Introduction

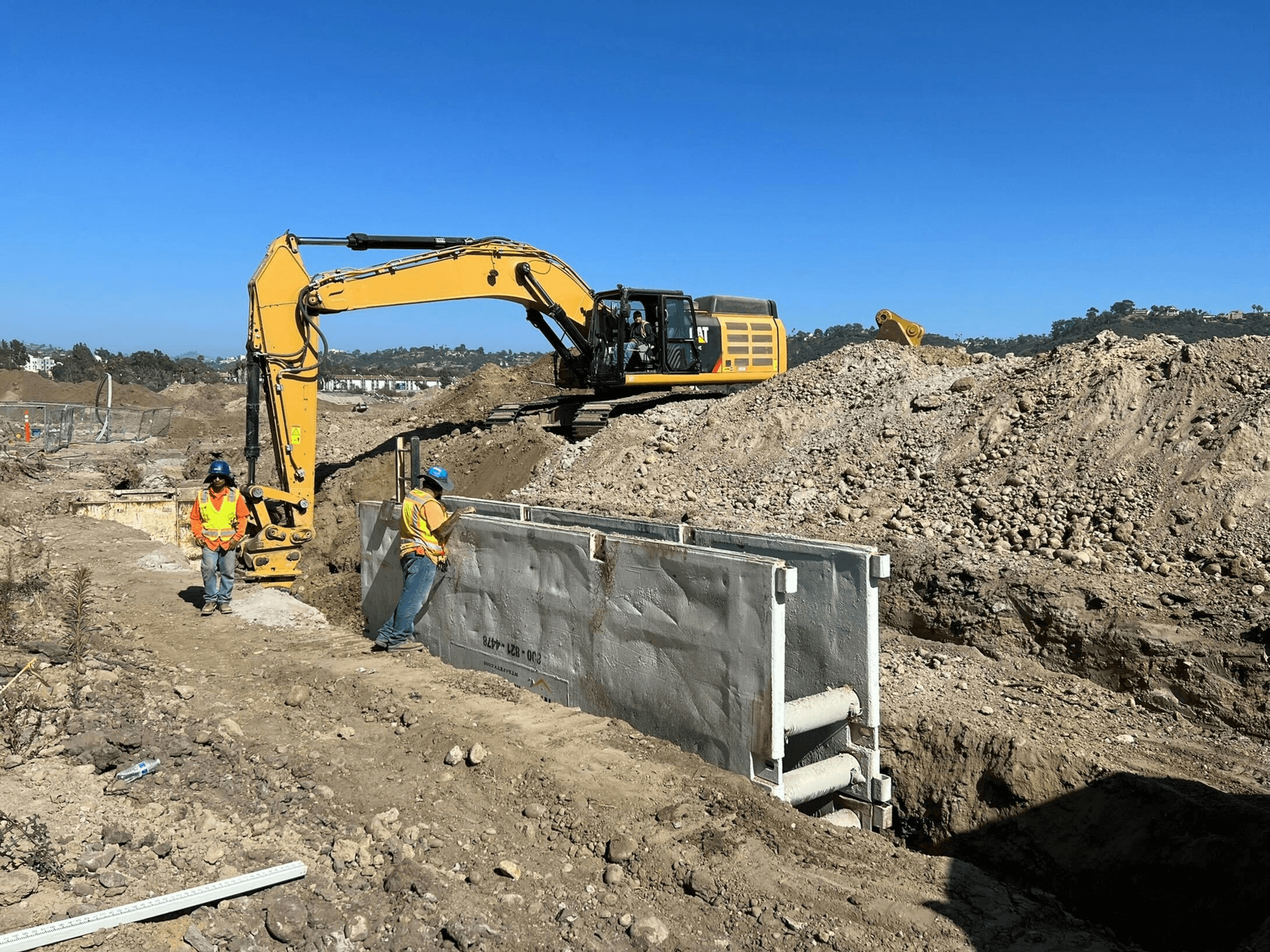

Heavy equipment inspections are a crucial aspect of ensuring safety and efficiency in construction, mining, and various industrial operations. Regular inspections not only help in identifying potential issues before they escalate but also play a significant role in prolonging the lifespan of the machinery. The importance of heavy equipment inspections cannot be overstated, as they are vital for maintaining operational integrity and compliance with safety regulations.

Importance of Heavy Equipment Inspections

Heavy equipment inspections serve as a preventive measure that can save companies from costly repairs and downtime due to unexpected failures. By regularly conducting these inspections, organizations can ensure that their equipment operates smoothly and safely, minimizing risks for operators and bystanders alike.

The Role of Professionals in Inspections

While some may think that heavy equipment inspections can be performed by anyone with a basic understanding of machinery, the reality is far more complex. Professionals bring specialized knowledge and experience to the table, enabling them to identify subtle issues that an untrained eye might overlook. Their expertise is invaluable in providing comprehensive assessments that not only highlight existing problems but also suggest proactive measures for maintenance.

Benefits of Regular Inspections

Regular heavy equipment inspections yield numerous benefits beyond just safety compliance; they enhance productivity too! With well-maintained machinery operating at peak performance levels, businesses can avoid interruptions caused by breakdowns or malfunctions. Additionally, these inspections contribute to better budgeting for maintenance costs by identifying wear-and-tear early on—so you won't be caught off guard when it's time for repairs.

Understanding Heavy Equipment Inspections

Heavy equipment inspections are a critical component of maintaining operational efficiency and safety in construction and industrial environments. These inspections ensure that machinery is functioning correctly, thereby reducing the risk of accidents and costly downtime. By understanding the definition, types, and frequency of these inspections, organizations can better safeguard their investments.

Definition and Purpose

Heavy equipment inspections refer to systematic evaluations of machinery to assess their condition, functionality, and compliance with safety standards. The primary purpose is to identify any issues before they escalate into major problems that could lead to accidents or equipment failure. In essence, regular heavy equipment inspections serve as a proactive approach to maintenance that protects both personnel and assets.

Types of Inspections

There are several types of heavy equipment inspections tailored to various needs: pre-operation checks, routine maintenance inspections, annual comprehensive assessments, and specialized inspections for specific issues or repairs. Pre-operation checks are quick assessments performed before using the equipment each day, while routine maintenance inspections occur at scheduled intervals based on usage or time. Comprehensive assessments provide an in-depth evaluation annually or biannually to ensure everything meets regulatory standards.

Frequency of Inspections

The frequency of heavy equipment inspections can vary widely depending on factors such as usage intensity, manufacturer recommendations, and regulatory requirements. Generally speaking, daily pre-operation checks are essential for ensuring immediate safety before use. More extensive routine checks might occur weekly or monthly for high-use machines; however, comprehensive annual reviews should not be overlooked for all types of heavy machinery.

Preparing for Inspections

Required Documentation

Before diving into heavy equipment inspections, gathering all necessary documentation is essential. This includes maintenance records, operator manuals, and previous inspection reports that provide valuable insights into the equipment's history and any recurring issues. Having this paperwork on hand not only streamlines the inspection process but also helps inspectors identify patterns or concerns that may require immediate attention.

Additionally, it's crucial to verify compliance with local regulations and safety standards relevant to your industry. This means checking for certifications or licenses that may be required for specific types of heavy machinery. With all documentation in order, inspectors can focus on what truly matters—ensuring your equipment runs safely and efficiently.

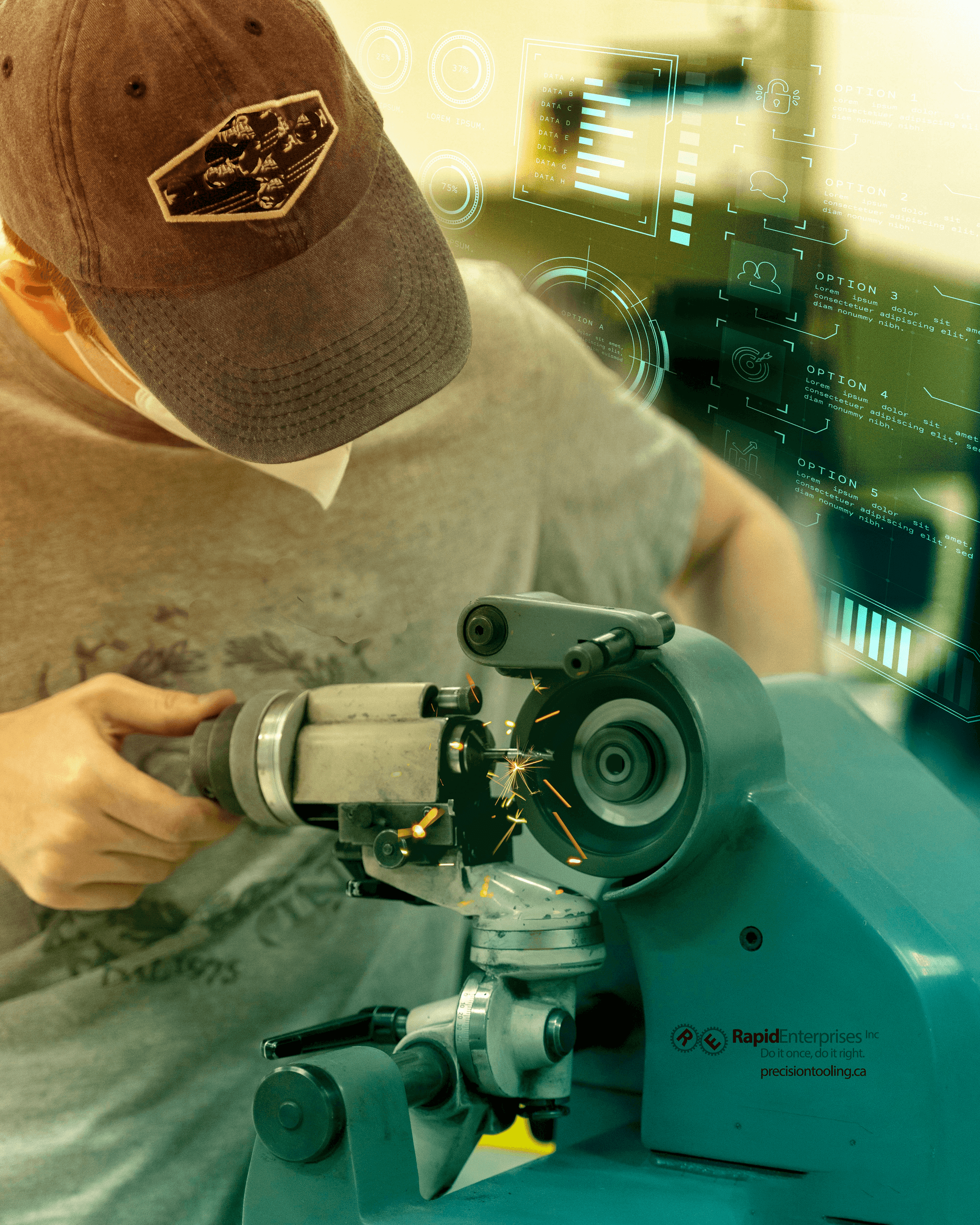

Key Equipment and Tools

Equipping yourself with the right tools can elevate your heavy equipment inspections from good to great! Essential tools include measuring devices like calipers or gauges for checking tolerances, as well as diagnostic machines that can read error codes from electronic systems. Beyond technical gear, having basic hand tools like wrenches and screwdrivers ensures you can address minor repairs on-the-spot if needed.

Moreover, personal protective equipment (PPE) should never be overlooked during these inspections. Hard hats, gloves, safety goggles, and steel-toed boots are vital in keeping inspectors safe while they navigate around potentially hazardous machinery. Remember: a safe inspector is an effective inspector!

Developing an Inspection Checklist

A comprehensive checklist is your best friend when conducting heavy equipment inspections; it’s like having a roadmap guiding you through every nook and cranny of the machinery! Start by listing out all critical components of each machine type—think brakes, hydraulics, electrical systems—and ensure nothing slips through the cracks during your evaluation.

Don’t forget to customize your checklist based on specific equipment models or unique operational environments; this tailored approach helps catch issues that might be overlooked in a generic list. Regularly updating this checklist based on new findings or technological advancements will keep it relevant and useful over time.

An organized checklist not only aids inspectors but also serves as an excellent communication tool among team members involved in maintaining heavy equipment operations—everyone stays informed about what has been checked off!

Conducting an Effective Inspection

This method involves breaking down the inspection process into manageable steps, allowing inspectors to focus on each component without feeling overwhelmed. By adhering to a structured methodology, professionals can ensure that no detail is overlooked, ultimately enhancing the safety and performance of the equipment.

Systematic Approach

A systematic approach to heavy equipment inspections begins with a clear plan that outlines each stage of the evaluation process. Inspectors should prioritize various components based on their importance and frequency of use, ensuring that critical areas receive adequate attention. This organized strategy not only streamlines the inspection but also helps in documenting findings more effectively, facilitating better communication among team members.

Detailed Checklist Review

One of the cornerstones of effective heavy equipment inspections is a detailed checklist review. A well-prepared checklist serves as a roadmap for inspectors, guiding them through every aspect of the machinery while minimizing the risk of oversight. By cross-referencing each item against established standards and regulations, inspectors can ensure compliance and identify any deviations from expected performance levels.

Importance of Hands-On Evaluation

While checklists are invaluable tools during heavy equipment inspections, nothing beats the insight gained from hands-on evaluation. Physically interacting with machinery allows inspectors to detect subtle signs of wear or malfunction that may not be evident on paper. This tactile experience enhances understanding and fosters a deeper appreciation for how equipment operates—ensuring that every nook and cranny is examined for potential issues.

Common Issues In Heavy Equipment

When it comes to heavy equipment inspections, understanding the common issues that can arise is essential for maintaining safety and efficiency on the job site. Mechanical failures, safety hazards, and maintenance record assessments are critical areas to focus on during inspections. Identifying these problems early can help prevent costly downtime and ensure that your equipment is always in peak condition.

Identifying Mechanical Failures

Mechanical failures are often the silent saboteurs of heavy equipment performance. These issues can range from minor wear and tear to catastrophic breakdowns that halt operations entirely. By conducting thorough heavy equipment inspections, operators can spot signs of mechanical failure early, such as unusual noises, vibrations, or leaks—indicators that something may be amiss before it escalates into a major problem.

Regular inspections should include checking key components like hydraulic systems, engines, and electrical systems for any signs of malfunction. A proactive approach not only saves money but also extends the lifespan of your machinery. Remember, ignoring these signs could lead to significant repair costs or even accidents on-site.

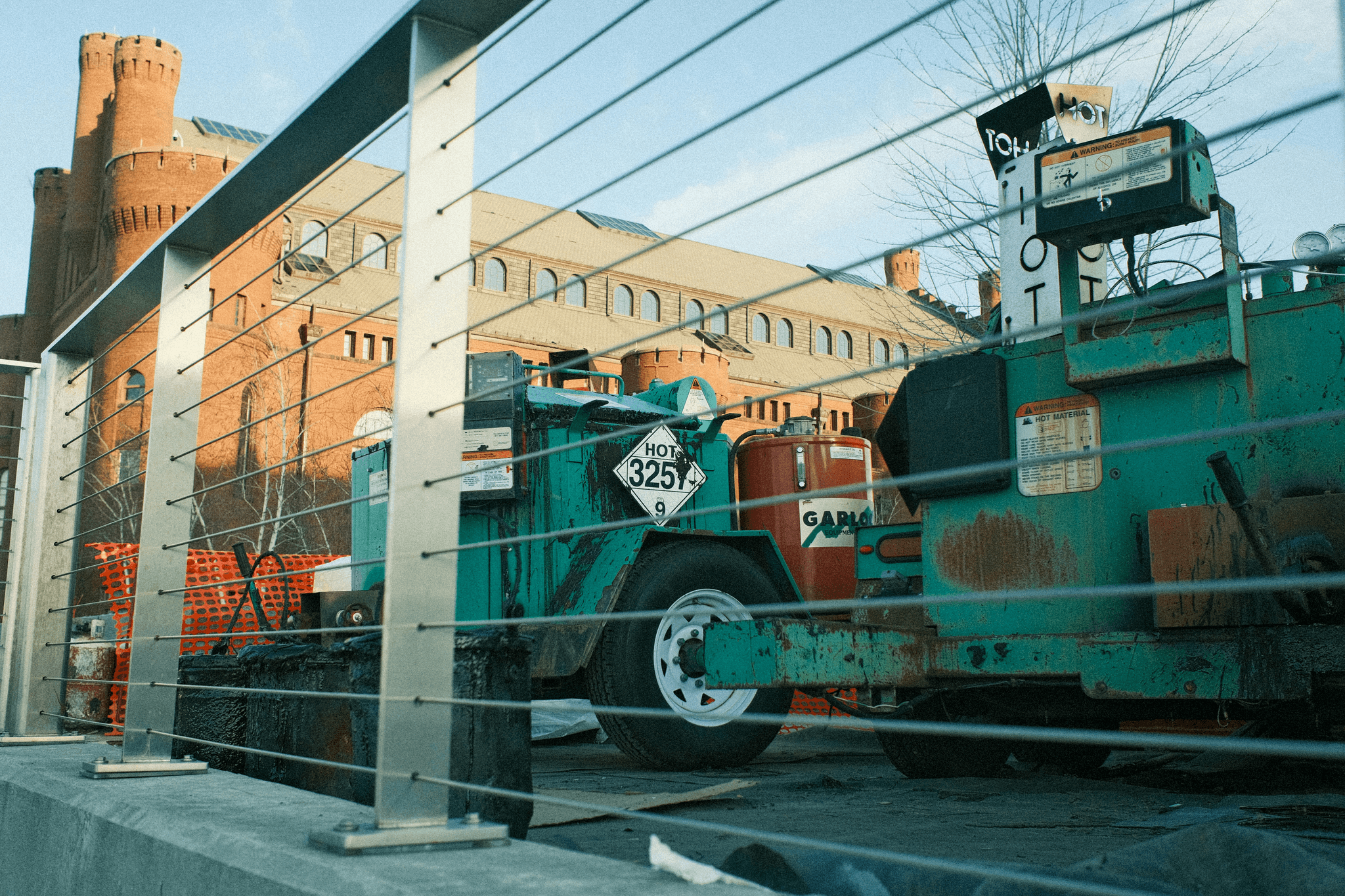

Recognizing Safety Hazards

Safety hazards are a top priority when performing heavy equipment inspections because they directly impact worker safety and compliance with regulations. From faulty brakes to inadequate safety guards, recognizing potential dangers is crucial for creating a safe working environment. Inspectors should be trained to identify risks such as improper load distribution or worn-out tires—issues that could lead to accidents if left unchecked.

Additionally, operators should ensure that all safety features are functional and up-to-date according to industry standards during their heavy equipment inspections. This includes checking emergency shut-off systems and ensuring proper signage is displayed around hazardous areas. By prioritizing safety in inspection routines, companies not only protect their workforce but also enhance overall productivity.

Assessing Maintenance Records

Assessing maintenance records is another vital aspect of effective heavy equipment inspections that shouldn't be overlooked. These records provide insight into how well the machinery has been cared for over time and highlight any recurring issues that may need addressing before they become severe problems. A comprehensive review allows inspectors to gauge whether regular maintenance schedules have been adhered to or if there have been lapses in care.

Moreover, detailed maintenance logs can reveal patterns in mechanical failures or operational inefficiencies that might not be immediately evident during an inspection alone. By keeping meticulous records of past repairs and services performed on each piece of equipment, companies can make informed decisions about future investments or replacements needed for optimal performance in their fleet of machines.

Leveraging Expert Services

When it comes to heavy equipment inspections, enlisting the help of professionals can make a world of difference. The complexities involved in ensuring that machinery is safe and operational require specialized knowledge that only seasoned experts possess. This is where services like China Inspection Pro come into play, providing invaluable support for effective inspections.

Why Choose China Inspection Pro

China Inspection Pro stands out in the crowded field of inspection services due to its extensive experience and deep understanding of heavy equipment inspections. Their team comprises skilled professionals who are well-versed in industry standards and regulations, ensuring that every inspection is thorough and compliant. By choosing China Inspection Pro, you gain access to a wealth of expertise that can significantly enhance the reliability of your machinery evaluations.

Advantages of Professional Insights

Utilizing professional insights during heavy equipment inspections offers numerous advantages that can’t be overstated. Experts can identify potential issues that might be overlooked by less experienced personnel, leading to early detection and resolution before they escalate into costly repairs or safety hazards. Moreover, their familiarity with various types of equipment allows them to provide tailored recommendations for maintenance and improvements, ultimately extending the lifespan of your assets.

Enhancing Inspection Accuracy

Accuracy is paramount when conducting heavy equipment inspections; even minor oversights can lead to serious consequences down the line. By leveraging expert services like those offered by China Inspection Pro, businesses can ensure a meticulous approach to every inspection phase—from initial assessments to detailed reporting on findings. With their systematic methods and advanced tools at hand, you can rest assured knowing your heavy equipment inspections are not only thorough but also precise.

Conclusion

In summary, heavy equipment inspections are not just a regulatory requirement but a crucial practice that ensures safety, efficiency, and longevity of machinery. Regular inspections can help identify potential issues before they escalate into costly repairs or accidents, making them an essential part of equipment management. By prioritizing these inspections and leveraging professional insights, operators can maintain high standards of safety and performance.

Key Takeaways on Heavy Equipment Inspections

Heavy equipment inspections are vital for ensuring operational integrity and worker safety on job sites. The process encompasses various types of evaluations that should be conducted regularly to catch mechanical failures or safety hazards early on. Remember, investing in thorough heavy equipment inspections today can save you time, money, and headaches tomorrow.

Future Trends in Equipment Safety

Looking ahead, the future of heavy equipment inspections is likely to be influenced by advancements in technology such as automation and AI-driven analytics. These innovations promise to enhance the accuracy and efficiency of inspections while minimizing human error. As regulations continue to evolve alongside these technologies, staying informed will be key for those involved in heavy equipment management.

Continuing Education in Equipment Management

To keep pace with advancements in heavy equipment technology and inspection techniques, ongoing education is essential for professionals in the field. Workshops, certifications, and training programs offer valuable insights into best practices for conducting effective heavy equipment inspections. By committing to lifelong learning, operators not only enhance their skills but also contribute to a safer work environment.