Introduction

In the intricate world of manufacturing, the importance of a material certificate of compliance cannot be overstated. These certificates serve as vital documents that validate that materials used in production meet specific standards and regulations, ensuring quality and safety for consumers. As industries become increasingly regulated, understanding compliance in manufacturing has emerged as an essential aspect for businesses aiming to maintain credibility and operational efficiency.

Importance of Material Certificates

Material certificates of compliance are crucial not only for legal adherence but also for fostering trust between manufacturers and consumers. These documents provide transparency regarding the sourcing and quality of materials, which is particularly significant in sectors like food safety audit companies or consumer products testing. Without these certificates, companies risk potential legal repercussions and damage to their reputation due to non-compliance with industry standards.

Understanding Compliance in Manufacturing

Compliance in manufacturing encompasses a range of practices designed to ensure that products meet established guidelines and regulations. This often involves collaboration with quality control companies that specialize in production quality management, helping organizations navigate complex regulatory landscapes. By prioritizing compliance, manufacturers can enhance their operational processes while minimizing risks associated with product failures or recalls.

Key Players in Quality Control

Quality control monitoring involves various key players who contribute to maintaining high standards throughout the production process. This includes third party inspection agency lists that help identify reliable partners for thorough inspections and audits. Additionally, food safety audit companies play an integral role by setting benchmarks for safety practices, ensuring that all aspects of production align with compliance requirements while safeguarding consumer health.

What is a Material Certificate of Compliance

A Material Certificate of Compliance (MCC) serves as a vital document in the landscape of production quality management. It verifies that materials used in manufacturing meet specified standards and regulations, ensuring safety and reliability. This certificate is not just a formality; it plays a crucial role in guaranteeing that products are made with integrity and adhere to industry norms.

Definition and Purpose

At its core, a material certificate of compliance is an official document issued by manufacturers or suppliers confirming that their products comply with applicable standards or specifications. The purpose of this certificate extends beyond mere paperwork; it provides assurance to all stakeholders involved—from manufacturers to end consumers—that the materials used are safe, reliable, and fit for purpose. In essence, it acts as both a shield against liability and a badge of honor for companies committed to quality.

Importance in Various Industries

The importance of the material certificate of compliance cannot be overstated; it spans multiple industries including construction, automotive, aerospace, and food safety audit companies. In construction, for instance, ensuring that structural materials meet safety standards can mean the difference between life and death—a reality underscored by stringent regulations. Similarly, in consumer products testing, certificates assure consumers that items like toys or electronics are free from harmful substances and manufactured according to safety guidelines.

Legal Implications of Non-Compliance

Failing to obtain or present a valid material certificate of compliance can lead to dire legal implications for businesses across industries. Non-compliance may result in hefty fines, lawsuits from customers or regulatory bodies, and even product recalls—nightmares no company wants to face! Additionally, being on the wrong side of compliance can tarnish reputations built over years and cost businesses valuable consumer trust.

Essential Steps for Obtaining Compliance

Navigating the complex landscape of compliance can be daunting, but breaking it down into essential steps can make the journey smoother. The first step involves meticulous document preparation, followed by collaboration with quality control companies and finally engaging a third party inspection agency list. Each of these steps plays a crucial role in ensuring that you secure your material certificate of compliance efficiently.

Initial Document Preparation

Before diving into the world of compliance, it's vital to gather all necessary documents that demonstrate adherence to industry standards. This includes specifications, test results, and any previous material certificates of compliance that may apply to your products or processes. Proper documentation not only streamlines your path to obtaining compliance but also serves as a foundation for effective production quality management.

In this phase, clarity is key; ensure that every document is accurate and up-to-date. Any discrepancies or missing information can delay the process significantly and might even jeopardize your chances of receiving that all-important material certificate of compliance. Remember, thorough initial document preparation sets the tone for successful collaboration with quality control companies later on.

Collaborating with Quality Control Companies

Once your documents are in order, the next step is to partner with quality control companies that specialize in your industry. These experts bring invaluable insights into production quality management and can help identify potential gaps in compliance before they become issues. Their experience allows them to guide you through the labyrinth of regulations while ensuring that you meet all necessary standards.

Moreover, collaborating with these companies provides an opportunity for ongoing education about best practices in quality control monitoring. They often have established relationships with food safety audit companies and other relevant entities, which can further streamline your path toward securing a material certificate of compliance. By leveraging their expertise, you not only enhance product integrity but also build a reputation for reliability in your market.

Engaging a Third Party Inspection Agency List

Engaging a reputable third party inspection agency list is an essential final step toward achieving compliance certification. These agencies conduct independent assessments to verify that your products meet regulatory requirements and industry standards effectively—think of them as the referees in this game! Their objective evaluations provide an extra layer of assurance for both manufacturers and consumers alike.

When selecting from a third party inspection agency list, consider factors such as their track record, areas of expertise (especially regarding consumer products testing), and client testimonials. This due diligence ensures you choose an agency capable of delivering thorough inspections while aligning with your specific needs regarding production quality management practices. Ultimately, working closely with these agencies will help solidify your standing within the industry by securing those crucial material certificates of compliance.

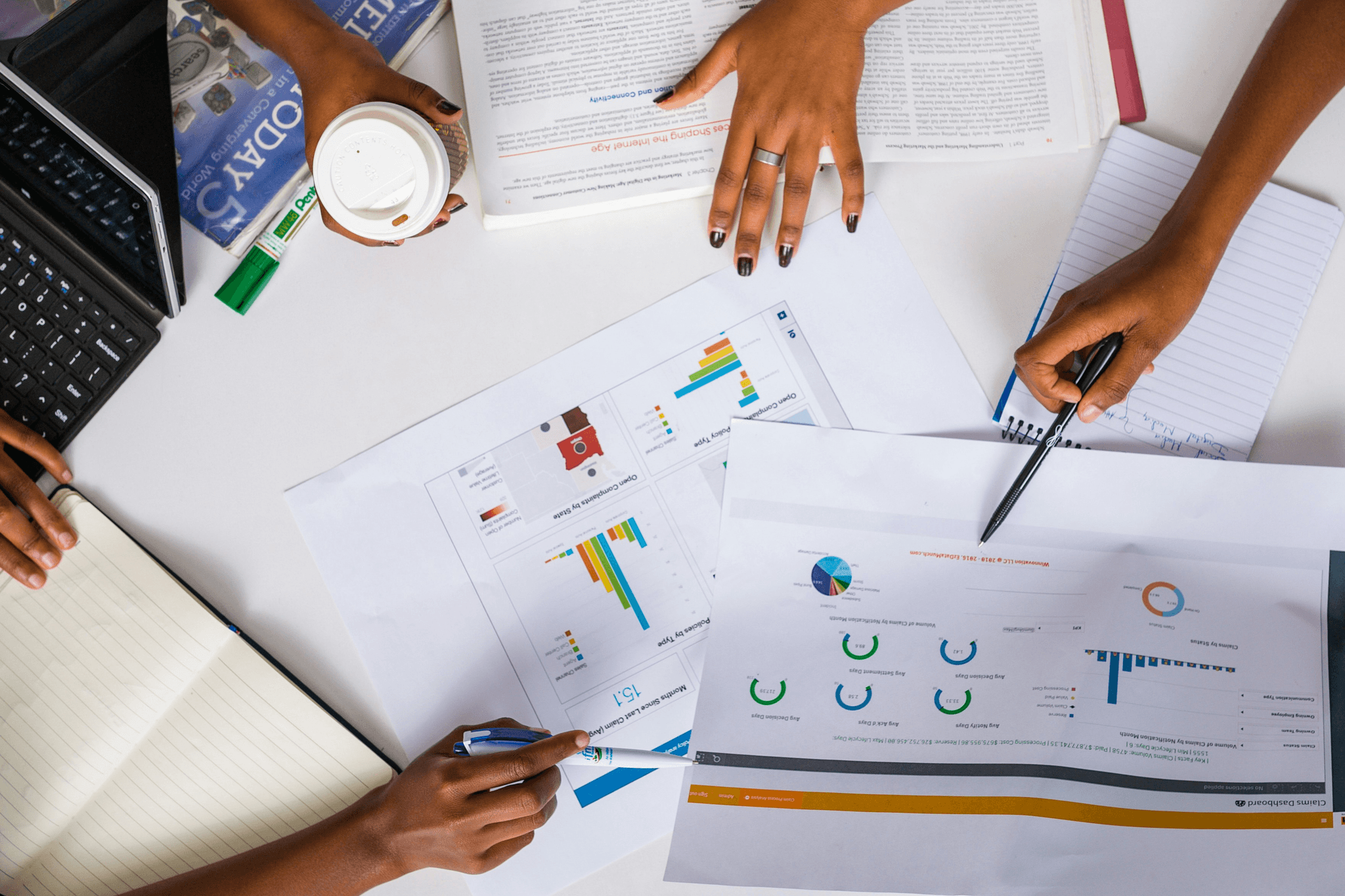

Working with Quality Control Monitoring

In today's manufacturing landscape, effective quality control monitoring is crucial for ensuring compliance and maintaining a competitive edge. By collaborating with the right quality control companies, businesses can navigate the complexities of obtaining a material certificate of compliance more efficiently. This section will guide you through selecting the ideal agency, what to expect during inspections, and the benefits of robust quality control monitoring.

How to Choose the Right Agency

Choosing the right quality control company can feel like finding a needle in a haystack, especially when you consider the plethora of options available. Start by reviewing a comprehensive third party inspection agency list to identify agencies that specialize in your industry and have a solid reputation for delivering reliable services. Look for agencies that not only provide material certificates of compliance but also have experience in production quality management and understand your specific regulatory requirements.

Once you've narrowed down your choices, consider reaching out to potential agencies for consultations. Ask about their methodologies, past client experiences, and how they handle consumer products testing or food safety audits if applicable to your business model. Ultimately, choosing an agency that aligns with your values and understands your needs will lead to smoother inspections and better overall compliance outcomes.

What to Expect During Inspections

When it comes time for an inspection, being prepared can help ease any anxiety associated with this critical phase of quality control monitoring. Inspectors from chosen agencies will review documentation related to material certificates of compliance while also evaluating production processes against established standards. Expect them to assess everything from raw materials used in production to final product testing procedures—ensuring every aspect meets regulatory requirements.

During these inspections, transparency is key; be ready to answer questions about your processes or provide additional documentation as needed. It's also common for inspectors to take samples for further analysis under consumer products testing guidelines or food safety audit requirements if relevant. Remember that these inspections are not just about ticking boxes; they are opportunities for valuable feedback that can enhance your overall production quality management strategy.

Benefits of Quality Control Monitoring

Investing in quality control monitoring yields numerous benefits beyond just obtaining a material certificate of compliance; it fosters trust among consumers and partners alike. Regular inspections by reputable quality control companies help identify potential issues before they escalate into costly problems or product failures—saving both time and resources in the long run. Additionally, consistent adherence to high-quality standards enhances brand reputation while minimizing risks associated with non-compliance.

Moreover, working closely with food safety audit companies or third-party inspection agencies provides an extra layer of assurance regarding product safety and efficacy—especially critical in industries where consumer health is at stake. The insights gained from routine assessments can lead directly to improved practices within production environments as well as heightened awareness among staff regarding compliance protocols. Ultimately, embracing rigorous quality control monitoring sets organizations on a path toward sustainable success.

Role of Food Safety Audit Companies

Food safety audit companies play a pivotal role in ensuring that products meet health and safety standards, which is crucial for compliance across various sectors. These organizations specialize in evaluating the practices of food producers and manufacturers, ensuring that they adhere to regulations that protect consumers. By conducting thorough audits, these companies help businesses secure their material certificate of compliance, which validates their commitment to quality and safety.

Importance of Food Safety in Compliance

The significance of food safety cannot be overstated; it directly impacts public health and consumer trust. Compliance with food safety regulations not only safeguards consumers but also enhances a company's reputation within the industry. When businesses partner with food safety audit companies, they benefit from expert insights into production quality management, ultimately leading to better compliance outcomes and reduced risk of costly recalls.

Key Requirements and Standards

Food safety audit companies operate under stringent requirements and standards set by regulatory bodies such as the FDA or USDA. These guidelines encompass everything from hygiene practices to proper storage conditions, ensuring that all aspects of production are scrutinized for compliance. Adhering to these key requirements is essential for obtaining a material certificate of compliance, which serves as proof that products meet necessary safety benchmarks.

Case Studies of Successful Audits

Several notable case studies illustrate the effectiveness of food safety audits in enhancing compliance and product quality. For instance, one major beverage manufacturer improved its operational processes after engaging a third-party inspection agency list for comprehensive audits, resulting in fewer violations during inspections and an enhanced material certificate of compliance status. Another example involves a snack food producer who revamped its quality control monitoring system after receiving feedback from an audit company, significantly reducing contamination risks while boosting consumer confidence.

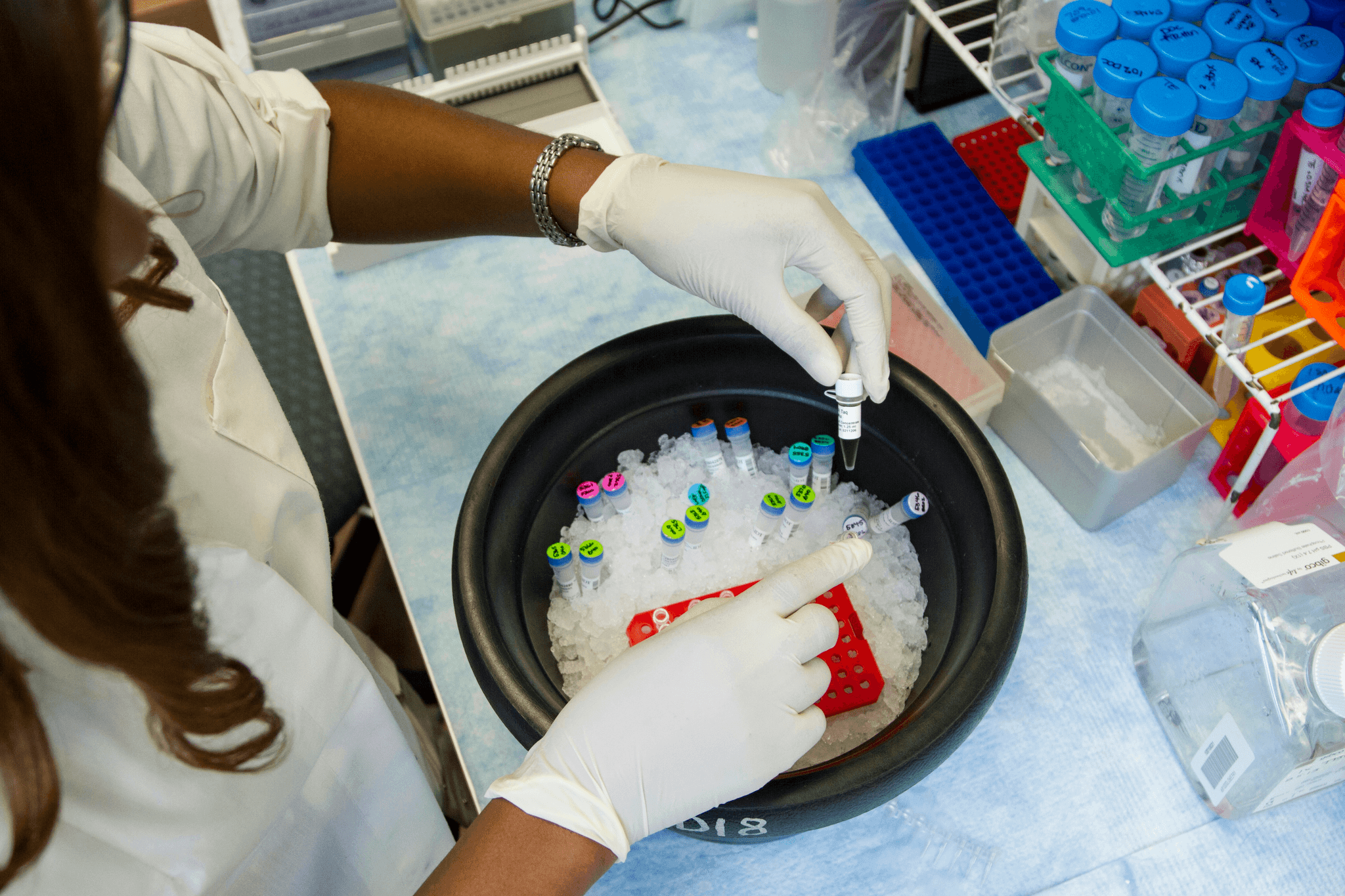

Consumer Products Testing Explained

In the realm of manufacturing, consumer products testing is a crucial step that ensures products meet safety and quality standards before they hit the market. This process involves systematic evaluation of materials and finished goods to confirm their compliance with regulatory requirements. By obtaining a material certificate of compliance, manufacturers can demonstrate that their products have passed rigorous testing, thereby boosting consumer trust and brand reputation.

Overview of Testing Procedures

Consumer products testing typically begins with the identification of relevant standards applicable to the product in question. Quality control companies often provide guidance on these standards, which may vary across industries such as electronics, textiles, and food safety. The testing procedures can include mechanical tests, chemical analyses, and performance evaluations to ensure that every aspect of production quality management aligns with established guidelines.

Once the standards are identified, samples are collected for laboratory analysis or field testing by a third party inspection agency list. These agencies play an essential role in maintaining impartiality throughout the testing process, ensuring that results are credible and unbiased. The outcome of these tests is documented in a material certificate of compliance, which serves as proof that the product meets all necessary regulations.

How Testing Affects Compliance

Testing directly impacts compliance by providing manufacturers with tangible evidence that their products meet safety and quality benchmarks. Without thorough consumer products testing, companies risk releasing items that may not adhere to industry regulations or customer expectations. This could lead to costly recalls or legal repercussions if consumers experience harm due to non-compliant products.

Moreover, successful completion of these tests enhances a company's reputation within its sector while also fostering trust among consumers who rely on certifications like the material certificate of compliance for assurance about product safety. Compliance becomes not just an obligation but a competitive advantage—companies known for rigorous quality control monitoring often stand out in crowded markets where consumers prioritize reliability.

Real-World Examples of Product Failures

A notable example highlighting the importance of consumer products testing occurred when a popular toy manufacturer faced significant backlash after several toys were found to contain hazardous materials due to inadequate inspections during production quality management processes. The absence of proper certification led to widespread recalls and legal challenges against the company—an expensive lesson underscoring how vital it is for businesses to engage reputable quality control companies early on.

Another case involved food safety audit companies discovering harmful bacteria in packaged foods during routine inspections—a scenario that could have been avoided had thorough consumer products testing been conducted prior to distribution. Such incidents remind us how critical it is for manufacturers to prioritize comprehensive testing protocols so they can confidently issue material certificates of compliance without fear of future repercussions.

In conclusion, investing time and resources into effective consumer products testing not only safeguards public health but also strengthens brand integrity within competitive markets where compliance is paramount.

Conclusion

Navigating the compliance process can feel like traversing a maze, especially with the myriad regulations and standards that vary across industries. Understanding the significance of a material certificate of compliance is crucial for businesses aiming to meet legal requirements and maintain high production quality management. By implementing effective strategies, such as engaging quality control companies and utilizing a third-party inspection agency list, organizations can streamline their compliance journey.

Navigating the Compliance Process

The first step in navigating the compliance process is familiarizing yourself with relevant regulations and standards that apply to your industry. This includes understanding how a material certificate of compliance plays a pivotal role in validating product quality and safety. Companies should invest time in preparing initial documents meticulously, ensuring they align with industry standards to facilitate smoother inspections down the line.

Moreover, collaboration with quality control companies can provide invaluable insights into best practices for maintaining compliance throughout production cycles. By leveraging their expertise, businesses can enhance their production quality management systems, minimizing risks associated with non-compliance. Additionally, staying proactive about updates in regulations helps companies adapt quickly and avoid potential pitfalls.

Building Relationships with Key Agencies

Building strong relationships with key agencies is essential for ensuring ongoing compliance and fostering trust within your supply chain. Engaging food safety audit companies early on can help identify gaps in your processes while providing guidance on meeting critical requirements and standards. These partnerships not only enhance credibility but also create opportunities for continuous improvement through shared knowledge.

Moreover, maintaining open lines of communication with third-party inspection agencies fosters transparency during audits and inspections. This rapport allows companies to address issues promptly while demonstrating commitment to high-quality production practices. Ultimately, these relationships contribute significantly to an organization’s reputation as a reliable supplier or manufacturer.

Ensuring Long-Term Quality and Compliance

Ensuring long-term quality and compliance requires an ongoing commitment to monitoring processes effectively through established protocols like consumer products testing. Regular assessments help identify areas needing improvement while ensuring adherence to regulatory requirements over time. Companies should also consider integrating robust quality control monitoring systems that provide real-time data on production processes.

Investing in training staff on best practices related to material certificates of compliance ensures everyone understands their role in maintaining product integrity from start to finish. By fostering a culture centered around quality management principles, organizations position themselves as leaders within their industries while minimizing risks associated with non-compliance issues down the road.

In conclusion, navigating the complex world of compliance doesn’t have to be daunting if approached strategically through collaboration and continuous improvement efforts focused on key areas such as food safety audits and consumer products testing.