Introduction

In the ever-evolving world of fashion, China Manufacturing Clothing stands out as a powerhouse, producing garments for brands worldwide. With its vast resources and skilled labor force, China has become synonymous with apparel production. However, to truly harness the potential of this manufacturing giant, understanding quality assurance consulting is essential for ensuring that products meet international standards.

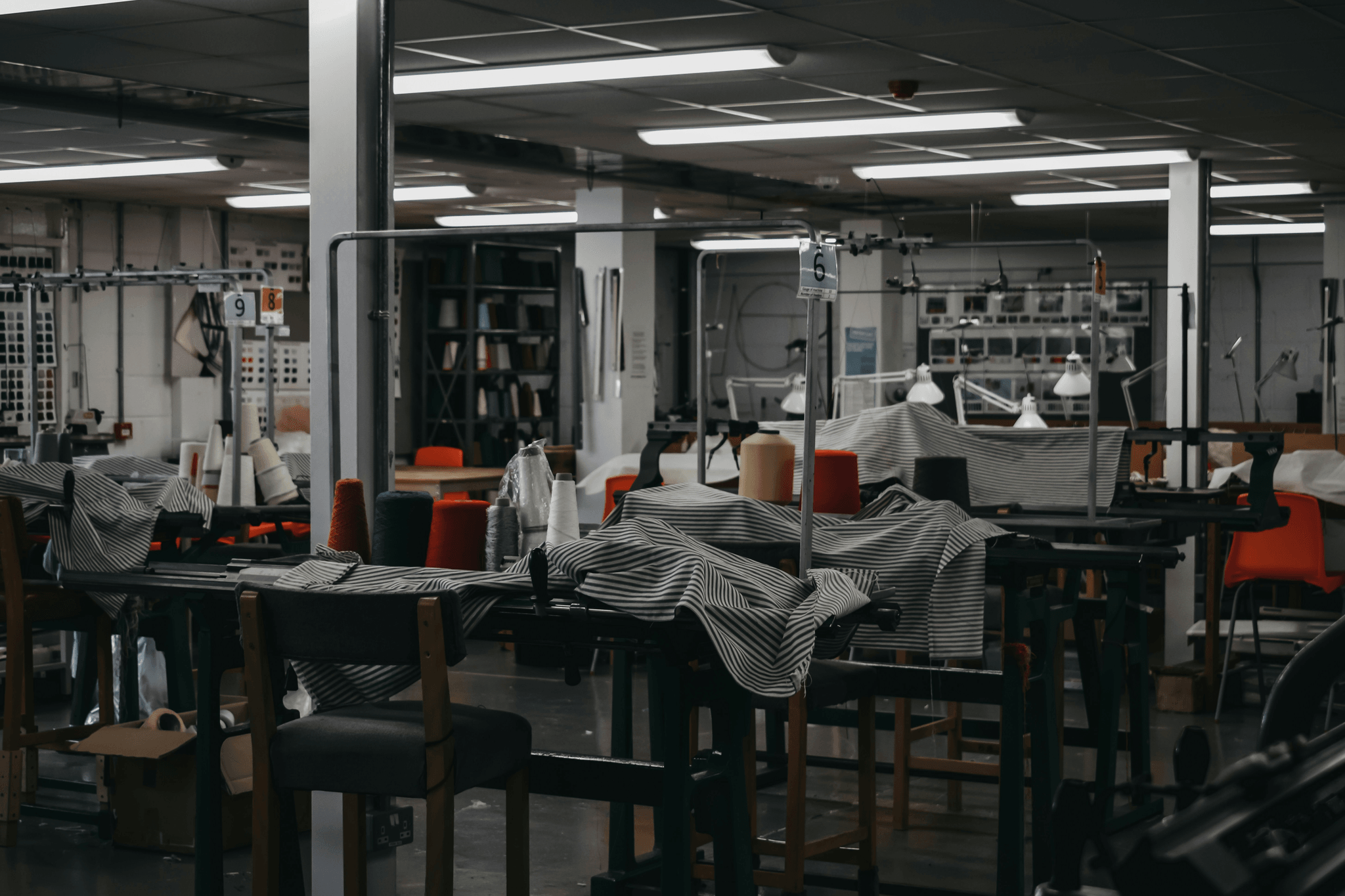

Understanding China Manufacturing Clothing

China's dominance in the garment industry can be attributed to its ability to deliver high volumes at competitive prices. The country boasts a rich tapestry of textile traditions combined with modern manufacturing techniques that cater to diverse market needs. As businesses seek to navigate this landscape, they often wonder: what is a quality inspector? This role is pivotal in maintaining the integrity of products throughout the production process.

The Role of Quality Assurance in Apparel

Quality assurance serves as the backbone of successful apparel production, ensuring that garments are not only aesthetically pleasing but also durable and safe for consumers. Inspection agencies play a crucial role in this process by conducting thorough evaluations at various stages of production. By leveraging third-party inspection services, companies can gain unbiased insights into their products' quality and compliance with industry standards.

Why Choose China for Garment Production

Choosing China for garment production offers numerous advantages beyond cost savings; it provides access to cutting-edge technology and an extensive network of suppliers and materials. The combination of these factors creates an environment ripe for innovation and efficiency in clothing manufacturing. Furthermore, partnering with a reputable inspection agency ensures that brands maintain high-quality standards while navigating the complexities of international trade.

The Advantages of China Manufacturing Clothing

China has established itself as a powerhouse in garment production, and for good reason. When it comes to clothing manufacturing, the advantages are numerous and compelling. From cost efficiency to access to cutting-edge technology, businesses looking to produce apparel can greatly benefit from partnering with Chinese manufacturers.

Cost Efficiency and Economies of Scale

One of the primary reasons companies opt for China manufacturing clothing is the significant cost savings involved. With an abundance of factories operating at scale, manufacturers can leverage economies of scale that lead to lower production costs per unit. This financial advantage enables brands to allocate resources more effectively, invest in quality assurance consulting, and ultimately offer competitive pricing in their markets.

Moreover, labor costs in China remain relatively low compared to many Western countries, making it feasible for brands to produce high-quality garments without breaking the bank. By choosing China manufacturing clothing, businesses can maintain healthy profit margins while ensuring they do not compromise on quality. This affordability is further enhanced by streamlined logistics and supply chains that minimize additional expenses.

Access to Advanced Technology and Machinery

In addition to cost benefits, China's garment sector boasts some of the most advanced technology and machinery available globally. Manufacturers often utilize state-of-the-art equipment that enhances production efficiency while maintaining high standards for quality assurance. This technological edge allows for intricate designs and innovative materials that can elevate a brand's offerings.

When brands collaborate with Chinese factories equipped with modern machinery, they gain access not only to superior production capabilities but also to skilled labor familiar with these technologies. As a result, companies can confidently ensure their products meet market demands while adhering strictly to quality control measures—thanks largely in part to what is a quality inspector’s role within these facilities.

A Vast Network of Suppliers and Materials

Another significant advantage of China manufacturing clothing lies in its extensive network of suppliers and materials readily available across the country. This vast ecosystem allows manufacturers quick access to various textiles and components necessary for garment production without long lead times or excessive shipping costs. Whether it's cotton from Xinjiang or silk from Suzhou, sourcing materials becomes seamless.

Additionally, this interconnected network fosters collaboration between different stakeholders involved in apparel production—from fabric suppliers to sewing factories—creating an environment conducive for innovation and rapid response times when adapting designs or addressing issues related to third-party inspection services. Companies benefit immensely by tapping into this rich resource pool while ensuring they meet stringent quality standards set forth by inspection agencies.

Quality Assurance and Its Importance

Quality assurance is the backbone of any successful production process, especially in China manufacturing clothing. It ensures that each garment meets specific standards and expectations before reaching the consumer. Without robust quality assurance consulting, brands risk facing costly returns, damaged reputations, and dissatisfied customers.

What is a Quality Inspector in Clothing Production

A quality inspector in clothing production is a crucial figure who meticulously examines garments to ensure they meet predefined quality standards. These professionals assess everything from fabric integrity to stitching precision, ensuring that every piece aligns with the brand's specifications. In the realm of China manufacturing clothing, understanding what is a quality inspector helps businesses appreciate their role in maintaining high-quality outputs.

The Role of Inspection Agencies in Quality Control

Inspection agencies play an essential role in maintaining quality control throughout the manufacturing process. They provide independent assessments of products at various stages, helping brands identify potential issues before they escalate into larger problems. By collaborating with reputable inspection agencies, companies involved in China manufacturing clothing can enhance their overall product quality and reliability.

Benefits of Third-Party Inspection Services

Third-party inspection services offer numerous advantages for brands looking to maintain high-quality standards in their clothing lines. These services provide an unbiased evaluation of products, giving companies peace of mind that their garments meet industry standards without favoritism or bias towards manufacturers. Engaging a reliable china third party inspection agency can significantly reduce risks associated with poor-quality products while improving overall customer satisfaction.

Navigating Challenges in China Manufacturing Clothing

China Manufacturing Clothing is a dynamic arena filled with opportunities, but it's not without its hurdles. Understanding and addressing the challenges can make or break your garment production journey. From communication barriers to navigating cultural differences and regulatory hurdles, let’s dive into what you need to know.

Addressing Communication Barriers

Communication is key in any business relationship, especially in China Manufacturing Clothing where language differences can lead to misunderstandings. Many manufacturers may not be fluent in English, causing potential miscommunications about design specifications or quality standards. Utilizing quality assurance consulting services can help bridge this gap by providing translators or bilingual quality inspectors who ensure that everyone is on the same page.

When discussing what is a quality inspector's role in this context, it's essential to highlight their ability to facilitate clear communication between parties. They serve as the vital link that translates not just words but also intentions and expectations regarding quality assurance. By engaging third-party inspection services, you can mitigate risks associated with miscommunication and ensure that your production aligns perfectly with your vision.

Moreover, investing time in building relationships through regular check-ins can further enhance communication channels. This proactive approach fosters trust and understanding, making it easier for both sides to navigate the complexities of clothing manufacturing together.

Dealing with Cultural Differences

Cultural nuances play a significant role in China Manufacturing Clothing; understanding them can enhance collaboration and efficiency. The Chinese business culture often emphasizes relationship-building (or guanxi) over transactional interactions, which may seem foreign to Western businesses accustomed to direct dealings. Recognizing this difference is crucial for establishing long-term partnerships with suppliers.

Quality assurance consulting firms often provide insights into these cultural dynamics, helping foreign brands adapt their strategies accordingly. For instance, knowing when to engage formally versus informally can significantly impact negotiations and project outcomes. Involving an inspection agency familiar with local customs ensures that your approach resonates well within the cultural context of Chinese manufacturers.

Additionally, patience goes a long way when navigating these cultural landscapes; rushing decisions might lead to friction rather than fruitful collaborations. Embracing a learning mindset will enable you to appreciate diverse perspectives while fostering an environment where mutual respect thrives throughout the production process.

Overcoming Regulatory Hurdles

Regulatory compliance is another critical challenge faced by those involved in China Manufacturing Clothing; understanding local laws is paramount for smooth operations. The garment industry is subject to various regulations concerning labor practices, environmental standards, and product safety—navigating these regulations without local expertise could result in costly delays or penalties.

This is where third-party inspection agencies come into play—they are well-versed in local regulations and can guide you through compliance requirements effectively. Engaging an inspection agency allows you not only access to their expertise but also peace of mind knowing that your products meet necessary standards before they hit the market.

Furthermore, staying updated on regulatory changes will empower businesses operating within this space; regular consultations with quality assurance consulting experts ensure you're always ahead of the curve regarding compliance matters related to China Manufacturing Clothing. By proactively addressing regulatory challenges through strategic partnerships and expert guidance, you'll position yourself for success while minimizing risks along the way.

Partnering with the Right Inspection Agency

Choosing the right inspection agency is a pivotal step in ensuring the success of your China manufacturing clothing endeavors. With a multitude of options available, it’s essential to select an agency that aligns with your quality assurance goals and understands the intricacies of garment production. The right partner can help you navigate challenges while enhancing product quality and compliance.

Why Choose China Inspection Pro

When it comes to quality assurance consulting in China, China Inspection Pro stands out as a premier choice for businesses engaged in clothing manufacturing. Their extensive experience in the industry equips them with knowledge about local suppliers, production processes, and common pitfalls that can affect quality. Moreover, they specialize in third-party inspection services tailored specifically for garment production, ensuring that your products meet international standards before they hit the market.

China Inspection Pro understands what is a quality inspector and how crucial their role is within the apparel supply chain. With trained professionals who are well-versed in both textile technology and regulatory requirements, they provide comprehensive inspections that cover everything from raw materials to finished garments. Choosing this agency means investing in peace of mind—knowing that your products are being evaluated by experts dedicated to maintaining high-quality standards.

How an Inspection Agency Enhances Quality Assurance

An effective inspection agency plays a vital role in bolstering quality assurance throughout the manufacturing process. By engaging third-party inspection services, businesses can benefit from unbiased evaluations at various stages of production—from initial fabric checks to final product assessments. This proactive approach helps identify potential issues before they escalate into costly problems or delays.

In addition to conducting rigorous inspections, these agencies often provide invaluable insights into best practices for improving manufacturing processes. They offer recommendations on material selection and production techniques that align with industry standards for durability and safety—key factors when competing globally in China manufacturing clothing markets. Ultimately, partnering with an inspection agency elevates your brand's reputation by ensuring consistent delivery of high-quality products.

Key Considerations for Selecting an Agency

Selecting an appropriate inspection agency is not just about credentials; it requires careful consideration of several factors to ensure alignment with your business needs. First and foremost, assess their expertise specifically related to apparel; experience with what is a quality inspector relevant to clothing production can make all the difference when evaluating potential partners. Look for agencies that have established relationships within local markets as this can enhance communication efficiency during inspections.

Another critical factor is transparency regarding their processes and reporting methods; you want clear insights into how evaluations are conducted and results communicated back to you as part of your quality assurance consulting strategy. Additionally, consider their ability to adapt services based on changing regulations or market demands—flexibility can be invaluable as trends evolve within China manufacturing clothing sectors.

Lastly, don’t underestimate the importance of customer service; having responsive support during critical phases can significantly impact project timelines and outcomes when dealing with complex international logistics involved in garment production.

Future Trends in China Manufacturing Clothing

As the world of fashion evolves, so does China Manufacturing Clothing. The industry is witnessing transformative trends that not only enhance production but also address global concerns such as sustainability and technological advancements. These changes are crucial for maintaining competitiveness and ensuring quality assurance consulting in an ever-changing market landscape.

The Rise of Sustainable Apparel Production

Sustainability has become a buzzword in the fashion industry, and China Manufacturing Clothing is no exception. With increasing awareness about environmental issues, manufacturers are adopting eco-friendly practices, from sourcing sustainable materials to implementing waste reduction strategies. Quality assurance consulting plays a vital role here, ensuring that these sustainable methods meet global standards while maintaining product integrity.

Moreover, brands are now more focused on transparency throughout their supply chains, leading to a demand for reliable inspection agencies that can verify compliance with sustainability claims. This shift not only enhances brand reputation but also aligns with consumer preferences for ethically produced clothing. As we look ahead, the rise of sustainable apparel production will undoubtedly shape the future of garment manufacturing in China.

Innovations in Smart Textiles

The integration of technology into textiles is revolutionizing China Manufacturing Clothing like never before. Innovations such as smart textiles—fabrics embedded with sensors or electronics—are gaining traction, offering functionalities like moisture-wicking or temperature regulation. This evolution requires rigorous quality control measures; thus, understanding what is a quality inspector becomes essential to ensure these advanced materials meet performance expectations.

Inspection agencies specializing in high-tech textiles are emerging to cater to this niche market, providing third-party inspection services that validate product claims and functionality. By leveraging cutting-edge technology alongside traditional craftsmanship, manufacturers can create garments that not only look good but also perform exceptionally well under various conditions.

Adapting to Global Market Changes

The dynamic nature of global markets necessitates agility within the China Manufacturing Clothing sector. Manufacturers must stay attuned to shifting consumer preferences and economic conditions while adhering to international standards and regulations—this is where third-party inspection comes into play as a critical component for success. Engaging with an inspection agency ensures that products not only comply with local regulations but also resonate with international buyers seeking high-quality garments.

To thrive amidst these changes, businesses must embrace flexibility and innovation while maintaining stringent quality assurance protocols through collaboration with reputable inspection agencies. By doing so, they can effectively navigate challenges while seizing new opportunities presented by evolving market demands.

Conclusion

In summation, China manufacturing clothing offers a wealth of opportunities for businesses looking to optimize their production processes and tap into a global market. By understanding the nuances of this industry, companies can maximize their benefits while ensuring that quality remains at the forefront of their operations. The dynamic landscape of garment production in China demands a strategic approach that balances cost efficiency with high standards.

Maximizing Benefits of China Manufacturing Clothing

The allure of cost efficiency in China manufacturing clothing is undeniable, but it’s the combination of scale and innovation that truly sets it apart. Companies can leverage advanced technologies and a vast network of suppliers to streamline production and reduce lead times. By partnering with local experts, businesses can navigate the complexities of sourcing materials and managing logistics effectively.

Moreover, quality assurance consulting plays a pivotal role in this equation. Firms must prioritize what is a quality inspector's role in maintaining product standards throughout the manufacturing process. Engaging third-party inspection services ensures that every garment meets international benchmarks before reaching consumers, thereby safeguarding brand reputation.

Ensuring Quality Through Dedicated Inspection

Quality assurance isn’t just an afterthought; it's integral to successful apparel production in China. Inspection agencies provide critical oversight at various stages of manufacturing, ensuring compliance with industry standards and customer expectations. This proactive approach helps mitigate risks associated with poor-quality products entering the market.

Third-party inspection adds another layer of credibility to the process by offering unbiased evaluations from experienced professionals who understand local regulations and global market trends. When businesses engage a reliable china third party inspection agency, they gain peace of mind knowing their products are thoroughly vetted for quality before shipment. This not only enhances consumer trust but also fosters long-term partnerships between manufacturers and brands.

Looking Ahead: The Future of Clothing Production

As we look toward the future, several trends are shaping the landscape of China manufacturing clothing—sustainability being at the forefront. The rise in eco-conscious consumerism is prompting manufacturers to adopt sustainable practices that minimize environmental impact while maximizing resource efficiency. Innovations such as smart textiles are also gaining traction, paving the way for more functional garments that cater to modern lifestyles.

Adapting to global market changes will require agility and foresight from all stakeholders involved in apparel production. Companies must stay informed about emerging technologies, regulatory shifts, and evolving consumer preferences to remain competitive in this fast-paced environment. Ultimately, by prioritizing quality assurance through dedicated inspection services, businesses can not only thrive but also contribute positively to shaping a more sustainable future for clothing production.