Introduction

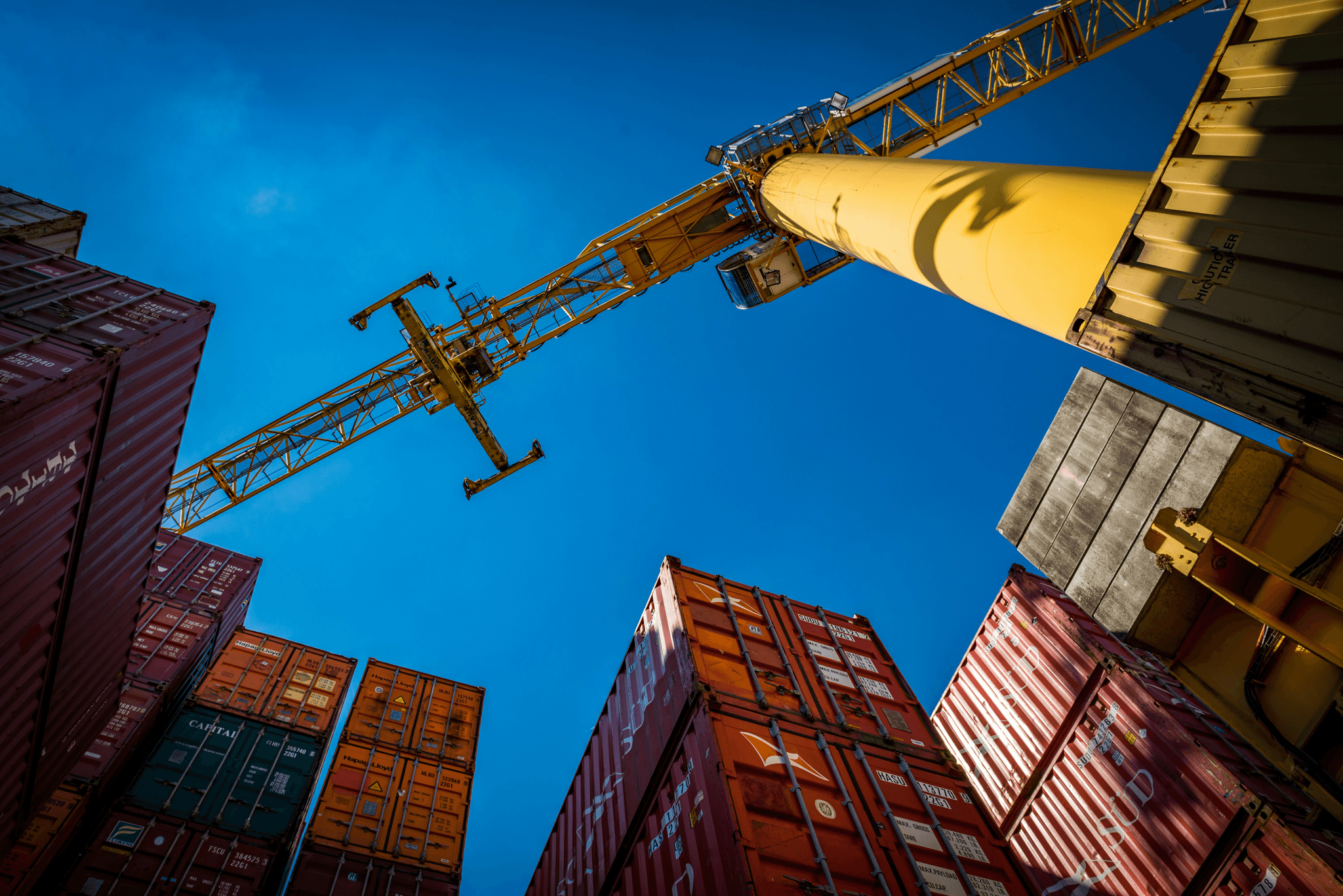

Cargo container inspection is a critical aspect of ensuring the safety and integrity of goods transported across the globe. With the rise in international trade, understanding how to effectively assess cargo containers has become paramount for businesses and logistics providers alike. This introduction will explore the various facets of container serviceability inspections, emphasizing their importance and highlighting common inspection types.

Understanding Container Serviceability Inspections

Container serviceability inspections involve a systematic evaluation of cargo containers to determine their fitness for use. These inspections assess various factors, including structural integrity, weatherproofing, and contamination risks that may affect the cargo within. By understanding these inspections, stakeholders can ensure that containers meet regulatory standards and are safe for transporting valuable goods.

Importance of Cargo Container Inspection

The importance of cargo container inspection cannot be overstated; it safeguards both product quality and company reputation. Regular inspections help identify potential issues before they escalate into costly problems or delays in shipping schedules. Moreover, thorough evaluations protect against liability risks associated with damaged or contaminated goods during transit.

Common Inspection Types for Containers

These include visual inspections that identify external damage, structural integrity checks ensuring soundness under stress, weatherproofing and sealing assessments to prevent moisture intrusion, contamination risk inspections detecting harmful substances, and reefer-specific inspections tailored for refrigerated units. Each type plays a crucial role in guaranteeing that containers remain reliable throughout their journey.

Types of Inspections Required

Each inspection type serves a specific purpose, addressing different potential issues that could affect the container's performance and the cargo within. From visual inspections to more specialized checks like reefer-specific inspections, knowing what to look for can save time and money in the long run.

Overview of Various Inspection Types

There are several types of inspections required for cargo containers, each tailored to address specific concerns. The most common include visual inspections, structural integrity checks, weatherproofing & sealing assessments, contamination risk inspections, and reefer-specific inspections for refrigerated containers. By conducting these diverse types of inspections regularly, businesses can ensure that their cargo remains safe and secure throughout its journey.

Visual inspection is often the first line of defense against visible damage or wear on a container's exterior. Structural integrity checks delve deeper into assessing whether a container can withstand loads without compromising safety. Weatherproofing & sealing evaluations focus on ensuring that containers are adequately sealed against environmental factors while contamination risk inspections help identify any potential threats to cargo quality.

Role of China Inspection Pro in Inspections

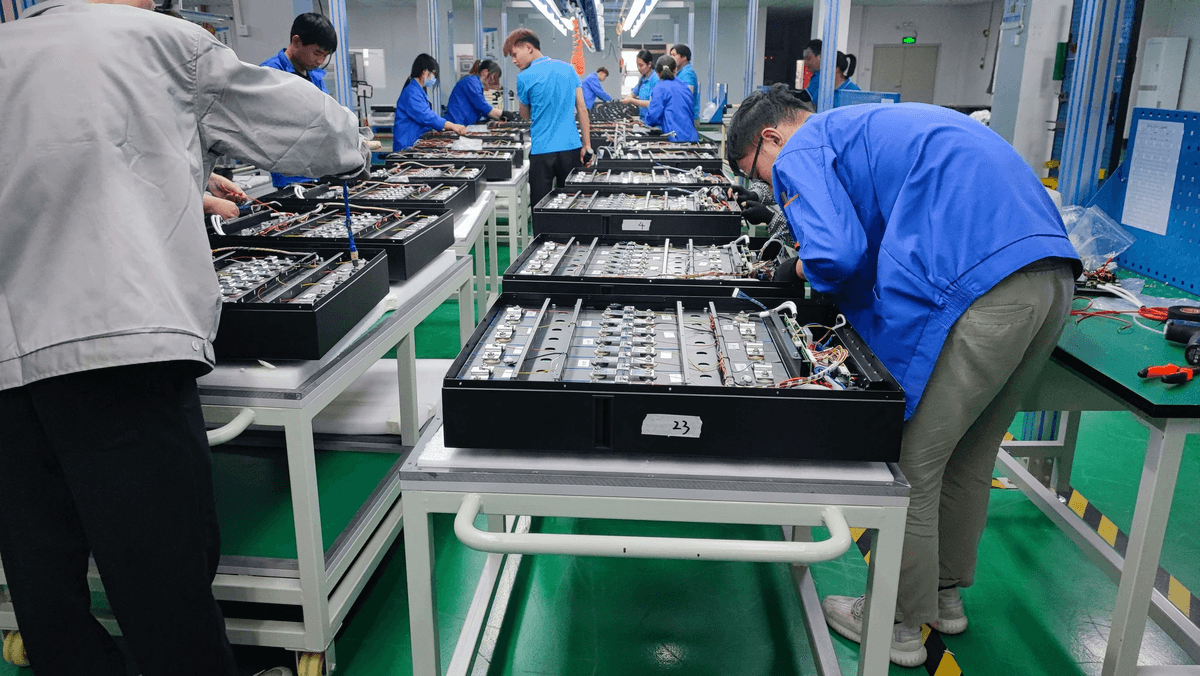

China Inspection Pro plays an essential role in facilitating thorough cargo container inspection processes across various industries. Their expertise ensures that all types of inspections required are conducted professionally and efficiently, adhering to industry standards while providing actionable insights for clients. With their comprehensive services covering everything from visual assessments to contamination risk evaluations, they help businesses maintain high-quality shipping practices.

By leveraging advanced technology and skilled inspectors, China Inspection Pro ensures that all aspects of a cargo container inspection are addressed meticulously. Their specialized team is well-versed in recognizing issues during structural integrity checks or weatherproofing assessments that may go unnoticed by less experienced personnel. This level of diligence not only protects goods but also enhances overall operational efficiency.

Moreover, China Inspection Pro remains updated on regulatory standards governing cargo container inspection procedures worldwide, which adds another layer of reliability to their services. Their commitment ensures compliance with local regulations while helping clients navigate complex international shipping requirements seamlessly.

Regulatory Standards for Container Inspections

Regulatory standards play a vital role in shaping how cargo container inspection processes are carried out globally. These standards set forth guidelines regarding safety protocols during visual inspections as well as detailed requirements for structural integrity checks and other specialized evaluations like weatherproofing & sealing assessments or contamination risk examinations. Adhering to these regulations not only safeguards cargo but also promotes ethical practices within the industry.

Organizations such as the International Maritime Organization (IMO) provide frameworks outlining essential criteria that must be met during various types of inspections required for containers used in global trade routes. Compliance with these regulations helps mitigate risks associated with improperly maintained containers while fostering trust between trading partners and consumers alike.

In summary, understanding regulatory standards is paramount when conducting any form of cargo container inspection—be it visual or more intricate assessments like reefer-specific checks—ensuring both legal compliance and optimal protection against potential hazards throughout transportation processes.

Visual Inspection

Key Elements to Examine

During a visual inspection, several key elements must be scrutinized to ensure a thorough evaluation. Inspectors should look at the container's exterior for signs of rust, dents, or corrosion that can compromise its structural integrity. Additionally, checking doors, seals, and hinges is crucial since these components protect against weather-related damage and contamination.

Another essential aspect includes inspecting the flooring inside the container for any signs of wear or damage that could affect cargo stability. The overall cleanliness of the container is also vital; dirt or debris can lead to contamination risks during transport. In summary, a comprehensive visual inspection encompasses both external and internal assessments to guarantee safety and compliance with regulatory standards.

Identifying External Damage

Identifying external damage is one of the most critical aspects of a visual inspection during cargo container inspections. Common indicators include visible dents or scratches that may suggest mishandling during loading or unloading processes. Inspectors should pay close attention to areas where containers may rub against each other or other surfaces, as these spots are prone to wear and tear.

Beyond just aesthetics, any cracks or holes found on the exterior can lead to severe consequences if left unaddressed—especially when considering weatherproofing & sealing measures necessary for protecting contents from environmental factors. Spotting these issues early allows companies to take corrective actions before they escalate into larger problems requiring costly repairs.

Benefits of Regular Visual Checks

Regular visual checks provide numerous benefits that extend beyond mere compliance with Types of Inspections Required regulations; they enhance overall operational efficiency as well. By routinely inspecting cargo containers for potential issues such as contamination risks or structural deficiencies, businesses can mitigate downtime caused by damaged equipment or spoiled goods during transit.

Moreover, consistent visual inspections foster a culture of safety within an organization by emphasizing proactive maintenance over reactive measures when problems arise unexpectedly—this ultimately leads to increased trust among clients who depend on timely deliveries without compromising quality standards. In short, incorporating regular visual checks into your inspection routine not only safeguards your cargo but also elevates your business reputation in an increasingly competitive market.

Structural Integrity Check

A well-maintained structure not only protects the cargo but also ensures the safety of those handling it. Ignoring structural soundness can lead to catastrophic failures, making this check a critical part of Types of Inspections Required.

Importance of Structural Soundness

Structural soundness is paramount for the longevity and effectiveness of cargo containers. If a container's structure is compromised, it can lead to significant damage or loss of cargo, which could be financially devastating for businesses. Regular assessments during inspections help identify potential issues before they escalate into costly repairs or replacements.

Techniques to Assess Integrity

To assess structural integrity effectively, several techniques come into play during a cargo container inspection. Visual inspections are often the first step, allowing inspectors to spot obvious signs of wear and tear. More advanced techniques may include ultrasonic testing or magnetic particle testing, which help detect hidden flaws that could compromise the container’s stability.

Common Structural Issues Found

During structural integrity checks, inspectors frequently encounter a range of common issues that can affect performance. Corrosion is often at the top of the list, especially in older containers exposed to harsh weather conditions without proper weatherproofing & sealing measures. Additionally, dents and deformations from mishandling can weaken a container's structure over time, highlighting why regular inspections are essential for maintaining cargo safety.

Weatherproofing & Sealing

Ensuring Container Durability

The durability of a cargo container hinges on its ability to withstand various weather elements such as rain, snow, and extreme temperatures. Regular inspections should focus on identifying wear and tear in seals and coatings that could compromise the container's integrity. By prioritizing durability through effective weatherproofing measures, businesses can ensure their investments remain secure over time.

Methods for Effective Sealing

Effective sealing methods are essential in safeguarding cargo from moisture and contaminants during transport. One popular approach is applying high-quality sealants around doors and joints, which helps prevent water ingress while maintaining structural integrity during visual inspections or structural integrity checks. Additionally, using specialized tapes or gaskets can enhance the sealing process, ensuring that containers remain tightly closed against adverse conditions.

Preventing Weather-Related Damage

Preventing weather-related damage is a critical aspect of cargo container inspection that should never be overlooked. Regular maintenance checks focusing on seals and protective coatings can help identify potential weaknesses before they escalate into larger issues requiring extensive repairs or replacement—a key consideration in contamination risk inspection as well. By investing time in proper sealing techniques, companies can significantly reduce the likelihood of spoilage or damage due to environmental factors.

Contamination Risk Inspection

Contaminants can range from biological agents to chemical residues, and understanding these risks is crucial for maintaining the integrity of the cargo. A thorough contamination risk inspection not only protects the goods but also ensures compliance with regulatory standards.

Understanding Contamination Risks

Contamination risks in cargo containers can arise from various sources, including previous shipments, environmental exposure, and improper cleaning practices. For example, a container that previously held food products may harbor bacteria or pests if not adequately sanitized before being used again. Additionally, chemical residues from industrial materials can pose serious health risks if they come into contact with sensitive cargo such as pharmaceuticals or food items.

Understanding these contamination risks is essential for effective cargo container inspection. It allows stakeholders to implement appropriate measures during Types of Inspections Required to ensure that all potential hazards are identified and mitigated before loading goods. By recognizing the types of contaminants that could affect their specific products, businesses can better protect their investments and reputation.

Techniques for Detecting Contaminants

Detecting contaminants during a cargo container inspection involves several techniques tailored to identify specific types of risks effectively. Visual inspections are often the first line of defense; inspectors look for signs of spills, stains, or residue on surfaces within the container. However, visual checks alone may not suffice; advanced methods such as swabbing surfaces for lab analysis or using portable detection devices can provide more comprehensive results.

Incorporating structural integrity checks into inspections also aids in identifying potential contamination sources hidden within cracks or crevices where debris might accumulate. Weatherproofing & sealing techniques play a role here too—ensuring containers are sealed properly helps prevent external contaminants from entering during transport. By employing a multi-faceted approach to detecting contaminants, businesses enhance their ability to safeguard their cargo effectively.

Safeguarding Cargo from Spoilage

To safeguard cargo from spoilage due to contamination risks, companies must establish robust protocols throughout the supply chain process—from packaging through transportation and storage. Reefer-specific inspections are particularly vital when dealing with temperature-sensitive goods; maintaining proper temperature control minimizes spoilage caused by biological growth fueled by heat and moisture levels inside containers.

Regularly scheduled visual inspections help ensure that all containers remain clean and free of contaminants before they are loaded with new shipments. Implementing strict cleaning procedures after each use enhances overall safety while reducing the likelihood of cross-contamination between different types of products transported in the same unit over time. Ultimately, prioritizing effective contamination risk inspections protects both product quality and consumer health.

Reefer-Specific Inspections

When it comes to cargo container inspection, refrigerated containers—or reefers—demand special attention due to their unique requirements. These containers are designed to maintain specific temperature ranges for perishable goods, making their integrity crucial for preventing spoilage. Therefore, understanding the nuances of reefer-specific inspections is essential for ensuring that your cargo arrives in optimal condition.

Special Considerations for Refrigerated Containers

Reefers come with a host of special considerations that set them apart from standard cargo containers. First and foremost, the refrigeration unit must be thoroughly inspected as part of any cargo container inspection process; this includes checking the compressor, condenser, and evaporator coils for any signs of wear or malfunction. Additionally, insulation integrity should be evaluated to ensure that temperature control is maintained throughout transit.

Another important aspect involves monitoring airflow within the container; inadequate airflow can lead to uneven cooling and spoilage of goods. Inspectors should also pay close attention to door seals and gaskets since any gaps can compromise temperature stability and allow warm air inside. By focusing on these special considerations during reefer-specific inspections, you can greatly enhance the reliability of your refrigerated shipping processes.

Monitoring Temperature Control

Temperature control is at the heart of successful reefer operations; without proper monitoring, even minor fluctuations can lead to disastrous results in terms of product quality. During a cargo container inspection focused on reefers, it’s vital to check both digital readouts and backup systems that monitor temperatures continuously throughout transport. This proactive approach helps catch potential issues before they escalate into costly losses.

Regular checks should include verifying calibration settings on temperature sensors as well as testing alarms designed to alert operators if temperatures deviate from acceptable ranges. Additionally, inspecting insulation quality ensures that external temperatures do not affect internal conditions adversely—a key factor often overlooked during routine inspections like visual checks or structural integrity assessments. By prioritizing effective temperature control monitoring in reefer-specific inspections, you safeguard your valuable cargo against spoilage.

Ensuring Proper Functionality

To ensure proper functionality in refrigerated containers, a comprehensive approach is necessary during every cargo container inspection phase—particularly when dealing with reefers. Inspectors should evaluate not only mechanical components but also electronic systems responsible for regulating temperature and humidity levels inside the unit. A failure in any one area could jeopardize the entire shipment.

Moreover, performing regular maintenance checks helps identify potential issues proactively; this might include replacing worn-out parts or recalibrating equipment before they become critical problems down the line—a strategy that aligns well with broader types of inspections required across various container categories such as visual inspection or weatherproofing & sealing evaluations. Ultimately, ensuring proper functionality through diligent reefer-specific inspections translates into enhanced reliability for transporting perishable goods safely.

Conclusion

In summary, cargo container inspection is an essential practice that ensures the safety and integrity of goods during transit. Understanding the various types of inspections required, such as Visual Inspection, Structural Integrity Check, Weatherproofing & Sealing, Contamination Risk Inspection, and Reefer-Specific Inspections is vital for maintaining high shipping standards. By prioritizing these inspections, businesses can mitigate risks associated with damaged or contaminated cargo.

Key Takeaways on Container Inspections

When it comes to cargo container inspection, knowledge is power. Familiarity with the different Types of Inspections Required allows operators to tailor their approach effectively—whether it's a quick Visual Inspection or a thorough Structural Integrity Check. Remember that each inspection type plays a crucial role in ensuring containers are safe for use and that they meet regulatory standards.

Benefits of Regular Cargo Container Inspection

Regular cargo container inspection offers numerous advantages that extend beyond mere compliance with regulations. For one, consistent inspections help identify potential issues early on, reducing costly repairs down the line and enhancing overall operational efficiency. Furthermore, conducting Weatherproofing & Sealing checks can significantly decrease the risk of weather-related damage to cargo while ensuring that containers remain in optimal condition for future shipments.

Engaging Professional Services for Inspections

While DIY inspections may seem tempting, engaging professional services for your cargo container inspection can provide invaluable expertise and peace of mind. Professionals are well-versed in all Types of Inspections Required and have access to advanced tools that enhance accuracy during assessments like Contamination Risk Inspection or Reefer-Specific Inspections. Ultimately, investing in expert services not only safeguards your cargo but also boosts your reputation as a reliable player in the logistics industry.