Introduction

In today's fast-paced and competitive landscape, the importance of quality control cannot be overstated. Businesses across various sectors are recognizing that effective quality management is not merely a regulatory requirement but a strategic advantage that can enhance their reputation and profitability. With the growing complexity of products and services, ensuring control and quality has become paramount to success.

The Importance of Quality Control Today

Quality control is essential for maintaining customer trust and satisfaction in an era where consumers are more informed than ever. Companies that prioritize quality assurance often see reduced returns, fewer complaints, and increased customer loyalty, all of which contribute to a healthier bottom line. As industries evolve, the need for robust quality management systems becomes increasingly critical to adapt to changing market demands.

What Quality Control Consultants Offer

Quality control consultants bring specialized expertise to organizations aiming to improve their processes and outcomes. They assess existing systems, identify gaps in quality management practices, and provide actionable recommendations tailored to each business's unique needs. By leveraging their knowledge, these consultants help organizations effectively control the quality of their products or services while fostering a culture of continuous improvement.

Industries That Benefit from Quality Assurance

From manufacturing to healthcare, virtually every industry can reap the rewards of implementing effective quality assurance measures. In manufacturing settings, maintaining rigorous standards ensures product consistency and safety; meanwhile, in healthcare environments, it promotes better patient outcomes through reliable practices. Ultimately, investing in quality control consultants empowers businesses across sectors to achieve excellence while minimizing risks associated with poor-quality outputs.

Understanding Quality Control Consultants

In today's fast-paced world, understanding the role of quality control consultants is essential for businesses aiming to maintain high standards. These professionals specialize in ensuring that products and services meet established benchmarks of quality. By focusing on both quality control and assurance, they help organizations enhance their overall performance.

Defining Quality Control and Assurance

Quality control refers to the processes and techniques used to ensure that a product or service meets specified requirements. It involves monitoring various aspects of production, from raw materials to finished goods, to identify any deviations from quality standards. On the other hand, quality assurance encompasses the systematic activities implemented within a quality system to provide confidence that a product will satisfy given requirements for quality and assurance.

Understanding both concepts is crucial for organizations looking to improve their operational effectiveness. Quality control focuses on identifying defects after they occur, while quality assurance aims at preventing defects before they happen through proactive measures. Together, these practices form a comprehensive approach to maintaining high-quality standards across industries.

The Role of Quality Management

Quality management plays an integral part in any successful business strategy by establishing policies and procedures that govern how an organization approaches its operations. This includes defining roles within teams dedicated to maintaining high levels of control and quality throughout all stages of production or service delivery. Effective quality management not only enhances customer satisfaction but also fosters continuous improvement within the organization.

Quality control consultants often take on advisory roles in implementing robust management systems tailored specifically for each business's unique needs. They assess existing processes, recommend improvements, and guide teams in adopting best practices for achieving excellence in both product output and service delivery. Ultimately, strong quality management leads to increased efficiency and reduced costs associated with rework or non-compliance.

How Consultants Control the Quality

Quality control consultants utilize a variety of tools and methodologies to effectively control the quality within an organization’s processes. They conduct thorough assessments of current operations, identifying areas where improvements can be made while ensuring compliance with industry standards and regulations related to quality assurance. By leveraging data analytics, statistical process control methods, and risk assessment techniques, these consultants provide actionable insights that drive meaningful change.

Moreover, effective communication is key as consultants work closely with internal teams during implementation phases—training staff on new protocols designed to enhance overall performance while fostering a culture centered around continuous improvement in both control and quality measures. Their expertise enables organizations not only to meet regulatory requirements but also exceed customer expectations through consistent delivery of high-quality products or services.

Key Benefits of Hiring Quality Control Consultants

When businesses engage quality control consultants, they unlock a treasure trove of advantages that can significantly enhance their operations. These experts bring specialized knowledge and experience to the table, ensuring that products meet the highest standards of quality and safety. In an increasingly competitive market, the benefits of effective quality assurance cannot be overstated.

Enhancing Product Consistency

One of the primary roles of quality control consultants is to enhance product consistency across production lines. By implementing robust quality management systems, these professionals help ensure that every item produced meets predetermined specifications and standards. This level of consistency not only builds customer trust but also strengthens brand reputation in a crowded marketplace.

Moreover, with effective strategies in place to control the quality during manufacturing processes, businesses can minimize variations that often lead to defects or customer dissatisfaction. Quality assurance practices help identify potential issues before they snowball into larger problems, resulting in a smoother production flow. When customers know they can rely on consistent product quality, it fosters loyalty and repeat business.

Reducing Operational Risks

Quality control consultants play a crucial role in reducing operational risks associated with product failures or non-compliance with regulatory standards. By conducting thorough assessments and audits, these experts identify vulnerabilities within existing processes that could lead to costly errors or recalls. Their proactive approach helps organizations mitigate risks before they escalate into major setbacks.

Additionally, by emphasizing proper training and adherence to best practices in quality management, consultants empower employees to take ownership of their roles in maintaining high-quality standards. This cultural shift not only reduces operational risks but also enhances overall workplace morale as employees feel more engaged and responsible for their work outcomes. The result is a safer working environment where everyone contributes to maintaining exceptional control and quality.

Saving Time and Resources

Hiring quality control consultants ultimately leads to significant savings in both time and resources for businesses striving for excellence in their products or services. With their expertise guiding process improvements, companies can streamline operations by eliminating inefficiencies that often waste valuable resources. This means less time spent on rework or addressing customer complaints related to poor-quality products.

Furthermore, by investing in expert guidance for implementing effective quality assurance measures upfront, organizations avoid costly mistakes down the line—saving money on recalls or damage control efforts after issues arise. Quality management becomes more efficient as teams learn best practices from seasoned professionals who know how to optimize workflows while maintaining high standards of performance across all areas involved with controlling the quality of outputs.

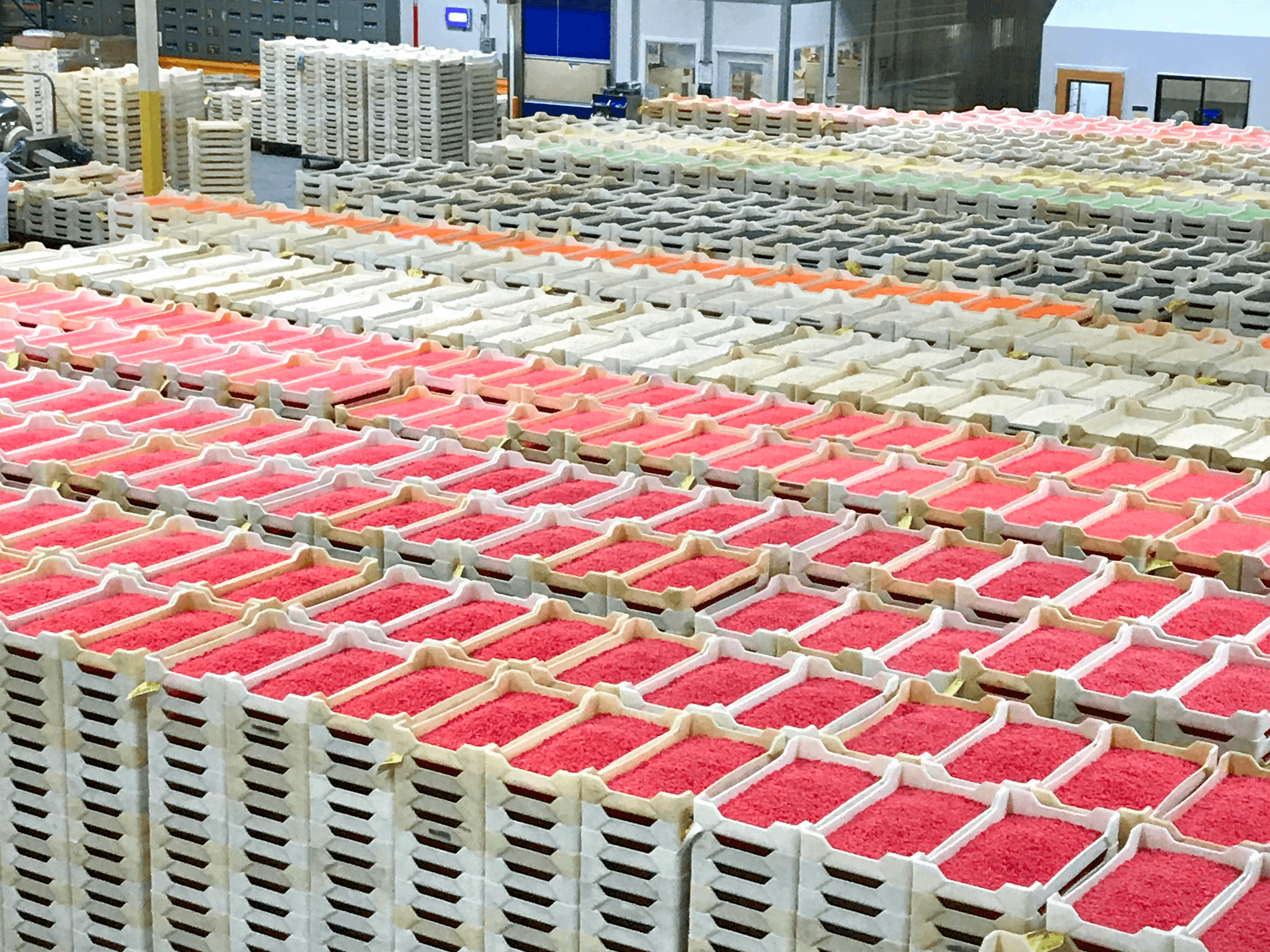

Quality Control in Manufacturing

In the manufacturing sector, quality control is not just a checkbox on a to-do list; it’s the backbone of operational success. Implementing effective quality management techniques ensures that products meet both safety standards and consumer expectations. By harnessing the expertise of quality control consultants, manufacturers can enhance their processes and ultimately improve their bottom line.

Effective Quality Management Techniques

To truly master quality control in manufacturing, companies must adopt a range of effective management techniques. These include statistical process control (SPC), which utilizes data analysis to monitor and control production processes, ensuring consistent product quality. Additionally, implementing Total Quality Management (TQM) fosters a culture where all employees are engaged in continuous improvement efforts focused on enhancing quality and assurance throughout the organization.

Another critical technique is the use of Six Sigma methodologies, which aim to reduce defects and variability in manufacturing processes. By employing these strategies, businesses can not only control the quality but also streamline operations for maximum efficiency. Ultimately, these effective techniques help organizations achieve higher customer satisfaction through reliable products that meet stringent quality standards.

Case Study: China Inspection Pro's Impact

One compelling example of effective quality management comes from China Inspection Pro, a leading provider of inspection services for manufacturers worldwide. Their team of seasoned quality control consultants has significantly influenced production practices by implementing rigorous inspection protocols that ensure compliance with international standards. This case study illustrates how their expertise in controlling the quality has led to reduced defect rates and increased client trust across various industries.

By conducting thorough inspections at different stages of production—raw materials, in-process checks, and final product evaluations—China Inspection Pro helps manufacturers identify potential issues before they escalate into costly problems. The results speak for themselves: clients have reported enhanced product consistency and significant savings due to fewer returns and reworks thanks to improved adherence to quality assurance practices. This success story underscores the importance of investing in expert guidance when it comes to managing manufacturing processes.

Best Practices for Quality Assurance

When it comes to maintaining high standards in manufacturing, adopting best practices for quality assurance is essential. First on this list is developing clear documentation procedures that outline every step of production; this transparency allows teams to identify areas needing improvement quickly. Furthermore, regular training sessions for staff about new technologies or methods reinforce a commitment to maintaining high-quality benchmarks within the organization.

Another best practice involves leveraging technology such as automated inspection tools or software solutions designed specifically for monitoring production metrics related to control and quality measures effectively. These innovations not only streamline processes but also provide real-time data analytics that can help managers make informed decisions swiftly regarding adjustments needed on the shop floor.

Lastly, fostering an open environment where employees feel comfortable reporting issues or suggesting improvements plays an integral role in sustaining long-term success with regard to both product reliability and overall operational excellence within manufacturing settings.

Quality Control in Food and Beverage

In the food and beverage industry, quality control is not just a standard; it's a necessity. With the increasing demand for safe, high-quality products, quality control consultants play a pivotal role in ensuring that every item meets stringent safety regulations and consumer expectations. This sector demands rigorous quality management practices to uphold both health standards and brand reputation.

Ensuring Safety and Compliance

Ensuring safety and compliance within the food and beverage industry is paramount. Quality control consultants help businesses navigate complex regulations, ensuring that all processes meet local and international standards for safety. By implementing systematic quality assurance protocols, these experts help control the quality of ingredients, production methods, and final products to mitigate risks associated with contamination or non-compliance.

Quality assurance extends beyond mere compliance; it fosters consumer trust in brands. When customers know that a company prioritizes rigorous quality control measures, they are more likely to choose its products over competitors’. Moreover, maintaining high safety standards can prevent costly recalls or legal issues down the line.

The Value of Expert Quality Control

The value of expert quality control cannot be overstated in today's competitive market. Quality control consultants bring specialized knowledge that helps companies implement effective strategies tailored to their unique challenges. From developing testing protocols to training staff on best practices, these professionals ensure that businesses can consistently deliver safe and high-quality products.

Investing in expert quality management also leads to operational efficiencies—reducing waste while maximizing output. By streamlining processes based on data-driven insights from seasoned consultants, companies can enhance productivity without compromising on safety or compliance efforts. Ultimately, this results in better profit margins while maintaining customer satisfaction through reliable product offerings.

Examples of Successful Quality Management

Numerous companies have successfully implemented robust quality management systems with the help of quality control consultants. For instance, a leading beverage manufacturer collaborated with experts to overhaul its production lines by introducing advanced testing techniques for raw materials and finished goods alike. This proactive approach not only improved product consistency but also significantly reduced instances of recalls due to contamination.

Another example involves a popular snack food company that partnered with consultants specializing in food safety audits. By conducting thorough assessments and refining their manufacturing processes based on findings from these audits, they were able to achieve higher compliance ratings while enhancing overall product taste and texture—factors crucial for consumer loyalty.

These examples illustrate how effective collaboration with quality control consultants can elevate standards within the food industry while promoting long-term success through sustainable practices.

Quality Control in Healthcare

In the healthcare sector, quality control is not just a regulatory requirement; it's a fundamental aspect that can mean the difference between life and death. Quality control consultants play an essential role in establishing stringent quality assurance protocols that ensure patient safety and service excellence. As healthcare systems evolve, the emphasis on quality management becomes increasingly crucial to address emerging challenges and improve overall health outcomes.

Importance of Quality Assurance in Medicine

Quality assurance in medicine is vital for maintaining high standards of patient care and safety. Through effective quality control practices, healthcare organizations can minimize errors, enhance treatment efficacy, and ensure compliance with industry regulations. The presence of qualified quality control consultants helps institutions develop comprehensive frameworks that prioritize both patient well-being and operational efficiency.

Balancing Quality and Patient Care

Striking a balance between exceptional quality and compassionate patient care can be challenging for healthcare providers. While it’s essential to implement rigorous quality management protocols, it’s equally important to maintain a human touch in patient interactions. Quality control consultants aid healthcare facilities by designing systems that uphold high standards without compromising the empathetic nature of caregiving.

Innovative Quality Control Strategies

The landscape of healthcare is rapidly changing, necessitating innovative approaches to quality control and assurance. From leveraging technology like AI-driven analytics to employing lean management techniques, there are numerous ways to enhance quality management processes effectively. By collaborating with experienced quality control consultants, healthcare organizations can implement cutting-edge strategies that not only streamline operations but also elevate the standard of care provided to patients.

Conclusion

In the ever-evolving landscape of business, choosing the right quality control consultants is crucial for maintaining high standards. These professionals are not just experts in quality assurance; they are your partners in navigating the complexities of quality management. By selecting consultants who align with your specific needs, you can ensure that your organization not only meets but exceeds industry standards.

Choosing the Right Quality Control Consultants

When it comes to selecting quality control consultants, experience and expertise should be at the top of your checklist. Look for consultants with a proven track record in your industry, as they will understand the unique challenges you face in controlling quality and assurance processes. Additionally, consider their approach to quality management—do they prioritize collaboration and communication? The right fit will enable you to control the quality effectively while fostering a culture of continuous improvement.

The Future of Quality Management

The future of quality management is bright, driven by advancements in technology and an increasing emphasis on sustainability. As industries evolve, so do the methods used by quality control consultants to ensure compliance and excellence. Expect to see more data-driven approaches that leverage analytics and artificial intelligence to enhance decision-making processes related to control and quality.

Elevating Standards with Quality Assurance

Quality assurance is not just about meeting minimum requirements; it's about elevating standards across all facets of an organization. By investing in robust systems for managing quality, businesses can foster trust among customers and stakeholders alike. Ultimately, as organizations embrace comprehensive strategies for controlling quality, they pave the way for innovation and long-term success.

[Image description=group of diverse professionals discussing charts and metrics around a table, documents scattered with graphs showing trends in product consistency, modern office environment], Image name=quality_control_consultants_meeting, Alt tag=Quality control consultants collaborating on improving industry standards