Introduction

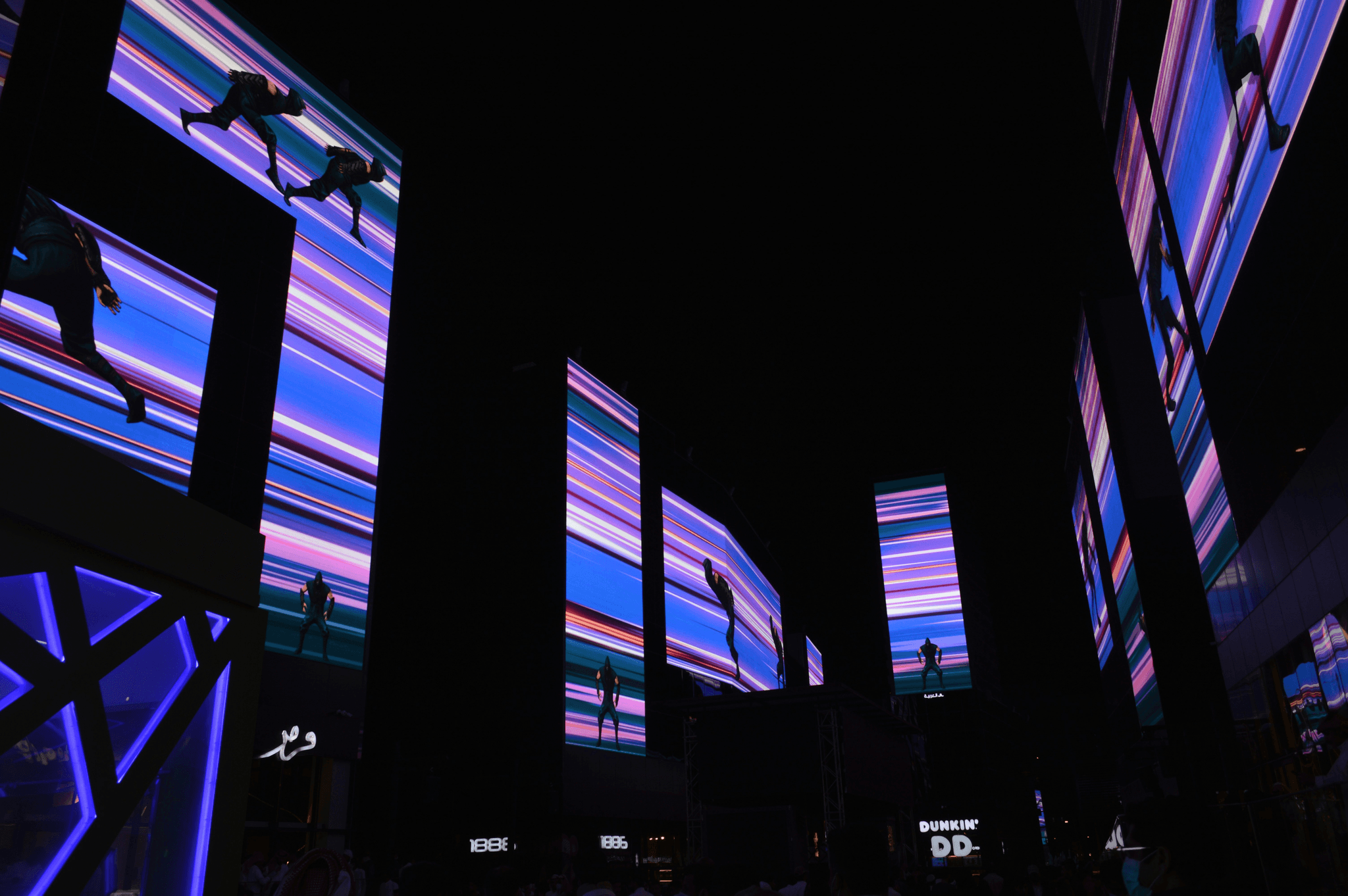

In the fast-evolving world of technology, LED screen inspection has become a vital process to ensure product quality and performance. With the increasing demand for high-definition displays in various applications, from televisions to smartphones, the importance of thorough inspections cannot be overstated. Effective quality control measures are essential to identify defects early and maintain customer satisfaction.

Importance of LED Screen Inspection

LED screen inspection plays a crucial role in guaranteeing that every display meets stringent quality standards before reaching consumers. This process encompasses several stages, including raw material and component inspection, display module inspection, and full-screen assembly inspection. By addressing potential issues at each phase, manufacturers can significantly reduce the risk of defective products entering the market.

Key Phases in Quality Control

Quality control in LED screen production involves multiple key phases that ensure each component is up to par with industry standards. Starting with raw material and component inspection, this phase verifies that all materials meet necessary specifications before assembly begins. Following this are display module inspections that focus on identifying defects within individual modules, ultimately leading to full-screen assembly inspections where functional tests confirm overall performance.

Role of Third-Party Inspections

Third-party inspections serve as an independent check on the quality assurance processes employed by manufacturers during LED screen production. These external evaluations provide an unbiased assessment of compliance with industry standards across all phases—raw material and component inspection, display module inspection, and full-screen assembly inspection. By partnering with reputable third-party inspectors, companies can enhance their credibility while ensuring their products consistently meet customer expectations.

Understanding LED Screen Inspection

When it comes to LED Screen Inspection, the process is essential for ensuring that every display meets the highest standards of quality. It encompasses various stages, including Raw Material and Component Inspection, Display Module Inspection, and Full-Screen Assembly Inspection. Each phase plays a critical role in identifying defects and ensuring that the final product performs optimally.

What is LED Screen Inspection?

LED Screen Inspection refers to a comprehensive evaluation process aimed at assessing the quality of LED displays from start to finish. This inspection includes scrutinizing raw materials, components, modules, and assembled screens to ensure they meet industry standards. By employing systematic checks throughout production, manufacturers can catch issues early on and avoid costly errors later in the assembly process.

Importance of Quality Control in Displays

Quality control in displays is paramount as it directly impacts user experience and product longevity. Poorly inspected displays can lead to issues such as color inconsistencies or screen failures that frustrate users and tarnish brand reputation. By implementing thorough LED Screen Inspections at every stage—from Raw Material and Component Inspection through Display Module Inspection to Full-Screen Assembly Inspection—manufacturers can deliver superior products that stand out in a competitive market.

Common Issues Found During Inspection

During LED Screen Inspections, several common issues may arise that could jeopardize product integrity. These include dead pixels, color discrepancies, brightness variations, and assembly defects like misaligned components or poor soldering connections. Identifying these problems early through rigorous inspections helps manufacturers rectify them before reaching consumers, ultimately enhancing overall satisfaction with their products.

Raw Material and Component Inspection

In the world of LED screen manufacturing, the foundation of quality lies in the raw materials and components used. Effective Raw Material and Component Inspection is crucial for ensuring that every screen meets industry standards and customer expectations. A rigorous inspection process not only identifies potential issues but also enhances overall product reliability.

Sourcing High-Quality Components

Sourcing high-quality components is paramount in achieving superior LED screen performance. Manufacturers must prioritize suppliers who provide durable materials that can withstand the test of time, ensuring longevity in their displays. By focusing on quality during this initial phase, companies set a solid groundwork for subsequent stages like Display Module Inspection and Full-Screen Assembly Inspection.

It's essential to consider factors such as material composition, supplier certifications, and past performance records when sourcing components. This proactive approach minimizes risks associated with low-quality inputs that could lead to defects later on. Ultimately, investing time in sourcing high-quality components pays off by reducing costly rework down the line.

Evaluating Suppliers for Quality Assurance

Evaluating suppliers for quality assurance is a critical step in maintaining high standards throughout the LED screen production process. Manufacturers should develop a comprehensive evaluation framework that includes audits of supplier facilities, reviews of production processes, and assessments of previous product batches. Such thorough evaluations help ensure that only reliable suppliers contribute to Raw Material and Component Inspection.

Additionally, fostering strong relationships with key suppliers can lead to better communication regarding quality expectations and improvements over time. Regularly revisiting these evaluations allows manufacturers to adapt their supply chain strategies based on performance metrics or emerging technologies. In an industry where innovation is constant, having trustworthy suppliers can make all the difference.

Standards for Raw Material Inspection

Establishing clear standards for raw material inspection is vital to ensure consistency across all products manufactured within an organization. These standards should encompass various aspects including material specifications, testing methods, and acceptable tolerances for defects during inspections. By adhering to these guidelines during both Raw Material and Component Inspection phases, manufacturers can significantly reduce variability in their final products.

Moreover, regulatory compliance plays a significant role in shaping these standards; manufacturers must stay abreast of current regulations pertaining to safety and environmental impact related to display technologies. Implementing rigorous testing protocols helps identify any deviations from established norms early on—before they escalate into larger issues during Display Module or Full-Screen Assembly Inspections later in production cycles.

In conclusion, focusing on high-quality component sourcing, thorough supplier evaluations, and strict adherence to inspection standards lays a robust foundation for successful LED screen manufacturing processes.

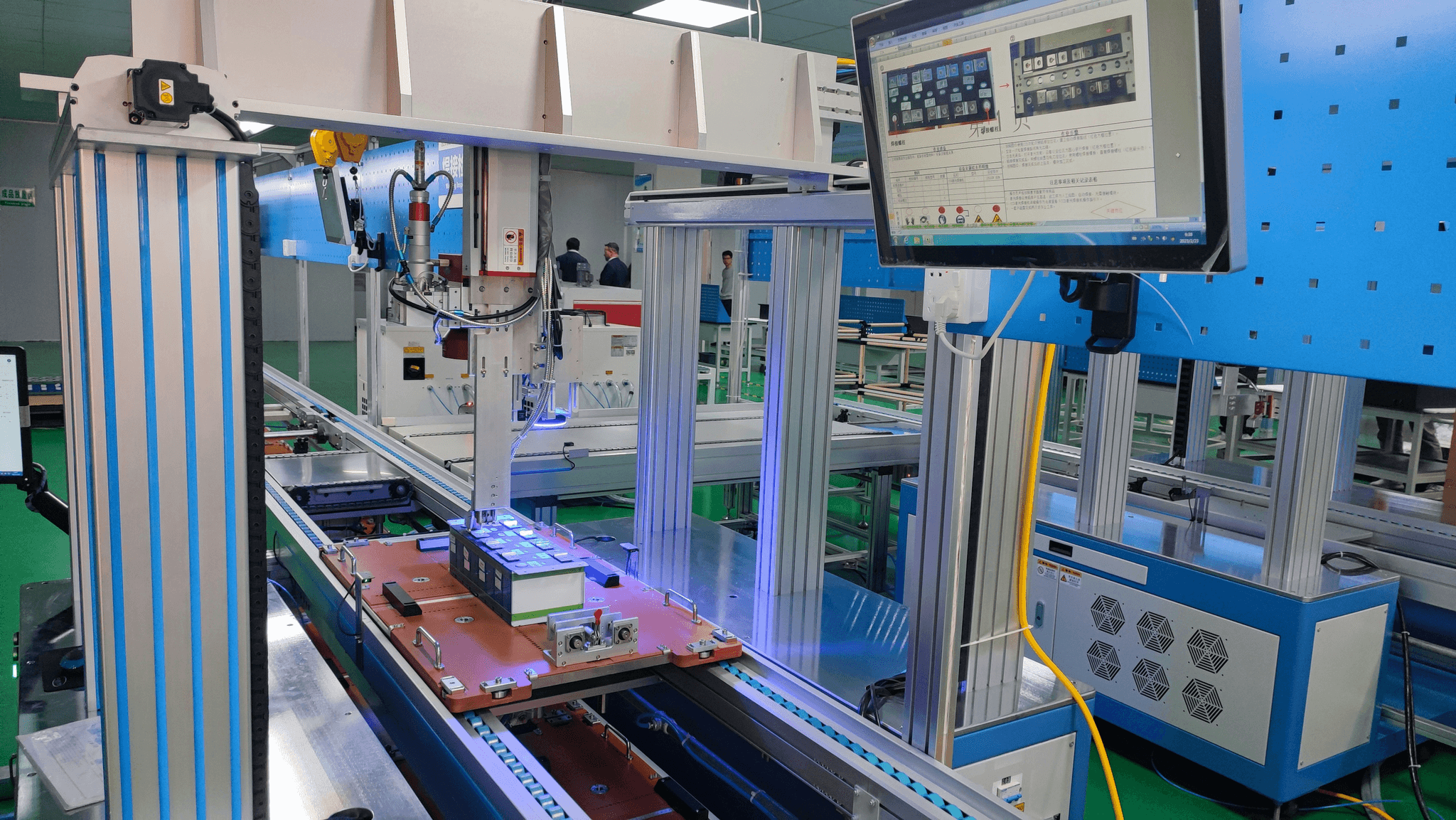

Display Module Inspection

In the world of LED screens, display module inspection is a critical phase that ensures the quality and performance of the final product. This process goes beyond mere aesthetics; it involves rigorous checks to confirm that each module meets industry standards before moving on to full-screen assembly inspection. By focusing on this stage, manufacturers can catch potential issues early, saving time and resources down the line.

Techniques for Inspecting Display Modules

When it comes to LED screen inspection, various techniques are employed to thoroughly examine display modules. Visual inspections are often the first line of defense against defects, allowing inspectors to spot any irregularities in manufacturing or assembly. Alongside visual checks, more advanced methods such as automated optical inspection (AOI) and functional testing come into play, ensuring that every aspect of the module performs as intended.

These techniques not only help identify visible flaws but also assess functionality under different conditions. For instance, during functional testing, modules may be subjected to varying brightness levels and color displays to ensure they operate correctly across a range of scenarios. Such comprehensive evaluations are essential for maintaining high standards in raw material and component inspection.

Identifying Defects in Modules

Identifying defects in display modules is crucial for effective LED screen inspection. Common issues include dead pixels, color inconsistencies, and uneven brightness distribution—each capable of compromising user experience significantly. By implementing systematic checking protocols during display module inspection, manufacturers can pinpoint these defects early on.

Moreover, employing specialized tools like thermal cameras can assist in detecting overheating components or solder joint failures that may not be visible to the naked eye. The goal is not just to find faults but also to understand their root causes so that corrective measures can be taken before proceeding with full-screen assembly inspection. This proactive approach ensures a higher quality end product.

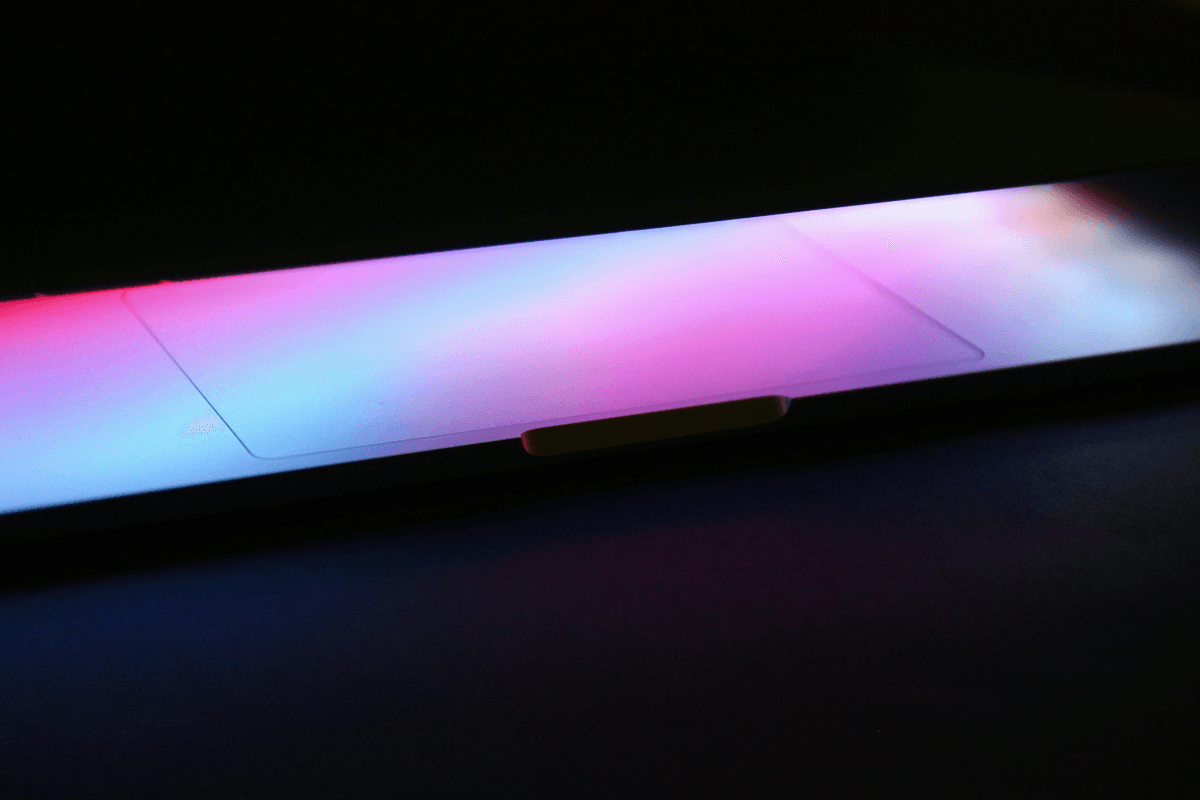

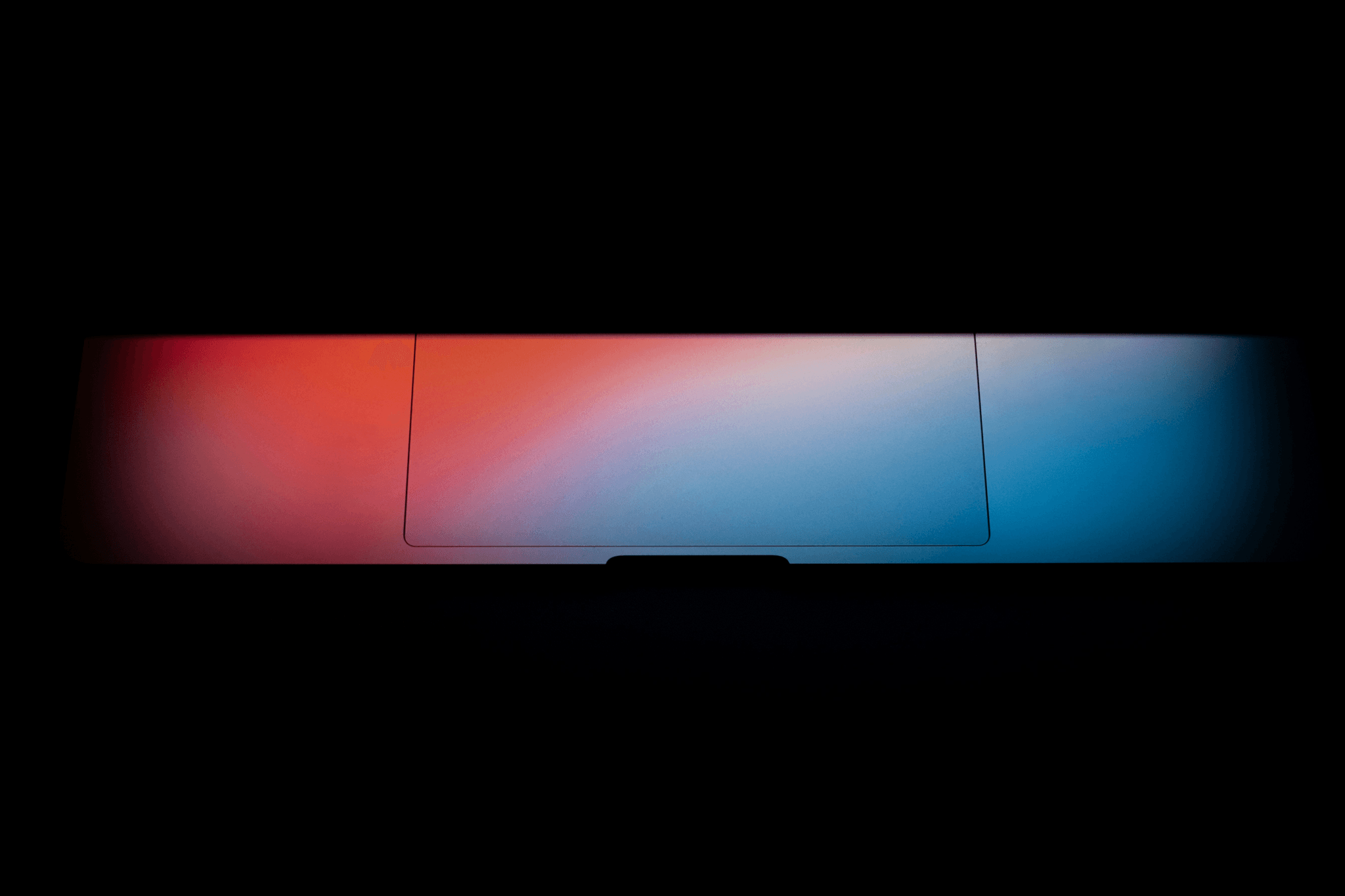

Ensuring Color Accuracy and Brightness

Ensuring color accuracy and brightness is paramount during display module inspection because these factors directly influence viewer experience with LED screens. Calibration tools are often used during this phase to adjust colors so they match specified standards precisely—think vibrant reds and deep blues that pop! If discrepancies are found during testing, adjustments can be made before any further assembly takes place.

Brightness testing also plays an essential role; inspectors measure luminance levels under various lighting conditions to guarantee optimal visibility regardless of where the screen will be used—be it indoors or outdoors. This attention to detail helps prevent issues related to poor visibility later on when users rely on these displays for critical information or entertainment purposes. Ultimately, thorough inspections at this stage pave the way for successful full-screen assembly inspections.

Full-Screen Assembly Inspection

When it comes to LED Screen Inspection, the full-screen assembly stage is critical for ensuring that all components work harmoniously together. This phase encompasses a series of quality checks that scrutinize not only the physical assembly but also the functionality of the entire screen. A meticulous approach during this inspection can help identify potential issues before they escalate into costly problems.

Process of Full-Screen Assembly Quality Checks

The process begins with a thorough visual inspection, where technicians assess the overall appearance and alignment of components in the assembled LED screen. Following this, various tests are conducted to verify that each part is securely attached and functioning as intended. This includes checking for proper electrical connections and ensuring that all display elements are correctly positioned to achieve optimal performance.

In addition to visual checks, specialized equipment may be employed to measure color accuracy and brightness levels across different sections of the screen. This ensures that any discrepancies are caught early on, preventing them from affecting the end-user experience. By integrating these steps into the LED Screen Inspection process, manufacturers can uphold high standards in their final products.

Common Assembly Defects and How to Spot Them

During Full-Screen Assembly Inspection, several common defects can arise that need immediate attention. For instance, misalignment of display modules may lead to uneven brightness or color inconsistencies across the screen surface—an issue easily identifiable by a simple visual check or through automated testing equipment. Additionally, loose connections can cause flickering or complete failure of sections within the display.

Another defect often encountered is dust or debris trapped between layers during assembly, which can detract from image clarity and overall aesthetic appeal. Regular training for assembly staff on these issues enhances their ability to spot defects quickly and efficiently during Raw Material and Component Inspection as well as Display Module Inspection phases. Keeping an eye out for these common pitfalls helps maintain product integrity throughout manufacturing.

Importance of Functional Testing

Functional testing plays an indispensable role in Full-Screen Assembly Inspection by ensuring that every aspect of the LED screen operates flawlessly before it reaches consumers' hands. This process involves simulating real-world usage scenarios to confirm performance under various conditions—be it brightness adjustments or response times during video playback. Skipping this step could result in significant customer dissatisfaction if screens fail post-purchase due to undetected issues.

Moreover, functional testing provides valuable data that manufacturers can use for continuous improvement in their production processes—highlighting areas where Raw Material and Component Inspection or Display Module Inspection might need enhancement based on recurring defects encountered during assembly checks. Ultimately, investing time in thorough functional testing not only safeguards brand reputation but also enhances customer satisfaction through superior product quality.

Selecting a Reliable Inspection Partner

In the world of LED screen manufacturing, choosing the right inspection partner can make all the difference between a flawless product and a costly failure. With the increasing complexity of displays, from Raw Material and Component Inspection to Full-Screen Assembly Inspection, having an experienced ally ensures that quality is not just a checkbox but a fundamental aspect of production. This choice impacts everything from supplier relationships to customer satisfaction, making it crucial to select wisely.

Why Choose China Inspection Pro?

China Inspection Pro stands out as a leader in the field of LED Screen Inspection due to its extensive experience and commitment to quality assurance. Their team is well-versed in all aspects of display technology, including Raw Material and Component Inspection and Display Module Inspection, ensuring that every stage of production meets rigorous standards. Plus, their localized presence in China provides manufacturers with valuable insights into regional suppliers and market trends.

Benefits of Third-Party Inspections

Engaging third-party inspections brings several advantages that can significantly enhance your production process. These inspections provide an unbiased assessment during critical phases like Full-Screen Assembly Inspection, helping identify defects that internal teams might overlook due to familiarity or bias. Additionally, leveraging third-party expertise not only boosts your credibility but also fosters trust with clients who demand high-quality products backed by thorough scrutiny.

How to Evaluate Inspection Services

First off, look for providers with proven experience in Raw Material and Component Inspection as well as Display Module Inspection—this indicates they understand the nuances of each phase effectively. Moreover, consider their certification credentials and client testimonials; these can offer insights into their reliability and service quality while ensuring they meet industry standards.

Conclusion

In wrapping up our exploration of LED Screen Inspection, it's clear that the quality assurance process is vital for producing top-notch displays. From Raw Material and Component Inspection to Full-Screen Assembly Inspection, each phase plays a crucial role in ensuring the final product meets industry standards. By adhering to best practices and embracing continuous improvement, manufacturers can enhance their reputation and deliver exceptional products.

Best Practices for Effective Inspections

To ensure effective inspections, it’s essential to establish clear protocols at each stage of the LED Screen Inspection process. Regular training sessions for inspection teams can help them stay updated on the latest techniques in Display Module Inspection and common defect identification methods. Additionally, implementing a robust documentation system allows for tracking issues over time, fostering an environment of accountability and excellence.

Continuous Improvement in Quality Control

Quality control is not a one-time effort; it requires ongoing commitment and adaptation to new challenges in LED Screen Inspection. Manufacturers should continuously analyze inspection data to identify trends or recurring problems during Raw Material and Component Inspection or Full-Screen Assembly Inspection phases. By fostering a culture of feedback and innovation, companies can refine their processes, ultimately leading to superior product quality.

The Future of LED Screen Manufacturing

The future of LED screen manufacturing looks bright—pun intended! With advancements in technology, we can expect more sophisticated methods for Display Module Inspection that leverage AI and machine learning for quicker defect detection. As manufacturers prioritize sustainability alongside quality through improved Raw Material and Component Inspections, we may see a shift toward eco-friendly materials while maintaining high performance standards.