Introduction

In today's competitive business landscape, understanding the role of quality control is essential for any organization aiming to thrive. Quality control consultants play a pivotal role in ensuring that products and services meet established standards, ultimately enhancing overall quality management practices. By focusing on effective quality assurance strategies, businesses can not only improve their offerings but also gain a significant edge over competitors.

Understand the Role of Quality Control

Quality control serves as the backbone of any successful organization, ensuring that products and services adhere to predefined standards. It involves systematic processes designed to control the quality at various stages of production or service delivery. By implementing robust quality management systems, businesses can minimize errors and enhance their reputation in the marketplace.

Benefits of Hiring Quality Control Consultants

Hiring quality control consultants brings a wealth of expertise to organizations looking to improve their processes. These specialists offer tailored solutions that help businesses identify weaknesses in their current systems and implement effective strategies for improvement. Moreover, partnering with a quality assurance specialist allows companies to focus on core operations while ensuring that their products consistently meet high-quality standards.

Key Industries That Rely on Quality Assurance

Several industries heavily depend on rigorous quality assurance protocols to maintain safety and efficiency. Manufacturing, healthcare, food production, and pharmaceuticals are just a few sectors where controlling the quality is non-negotiable for compliance and customer satisfaction. In these fields, having dedicated quality control consultants ensures that organizations not only meet regulatory requirements but also foster trust among consumers.

The Importance of Quality Management

Quality management is the backbone of any successful organization, ensuring that products and services meet established standards. By implementing effective quality assurance practices, businesses can control the quality at every stage of production. This proactive approach not only mitigates risks but also enhances overall operational efficiency.

Establishing Standards and Protocols

Establishing clear standards and protocols is essential for effective quality management. Quality control consultants play a crucial role in this process by helping organizations define measurable criteria that align with industry benchmarks. These standards serve as a foundation for consistent performance and help control the quality throughout various stages of production.

In addition to setting standards, these protocols create a framework for continuous improvement, allowing companies to adapt to changing market demands. With well-defined guidelines in place, employees are empowered to take ownership of their work, leading to increased accountability and pride in their output. Ultimately, this structured approach fosters a culture where quality assurance becomes everyone's responsibility.

Reducing Costs Through Preventative Measures

Investing in quality management can significantly reduce costs through preventative measures rather than reactive fixes. When organizations prioritize quality assurance from the outset, they can identify potential issues before they escalate into costly problems. Quality control specialists help businesses implement strategies that minimize waste and rework while maximizing productivity.

By controlling the quality early in the production process, companies can avoid expensive recalls or reputational damage caused by subpar products reaching consumers. Additionally, these preventative measures lead to more efficient use of resources—saving time and money in the long run. In essence, an ounce of prevention truly is worth a pound of cure when it comes to maintaining high-quality standards.

Enhancing Customer Satisfaction

At its core, effective quality management is about enhancing customer satisfaction—after all, happy customers are repeat customers! By consistently delivering high-quality products or services that meet or exceed expectations, businesses build trust and loyalty among their clientele. Quality control consultants assist organizations in developing processes that prioritize customer feedback as part of their continuous improvement efforts.

Furthermore, when customers know they can rely on your brand for consistent quality assurance, it sets you apart from competitors who may not prioritize such measures. This competitive edge not only attracts new customers but also retains existing ones who appreciate your commitment to excellence. In today's marketplace where options abound, investing in robust quality management practices is essential for long-term success.

How Quality Control Consultants Operate

When it comes to enhancing quality management within an organization, quality control consultants play a pivotal role. They bring a fresh perspective and specialized knowledge that can help businesses identify gaps in their current processes. By understanding how these consultants operate, organizations can better appreciate the value they add to quality assurance initiatives.

Assessing Current Quality Processes

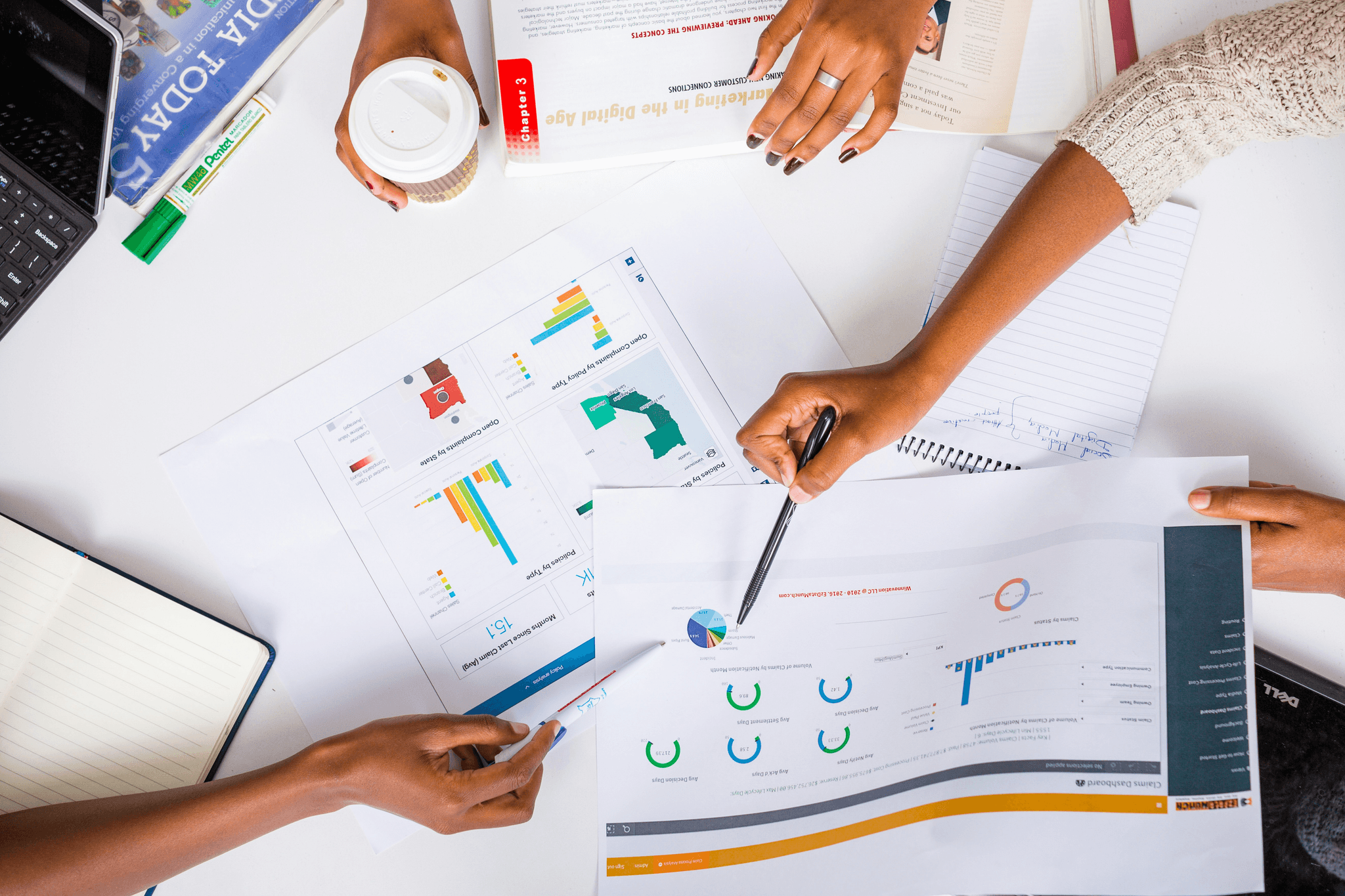

The first step for any quality control consultant is to conduct a comprehensive assessment of existing quality processes. This involves analyzing workflows, identifying inefficiencies, and determining how well current practices align with industry standards. By meticulously evaluating these elements, quality assurance specialists can pinpoint areas that require improvement and establish a solid foundation for future enhancements.

During this phase, consultants also engage with staff at various levels to gather insights about the challenges they face in controlling the quality of products or services. This collaborative approach ensures that the solutions proposed are practical and tailored to meet the unique needs of the organization. Ultimately, effective assessment lays the groundwork for successful implementation of new strategies that enhance overall quality management.

Implementing Effective Quality Assurance Strategies

Once the assessment is complete, it's time for quality control consultants to roll up their sleeves and implement effective strategies aimed at bolstering quality assurance. These strategies may include developing standardized procedures or introducing advanced technologies designed to control and enhance product quality consistently. The goal here is not just about meeting compliance but fostering an environment where excellence becomes part of the organizational culture.

Quality assurance specialists often employ tools such as Six Sigma or Lean methodologies to streamline processes and eliminate wasteful practices that compromise product integrity. By focusing on continuous improvement through these frameworks, organizations can achieve significant reductions in defects while simultaneously enhancing customer satisfaction levels. The emphasis here is on creating a proactive approach that empowers teams to take ownership of their roles in maintaining high-quality standards.

Continuous Monitoring and Improvement

The work of quality control consultants doesn’t stop after implementation; continuous monitoring is crucial for long-term success in any quality management system. Through regular audits and performance evaluations, these specialists ensure that established protocols are being adhered to while also identifying new opportunities for improvement as market demands evolve. This ongoing vigilance helps businesses stay ahead of potential pitfalls while reinforcing their commitment to controlling the quality effectively.

Moreover, by fostering a culture centered around feedback and adaptation, organizations become more resilient in navigating changes within their industries. Quality control becomes not just a function but an integral aspect of daily operations where everyone plays a part in sustaining high standards over time. In this way, continuous improvement becomes second nature rather than an occasional effort—an essential trait for thriving in today’s competitive landscape.

Real-World Applications of Quality Control

Quality control is not just a buzzword; it’s a critical component in various industries striving for excellence. The impact of quality control consultants can be seen across multiple sectors, where they help organizations implement robust quality assurance practices. By showcasing real-world applications, we can understand how effective quality management translates into tangible benefits for businesses.

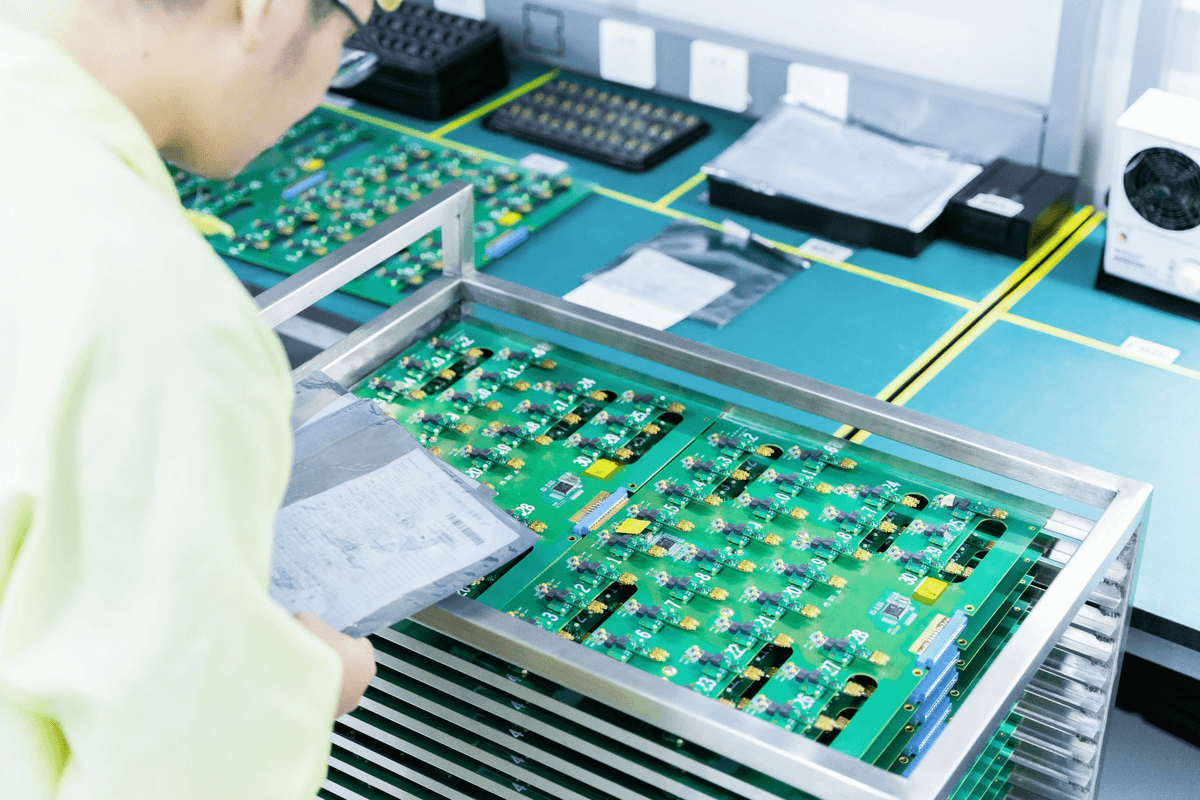

Case Study: China Inspection Pro

China Inspection Pro is a prime example of how quality control consultants can revolutionize operations in manufacturing and export sectors. This company specializes in providing comprehensive quality assurance services that help businesses maintain high standards while navigating the complexities of international trade. By employing skilled quality assurance specialists, China Inspection Pro has successfully helped numerous clients control the quality of their products, ensuring compliance with both local and international regulations.

Through meticulous assessments and tailored strategies, they have transformed their clients’ approach to quality management, resulting in fewer defects and increased customer satisfaction. Their model demonstrates how proactive measures in quality control can lead to significant cost savings and enhanced brand reputation. Ultimately, this case study illustrates the profound impact that dedicated quality control efforts can have on operational efficiency.

Elevating Manufacturing Standards

In the manufacturing sector, elevating standards through effective quality assurance is paramount to success. Quality control consultants play a vital role by introducing rigorous protocols that ensure products meet or exceed industry benchmarks. By focusing on preventing defects rather than merely detecting them post-production, organizations can significantly enhance their overall output.

Implementing these elevated manufacturing standards not only reduces waste but also fosters a culture where every employee takes responsibility for controlling the quality at each stage of production. This shift leads to more consistent product performance and greater customer trust over time. As manufacturers embrace these practices, they position themselves as leaders within their respective markets.

Improving Food Safety Regulations

Quality control is particularly crucial in the food industry where safety regulations are stringent and constantly evolving. Quality assurance specialists are essential in helping food producers navigate these complex requirements while maintaining high-quality standards throughout their supply chains. By implementing thorough testing protocols and regular audits, these consultants ensure that companies adhere to food safety regulations designed to protect consumers.

Moreover, by focusing on continuous improvement initiatives within food production processes, businesses can minimize risks associated with contamination or spoilage—ultimately safeguarding public health while enhancing product integrity. As consumer awareness grows regarding food safety issues, those who prioritize effective quality management will undoubtedly stand out from competitors who neglect these vital aspects of operation.

Choosing the Right Quality Control Consultant

Selecting the right quality control consultant is crucial for any organization aiming to enhance its quality assurance processes. The ideal consultant not only understands your specific needs but also has a proven track record in quality management and control strategies. By making informed choices, businesses can ensure they partner with professionals who truly understand how to control the quality of their operations.

Identifying Your Business Needs

Before you dive into the world of quality control consultants, it's essential to identify what your business specifically requires. Are you looking to improve existing protocols, or do you need help establishing new standards? By pinpointing your needs, you can better communicate with potential consultants about how they can assist in enhancing your quality assurance efforts.

Understanding whether you're dealing with manufacturing defects, compliance issues, or customer satisfaction challenges will guide you in choosing a consultant who specializes in those areas. This clarity not only streamlines the hiring process but also ensures that the selected expert aligns perfectly with your goals for quality management and effective control of processes. After all, a good fit can significantly influence the success of your initiatives.

Evaluating Consultant Expertise

Once you've identified your business needs, evaluating the expertise of potential quality control consultants is next on the agenda. Look for candidates who have substantial experience in your industry and a solid understanding of various quality assurance methodologies. A well-rounded background indicates that they are capable of tailoring their approach to suit your unique requirements.

Don’t shy away from asking for case studies or references from previous clients; this will give you insight into their problem-solving capabilities and effectiveness in controlling quality issues. Additionally, checking certifications and professional affiliations can provide further validation of their skills as a quality assurance specialist. Remember, expertise isn't just about years on paper—it's about real-world success stories that demonstrate their ability to elevate standards.

Understanding Service Offerings

Finally, understanding what services each potential consultant brings to the table is vital for making an informed decision. Quality control consultants may offer a range of services—from initial assessments and strategy development to ongoing monitoring and training sessions aimed at embedding a culture of quality within your organization. Knowing what’s included helps ensure that you're getting comprehensive support tailored to both immediate and long-term goals.

Evaluate whether these offerings align with both current challenges and future aspirations regarding quality management practices within your company. It’s essential to choose someone whose service package complements your operational framework while providing flexibility as needs evolve over time—after all, controlling the quality effectively requires adaptability!

The Future of Quality Assurance

As industries evolve and consumer expectations rise, the future of quality assurance is set to undergo significant transformations. Quality control consultants are at the forefront of this revolution, leveraging technology to enhance quality management processes. Innovations in quality control not only streamline operations but also ensure that businesses can maintain high standards in an ever-competitive landscape.

Technology and Quality Control Innovations

The integration of advanced technologies into quality management has become a game changer for many organizations. From artificial intelligence to machine learning, these innovations enable quality control consultants to analyze data more effectively and identify potential issues before they escalate. Furthermore, utilizing software solutions designed for quality assurance allows companies to automate routine tasks, thus freeing up valuable resources for more strategic initiatives.

Quality assurance specialists can now harness real-time data analytics to monitor production processes continuously, ensuring that control and quality remain paramount throughout the supply chain. This proactive approach helps companies control the quality of their products while minimizing waste and inefficiencies. As technology continues to advance, we can expect even more sophisticated tools that will redefine how businesses manage their quality assurance efforts.

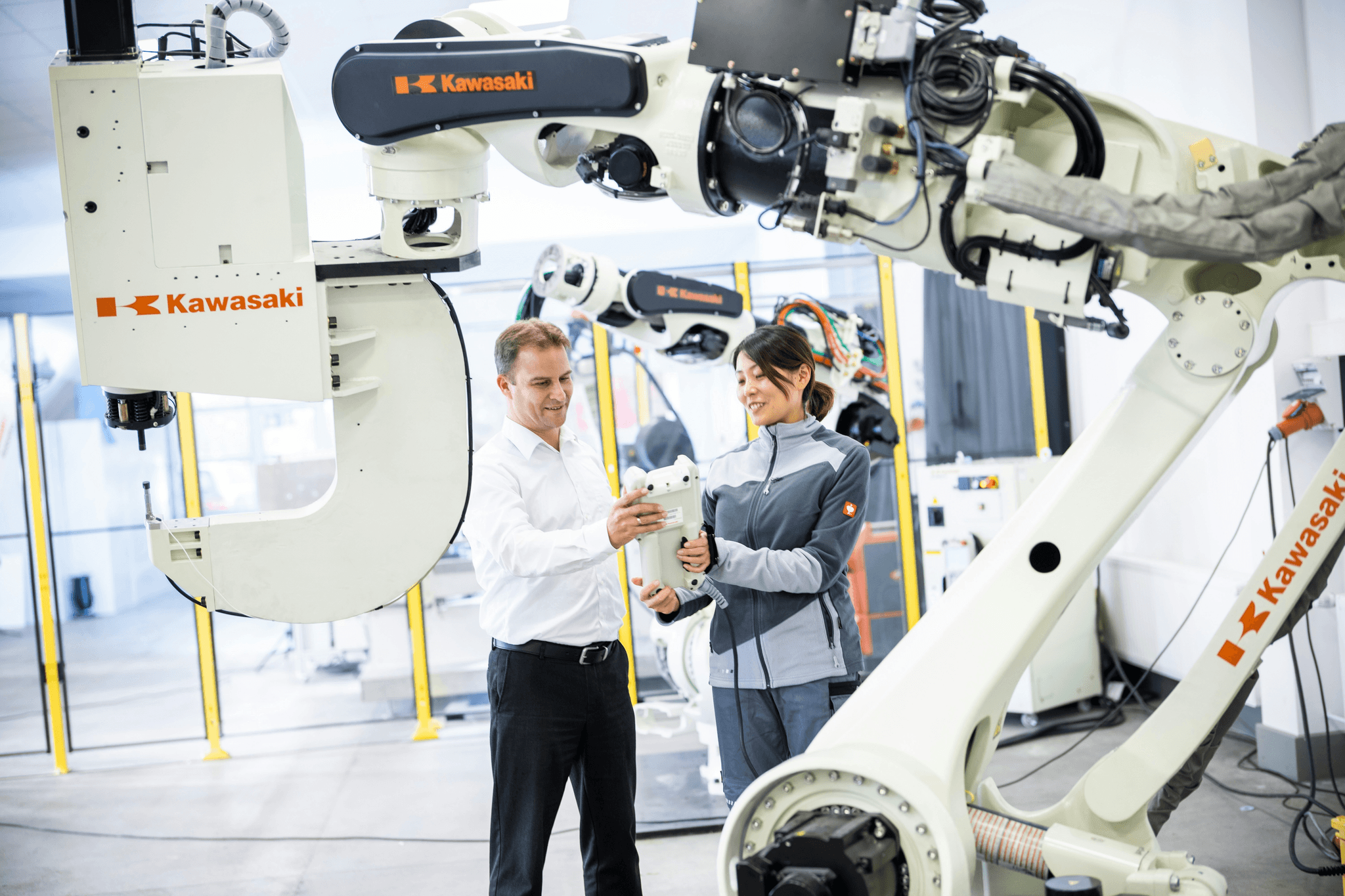

The Role of Automation in Quality Management

Automation is quickly becoming indispensable in the realm of quality management, allowing organizations to enhance precision while reducing human error. By automating repetitive tasks related to monitoring and reporting, companies can ensure that their focus remains on critical aspects of production that require human oversight and creativity. This shift not only improves overall efficiency but also empowers teams to prioritize strategic decision-making over mundane tasks.

Quality control consultants are essential in implementing these automation strategies effectively within various industries. They help businesses identify areas where automation can be integrated seamlessly into existing workflows without disrupting operations. As a result, organizations gain greater confidence in their ability to maintain high-quality standards while reducing costs associated with manual processes.

Building a Culture of Quality in Organizations

Fostering a culture centered around quality is vital for long-term success in any organization aiming for excellence in its offerings. This culture emphasizes accountability at all levels, encouraging employees to take ownership of their roles in maintaining high standards for products and services alike. By investing time and resources into training programs led by quality assurance specialists, companies can cultivate an environment where everyone understands the importance of controlling the quality from inception through delivery.

Moreover, when leadership prioritizes a commitment to continuous improvement as part of their core values, it sends a powerful message throughout the organization about the significance placed on quality control processes. Employees feel empowered when they see tangible support from management regarding initiatives aimed at enhancing overall performance metrics tied directly back to effective quality management practices. Ultimately, this cultural shift leads not just towards compliance with regulations but also positions businesses as leaders within their respective markets.

Conclusion

In the world of business, quality control is not just a luxury; it’s a necessity for maximizing efficiency and ensuring success. Quality control consultants play a pivotal role in helping organizations establish robust quality management systems that streamline processes and enhance productivity. By focusing on effective quality assurance practices, businesses can achieve operational excellence while minimizing waste and errors.

Maximizing Efficiency with Quality Control

To maximize efficiency, companies must prioritize quality control at every stage of their operations. Quality control consultants assist organizations in developing customized strategies that focus on controlling the quality of outputs, which in turn reduces rework and improves turnaround times. This proactive approach to quality management not only boosts productivity but also fosters a culture where excellence becomes the norm.

The Competitive Edge in Quality Assurance

In today’s competitive landscape, having a solid foundation in quality assurance can set businesses apart from their rivals. Organizations that invest in quality control stand to gain significant advantages, such as enhanced customer loyalty and improved brand reputation. With the expertise of a quality assurance specialist, companies can implement best practices that ensure consistent delivery of high-quality products or services.

Investing in Long-Term Business Success

Investing in effective quality management is crucial for long-term business success and sustainability. By employing qualified quality control consultants, organizations can build resilient systems that adapt to changing market demands while maintaining high standards of performance. Ultimately, this investment not only safeguards against potential pitfalls but also paves the way for future growth and innovation.