Introduction

In the world of imported footwear, the significance of quality inspection cannot be overstated. Quality Inspection for Imported Footwear is a critical process that ensures products meet stringent standards before they reach consumers. With the ever-increasing demand for high-quality footwear, understanding how quality assurance plays a pivotal role in maintaining brand reputation is essential for any business aiming to thrive in this competitive market.

Understanding Quality Inspection for Imported Footwear

Quality inspection serves as the backbone of the footwear industry, particularly when it comes to imported goods. It involves meticulous evaluation processes that assess various aspects of footwear, including materials, construction, and overall performance. By implementing effective quality testing services, businesses can identify potential issues early on and address them before products hit store shelves.

The Importance of Quality Assurance in Footwear

Quality assurance is not just a buzzword; it's an integral part of ensuring customer satisfaction and brand loyalty. In an industry where consumer expectations are higher than ever, brands must prioritize quality control to avoid costly recalls and negative reviews. A robust quality management system helps companies maintain consistency and reliability in their offerings while also adapting to changing market demands.

How Quality Control Impacts Your Brand

The impact of quality control on your brand can be profound—both positively and negatively. High-quality products build trust with consumers, leading to repeat purchases and word-of-mouth recommendations that fuel growth. Conversely, lapses in quality can tarnish a brand's reputation almost overnight; thus, investing in thorough quality inspection processes is not just wise but essential for long-term success.

Why Quality Inspection Matters

Quality inspection is a crucial element in the footwear industry, particularly for imported products. The stakes are high when it comes to quality assurance; subpar footwear can lead to serious implications for brands and consumers alike. By investing in quality control measures, companies not only protect their reputation but also ensure customer satisfaction and loyalty.

The Risks of Poor Quality in Footwear

The risks associated with poor quality in footwear can be severe, ranging from financial losses to reputational damage. Defective products may lead to injury or discomfort for consumers, resulting in costly recalls and legal ramifications that no brand wants to face. Moreover, poor quality often translates into negative reviews and diminished market presence, making it essential for businesses to prioritize effective quality testing services throughout the production process.

Consumer Expectations and Market Demand

In today’s competitive landscape, consumer expectations have never been higher. Shoppers demand not only stylish designs but also durability and comfort from their footwear choices; anything less can drive them straight into competitors' arms. Meeting these market demands requires a robust approach to quality assurance that encompasses every stage of production—from material selection to final inspection—ensuring that customers receive nothing short of excellence.

Regulatory Standards in the Footwear Industry

Navigating regulatory standards is another critical aspect of maintaining high-quality footwear products. Compliance with safety regulations is non-negotiable; failure to adhere can result in hefty fines or even a ban on selling certain items altogether. Implementing rigorous quality management practices helps brands stay ahead of these requirements while fostering trust with consumers who expect safe, reliable products that meet industry benchmarks.

Key Steps in Quality Control

Quality control is a multi-faceted process that ensures the integrity of imported footwear from start to finish. By implementing a structured approach to quality inspection for imported footwear, brands can safeguard their reputation and deliver products that meet consumer expectations. This section delves into the essential steps of quality assurance, highlighting how each phase contributes to overall product excellence.

Pre-Production Quality Assurance

Pre-production quality assurance is the foundational step in establishing high standards for imported footwear. It involves assessing materials, components, and manufacturing processes before production begins. By conducting thorough inspections during this phase, companies can identify potential issues early on, ensuring that only the best materials are used and that designs align with quality management goals.

During this stage, it’s crucial to collaborate closely with suppliers to set clear quality expectations and standards. This proactive approach not only mitigates risks but also fosters stronger relationships between brands and manufacturers. With effective pre-production quality testing services in place, businesses can confidently move forward knowing they have laid a solid groundwork for success.

In-Production Quality Testing Services

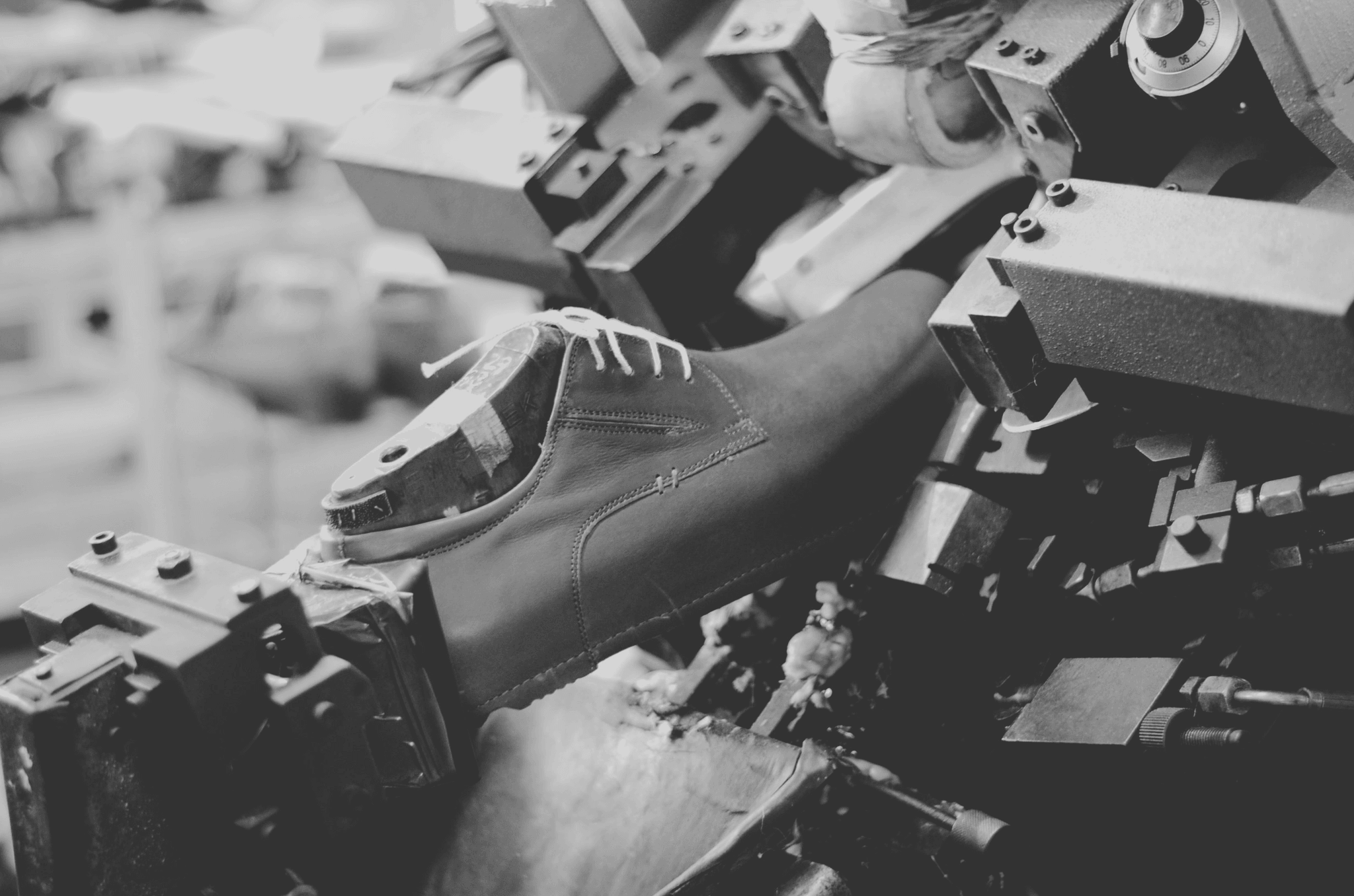

Once production commences, in-production quality testing services become vital for maintaining high-quality standards throughout the manufacturing process. Regular inspections during this phase allow brands to monitor compliance with established guidelines and quickly address any deviations from expected norms. This real-time oversight helps prevent minor issues from escalating into major problems that could jeopardize product integrity.

Implementing rigorous quality control measures during production also enables manufacturers to fine-tune their processes dynamically. By utilizing advanced methodologies and technologies for quality inspection, teams can gather data that informs adjustments on-the-fly—ensuring consistency across batches of footwear. The result? A streamlined production process where every pair meets or exceeds consumer expectations.

Post-Production Inspection and Feedback

Post-production inspection is the final checkpoint before products reach consumers—a critical step in ensuring that all aspects of quality assurance have been met successfully. At this stage, comprehensive evaluations are conducted on finished goods to assess durability, comfort, aesthetic appeal, and overall compliance with regulatory standards in the footwear industry. This thorough examination not only guarantees product excellence but also provides valuable insights into areas for improvement.

Feedback gathered from post-production inspections plays an essential role in shaping future production runs as well as enhancing supplier relationships through transparent communication about performance metrics. By addressing any shortcomings identified during these evaluations promptly, brands can continuously refine their offerings while reinforcing their commitment to quality control practices. Ultimately, robust post-production inspection processes help elevate brand reputation by consistently delivering exceptional products.

Essential Metrics for Quality Testing

When it comes to Quality Inspection for Imported Footwear, establishing essential metrics is crucial for ensuring the highest standards of quality assurance. These metrics not only help in maintaining consistency but also play a significant role in enhancing brand reputation and consumer trust. By focusing on key areas such as durability, comfort, and aesthetic appeal, businesses can implement effective quality control measures that resonate with market demands.

Defining Quality Standards in Footwear

Quality standards serve as the benchmark for evaluating footwear products throughout the quality testing services process. These standards encompass various aspects, including material specifications, manufacturing processes, and performance attributes that align with consumer expectations. Establishing clear quality and assurance benchmarks not only helps manufacturers meet regulatory requirements but also fosters a culture of excellence within the organization.

To define these quality standards effectively, it’s vital to consider industry best practices alongside customer feedback. This collaborative approach ensures that the defined metrics are relevant and achievable while promoting continuous improvement in overall product quality. Ultimately, a well-defined set of quality standards leads to enhanced customer satisfaction and loyalty.

Measuring Durability and Comfort

Durability is one of the primary metrics used in quality inspection to assess how well footwear can withstand wear and tear over time. Testing methods such as abrasion resistance tests or flexing tests provide valuable insights into a product's longevity under various conditions. On the other hand, comfort measurements often involve evaluating factors like cushioning support and fit—elements that significantly influence consumer purchasing decisions.

Quality management systems play an integral role here by systematically tracking durability performance across different batches of footwear. By implementing rigorous testing protocols during production phases, brands can identify potential issues early on and make necessary adjustments before products hit the market. This proactive approach ultimately contributes to improved comfort levels while ensuring compliance with established durability benchmarks.

Evaluating Aesthetic Quality and Design

Aesthetic appeal is another critical metric that influences consumers' perceptions of footwear brands—often more than one might expect! Evaluating design elements such as color accuracy, stitching precision, and overall finish requires meticulous attention during the quality inspection process. Ensuring these aesthetic qualities meet predefined standards not only enhances brand image but also reinforces customer loyalty through visual appeal.

Moreover, incorporating consumer feedback into design evaluations can provide invaluable insights into what resonates with target audiences—allowing brands to adapt their offerings accordingly. This alignment between aesthetics and performance creates a holistic approach towards product development that prioritizes both functionality and style within every pair of shoes produced through effective quality control measures.

The Role of Quality Management Systems

Quality Management Systems (QMS) are essential in establishing a consistent framework for quality inspection for imported footwear. They ensure that every stage of production adheres to established quality assurance protocols, ultimately enhancing product reliability and brand reputation. By integrating QMS into your footwear production process, you can foster a culture of quality control that permeates every level of your organization.

Implementing Effective Quality Management Practices

To implement effective quality management practices, it is crucial to develop clear policies and procedures that define quality standards across all operations. This includes training staff on the importance of quality assurance and how their roles contribute to overall product excellence. Regular audits and assessments can help identify areas for improvement, ensuring that your quality testing services remain robust and effective.

A well-structured QMS not only aligns with regulatory requirements but also meets consumer expectations in the competitive footwear market. By documenting processes and maintaining transparency, brands can build trust with stakeholders while minimizing risks associated with poor-quality products. Ultimately, these practices create a solid foundation for long-term success in the footwear industry.

Continuous Improvement Strategies in Footwear Production

Continuous improvement is at the heart of any successful QMS; it involves regularly evaluating processes to enhance efficiency and effectiveness in producing high-quality footwear. Techniques such as Plan-Do-Check-Act (PDCA) cycles allow companies to systematically test changes, measure outcomes, and refine practices based on data-driven insights. This iterative approach ensures that quality control remains dynamic and responsive to evolving market demands.

Moreover, fostering an organizational culture that encourages feedback from employees at all levels can lead to innovative solutions for enhancing product quality. Engaging team members in discussions about potential improvements not only boosts morale but also empowers them to take ownership of their contributions toward achieving excellence in quality inspection. These strategies ultimately lead to better products that satisfy both consumer desires and regulatory standards.

The Impact of Technology on Quality Control

Technology plays a transformative role in modernizing quality management systems within the footwear industry by streamlining processes and improving accuracy in inspections. Advanced tools such as automated testing equipment, data analytics software, and real-time monitoring systems can greatly enhance the effectiveness of your quality testing services. These innovations allow brands like China Inspection Pro to deliver professional services focused on product excellence more efficiently than ever before.

Furthermore, technology enables better traceability throughout the supply chain—an essential aspect when conducting thorough quality inspections for imported footwear. With enhanced visibility into each step of production, companies can quickly identify issues or bottlenecks that may compromise product integrity or compliance with industry standards. By leveraging technology effectively within your QMS framework, you position your brand favorably against competitors while elevating overall customer satisfaction.

Choosing the Right Quality Inspection Partner

Selecting the right quality inspection partner is crucial for ensuring that your imported footwear meets the highest standards of quality assurance. With a multitude of options available, businesses must focus on partners who not only understand the intricacies of quality control but also possess a proven track record in quality testing services. By collaborating with a reliable inspection partner, you can enhance your brand’s reputation and ensure that your products resonate with consumer expectations.

Why China Inspection Pro Stands Out

China Inspection Pro distinguishes itself as a leader in quality inspection for imported footwear through its commitment to excellence and thoroughness. Our specialists rigorously examine every detail, ensuring that your products meet or exceed industry standards while offering actionable insights for continuous improvement. With deep experience and advanced methodologies, we navigate complex challenges to help you satisfy both market expectations and regulatory requirements.

Evaluating Inspection Services and Credentials

When evaluating potential inspection services, it’s essential to scrutinize their credentials and expertise in quality management practices relevant to footwear production. Look for partners with certifications from recognized bodies and those who have successfully worked with brands similar to yours. Additionally, consider their approach to quality testing services; do they offer comprehensive pre-production assessments, in-production checks, and post-production evaluations?

Building a Long-Term Partnership for Success

Building a long-term partnership with an inspection provider like China Inspection Pro can significantly elevate your brand's standing in the competitive footwear market. A successful collaboration fosters open communication channels where feedback flows freely, allowing both parties to adapt strategies based on real-time data from quality inspections. This synergy not only enhances product excellence but also cultivates trust between your business and consumers through consistent delivery of high-quality footwear.

Conclusion

In the competitive landscape of the footwear industry, ensuring product excellence through inspection is not just a luxury; it’s a necessity. Quality Inspection for Imported Footwear serves as the backbone of quality assurance, allowing brands to maintain high standards and meet consumer expectations. By implementing robust quality control measures, businesses can significantly reduce risks associated with poor-quality products and enhance their market reputation.

Ensuring Product Excellence Through Inspection

Quality inspection plays a pivotal role in achieving product excellence by meticulously evaluating each stage of production. With services like those offered by China Inspection Pro, brands can ensure that their imported footwear adheres to stringent quality management practices. This rigorous approach not only identifies defects but also provides actionable insights that lead to continuous improvement and superior product offerings.

The Benefits of Rigorous Quality Testing

The benefits of rigorous quality testing extend far beyond mere compliance; they encompass customer satisfaction and brand loyalty as well. When consumers receive high-quality footwear that meets their expectations, they are more likely to return for repeat purchases and recommend the brand to others. Moreover, consistent quality assurance fosters trust in your brand, which is crucial in today’s discerning market where consumers demand transparency and reliability.

Elevating Your Brand with Quality Assurance

Elevating your brand with quality assurance is about more than just meeting standards; it’s about exceeding them and setting benchmarks within the industry. By investing in comprehensive quality testing services, brands can distinguish themselves from competitors who may overlook these critical processes. Ultimately, a commitment to quality inspection not only enhances product performance but also solidifies your brand's reputation as a leader in the footwear market.