Introduction

In the fast-paced world of manufacturing, ensuring product quality is paramount. This is where initial production inspections come into play, serving as a crucial step in the quality assurance process. These inspections not only help identify potential defects early but also set the stage for consistent quality control throughout production.

Importance of Initial Production Checks

Initial production checks are vital for maintaining high standards in product quality and reliability. By catching issues before they escalate, companies can save time and resources while avoiding costly recalls or customer dissatisfaction down the line. Furthermore, these checks foster a culture of accountability and transparency within manufacturing processes, ultimately enhancing trust between manufacturers and consumers.

Key Benefits of Initial Production Inspections

The benefits of initial production inspections extend beyond mere compliance with regulations; they significantly enhance overall operational efficiency. For instance, identifying defects early allows manufacturers to rectify problems swiftly, reducing waste and downtime. Additionally, these inspections provide valuable insights that can inform future quality control measures and improve overall product design.

How Initial Production Inspections Work

Initial production inspections typically involve a thorough examination of materials and processes at the beginning stages of production. A qualified quality control inspector assesses various aspects such as workmanship, material specifications, and adherence to safety standards during these inspections. The findings from these evaluations are then used to implement necessary adjustments in real-time, ensuring that products meet both regulatory requirements and customer expectations.

Understanding Initial Production Inspections

When diving into the world of manufacturing and production, understanding initial production inspections is crucial for maintaining quality assurance and ensuring that products meet industry standards. These inspections serve as a proactive approach to identify potential issues before mass production begins, thus safeguarding the integrity of the final product. By implementing thorough quality control measures, businesses can enhance their reputation and customer satisfaction.

Definition and Purpose

Initial production inspection (IPI) refers to a systematic evaluation conducted early in the manufacturing process to assess whether products meet specified quality standards and requirements. The primary purpose of an IPI is to detect defects or non-conformance issues before they escalate, allowing for timely rectifications that save time and money. Essentially, it acts as a safety net that ensures quality assurance throughout the production lifecycle.

Common Industries Requiring Inspections

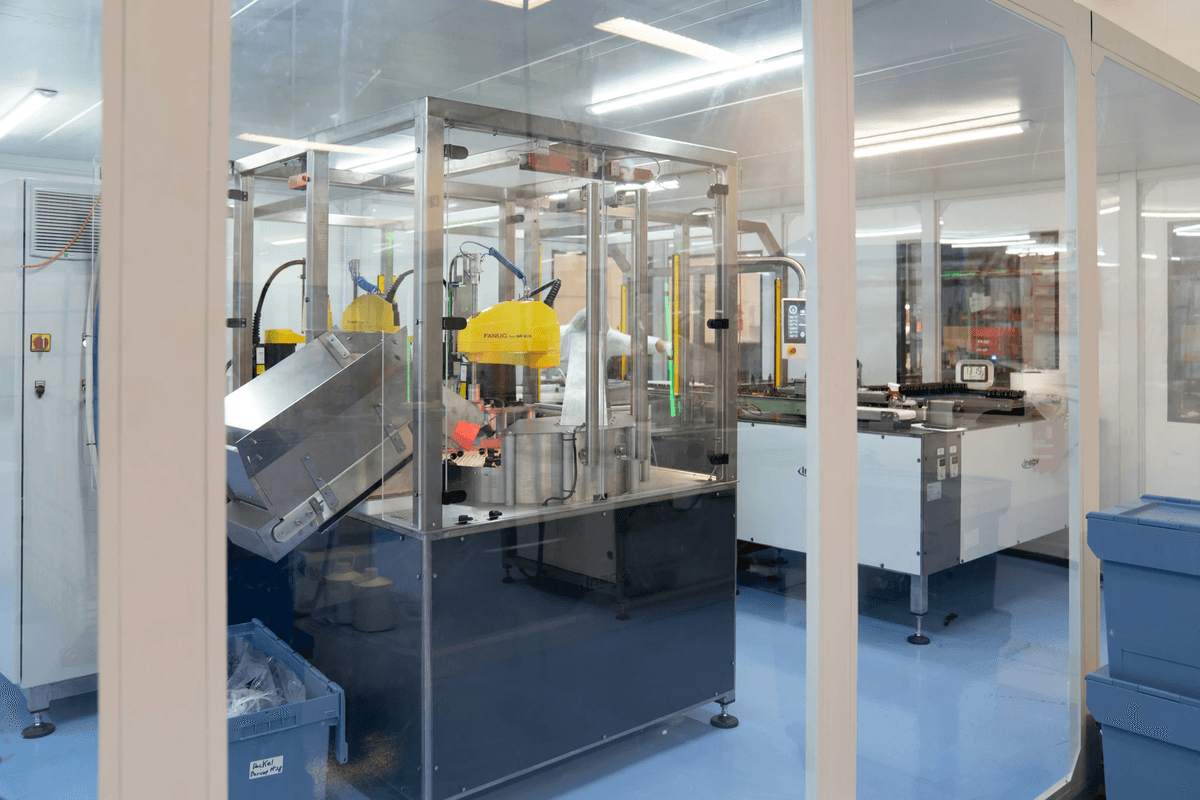

Several industries rely heavily on initial production inspections to maintain high-quality standards, including textiles, electronics, automotive, and consumer goods. In these sectors, where precision and compliance with regulatory standards are paramount, quality inspection becomes non-negotiable. Companies in these industries often engage specialized inspection services to ensure their products not only meet market expectations but also adhere to safety regulations.

Role of Quality Control

Quality control plays an indispensable role in the landscape of initial production inspections by providing structured methodologies for evaluating product integrity. Quality control inspectors utilize various techniques and tools during inspections to identify defects or deviations from established specifications effectively. By integrating both quality control and quality assurance practices within their processes, businesses can cultivate a culture of continuous improvement that enhances overall product reliability.

The Process of Initial Production Checks

When it comes to ensuring product quality, the process of initial production checks is a critical step that cannot be overlooked. This systematic approach not only helps in identifying potential issues early on but also fosters a culture of quality assurance throughout the production cycle. Understanding how these checks work can significantly enhance your overall quality control strategy.

Step-by-Step Guide

The initial production inspection typically begins with a thorough review of the production line and materials being used. A quality control inspector will assess samples from the first batch to ensure they meet specified standards and requirements. Following this, detailed observations are documented, including any deviations from expected quality levels, which helps in formulating actionable insights for improvement.

Next, the inspector evaluates various aspects such as dimensions, functionality, and aesthetics to ensure compliance with predetermined specifications. If any non-conformance is detected during this stage, immediate corrective actions can be recommended to prevent further issues down the line. Finally, a comprehensive report summarizing findings and recommendations is generated to keep all stakeholders informed and engaged in maintaining high standards.

Essential Tools and Resources

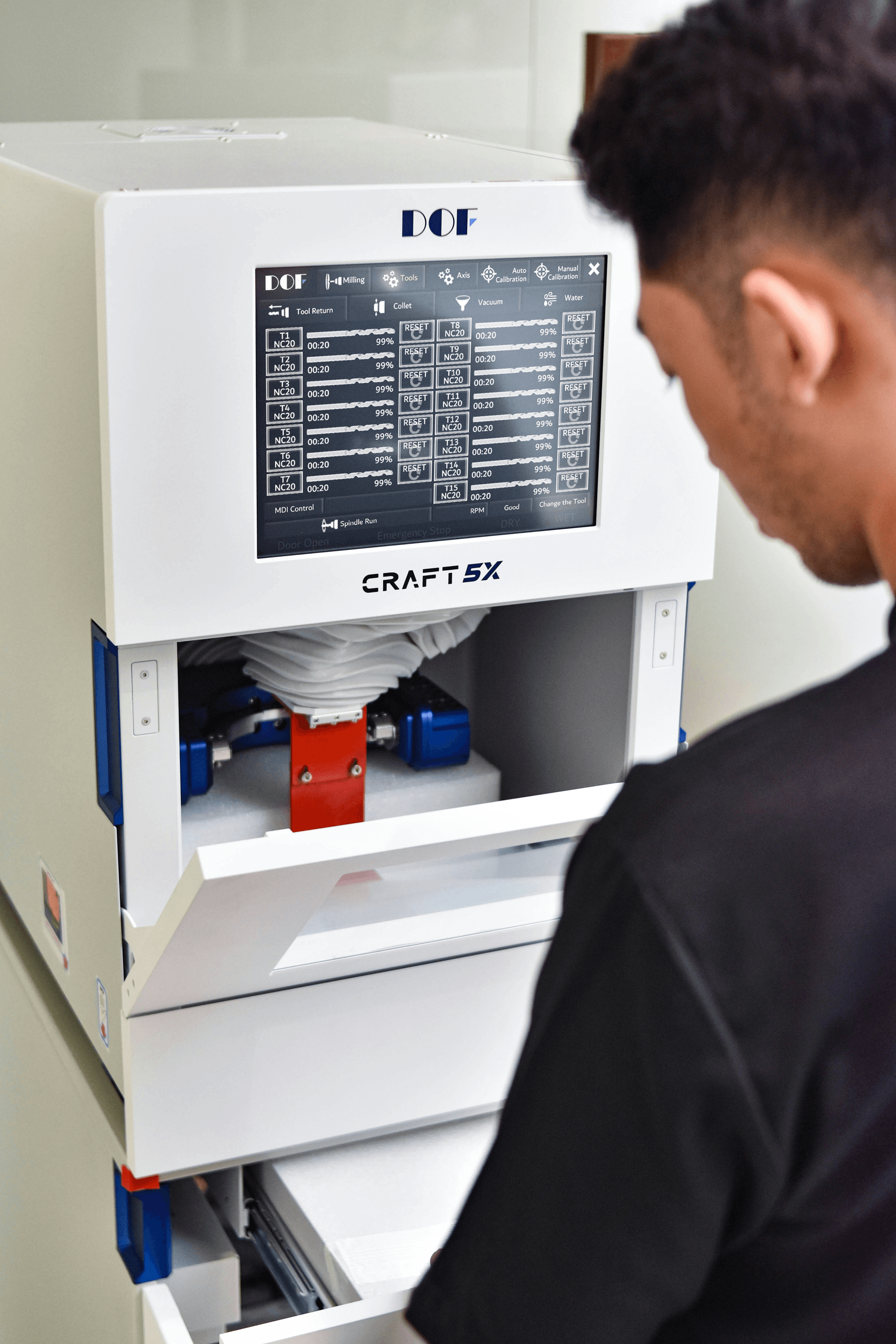

To conduct an effective initial production inspection, several essential tools and resources are required to facilitate accurate assessments. Commonly used instruments include calipers for measuring dimensions, gauges for checking tolerances, and visual aids for evaluating surface finishes or color consistency. Additionally, software solutions that streamline data collection and analysis can significantly enhance reporting accuracy.

Having access to industry-specific standards or guidelines is also crucial for a successful inspection process; these benchmarks help guide the quality control inspector in evaluating compliance effectively. Furthermore, training resources for inspectors ensure they are well-versed in current best practices within quality assurance inspections. By equipping your team with these tools and knowledge bases, you set up a robust framework for ongoing quality control.

Timing and Frequency of Inspections

Timing plays an integral role in the effectiveness of initial production inspections; conducting them too late may lead to costly rework or product recalls down the road. Ideally, inspections should occur at multiple stages throughout the manufacturing process—beginning at pre-production meetings where material specifications are discussed right through to final product evaluations before shipping. This proactive approach allows manufacturers to catch defects early while reinforcing a culture of continuous improvement within their operations.

Frequency is equally important; regular inspections can help maintain consistent product quality while minimizing risks associated with supply chain discrepancies or regulatory non-compliance issues that may arise during production runs. Establishing a clear schedule based on factors such as batch size or complexity helps ensure that each inspection aligns with overall project timelines without causing unnecessary delays or disruptions in workflow.

In summary, understanding the process behind initial production checks—from step-by-step execution through essential tools—can empower companies to achieve higher levels of quality assurance across their operations while mitigating risks associated with poor-quality products.

Choosing a Reliable Inspection Service

Finding the right inspection service can feel like searching for a needle in a haystack, especially when it comes to initial production inspections. With so many options available, it's crucial to know what to look for in a provider that will ensure quality assurance and effective quality control. A reliable inspection service can make all the difference in maintaining high standards and preventing costly mistakes down the line.

What to Look for in a Service Provider

When selecting an inspection service, prioritize experience and expertise in quality control and quality assurance practices relevant to your industry. Look for providers that offer comprehensive initial production inspections, as well as those who have established protocols for handling defects and non-conformance issues. Additionally, consider their accreditation and reputation; reputable companies often have certifications from recognized bodies that validate their commitment to quality inspection.

Another important factor is the range of services offered by the provider. You want an inspection service that not only conducts thorough inspections but also provides guidance on implementing improvements based on their findings. The ability of a quality control inspector to communicate effectively with your team is vital; after all, clear communication leads to better understanding and quicker resolutions.

Finally, assess their geographical reach if you are sourcing products internationally. A local presence or strong partnerships with overseas inspectors can streamline communication and expedite the inspection process during initial production checks.

Top Companies in the Industry

The landscape of inspection services is populated with several key players known for their commitment to excellence in quality control and assurance inspections. Companies like SGS, Bureau Veritas, and Intertek are industry giants with extensive experience offering various inspection services across multiple sectors. These companies are renowned not only for their technical expertise but also for their global reach, ensuring compliance with international standards.

Another noteworthy contender is China Inspection Pro, which specializes in providing tailored solutions specifically designed for businesses operating within China’s manufacturing landscape. Their deep understanding of local regulations combined with rigorous quality assurance practices makes them a popular choice among international brands looking to maintain high-quality standards during initial production inspections.

Don’t forget smaller niche players who may offer specialized services or more personalized attention than larger companies can provide! Sometimes these hidden gems deliver top-notch results without breaking the bank.

Benefits of Using China Inspection Pro

Choosing China Inspection Pro comes with numerous benefits tailored specifically towards enhancing your initial production inspections while ensuring top-notch quality control and assurance processes. One standout feature is their localized expertise; they understand China's complex manufacturing environment intimately which means they’re adept at identifying potential pitfalls before they escalate into major issues.

Moreover, they offer flexible scheduling options suited to your timeline—ensuring timely interventions that keep your production on track without unnecessary delays! Their team of experienced quality control inspectors utilizes state-of-the-art technology during inspections which guarantees accuracy when assessing compliance against regulatory standards.

Additionally, clients appreciate China Inspection Pro's transparent reporting system that allows stakeholders easy access to detailed insights from each inspection visit—making it simpler than ever to communicate findings across teams! By leveraging such an efficient service provider, businesses can transform data from initial production checks into actionable strategies aimed at continuous improvement.

Common Issues Identified During Inspections

When conducting initial production inspections, various issues can arise that may affect product quality and compliance. Understanding these common problems is crucial for manufacturers and suppliers seeking to enhance their quality assurance processes. By identifying defects, discrepancies, and compliance issues early on, businesses can mitigate risks and improve overall production outcomes.

Defects and Non-Conformance

Defects are one of the most significant concerns during initial production inspections. These can range from minor cosmetic flaws to major functional issues that could render a product unusable. Quality control inspectors play a vital role in identifying such non-conformance, ensuring that products meet established standards before they reach the market.

Non-conformance not only affects customer satisfaction but can also lead to costly recalls or reputational damage if not addressed promptly. Regular quality inspections help catch these defects early in the production process, allowing manufacturers to make necessary adjustments before large quantities are produced. Ultimately, maintaining high-quality standards through effective inspection services helps build trust with consumers and partners alike.

Supply Chain Discrepancies

Another common issue identified during initial production inspections is supply chain discrepancies. These discrepancies may occur when materials or components do not match specifications or when there are inconsistencies between suppliers' products. Quality assurance measures must be in place to ensure that all aspects of the supply chain align with quality control standards.

Addressing these discrepancies is essential for maintaining a smooth production flow and preventing delays or increased costs down the line. A proactive approach involving regular communication with suppliers can help mitigate risks associated with supply chain variations. By employing thorough quality assurance inspections at various stages of the supply chain, businesses can enhance their overall operational efficiency.

Compliance with Regulatory Standards

Compliance with regulatory standards is non-negotiable in many industries, making it a critical focus during initial production inspections. Failing to adhere to these regulations can result in severe penalties, including fines or product bans from certain markets. Quality control inspectors must be well-versed in relevant industry regulations to ensure that products comply before they reach consumers.

Initial production inspections serve as an opportunity to verify compliance with safety standards, environmental regulations, and other legal requirements specific to each industry sector. By identifying potential compliance issues early on, companies can take corrective actions swiftly and avoid costly setbacks later in the process. In essence, rigorous quality assurance practices contribute significantly to a company's ability to navigate complex regulatory landscapes successfully.

Transforming Inspection Results into Action

Once the initial production inspection is completed, it’s time to roll up your sleeves and dive into the data. Analyzing inspection data is crucial for identifying patterns, recurring issues, and areas needing improvement. The insights gained from quality inspections can inform quality control processes and help shape future production strategies.

Analyzing Inspection Data

Analyzing inspection data involves sifting through the findings of your quality assurance inspections to draw meaningful conclusions. This process often reveals trends in defects or non-conformance that might not be immediately apparent during individual inspections. By leveraging statistical analysis tools, a quality control inspector can pinpoint specific issues that require attention, ensuring that quality control and quality assurance efforts are both targeted and effective.

Additionally, understanding the context of each defect is vital; for example, did it stem from a particular supplier or a specific stage in production? This kind of insight allows businesses to address root causes rather than merely treating symptoms. Ultimately, a thorough analysis not only enhances product quality but also strengthens partnerships with suppliers by fostering transparency and collaboration.

Implementing Improvement Recommendations

Once you have analyzed the inspection data, it's time to implement improvement recommendations based on your findings from initial production inspections. These recommendations should focus on enhancing processes, addressing identified defects, and improving overall product quality through actionable steps. For instance, if a recurring issue is detected in one part of the manufacturing process, adjustments can be made to machinery or workflow to mitigate future risks.

Moreover, involving team members in this phase can lead to greater buy-in for changes made within production lines or supply chains. Training sessions might be necessary to ensure all staff understand new protocols as part of your commitment to ongoing quality assurance and effective quality control practices. By actively engaging with these improvements, companies can foster a culture of continuous enhancement that benefits everyone involved—from the factory floor up to management.

Communicating Findings to Stakeholders

Effective communication of inspection results is key in transforming data into action; stakeholders need clear insights into what was found during initial production inspections and how it impacts their interests. Regular updates should be disseminated via reports or presentations that highlight significant findings alongside proposed actions for resolution—after all, knowledge is power!

In addition to formal reports, consider hosting meetings where stakeholders can discuss findings openly; this encourages collaboration while promoting transparency about challenges faced during production runs. Furthermore, maintaining an open line of communication ensures everyone—from suppliers to top management—understands their role in maintaining high-quality standards through consistent engagement with both quality control inspectors and processes.

By adopting these strategies for analyzing data, implementing improvements effectively, and communicating clearly with stakeholders about inspection results—companies set themselves up not just for immediate success but also long-term sustainability in their operations.

Conclusion

In wrapping up our discussion on initial production inspections, it’s clear that these checks are not just a formality—they're essential for ensuring product quality and compliance. By implementing thorough quality control measures, businesses can significantly reduce risks associated with defects and non-conformance. Ultimately, initial production inspections serve as a safeguard for both manufacturers and consumers, ensuring that only the highest quality products reach the market.

Key Takeaways on Production Inspections

The importance of initial production inspections cannot be overstated; they form the backbone of effective quality assurance practices. These inspections help identify issues early in the manufacturing process, allowing companies to address problems before they escalate into costly errors. Remember, a proactive approach to quality control can save time, money, and reputation in the long run.

How Inspections Enhance Product Quality

Quality inspections play a pivotal role in enhancing product quality by providing a systematic approach to identifying defects and ensuring compliance with regulatory standards. When performed by skilled quality control inspectors, these assessments help maintain consistency throughout production runs. The integration of robust inspection services into your workflow not only boosts consumer trust but also strengthens your brand's reputation for reliability.

Next Steps After Initial Production Checks

After conducting an initial production inspection, it's crucial to analyze the data collected thoroughly and implement any recommended improvements promptly. Engaging stakeholders with clear communication about findings fosters collaboration towards achieving higher standards of quality assurance and control. Finally, consider scheduling regular follow-up inspections to ensure ongoing compliance and continuous improvement in your manufacturing processes.