Introduction

In the ever-evolving landscape of manufacturing, understanding what NPI means in manufacturing is crucial for success. New Product Introduction (NPI) serves as a bridge between innovative ideas and tangible products, ensuring that companies can efficiently transition from concept to market-ready goods. This process not only streamlines production but also emphasizes the importance of quality in delivering goods and services that meet customer expectations.

Understanding NPI's Importance in Manufacturing

NPI plays a pivotal role in the manufacturing sector by enabling businesses to manage the complexities of bringing new products to life. By focusing on the production of quality goods and services, manufacturers can better meet market demands while minimizing costs and maximizing efficiency. In today's competitive environment, understanding what does NPI mean in manufacturing is essential for any company aiming to thrive.

Key Concepts Behind NPI in Today's Industry

At its core, NPI involves several key concepts that drive successful product launches. These include effective planning, collaboration among teams, and rigorous quality checks throughout the process—elements that are intertwined with tools like a quality inspection table and a piping inspection checklist. By integrating these components into their operations, companies can enhance their ability to deliver high-quality products consistently.

The Role of Quality in NPI Implementation

Quality assurance is not just an afterthought; it’s integral to successful NPI implementation. Organizations must establish robust systems for monitoring quality at every stage of production, which includes utilizing social compliance audits and third-party inspection services to ensure adherence to industry standards. Moreover, addressing issues such as non-conformities through effective management strategies helps maintain product integrity and reinforces customer trust.

What Does NPI Mean in Manufacturing?

New Product Introduction (NPI) is a crucial process in manufacturing that encompasses the planning, development, and launch of new products. Understanding what NPI means in manufacturing is essential for ensuring the production of quality goods and services that meet market demands. It serves as a structured approach to guide organizations through the complexities of bringing a product from concept to reality while maintaining high standards.

Exploring the NPI Process

The NPI process typically involves several stages: ideation, design, prototyping, testing, and final production. Each stage requires careful planning and execution to ensure that the end product aligns with customer expectations and quality standards. A well-defined quality inspection table is vital at each phase to monitor compliance with specifications and identify any potential issues early on.

During the exploration of the NPI process, teams often utilize tools like piping inspection checklists to verify that all components meet regulatory requirements. These checklists help streamline inspections and ensure thorough evaluations are conducted throughout development. Ultimately, this meticulous approach fosters a culture of quality assurance within manufacturing environments.

Historical Context and Evolution

Historically, New Product Introduction has evolved significantly from its early days when product launches were often unstructured and reactive. As industries grew more competitive, manufacturers recognized the need for systematic approaches to enhance efficiency and reduce time-to-market while ensuring quality outcomes. This evolution has led to modern practices where social compliance audits play an essential role in verifying adherence to industry standards during NPI.

The introduction of advanced technologies has also transformed how companies manage their NPI processes over time. Automation tools now assist in tracking progress through various stages while minimizing human error—a significant leap forward compared to earlier manual methods. As we delve deeper into what does NPI mean in manufacturing today, it becomes clear that historical advancements have shaped contemporary best practices.

NPI's Impact on Production Efficiency

NPI significantly enhances production efficiency by streamlining workflows and reducing redundancies throughout the manufacturing cycle. When effectively implemented, it leads to shorter lead times for new products while simultaneously ensuring high-quality outputs—essentially marrying speed with reliability in production processes. By addressing potential pitfalls early on through rigorous testing procedures such as textile testing or third-party inspection services, manufacturers can mitigate risks associated with non-conformities.

Understanding what is a non-conformity report becomes crucial here; these reports document any deviations from established standards during production phases and provide actionable insights for improvement efforts moving forward. Consequently, integrating feedback loops into the NPI process allows companies not only to learn from past mistakes but also continuously refine their approaches based on real-world data gathered during inspections or audits.

In summary, recognizing how pivotal effective NPI practices are helps manufacturers stay competitive while focusing on delivering exceptional products tailored for consumer needs.

The Connection Between NPI and Quality Control

In the dynamic world of manufacturing, understanding what NPI means in manufacturing is crucial for ensuring that the production of quality goods and services remains a top priority. New Product Introduction (NPI) is not just about launching new products; it's about embedding quality at every stage of the process. This connection between NPI and quality control ensures that manufacturers can consistently meet customer expectations while minimizing waste and maximizing efficiency.

Ensuring Production of Quality Goods and Services

To ensure the production of quality goods and services, manufacturers must integrate robust quality control measures within their NPI processes. This integration involves setting clear standards and benchmarks that guide each phase, from design to final inspection. By doing so, companies can identify potential issues early on, allowing for timely interventions that enhance product reliability.

Furthermore, effective communication across departments aids in maintaining these standards throughout the production cycle. For instance, utilizing tools like a piping inspection checklist during various stages can help in monitoring compliance with established quality norms. Ultimately, this proactive approach not only safeguards product integrity but also enhances customer satisfaction by delivering consistent results.

The Role of Quality Inspection Table in NPI

The quality inspection table plays a pivotal role in streamlining NPI efforts by providing a structured framework for evaluating products at different stages of development. This table serves as a comprehensive reference point where teams can assess compliance with specifications related to materials, dimensions, and functionality. By having this organized method in place, manufacturers can quickly pinpoint areas needing improvement or adjustment.

Incorporating social compliance audits into this framework further strengthens the connection between NPI and quality control by ensuring ethical practices are observed alongside technical specifications. The result is a holistic approach to production that addresses both operational efficiency and corporate responsibility. When teams effectively utilize the quality inspection table throughout the NPI process, they significantly reduce risks associated with non-conformities.

How NPI Addresses Non-Conformities

Understanding what is a non-conformity report is essential for any manufacturer aiming to maintain high-quality standards during their NPI initiatives. Non-conformities refer to deviations from established specifications or requirements that could compromise product integrity or performance. By implementing rigorous checks during the NPI phases—such as third-party inspection services—manufacturers can detect these discrepancies early on.

Addressing non-conformities promptly not only mitigates risks but also fosters continuous improvement within production processes. Regularly reviewing non-conformity reports allows teams to learn from past mistakes and refine their approaches accordingly; this leads to enhanced practices over time that benefit future projects as well as current ones like textile testing protocols or other specialized inspections required by clients or regulatory bodies.

By weaving together these elements—quality assurance through structured inspections and proactive measures—manufacturers position themselves for success in an increasingly competitive landscape while ensuring they deliver on their promise: producing high-quality goods efficiently.

Tools and Techniques for Effective NPI

In the fast-paced world of manufacturing, having the right tools and techniques for New Product Introduction (NPI) can mean the difference between success and failure. These tools not only streamline processes but also ensure that the production of quality goods and services remains a top priority. By leveraging effective strategies such as checklists, audits, and third-party inspection services, manufacturers can enhance their NPI efforts significantly.

Importance of a Piping Inspection Checklist

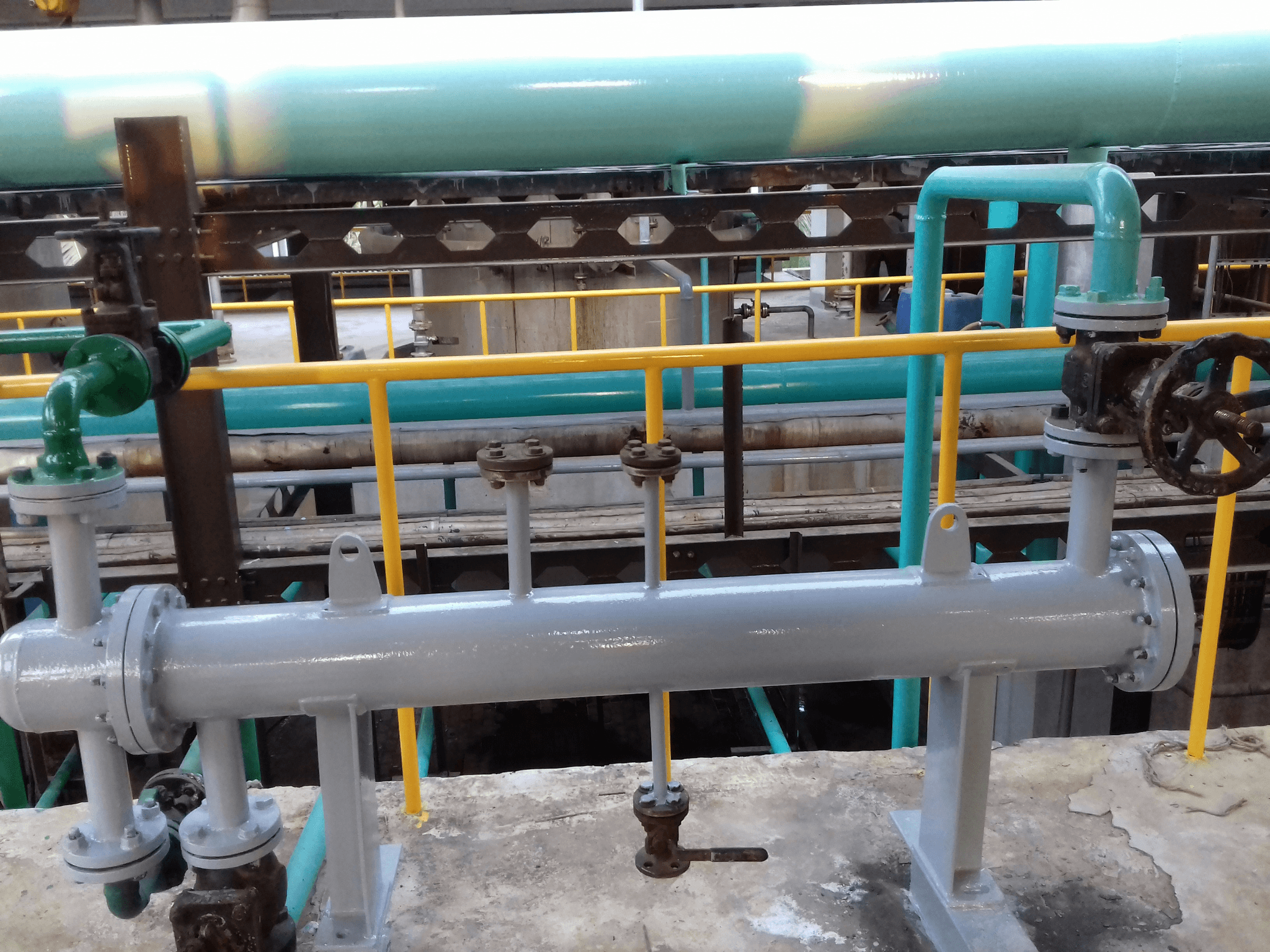

A piping inspection checklist is a vital tool in ensuring that all aspects of piping systems meet specified standards during the NPI process. This checklist helps identify potential issues before they escalate into costly problems, ultimately enhancing what does NPI mean in manufacturing by maintaining high-quality standards from the outset. By meticulously checking each component against this list, manufacturers can mitigate risks associated with non-conformities that could jeopardize production.

Moreover, using a piping inspection checklist allows teams to document their findings systematically, providing a clear record of compliance or areas needing improvement. This documentation plays a crucial role in quality assurance as it feeds into the quality inspection table used throughout the NPI process. Regular use of this checklist not only boosts efficiency but also reinforces a culture of quality within organizations.

Utilizing Social Compliance Audits for NPI Success

Social compliance audits are essential for manufacturers aiming to align with industry standards while implementing effective NPIs. These audits assess whether factories adhere to labor laws and ethical practices, thus ensuring that the production of quality goods and services is not just about physical products but also about responsible practices. Understanding what is non conformity report becomes easier when social compliance audits highlight discrepancies in operational practices during NPI.

By incorporating social compliance audits into their NPI strategy, companies can demonstrate their commitment to ethical manufacturing processes while simultaneously addressing potential risks early on. This proactive approach helps prevent issues related to non-conformities that could arise from neglecting worker rights or safety regulations. Furthermore, these audits often lead to improved employee morale and productivity—an added bonus for any manufacturer seeking long-term success.

Implementing Third Party Inspection Services

Third-party inspection services serve as an impartial eye within the NPI framework, ensuring that products meet required specifications before they hit the market. Engaging these services allows manufacturers to gain insights into areas such as textile testing—what is textile testing if not an essential component for ensuring product integrity? With third-party inspectors involved in your NPI process, you can rest assured knowing that every product undergoes thorough scrutiny before being deemed ready for consumers.

Moreover, these external auditors bring expertise and objectivity that internal teams may lack due to familiarity bias—a common pitfall in many organizations striving for excellence in production processes like textile testing or other manufacturing outputs. Their findings often contribute significantly to refining processes outlined in your quality inspection table by highlighting areas needing attention or adjustment during production cycles. Ultimately, leveraging third-party inspection services enhances trust among stakeholders while solidifying your reputation as a manufacturer committed to delivering high-quality goods.

Case Studies: Successful NPI Implementation

In the realm of manufacturing, successful New Product Introduction (NPI) implementation can transform the way companies operate and deliver products. By examining real-world examples, we can glean valuable insights into effective practices and strategies that enhance the production of quality goods and services. These case studies not only highlight what does NPI mean in manufacturing but also showcase how industry leaders navigate challenges to achieve excellence.

Lessons from Industry Leaders

Industry leaders have long recognized that a robust NPI process is crucial for maintaining a competitive edge. For instance, a leading electronics manufacturer revamped its approach by integrating a comprehensive quality inspection table into its NPI framework. This move allowed them to identify potential issues early on, ensuring that every stage of production adhered to high standards, ultimately enhancing their reputation for delivering quality goods and services.

Another notable example comes from an automotive company that utilized social compliance audits during its NPI phases. By prioritizing ethical practices alongside product quality, they not only improved their supply chain reliability but also fostered stronger relationships with stakeholders. Through these lessons learned, it becomes clear that aligning NPI with both quality control measures and ethical standards is essential for success.

NPI in Textile Testing and Compliance

When it comes to textile manufacturing, understanding what is textile testing is vital for ensuring compliance with industry regulations and customer expectations. Companies have begun incorporating rigorous textile testing procedures within their NPI processes to guarantee that materials meet safety standards before production begins. This proactive approach helps manufacturers avoid costly non-conformities later in the process.

Moreover, implementing third party inspection services has proven beneficial in this sector as well. By engaging external experts who specialize in textile testing, manufacturers can gain an unbiased perspective on product integrity while simultaneously adhering to social compliance audits requirements. As a result, they not only enhance the production of quality goods but also build trust with customers through transparency and accountability.

Analyzing Outcomes of Effective NPI Strategies

The outcomes of effective NPI strategies often speak volumes about their importance in manufacturing environments. Companies that embrace thorough piping inspection checklists during their introduction phases tend to experience fewer defects down the line; this leads directly to increased efficiency and reduced waste throughout production cycles. Analyzing these outcomes reveals a clear correlation between meticulous planning and enhanced operational performance.

Additionally, organizations that actively address what is non-conformity report findings during their NPI processes are better positioned to pivot quickly when issues arise. By establishing feedback loops within teams focused on continuous improvement, these companies cultivate an environment where quality thrives at every step of the manufacturing journey. Ultimately, this commitment leads to superior products—an undeniable testament to what does NPI mean in manufacturing today.

Challenges in NPI and How to Overcome Them

Navigating the waters of New Product Introduction (NPI) can feel like sailing through a stormy sea. Manufacturers often encounter various challenges that can hinder the effective implementation of NPI processes. Understanding these hurdles is crucial for ensuring the production of quality goods and services while maintaining efficiency.

Addressing Common Hurdles in NPI

What does NPI mean in manufacturing? It signifies a structured approach to launching new products, but it doesn't come without its challenges. Common hurdles include misalignment between departments, lack of clear objectives, and inadequate resources, which can all derail even the best-laid plans for quality inspection tables and other essential tools.

To overcome these obstacles, manufacturers should foster cross-departmental collaboration and establish clear goals from the outset. Regular training sessions can help team members understand their roles better, ensuring everyone is on the same page when it comes to implementing effective practices like piping inspection checklists or social compliance audits. By addressing these common hurdles head-on, organizations can streamline their NPI processes significantly.

The Role of Clear Communication in NPI

Clear communication serves as the backbone of any successful NPI initiative. When teams fail to communicate effectively about what is non-conformity report or how it relates to quality assurance measures, misunderstandings can lead to costly errors down the line. Establishing open lines of communication allows team members to share insights about textile testing procedures or third-party inspection services more effectively.

Moreover, regular updates during each stage of the NPI process ensure that everyone remains informed about changes or issues that arise. This proactive approach not only enhances teamwork but also contributes significantly to minimizing risks associated with non-conformities in product launches. Ultimately, fostering a culture where feedback is encouraged will pave the way for smoother transitions throughout each phase of development.

Strategies for Handling a Non-Conformity Report

Handling what is a non-conformity report might seem daunting at first glance; however, having well-defined strategies in place makes it manageable. First and foremost, manufacturers should prioritize timely investigations into any reported discrepancies related to production quality or compliance with standards like textile testing protocols. This allows teams to identify root causes swiftly and implement corrective actions before they spiral out of control.

Additionally, employing third-party inspection services can provide an unbiased perspective on product quality issues identified through non-conformity reports. These external audits not only enhance credibility but also strengthen internal processes by offering fresh insights into how existing systems might be improved—be it through refining piping inspection checklists or enhancing overall product compliance measures via social compliance audits. By taking these steps seriously, organizations position themselves favorably against potential pitfalls during their NPI journeys.

Conclusion

In the fast-paced world of manufacturing, understanding NPI (New Product Introduction) is crucial for success. It serves as a bridge between concept and production, ensuring that companies can efficiently deliver quality goods and services. By integrating effective NPI practices, manufacturers can streamline processes and significantly enhance production efficiency.

Recap of NPI's Essential Role in Manufacturing

So, what does NPI mean in manufacturing? It's not just a buzzword; it's a systematic approach that ensures the successful launch of new products while maintaining high standards. The connection between NPI and the production of quality goods and services cannot be understated, as it lays the groundwork for future operational excellence.

One major aspect of effective NPI is the implementation of tools like the quality inspection table, which helps monitor adherence to specifications throughout the process. Additionally, utilizing resources such as a piping inspection checklist ensures that every component meets safety and quality standards before moving forward. Thus, successful NPI ultimately hinges on meticulous planning and execution to avoid pitfalls.

Future Trends in NPI Practices

Looking ahead, several trends are expected to shape how we approach NPI in manufacturing. The integration of technology will play an increasingly vital role; for example, social compliance audits are becoming essential for businesses aiming to meet both ethical standards and customer expectations. Furthermore, leveraging third-party inspection services will likely gain traction as companies seek more objective assessments throughout their product development cycles.

Another trend is a heightened focus on sustainability within the context of textile testing—a critical area where manufacturers must adapt to changing consumer demands while ensuring compliance with environmental regulations. As these trends evolve, understanding what is non-conformity report will become fundamental for organizations striving to maintain high-quality outputs amid shifting industry landscapes.

Understanding Quality Assurance through NPI

Quality assurance through NPI means establishing rigorous protocols that guarantee every product meets predefined benchmarks before hitting the market. This involves continuous monitoring during production phases to ensure issues are addressed promptly—think back to our earlier discussion on non-conformity reports! A proactive approach not only enhances product reliability but also fosters consumer trust in brands committed to excellence.

Moreover, embracing comprehensive strategies like textile testing further solidifies this commitment by validating materials against industry standards before they go into mass production. In conclusion, by prioritizing effective NPI practices today, manufacturers can pave the way for a robust future filled with innovation and quality assurance.