Introduction

In today's competitive marketplace, the quality of products can make or break a brand's reputation. This is where a consumer product testing company steps in, ensuring that goods meet industry standards and consumer expectations. From the testing of electronic components to textile testing, thorough evaluations are essential for the production of quality goods and services.

Why Product Testing Matters

Product testing is not just a mere checkbox in the manufacturing process; it’s a critical component that safeguards both consumers and companies alike. By identifying potential defects early on, businesses can avoid costly recalls and foster trust with their customers. Moreover, rigorous quality inspections contribute to overall brand integrity, promoting long-term success in an ever-evolving market.

What to Look for in a Testing Company

When searching for a reliable testing company, it's crucial to consider their credentials and certifications as indicators of their expertise. Look for firms that offer comprehensive services like social compliance audits and have proven experience in various industries. Additionally, client testimonials can provide insight into the company's reliability and effectiveness—an invaluable resource when making your choice.

Understanding Different Testing Services

Different products require different types of tests; understanding these services is key to ensuring quality assurance across all sectors. For instance, what is textile testing? It involves assessing fabric durability and safety before they hit retail shelves. Similarly, evaluating electronic components through specialized methods guarantees that devices perform safely under various conditions—both critical aspects covered by reputable consumer product testing companies.

Overview of Consumer Product Testing

Consumer product testing is an essential process that ensures products meet established standards for safety, quality, and performance. A consumer product testing company specializes in evaluating various items to verify their compliance with regulations and customer expectations. By utilizing these services, businesses can enhance their reputation and ensure the production of quality goods and services.

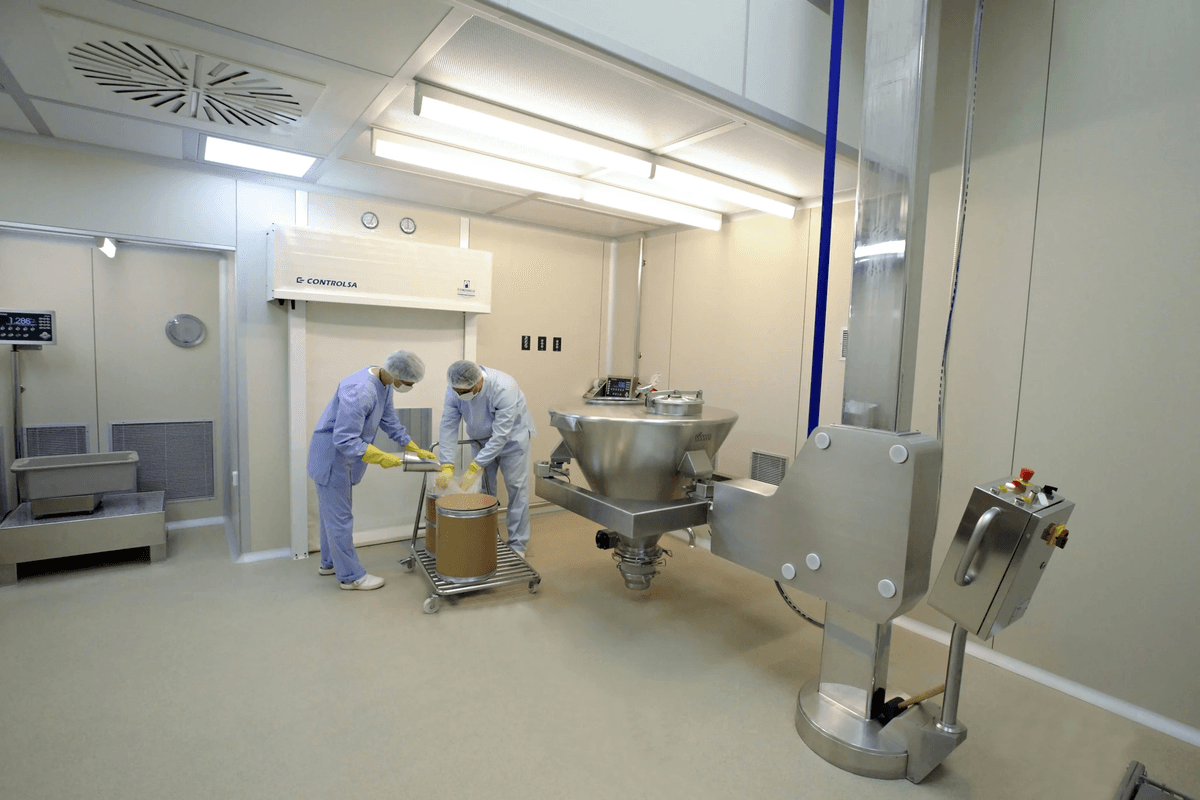

What is a Consumer Product Testing Company

A consumer product testing company conducts rigorous assessments on a wide range of products to determine their safety, functionality, and overall quality. These companies often employ specialized equipment and trained professionals to perform detailed evaluations, including the testing of electronic components and textile testing. Their expertise allows manufacturers to identify potential issues early in the production process, ultimately reducing risk and enhancing consumer trust.

Importance of Testing for Quality Assurance

Quality assurance is a critical aspect of any successful business strategy, as it directly impacts customer satisfaction and brand loyalty. By engaging a consumer product testing company, businesses can ensure that their products consistently meet or exceed industry standards. This proactive approach not only minimizes the chances of recalls but also fosters confidence among consumers regarding the durability and reliability of the goods they purchase.

Key Services Offered

Consumer product testing companies offer a diverse array of services tailored to meet specific industry needs. Key offerings typically include social compliance audits, which assess adherence to ethical manufacturing practices; textile testing to evaluate fabric durability; and piping inspection checklists that ensure plumbing components meet safety regulations. Additionally, many companies provide detailed reports on non-conformities—essentially answering the question: what is a non-conformity report? These insights are invaluable for guiding improvements during production processes.

Types of Testing Services

When it comes to ensuring the production of quality goods and services, understanding the various types of testing services is crucial. A consumer product testing company offers a wide range of specialized services tailored to different industries and products. This section delves into three key areas: the testing of electronic components, textile testing, and social compliance audits.

Testing of Electronic Components

The testing of electronic components is essential in today’s tech-driven world, where even a minor defect can lead to significant failures. A reputable consumer product testing company will perform rigorous assessments on circuit boards, semiconductors, and other electronic parts to ensure they meet industry standards. This process not only guarantees functionality but also enhances safety for end-users by identifying potential hazards early in the production cycle.

Moreover, these tests often include thermal cycling tests, electromagnetic compatibility evaluations, and reliability assessments that help manufacturers avoid costly recalls or repairs down the line. By employing a quality inspection table during these evaluations, companies can systematically track performance metrics and compliance with safety regulations. Ultimately, thorough electronic component testing is a vital part of delivering reliable technology products.

Textile Testing Explained

What is textile testing? It's a specialized process that evaluates various fabric characteristics such as strength, durability, colorfastness, and overall quality. A consumer product testing company typically conducts these tests to ensure that textiles meet both regulatory standards and consumer expectations for comfort and longevity. Understanding what is textile testing helps manufacturers produce high-quality garments that withstand wear while maintaining aesthetic appeal.

Textile testing encompasses several methodologies including physical inspections as well as chemical analyses to detect harmful substances like heavy metals or formaldehyde residues. The insights gained from these evaluations are invaluable for brands aiming for sustainability while adhering to strict regulations in their supply chains. In essence, effective textile testing not only safeguards consumers but also bolsters brand reputation by promoting ethically produced fabrics.

Social Compliance Audits

Social compliance audits are an integral part of ensuring ethical practices within manufacturing processes across various sectors. These audits assess whether companies adhere to labor laws regarding worker rights, safety conditions, and fair wages—essentially answering the question: Are we treating our workforce right? Engaging a consumer product testing company for social compliance audits helps businesses identify gaps in their practices while fostering trust among consumers who increasingly prioritize ethical sourcing.

These audits often follow specific guidelines set forth by international standards organizations which provide frameworks for evaluating workplace conditions globally. By utilizing tools like a piping inspection checklist during these evaluations—specifically in industries where piping systems are crucial—companies can ensure comprehensive oversight over all aspects of their operations related to social responsibility. Ultimately, conducting regular social compliance audits not only mitigates risks but also enhances corporate reputation in an increasingly conscientious market.

Evaluating a Testing Company

When it comes to selecting a consumer product testing company, evaluation is key. The right testing partner can significantly impact the production of quality goods and services, ensuring your products meet industry standards and consumer expectations. This section will guide you through essential criteria to consider when choosing a testing company.

Credentials and Certifications to Consider

Credentials and certifications are the gold stars of the testing world; they indicate that a consumer product testing company has met rigorous industry standards. Look for certifications such as ISO 17025, which demonstrates competence in laboratory operations, or specific accreditations relevant to the testing of electronic components and textile testing. These credentials not only enhance credibility but also assure you that the company adheres to best practices in quality assurance.

In addition to general certifications, consider specialized accreditations related to social compliance audits or specific industry requirements pertinent to your products. A well-certified company will often have a diverse portfolio showcasing its expertise across various sectors, including those requiring complex piping inspection checklists or stringent safety evaluations. Ultimately, these credentials serve as a solid foundation for establishing trust in your chosen testing partner.

Client Testimonials and Case Studies

Client testimonials are like gold nuggets buried in the vast landscape of reviews; they provide real-world insights into how effective a consumer product testing company truly is. Look for case studies that outline challenges faced by previous clients and how the company's services—be it textile testing or social compliance audits—helped them overcome those hurdles. Positive feedback can reveal not just reliability but also innovation in their approach to quality inspections.

Moreover, pay attention to testimonials that highlight specifics about their role in enhancing production of quality goods and services. If multiple clients rave about how their non-conformity reports led to actionable improvements, that's an encouraging sign! Remember, firsthand experiences often tell you more than any marketing brochure ever could.

Industry Reputation and Experience

The reputation of a consumer product testing company can often be gauged by its longevity in the field; experience tends to breed expertise. Companies that have been around for several years are likely familiar with both common pitfalls and emerging trends within various industries—including those involving electronic components or textiles—allowing them to offer tailored solutions for quality assurance needs.

Networking within your industry can also yield valuable insights into which companies are considered leaders in conducting effective social compliance audits or producing comprehensive quality inspection tables. Engaging with peers who have utilized these companies’ services can help you make an informed choice based on collective experiences rather than mere marketing claims. In short, don’t underestimate the power of reputation—it’s often built on years of consistent performance and client satisfaction.

The Role of Quality Inspection

Quality inspection plays a pivotal role in ensuring that products meet established standards before they reach consumers. It acts as a safeguard, helping businesses maintain the integrity of their offerings while also fostering trust among customers. By utilizing a consumer product testing company, organizations can streamline their processes and enhance the production of quality goods and services.

Quality Inspection Table: What You Need to Know

A quality inspection table serves as a vital tool for assessing various aspects of product quality during the testing process. This table typically includes criteria such as dimensions, materials used, functionality, and safety standards—essentially acting as a checklist that ensures nothing slips through the cracks. For instance, when conducting the testing of electronic components or textile testing, having a comprehensive piping inspection checklist can help identify potential flaws before they escalate into costly issues.

How Quality Inspections Enhance Product Standards

Quality inspections are more than just boxes to tick; they are essential for enhancing overall product standards across industries. By systematically evaluating products against stringent benchmarks, companies can identify areas needing improvement and ensure compliance with regulations like social compliance audits. The result? A significant reduction in what is non-conformity report instances, leading to higher customer satisfaction and brand loyalty.

Working with Companies Like China Inspection Pro

Partnering with reputable companies like China Inspection Pro can elevate your quality assurance efforts to new heights. These professionals specialize in various types of inspections—including those related to electronic components and textiles—ensuring that your products not only meet but exceed market expectations. With their expertise at your disposal, you’ll be better equipped to navigate challenges in production while ensuring continuous improvement in quality.

Understanding Reports and Compliance

In the realm of consumer product testing, understanding reports and compliance is crucial for maintaining high standards in the production of quality goods and services. With a variety of testing methods available, including social compliance audits and the testing of electronic components, companies can ensure that their products meet both safety regulations and market expectations. This section delves into key elements such as non-conformity reports, interpretation of test results, and actionable insights that can drive improvements in production processes.

What is Non Conformity Report?

A Non Conformity Report (NCR) serves as a formal document issued when a product or process fails to meet specified requirements or standards during inspections. It highlights discrepancies found during quality inspections, such as those outlined in a quality inspection table or piping inspection checklist. Understanding what is a non conformity report allows companies to take corrective actions promptly, ensuring that any issues are addressed before they escalate into larger problems affecting the production of quality goods and services.

Interpreting Results from Testing

Interpreting results from testing can seem daunting at first glance, but it’s essential for making informed decisions about product quality. Reports generated by consumer product testing companies provide detailed insights into various aspects of the tested items, including performance metrics related to electronic components or textile testing outcomes. By analyzing these results carefully, businesses can pinpoint areas needing improvement while also recognizing strengths that can be leveraged for marketing advantages.

Actionable Insights for Production Improvement

The ultimate goal of thorough testing and reporting is to derive actionable insights for production improvement that enhance overall efficiency and product reliability. By regularly reviewing findings from social compliance audits and other assessments, companies can implement targeted strategies that address identified weaknesses in their processes or products. This proactive approach not only elevates the standard of goods produced but also fosters long-term relationships with consumers who value quality assurance.

Conclusion

In the fast-paced world of production, making informed decisions about your testing partners is crucial for maintaining quality and compliance. A reliable consumer product testing company can be a game-changer, helping you navigate the complexities of quality assurance, from social compliance audits to textile testing. By understanding their services and how they align with your needs, you can ensure that your products meet industry standards while enhancing customer satisfaction.

Making an Informed Decision

When choosing a consumer product testing company, it’s vital to consider factors like their expertise in the testing of electronic components and their ability to conduct thorough quality inspections. Ask yourself: do they provide a detailed quality inspection table? Are they familiar with what is non-conformity report procedures? The answers to these questions can guide you toward a partner that not only meets regulatory requirements but also supports the production of quality goods and services.

Building Long-Term Relationships with Testing Companies

Establishing a long-term relationship with a reputable testing company offers numerous benefits beyond initial compliance checks. Continuous collaboration allows for better understanding of your specific needs, especially when dealing with complex areas like piping inspection checklists or social compliance audits. Moreover, as industries evolve, having an established partnership ensures that you remain ahead in maintaining high standards through consistent textile testing and ongoing improvements.

Ensuring Continuous Improvement in Quality

Quality isn’t just about meeting standards; it’s about striving for excellence through continuous improvement processes. Regular reviews of what is non-conformity report findings can help identify areas for enhancement in production practices and product design. By committing to ongoing assessments—whether through electronic component evaluations or comprehensive textile testing—you’ll foster an environment where quality becomes ingrained in every aspect of your operations.