Introduction

In the fast-paced world of manufacturing, Visual Inspection Techniques stand as a crucial pillar for ensuring product quality and reliability. These techniques are particularly vital in sectors like electronic manufacturing services, where precision is non-negotiable. As industries continue to evolve, understanding the significance of visual inspection becomes paramount to maintaining competitive advantage.

Importance of Visual Inspection Techniques

Visual Inspection Techniques play a pivotal role in identifying defects early in the production process, thereby reducing waste and ensuring high-quality outputs. In printed circuit assembly and PCB assembly manufacturing, these techniques help detect issues that could lead to costly failures down the line. By employing effective visual inspections, manufacturers can enhance their operational efficiency while safeguarding their reputation for quality.

Overview of Industrial Applications

The applications of Visual Inspection Techniques span various industries beyond just electronics; they are integral to sectors such as automotive, aerospace, and even consumer goods. Machine manufacturers rely heavily on these techniques to ensure that every component meets stringent safety and performance standards. This broad applicability underscores the versatility of visual inspections in enhancing product integrity across multiple domains.

Role of Quality Inspection in Manufacturing

Quality inspection serves as the backbone of any successful manufacturing operation, acting as a safeguard against defects that could compromise functionality or safety. In equipment manufacturing industry contexts, rigorous quality checks through visual inspection can mean the difference between customer satisfaction and costly recalls. Ultimately, by prioritizing Visual Inspection Techniques within their processes, manufacturers not only uphold standards but also foster trust with their clients.

Understanding Visual Inspection Techniques

In the realm of manufacturing, Visual Inspection Techniques stand as a cornerstone for quality assurance. These techniques involve the careful examination of products, particularly in printed circuit assembly and electronic manufacturing services, to ensure they meet specified standards. The significance of these methods cannot be overstated, as they help identify defects early in the production process, saving time and resources while enhancing product reliability.

Definition and Significance

Visual Inspection Techniques refer to systematic approaches used to evaluate products through sight alone. This method is crucial in industries like PCB assembly manufacturing, where precision is paramount; even minor defects can lead to significant failures down the line. The significance of these inspections lies in their ability to catch errors that automated processes might miss, thereby safeguarding both quality and customer satisfaction.

Benefits in Electronic Manufacturing Services

The benefits of implementing Visual Inspection Techniques in electronic manufacturing services are manifold. First and foremost, they enhance product reliability by catching defects before items reach consumers or clients. Additionally, these techniques can significantly reduce waste and rework costs associated with faulty circuit card assembly—saving manufacturers both time and money while ensuring that machine manufacturers maintain high standards.

Key Industries Utilizing Visual Inspections

Visual Inspections are not confined to one sector; they play a vital role across various industries. In addition to electronic manufacturing services, sectors like automotive, aerospace, and medical devices heavily rely on these techniques for quality control purposes. The equipment manufacturing industry also benefits greatly from rigorous visual inspection practices—ensuring that every component meets stringent safety regulations before reaching the market.

Best Practices for Printed Circuit Assembly

When it comes to printed circuit assembly, implementing best practices is essential for ensuring quality and efficiency. Visual inspection techniques play a pivotal role in this process, allowing machine manufacturers to identify defects early in the assembly line. By focusing on effective circuit card assembly, businesses can enhance their electronic manufacturing services and reduce costly errors.

Techniques for Effective Circuit Card Assembly

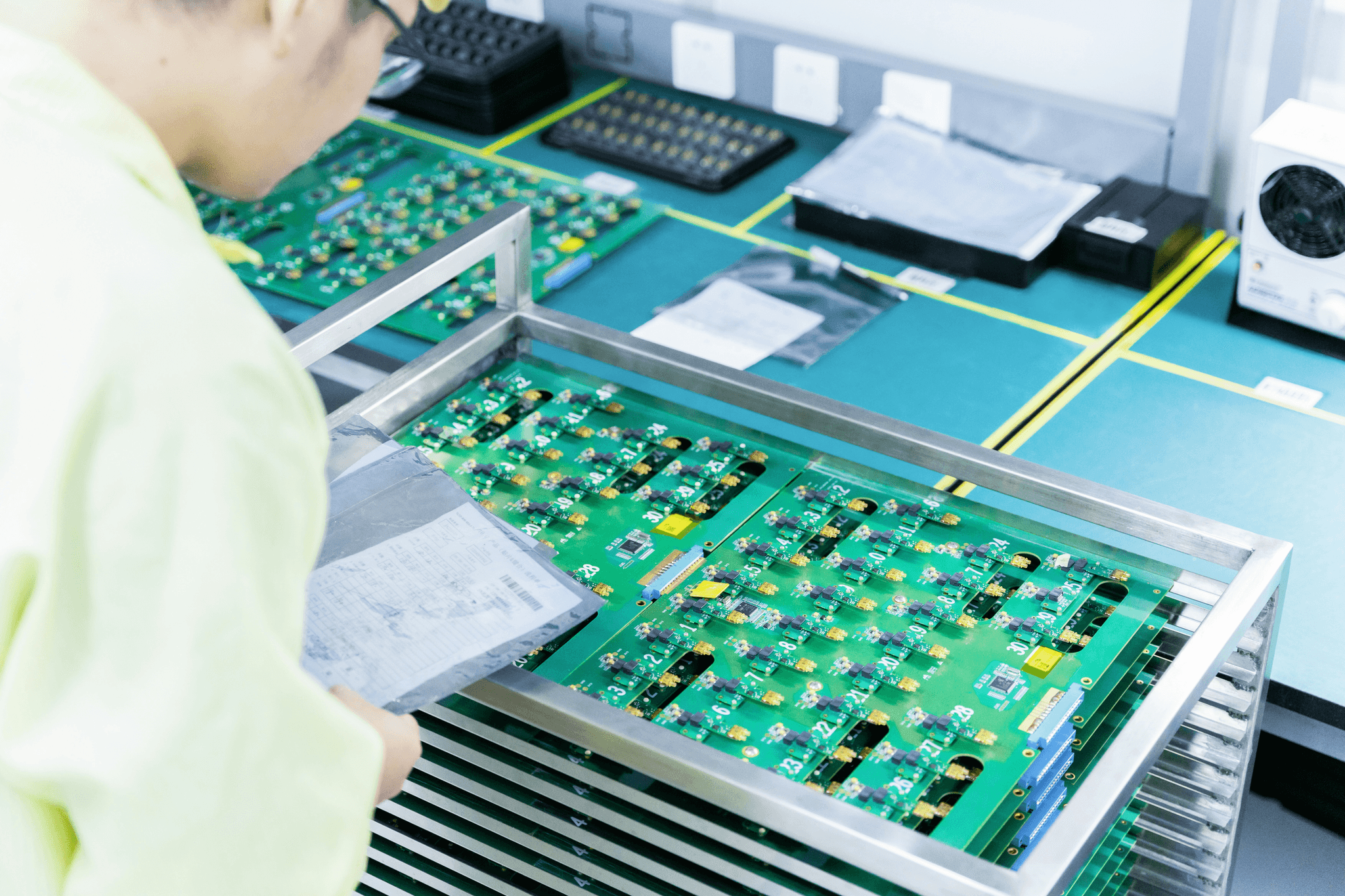

Effective circuit card assembly requires a blend of precision and methodical approaches. Utilizing visual inspection techniques at various stages—such as before soldering components and after final assembly—can significantly improve outcomes. Techniques like automated optical inspection (AOI) are invaluable, as they provide quick feedback on the integrity of the printed circuit board (PCB), ensuring that each component is correctly placed and soldered.

Another technique involves implementing a thorough checklist that guides inspectors through each step of the process. This not only streamlines operations but also reinforces the importance of consistency in quality checks throughout the entire production cycle. By integrating these techniques into daily workflows, equipment manufacturing industry leaders can enhance their reputation for reliability.

Importance of Consistency in Quality Checks

Consistency in quality checks is paramount in PCB assembly manufacturing; it ensures that every unit meets predefined standards before reaching customers. Visual inspection techniques help maintain this consistency by providing clear criteria against which each product can be evaluated. Regularly scheduled inspections minimize variations and ensure that all team members are aligned with quality expectations.

Moreover, establishing a routine inspection schedule fosters accountability among workers while enhancing their skills over time. When employees know what to look for during inspections, they become more adept at identifying potential issues early on, thus preventing larger problems down the line. This culture of vigilance not only boosts overall productivity but also cultivates trust with clients who rely on high-quality electronic manufacturing services.

Avoiding Common Pitfalls in PCB Assembly Manufacturing

Navigating the world of PCB assembly manufacturing isn't without its challenges; however, avoiding common pitfalls can save time and resources significantly. One major issue arises from inadequate training on visual inspection techniques; without proper education, inspectors may overlook critical defects or misinterpret guidelines leading to faulty assemblies. Investing in comprehensive training programs ensures that all team members understand best practices and are equipped to perform effective inspections.

Another pitfall is neglecting documentation during inspections; failing to record findings can lead to repeated mistakes or unresolved issues persisting through production runs. Establishing robust documentation practices not only aids future troubleshooting efforts but also provides valuable data for continuous improvement initiatives within electronic manufacturing services. Machine manufacturers who prioritize these aspects will find themselves ahead of competitors who underestimate their importance.

In conclusion, employing best practices for printed circuit assembly hinges on effective techniques, consistent quality checks, and avoiding common pitfalls through proactive measures like training and documentation strategies.

Advanced Tools for Visual Inspection

In the fast-paced world of manufacturing, advanced tools for visual inspection are revolutionizing how quality control is conducted. With the rise of technology, manufacturers can now utilize sophisticated equipment and software that enhance the accuracy and efficiency of visual inspections. These tools are particularly significant in industries like electronic manufacturing services, where precision is paramount in processes such as printed circuit assembly.

Leveraging Technology in Quality Control

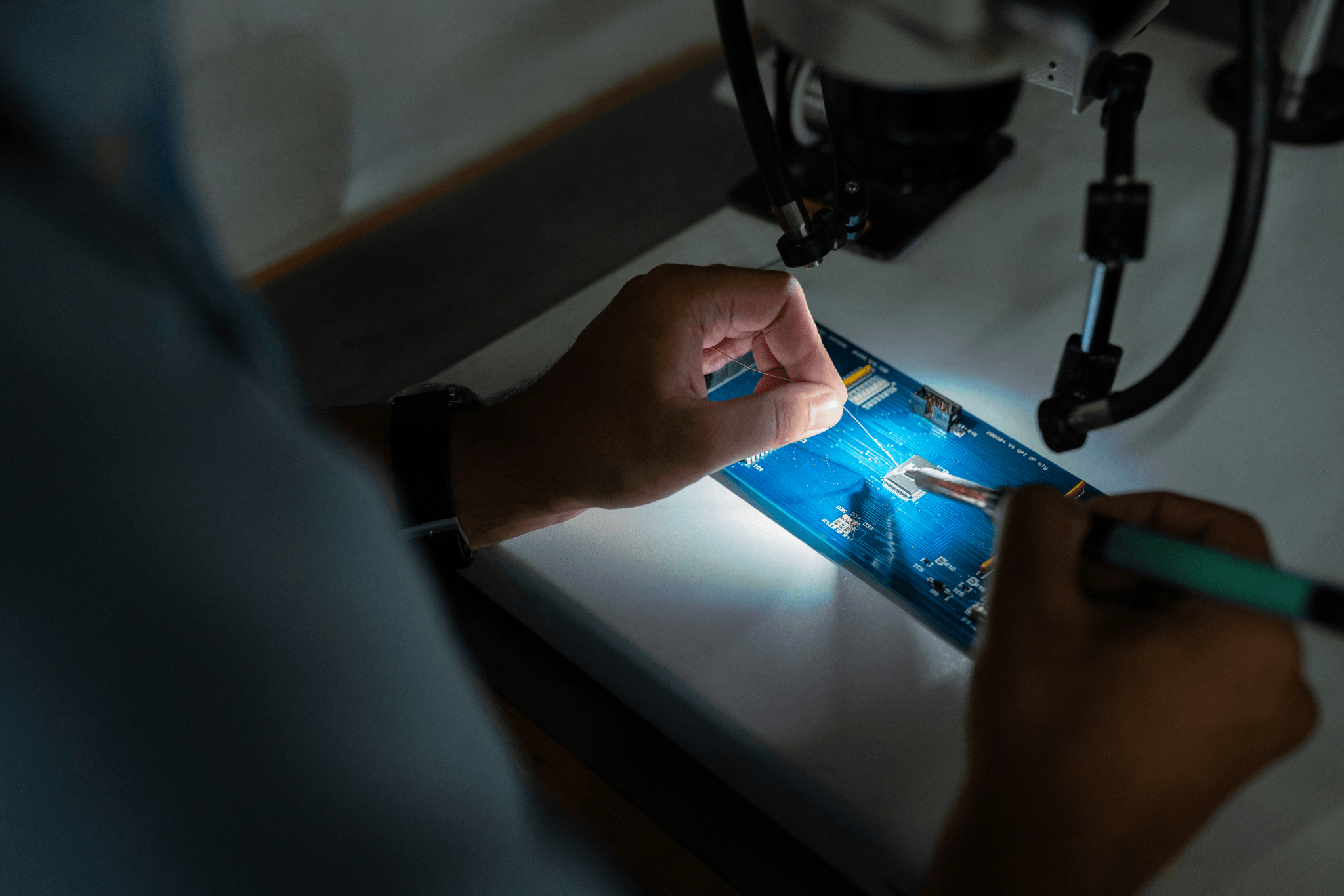

Technology has become a cornerstone in modern quality control practices, especially when it comes to visual inspection techniques. From high-resolution cameras to automated optical inspection (AOI) systems, these advancements allow machine manufacturers to detect defects that might be invisible to the naked eye. By integrating these technologies into circuit card assembly processes, companies can ensure that their products meet stringent quality standards while minimizing human error.

Moreover, leveraging technology not only increases detection rates but also speeds up the inspection process. This is particularly beneficial in PCB assembly manufacturing, where time is often of the essence and delays can lead to increased costs and customer dissatisfaction. As a result, adopting cutting-edge technology becomes not just an option but a necessity for staying competitive in the equipment manufacturing industry.

Role of Software in Enhancing Accuracy

Software plays an indispensable role in enhancing the accuracy of visual inspection techniques across various manufacturing sectors. By utilizing sophisticated algorithms and machine learning capabilities, software solutions can analyze images captured during inspections with remarkable precision. This capability allows inspectors to identify minute defects or inconsistencies that could compromise product integrity—critical elements within electronic manufacturing services.

Furthermore, software integration provides real-time feedback and data analytics that help manufacturers refine their processes continuously. For instance, by analyzing trends from past inspections within circuit card assembly operations, companies can proactively address potential issues before they escalate into larger problems. Thus, software not only enhances accuracy but also fosters a culture of continuous improvement within PCB assembly manufacturing environments.

Real-World Examples of Effective Tools

Several real-world examples illustrate how advanced tools have transformed visual inspection techniques across industries. One notable case involves a leading machine manufacturer that implemented AOI systems equipped with artificial intelligence (AI). This innovation drastically reduced false positives during inspections while improving defect detection rates—demonstrating significant gains in both efficiency and reliability.

Another example comes from an electronic manufacturing services provider that adopted 3D imaging technology for its PCB assembly operations. This tool allowed them to inspect complex components more accurately than traditional methods could achieve alone. The result was not only enhanced product quality but also a substantial decrease in rework costs—a win-win for both productivity and profitability within the equipment manufacturing industry.

Ultimately, these examples highlight how embracing advanced tools for visual inspection can yield significant benefits across various sectors—from ensuring impeccable quality standards to fostering innovation through continuous improvement initiatives.

Case Studies in the Equipment Manufacturing Industry

The equipment manufacturing industry has seen a significant evolution in quality assurance practices, particularly through the implementation of Visual Inspection Techniques. These techniques have not only improved product quality but also enhanced efficiency in processes like printed circuit assembly and circuit card assembly. By examining case studies, we can gain insights into successful applications and learn from both triumphs and setbacks.

Success Stories from Machine Manufacturers

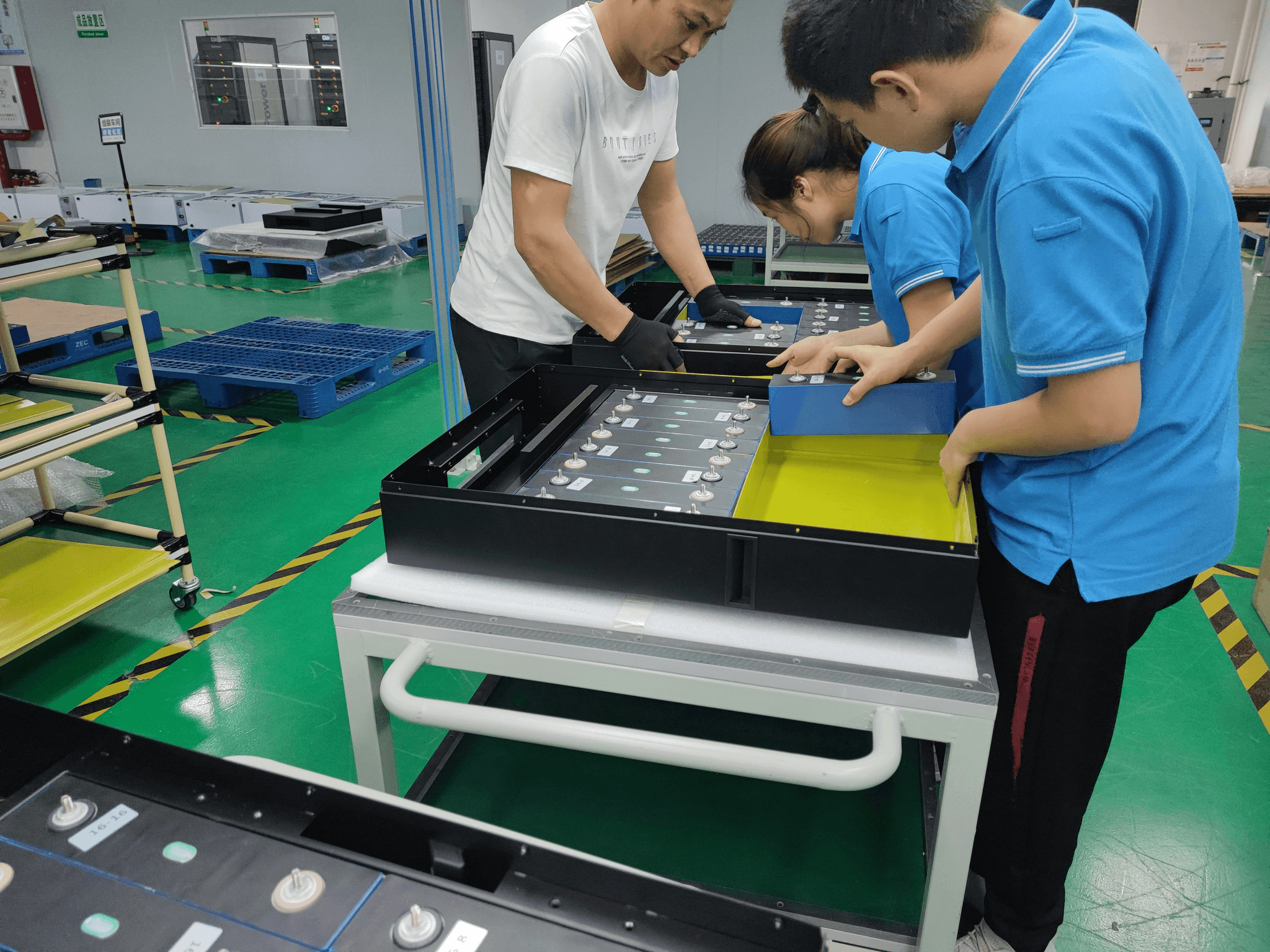

One notable success story comes from a leading machine manufacturer that integrated advanced Visual Inspection Techniques into their quality control processes. By utilizing automated inspection systems, they significantly reduced defects in their electronic manufacturing services, leading to a 30% decrease in rework costs. This transformation not only boosted their bottom line but also improved customer satisfaction, demonstrating how effective visual inspections can elevate overall performance.

Another example involves a company specializing in complex circuit card assembly for aerospace applications. They adopted rigorous visual inspection protocols that included both manual checks and automated systems, resulting in a remarkable improvement in defect detection rates. Their commitment to quality has positioned them as a trusted supplier within the industry, showcasing how strategic investments in visual inspection can yield substantial returns.

Lessons Learned from Failed Inspections

While there are many success stories, there are also valuable lessons to be learned from failed inspections within the equipment manufacturing industry. One company faced significant challenges when they neglected proper training for their inspectors on Visual Inspection Techniques, leading to overlooked defects during PCB assembly manufacturing. This oversight resulted in costly recalls and damaged reputations, emphasizing the critical importance of thorough training and adherence to established inspection protocols.

In another instance, an organization relied heavily on outdated technology for visual inspections without integrating modern tools or software enhancements. The consequences were dire; they experienced increased production delays due to undetected issues that escalated during later stages of manufacturing. These cases highlight that neglecting advancements in visual inspection can lead to detrimental outcomes that impact both quality and profitability.

The Role of China Inspection Pro in Quality Assurance

China Inspection Pro has emerged as a key player in enhancing quality assurance through effective Visual Inspection Techniques tailored for the equipment manufacturing industry. By offering comprehensive services that include thorough inspections of printed circuit assemblies and circuit card assemblies, they help manufacturers maintain high standards while navigating complex supply chains. Their expertise ensures that potential issues are identified early on, reducing risks associated with defective products.

Moreover, China Inspection Pro provides training programs aimed at equipping inspectors with essential skills needed for effective visual inspections across various sectors within electronic manufacturing services. Their commitment extends beyond mere compliance; they foster a culture of continuous improvement among machine manufacturers by emphasizing best practices and innovative solutions tailored to specific needs within PCB assembly manufacturing environments.

In conclusion, case studies illustrate both successes and failures related to Visual Inspection Techniques within the equipment manufacturing industry—each providing invaluable insights into best practices and pitfalls alike.

Training and Skill Development for Inspectors

In the fast-paced world of electronic manufacturing services, the training and skill development of inspectors are paramount. Visual inspection techniques play a critical role in ensuring quality and consistency, especially in printed circuit assembly and circuit card assembly processes. As industries evolve, ongoing education is essential to keep inspectors updated with the latest technologies and methodologies.

Importance of Ongoing Education

Ongoing education for inspectors is not just a luxury; it's a necessity in today’s equipment manufacturing industry. With rapid advancements in technology, visual inspection techniques must adapt to incorporate new tools and software that enhance accuracy and efficiency. Regular training sessions can help inspectors stay ahead of potential pitfalls encountered during PCB assembly manufacturing, ensuring that quality remains uncompromised.

Moreover, continuous learning fosters an environment where inspectors can share best practices and address challenges collectively. This collaborative approach not only improves individual skill sets but also strengthens the overall quality assurance process within organizations. Ultimately, investing in ongoing education translates into higher standards of quality across all aspects of manufacturing.

Essential Skills for Effective Visual Inspections

To excel at visual inspections, certain essential skills must be cultivated among inspectors. First and foremost is keen attention to detail; this is crucial when examining components during printed circuit assembly or assessing machinery on the production floor. Inspectors must be trained to identify even the most minute defects that could lead to larger issues down the line.

In addition to attention to detail, familiarity with various visual inspection techniques is vital for effective assessments. Inspectors should be well-versed in using both manual methods and advanced technological tools that aid in detecting flaws during circuit card assembly processes. Moreover, strong communication skills are necessary for articulating findings clearly with team members or machine manufacturers involved in production.

Lastly, adaptability plays a significant role as industries shift toward more automated solutions within electronic manufacturing services. Inspectors who can quickly learn new systems or adapt their techniques will contribute significantly to maintaining high-quality standards throughout PCB assembly manufacturing.

Creating a Culture of Quality in Manufacturing

Creating a culture of quality within an organization requires commitment from all levels—management through frontline workers—including those involved in visual inspections. This culture begins with leadership promoting the importance of quality assurance as integral to success rather than merely an afterthought during production processes like printed circuit assembly or equipment manufacturing industry tasks.

Encouraging open dialogue about quality-related challenges fosters an environment where employees feel empowered to voice concerns or suggest improvements regarding visual inspection techniques used on the shop floor. Regular team-building activities centered around quality goals can further solidify this culture by aligning everyone’s efforts towards common objectives related to circuit card assembly excellence.

Finally, recognition programs celebrating successful inspections or improvements can motivate individuals while highlighting their contributions toward maintaining high standards across all facets of PCB assembly manufacturing operations—ultimately leading to superior products that meet customer expectations.

Conclusion

In the fast-paced world of manufacturing, particularly within electronic manufacturing services, the role of visual inspection techniques cannot be overstated. These methods not only enhance efficiency but also ensure that products meet stringent quality standards throughout processes like printed circuit assembly and circuit card assembly. By integrating robust visual inspection practices, manufacturers can significantly reduce errors, leading to better outcomes and increased customer satisfaction.

Maximizing Efficiency with Visual Inspection Techniques

Maximizing efficiency through visual inspection techniques involves streamlining processes while ensuring accuracy in quality control. In the realm of PCB assembly manufacturing, these techniques help identify defects early in the production cycle, preventing costly rework down the line. By employing advanced tools and fostering a culture of consistency in inspections, manufacturers can achieve optimal performance without compromising on quality.

Future Trends in Quality Inspection

The future of quality inspection is poised to embrace innovative technologies that enhance traditional visual inspection techniques. With advancements such as artificial intelligence and machine learning becoming more prevalent, electronic manufacturing services will likely see a shift towards automated systems that improve accuracy and speed in inspections. As machine manufacturers adapt to these trends, they will find new ways to ensure that their equipment meets ever-evolving industry standards.

Partnering with Experts for Superior Outcomes

Collaborating with experts in visual inspection techniques is crucial for achieving superior outcomes in the equipment manufacturing industry. These partnerships provide access to specialized knowledge and cutting-edge tools that enhance the effectiveness of quality assurance processes across various sectors, including printed circuit assembly. By leveraging expert insights and best practices, companies can avoid common pitfalls associated with PCB assembly manufacturing while driving continuous improvement initiatives.