Introduction

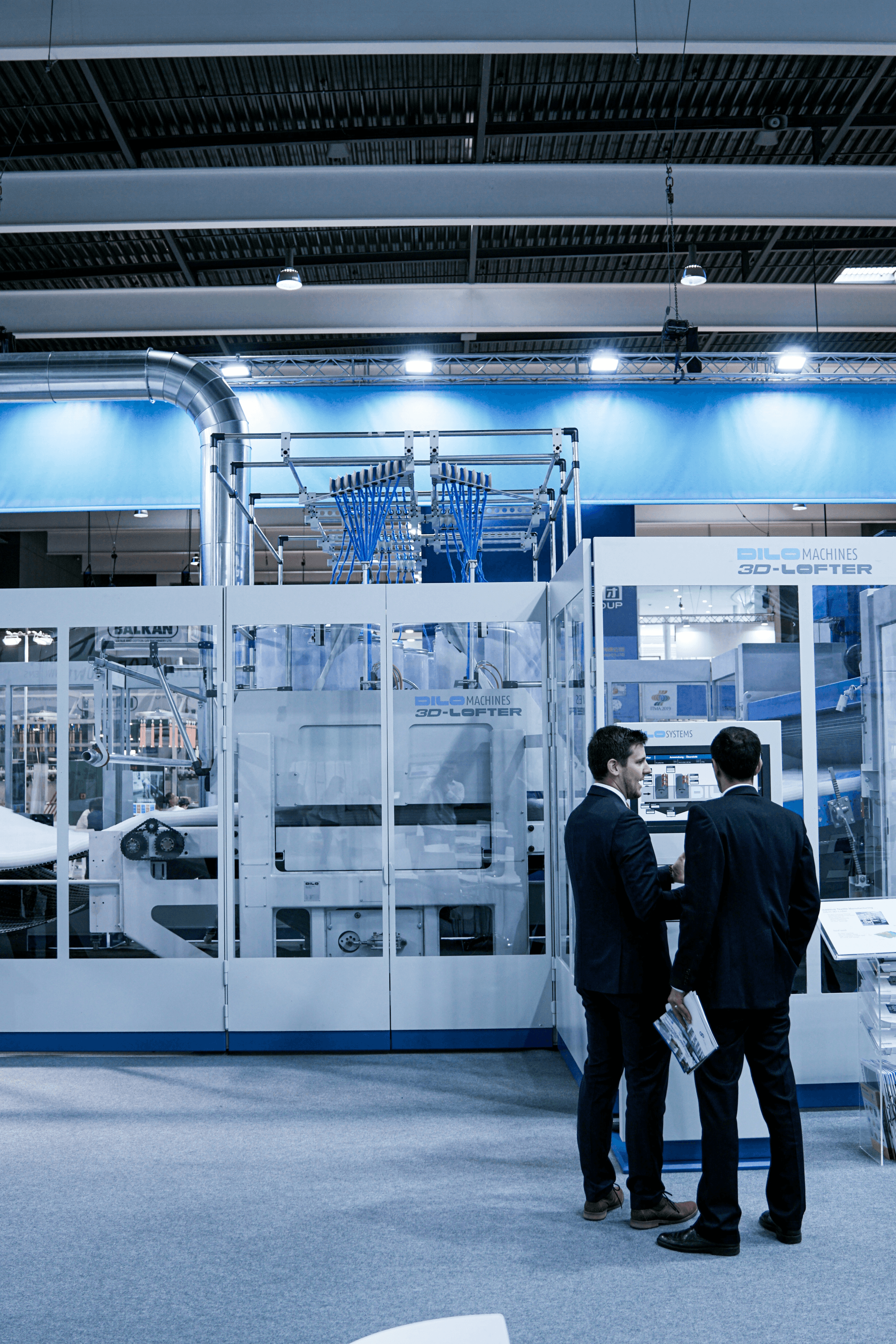

In the competitive world of manufacturing, audits play a crucial role in ensuring quality and compliance. Understanding the various types of audit in the manufacturing industry is essential for maintaining a robust company quality management system. By implementing effective audits, manufacturers can identify areas for improvement and enhance their overall operational efficiency.

Understanding Audits in Manufacturing

Audits are systematic examinations that assess processes and systems within manufacturing environments. They provide insights into how well a company adheres to its established quality management system, helping to identify gaps and opportunities for enhancement. From internal audits to external assessments, understanding these processes is vital for maintaining high standards.

Importance of Quality Management Systems

A solid quality management system serves as the backbone of any successful manufacturing operation. It ensures that products meet regulatory standards and customer expectations, ultimately fostering trust and reliability in the marketplace. Implementing an effective quality management platform not only streamlines operations but also enhances overall productivity.

Overview of Audit Types

There are several types of audit in the manufacturing industry, each serving distinct purposes and offering unique insights into operations. Internal audits focus on evaluating compliance with company policies, while external audits provide third-party perspectives on performance against industry standards. Compliance audits ensure adherence to regulatory requirements, making them critical for maintaining certifications like auditor ISO certification.

Types of Audit in Manufacturing

In the manufacturing industry, audits play a crucial role in ensuring that processes meet established standards and quality benchmarks. The types of audit in the manufacturing industry can vary significantly, each serving different purposes and focusing on various aspects of production. Understanding these types helps organizations streamline their quality management platform and enhance overall efficiency.

Internal Audits: The Backbone of Quality

Internal audits are often regarded as the backbone of quality management within a company’s quality management system. These audits are conducted by internal teams to assess adherence to established procedures and identify areas for improvement. By employing an effective audit checklist, internal auditors can systematically evaluate processes, ensuring that every component aligns with organizational goals.

The primary objective of a quality management system internal audit is to foster continuous improvement through self-assessment. This proactive approach not only helps identify weaknesses but also encourages a culture of accountability among employees. Ultimately, regular internal audits contribute significantly to maintaining high-quality standards and enhancing product reliability.

External Audits: Third-Party Perspectives

External audits provide an invaluable third-party perspective on a company’s operations and compliance with industry standards. Conducted by independent organizations or certification bodies, these audits offer insights that internal teams may overlook due to familiarity biases. External auditors bring expertise in evaluating the effectiveness of a company's quality management system audit against recognized benchmarks.

One significant benefit of external audits is their ability to validate compliance with necessary regulations, which is vital for maintaining credibility in the marketplace. They also help manufacturers prepare for auditor ISO certification by identifying gaps that need addressing before formal assessments occur. By leveraging external insights, companies can enhance their reputation while ensuring they meet customer expectations consistently.

Compliance Audits: Meeting Regulatory Standards

Compliance audits focus specifically on adherence to regulatory requirements within the manufacturing sector, making them essential for avoiding legal pitfalls and maintaining operational integrity. These types of audit in the manufacturing industry help ensure that all processes comply with local laws, safety regulations, and international standards relevant to specific products or services offered by the company.

Conducting thorough compliance audits requires a well-structured approach involving detailed documentation and an effective audit checklist tailored to regulatory requirements. This systematic evaluation not only safeguards companies from potential fines or penalties but also reinforces trust among stakeholders regarding product safety and reliability. Ultimately, regular compliance checks are integral for any organization striving for excellence within its operational framework.

Quality Management System Audit

In the realm of manufacturing, a Quality Management System (QMS) audit is essential for ensuring that processes align with established standards and practices. This type of audit in the manufacturing industry serves as a critical checkpoint to assess compliance, efficiency, and effectiveness within a company quality management system. By conducting regular audits, organizations can identify areas for improvement and maintain high-quality output.

Purpose of Quality Management System Audits

The primary purpose of quality management system audits is to evaluate whether an organization’s QMS effectively meets its objectives and complies with relevant standards. These audits help determine if the processes are aligned with the strategic goals of the company while also adhering to regulatory requirements. Additionally, they provide insights into how well a quality management platform is functioning and whether it supports continuous improvement initiatives.

Quality management system audits also serve to enhance accountability within teams by establishing clear expectations for performance. By identifying gaps in compliance or discrepancies in processes, organizations can take corrective action before issues escalate into significant problems. Ultimately, these audits contribute to building a culture of quality that permeates the entire organization.

Key Components of a Quality Management Audit

A comprehensive quality management audit encompasses several key components that ensure thorough evaluation and actionable insights. First and foremost is the audit checklist, which outlines specific criteria against which processes will be assessed during the audit process. This checklist typically includes elements such as documentation review, process observations, interviews with personnel, and assessment of compliance with ISO standards.

Another critical component involves engaging trained internal auditors who understand both the technical aspects of production and the nuances of quality assurance practices. Their expertise ensures that all relevant areas are scrutinized during a quality management system internal audit, leading to more accurate findings and recommendations for improvement. Furthermore, documenting findings meticulously allows organizations to track progress over time while facilitating transparency across departments.

Lastly, effective communication throughout the auditing process fosters collaboration between auditors and staff members involved in production activities. Encouraging open dialogue enables teams to share insights about challenges they face while adhering to quality standards—ultimately contributing to more robust solutions tailored specifically for their operations.

Benefits of a Robust Quality Management System

Implementing a robust quality management system offers numerous benefits that extend beyond mere compliance with regulatory frameworks or ISO certification requirements. One significant advantage is enhanced operational efficiency; streamlined processes reduce waste and improve productivity across various stages of manufacturing operations. Consequently, companies can achieve higher levels of customer satisfaction through consistent product delivery aligned with expected specifications.

Moreover, an effective QMS fosters innovation by encouraging employees at all levels to contribute ideas aimed at improving existing practices or developing new products/services altogether—this collaborative approach often leads manufacturers toward greater competitiveness in their respective markets. Additionally, regular audits within this framework help identify emerging trends or potential risks early on so businesses can adapt proactively rather than reactively when faced with challenges.

Lastly but importantly—the commitment demonstrated through maintaining an exemplary company quality management system cultivates trust among stakeholders including customers suppliers investors alike; this trust translates into stronger relationships which ultimately bolster long-term success within any given industry landscape.

System Audit Fundamentals

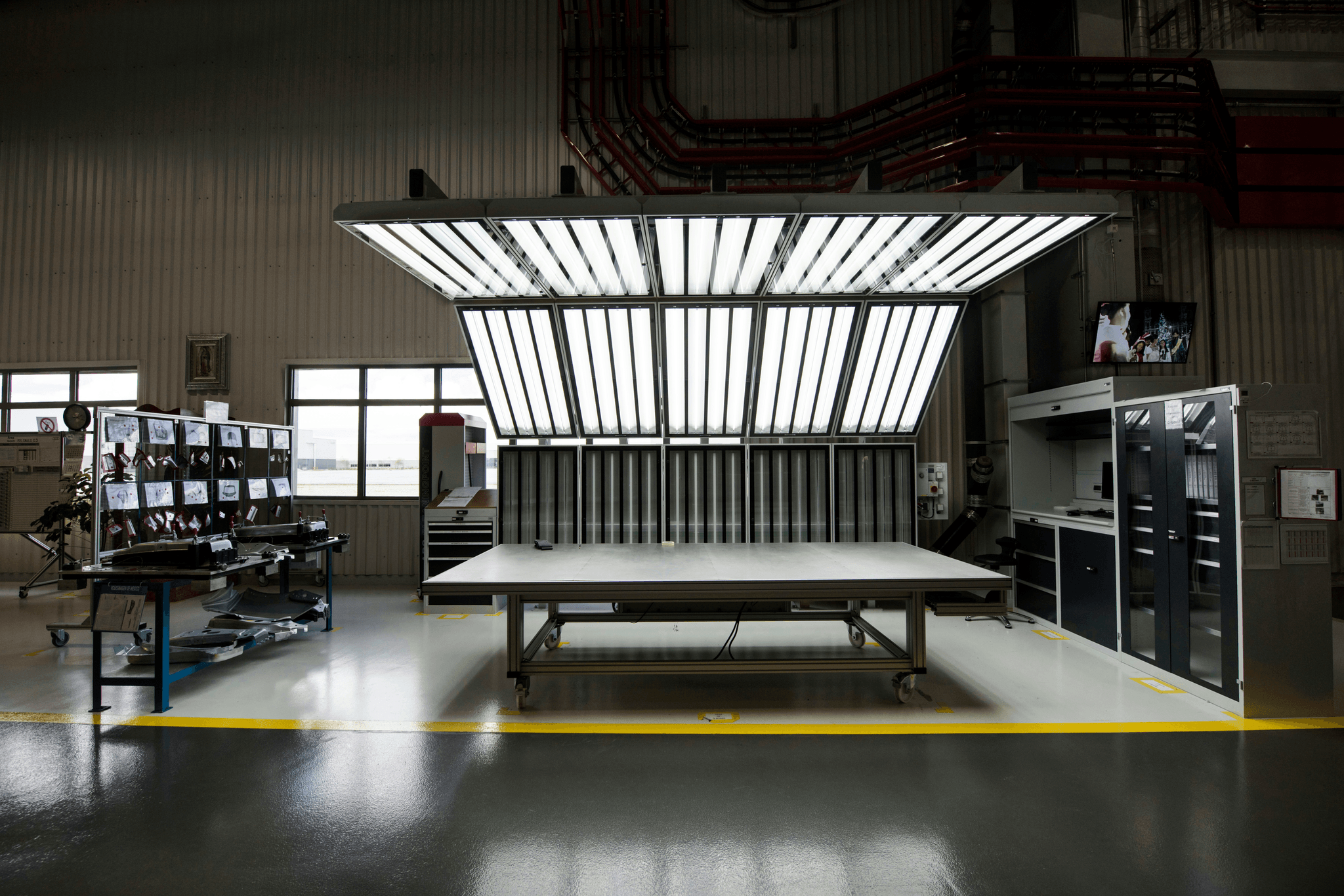

System audits are a crucial element in ensuring that manufacturing processes align with established quality standards and regulatory requirements. They provide a structured approach to evaluating the effectiveness of a company’s quality management system, ensuring that all components function cohesively. By focusing on both compliance and performance, system audits help organizations identify areas for improvement while reinforcing their commitment to quality.

Definition and Scope of System Audits

A system audit is an evaluation process designed to assess the effectiveness and efficiency of a company's quality management system. The scope typically includes examining procedures, processes, and controls within the organization to ensure they meet predefined standards. Understanding the types of audit in the manufacturing industry is essential, as each type—internal, external, or compliance—serves distinct purposes but ultimately contributes to enhancing overall quality.

Common Areas of Focus in System Audits

When conducting a system audit, several key areas warrant special attention. These include process documentation, adherence to safety regulations, resource management, and employee training protocols—all critical components of an effective company quality management system. Additionally, using an audit checklist can streamline this process by ensuring that auditors cover all necessary aspects during their evaluations.

Enhancing Efficiency through System Audits

System audits not only identify weaknesses but also provide opportunities for enhancing operational efficiency across various departments within an organization. By pinpointing areas where processes may be lagging or non-compliant with industry standards, companies can implement targeted improvements that yield significant benefits over time. Ultimately, regular system audits contribute to building a robust quality management platform that supports continuous improvement and drives organizational success.

Quality Management System Internal Audit

Internal audits are a crucial component of maintaining a robust quality management system in the manufacturing industry. They serve as an essential tool for assessing compliance with established processes and identifying areas for improvement within the company's quality management platform. By conducting regular internal audits, organizations can ensure they are aligned with both internal standards and external regulatory requirements, ultimately enhancing their overall operational efficiency.

Steps in Conducting Internal Audits

Conducting a quality management system internal audit involves several key steps that help ensure thoroughness and effectiveness. First, auditors should define the scope of the audit, identifying specific processes or departments to evaluate based on types of audit in manufacturing industry practices. Next, auditors gather relevant documentation and data to assess compliance against established criteria, followed by conducting interviews and site visits to observe operations firsthand.

Once all information is collected, auditors analyze findings to identify discrepancies or areas needing improvement within the company quality management system. This step culminates in drafting an audit report that highlights strengths and weaknesses while providing actionable recommendations for enhancement. Finally, follow-up actions must be taken to ensure that any identified issues are addressed promptly, fostering a culture of continuous improvement.

Creating an Effective Audit Checklist

An effective audit checklist is indispensable for streamlining the internal auditing process within any quality management system audit framework. The checklist should encompass critical elements such as regulatory requirements, company policies, and best practices relevant to the specific types of audit in manufacturing industry settings. By providing a structured approach to data collection and analysis, checklists help auditors maintain focus and consistency throughout their evaluations.

To create a successful checklist, it’s essential to involve various stakeholders who understand different aspects of the company’s operations; this ensures that no critical area is overlooked during audits. Additionally, checklists should be regularly updated based on changes in regulations or internal processes to remain relevant over time. Ultimately, an effective audit checklist enhances both the efficiency of internal audits and the reliability of results obtained from them.

The Role of Internal Auditors in Quality Assurance

Internal auditors play a vital role in ensuring that a company’s quality management system remains effective and compliant with established standards like ISO certification requirements. They act as impartial evaluators who provide objective insights into operational processes across various departments while assessing adherence to documented procedures outlined within the organization’s quality management platform. By doing so, they help identify risks before they escalate into significant issues that could jeopardize product quality or customer satisfaction.

Moreover, internal auditors contribute not only by identifying gaps but also by facilitating training sessions aimed at enhancing employees’ understanding of best practices related to quality assurance initiatives within their respective roles. Their involvement fosters collaboration across teams while promoting accountability towards maintaining high-quality standards throughout production processes—ultimately leading to improved performance metrics over time. Thus, investing in skilled internal auditors can significantly enhance your organization’s ability to meet its goals effectively while achieving auditor ISO certification when applicable.

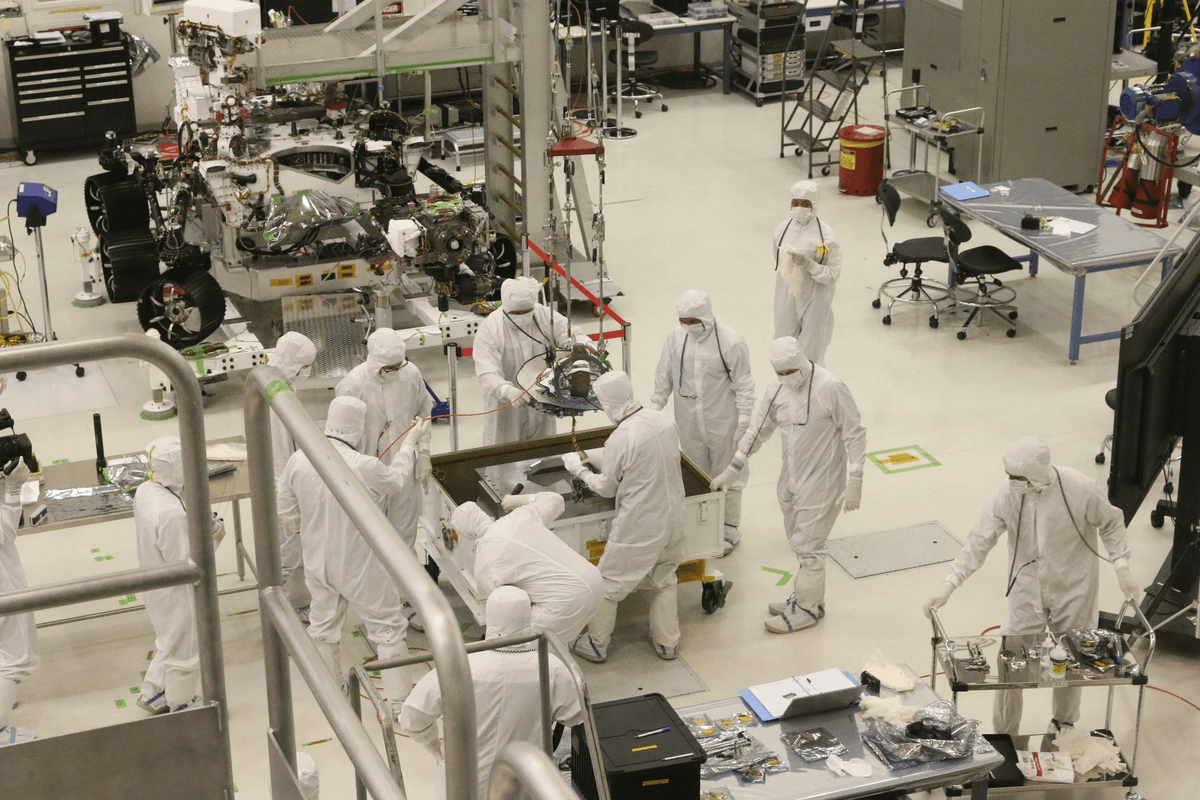

Auditor ISO Certification

In the manufacturing landscape, achieving ISO certification is not just a badge of honor; it's a way to demonstrate commitment to quality and consistency. Understanding the nuances of ISO standards is essential for manufacturers aiming to enhance their operational processes and meet global benchmarks. These standards provide a framework that integrates various types of audit in the manufacturing industry, ensuring that companies adhere to best practices in their quality management system.

Understanding ISO Standards in Manufacturing

ISO standards serve as guidelines for creating effective quality management systems that enhance product reliability and customer satisfaction. They encompass various aspects, including risk management, process efficiency, and continuous improvement—all vital components of a robust company quality management system. By familiarizing themselves with these standards, manufacturers can better prepare for audits and ensure compliance with both internal requirements and external regulations.

Benefits of ISO Certification for Manufacturers

Obtaining ISO certification offers numerous advantages beyond mere compliance; it can significantly elevate a manufacturer's reputation in the market. A certified company demonstrates its commitment to maintaining high-quality products through systematic processes validated by rigorous audits—both internal audits and external audits play key roles here. Furthermore, an effective quality management platform built around ISO principles can lead to increased operational efficiency, reduced waste, and enhanced customer trust.

Preparing for an ISO Audit: What to Expect

Preparing for an ISO audit involves thorough planning and meticulous attention to detail—after all, you want your company quality management system to shine! Start by reviewing your audit checklist against the relevant ISO standards; this will help identify any gaps in compliance or areas needing improvement before the auditors arrive. During the audit itself, expect a comprehensive examination of your practices related to quality management system audits and internal controls; transparency will be your best ally throughout this process.

Conclusion

In the evolving landscape of manufacturing, audits play an essential role in ensuring quality and compliance. As we look to the future, the types of audit in manufacturing industry will continue to adapt to new challenges and technologies. Embracing these changes will be crucial for companies seeking to maintain their competitive edge.

The Future of Audits in Manufacturing

The future of audits in manufacturing is poised for transformation, driven by advancements in technology and data analytics. Companies are increasingly recognizing that a robust quality management system audit can streamline processes and enhance product reliability. This shift means that internal audits may become more integrated with real-time monitoring systems, allowing manufacturers to proactively address issues before they escalate.

Leveraging Technology in Quality Management

Leveraging technology is no longer optional; it's a necessity for effective quality management platforms. By utilizing advanced software tools, manufacturers can create comprehensive audit checklists that ensure all critical components are examined during a quality management system internal audit. Furthermore, technologies like AI and machine learning can analyze data trends, offering insights that inform future audits and improve overall efficiency.

Partnering with Experts like China Inspection Pro

Navigating the complexities of auditor ISO certification requires expertise that many organizations may not possess in-house. Partnering with experts like China Inspection Pro can provide invaluable support throughout this process, ensuring your company quality management system meets international standards. Their experience with various types of audit in manufacturing industry allows them to offer tailored solutions that enhance compliance and drive continuous improvement.