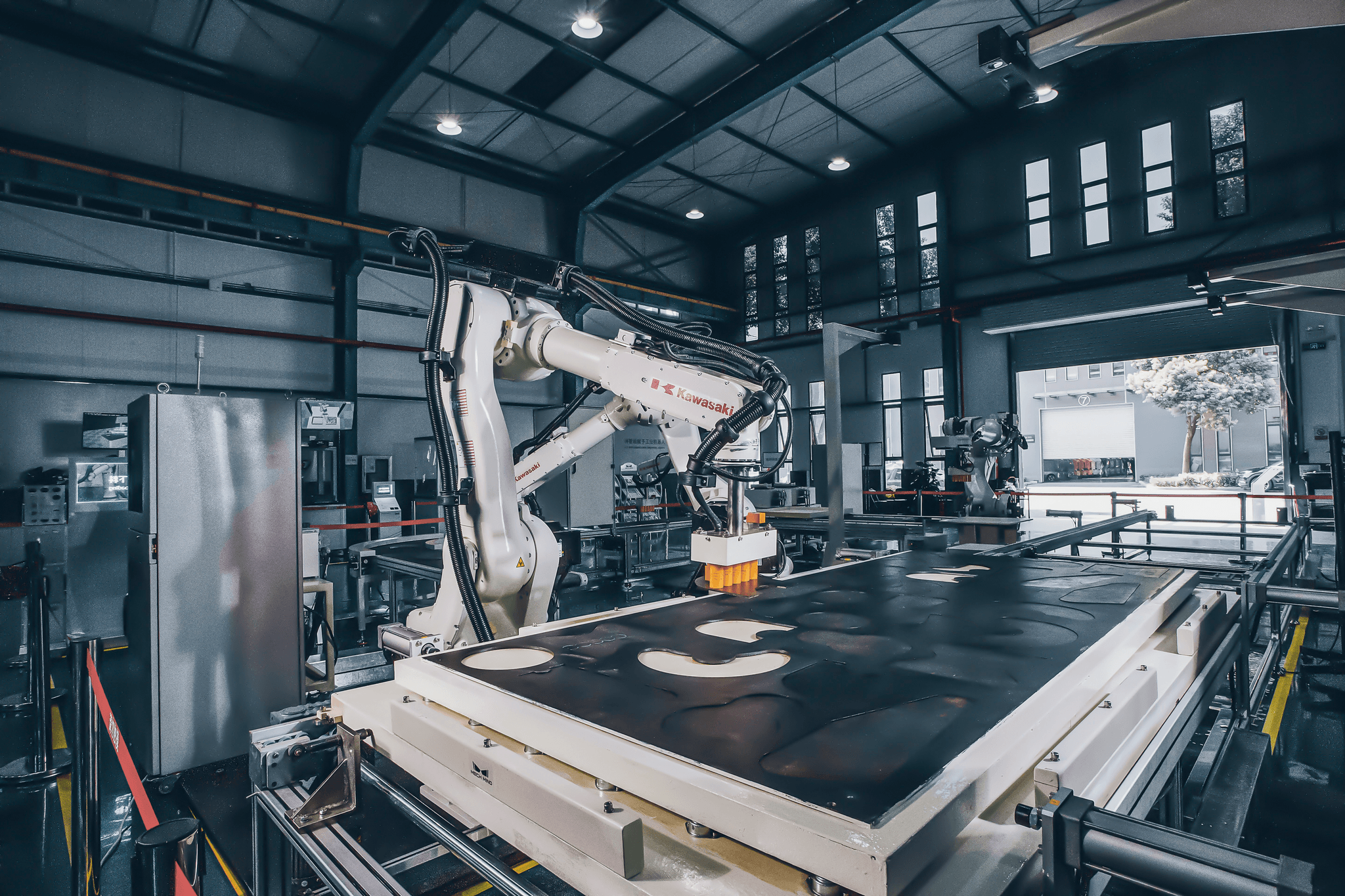

Furthermore, collaborative robots or cobots are emerging as valuable assets in the realm of visual inspection. By working alongside human inspectors, these robots can handle repetitive tasks with precision while allowing humans to focus on more complex evaluations that require intuition and experience. This symbiosis between humans and machines exemplifies the future direction of quality control systems.

Sustainability and Its Role in Quality Assurance

Sustainability is no longer just a buzzword; it’s becoming a cornerstone of modern manufacturing practices including visual inspection in manufacturing. Companies are recognizing that integrating sustainable practices into their quality control processes not only benefits the environment but also enhances their brand reputation and consumer trust. By adopting eco-friendly materials and energy-efficient technologies for inspections, manufacturers can significantly reduce their carbon footprint.

Moreover, sustainable practices lead to improved resource management within quality assurance frameworks. For instance, using digital tools for inspections minimizes paper waste while ensuring accurate documentation—an essential aspect of maintaining high standards in quality control systems. As manufacturers strive for sustainability certifications like ISO 14001, aligning visual inspection methods with these goals will become increasingly important.

The push towards sustainability also influences product design; manufacturers are focusing on creating goods that require less energy during production while maintaining high-quality standards through rigorous inspections. This paradigm shift ensures that consumers receive products that meet their expectations without compromising environmental integrity—a win-win situation for all involved.

Predictions for the Next Decade in Manufacturing

Looking ahead to the next decade, we anticipate significant changes in how visual inspection integrates with broader manufacturing trends such as Industry 4.0 initiatives focused on automation and connectivity. The fusion of IoT (Internet of Things) devices with visual inspection systems will enable real-time monitoring and analysis across entire production lines—enhancing overall efficiency while ensuring stringent adherence to quality assurance protocols.

Furthermore, as artificial intelligence continues to advance at a breakneck pace, we expect AI-driven analytics will play an even larger role in shaping future quality control strategies. These intelligent systems will not only streamline operations but also provide insights that help manufacturers make informed decisions about process improvements based on historical performance data derived from previous inspections.

Lastly, workforce dynamics will evolve alongside technological advancements; upskilling employees will be crucial as businesses adopt more sophisticated tools for visual inspection in manufacturing environments. Emphasizing training programs focused on both technology proficiency and critical thinking skills will empower workers to adapt seamlessly within this changing landscape—ensuring robust systems for maintaining high standards in quality control remain firmly intact.

Conclusion

In the ever-evolving landscape of manufacturing, visual inspection plays a pivotal role in maintaining high standards of quality control. The importance of quality inspection cannot be overstated, as it directly impacts product reliability and customer satisfaction. By ensuring that every component meets stringent criteria through effective visual inspection methods, manufacturers can uphold their reputation and foster trust with consumers.

Recapping the Importance of Visual Inspection

Visual inspection in manufacturing is not merely a checkbox on a production list; it’s a critical process that safeguards quality assurance at every stage. It helps identify defects early on, minimizing costly reworks and ensuring that only top-notch products reach the market. Ultimately, investing time and resources in robust visual inspection practices translates to enhanced operational efficiency and customer loyalty.

Engaging with Quality Control Systems

To truly harness the power of quality control, manufacturers must integrate visual inspection seamlessly into their existing quality systems. This engagement ensures that all team members are aligned with best practices and understand the significance of their roles in maintaining quality and control throughout production. By fostering a culture that prioritizes quality assurance, organizations can create an environment where continuous improvement thrives.

Steps to Improve Precision in Manufacturing

Improving precision in manufacturing requires a multifaceted approach that includes refining visual inspection techniques, investing in advanced technologies, and training personnel effectively. Manufacturers should consider adopting automated solutions alongside traditional methods to enhance accuracy while reducing human error during inspections. As technology continues to advance, staying ahead with innovative practices will ensure sustained success in delivering high-quality products.