Introduction

In the bustling world of appliance manufacturing, **Washing Machine Quality Inspections** stand as a critical gatekeeper, ensuring that each machine meets stringent standards before reaching consumers. The significance of these inspections cannot be overstated; they not only safeguard consumer safety but also enhance brand reputation and trust. By meticulously assessing every aspect of a washing machine, from its design to functionality, manufacturers can identify potential issues that might arise later, thus preventing costly recalls and fostering customer satisfaction.

Importance of Washing Machine Quality Inspections

Quality inspections are essential in the washing machine manufacturing process because they help pinpoint defects early on. A thorough inspection setup and overall findings can reveal workmanship issues that may compromise the machine's reliability and efficiency. Moreover, these inspections ensure compliance with industry standards, which is vital for maintaining consumer trust and avoiding legal ramifications.

The Role of Quality Control in Manufacturing

Quality control serves as the backbone of successful manufacturing operations by establishing processes that uphold product integrity. In the context of washing machines, it encompasses everything from initial design reviews to final packaging checks—ensuring that each unit is built to last. By addressing workmanship issues during production and implementing field tests and measurements pending completion, manufacturers can enhance their products' performance while minimizing risks.

Overview of Quality Inspection Processes

The quality inspection process involves several stages designed to evaluate various aspects of washing machines comprehensively. From preparing for inspections to documenting reference notes and photos for future analysis, each step plays a vital role in achieving desired outcomes and resolutions. By focusing on crucial elements like packaging and shipping marks as well as conducting field tests, manufacturers can guarantee their products not only meet but exceed consumer expectations.

Understanding Washing Machine Quality Inspections

Washing Machine Quality Inspections are essential for ensuring that appliances meet both consumer expectations and industry standards. These inspections serve a dual purpose: they help manufacturers identify potential defects before products reach the market and assure customers of the reliability of their purchases. By understanding the intricacies of these inspections, stakeholders can enhance product quality and reduce costly recalls.

Definition and Purpose

At its core, Washing Machine Quality Inspections involve a systematic evaluation of washing machines to assess their performance, safety, and overall quality. The primary purpose is to detect any workmanship issues or defects that could affect functionality or durability. By conducting thorough inspections, manufacturers can ensure that their products comply with regulatory standards and ultimately deliver satisfaction to consumers.

Key Components of Inspections

Several key components define effective Washing Machine Quality Inspections. These include visual checks for physical defects, functional testing to evaluate performance under various conditions, and adherence to packaging and shipping marks that ensure safe transit. Each component plays a crucial role in the Inspection Setup and Overall Findings, providing a comprehensive view of the product’s readiness for market launch.

Importance of Compliance with Standards

Compliance with industry standards is non-negotiable in Washing Machine Quality Inspections; it not only safeguards consumer safety but also enhances brand reputation. Meeting established guidelines ensures that appliances perform reliably over time while minimizing risks associated with poor workmanship issues. Manufacturers who prioritize compliance often see improved outcomes and resolutions in their quality assurance processes, fostering trust among consumers.

Inspection Setup and Overall Findings

When it comes to Washing Machine Quality Inspections, the setup phase is critical for ensuring a smooth and effective evaluation process. This stage involves meticulous planning, coordination with various stakeholders, and preparing the necessary tools and documentation. A well-structured inspection setup not only saves time but also enhances the accuracy of the findings.

Preparing for the Inspection

Preparing for Washing Machine Quality Inspections requires a comprehensive checklist that includes everything from tools to personnel assignments. Inspectors should gather all relevant standards and specifications to ensure compliance during evaluations, as well as coordinate with manufacturing teams to understand any recent changes in processes or materials. Additionally, arranging for adequate workspace and ensuring safety protocols are in place will set a solid foundation for the inspection.

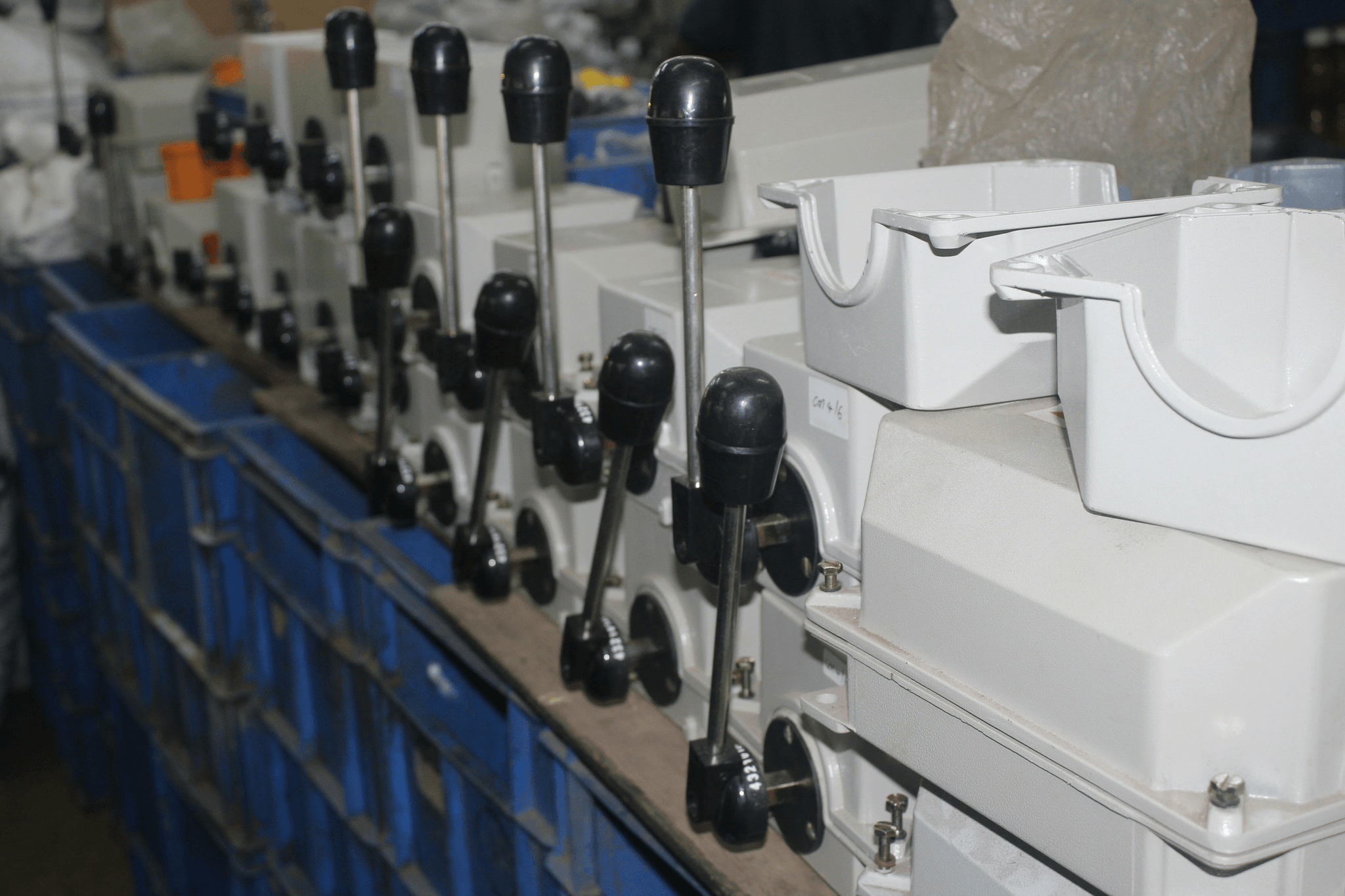

Initial Evaluations and Assessments

Once on-site, initial evaluations during Washing Machine Quality Inspections focus on assessing both the physical condition of the machines and adherence to established quality standards. This phase often involves visual inspections where inspectors look for obvious workmanship issues such as misalignments or surface defects that could impact performance. It’s crucial at this stage to document any findings meticulously so they can inform subsequent assessments and potential corrective actions.

Documenting Overall Findings

Documenting overall findings from Washing Machine Quality Inspections is essential for creating an actionable report that outlines both strengths and weaknesses identified during assessments. Each documented finding should be supported by clear evidence—be it photographs or reference notes—that substantiate observations made throughout the process. This comprehensive documentation not only aids in addressing workmanship issues but also serves as a vital resource in field tests and measurements pending future inspections.

Identifying Workmanship Issues

In the realm of Washing Machine Quality Inspections, identifying workmanship issues is crucial for ensuring that appliances perform reliably and efficiently. Poor craftsmanship can lead to a myriad of problems, from minor annoyances to significant malfunctions that affect consumer satisfaction. Therefore, a thorough understanding of common defects and their implications is essential for any quality control process.

Common Manufacturing Defects

Common manufacturing defects in washing machines can range from misaligned components to inadequate sealing, which may lead to water leaks or mechanical failures. Other frequent issues include improper electrical connections and substandard materials that degrade quickly under normal usage conditions. Recognizing these defects early during the Inspection Setup and Overall Findings phase allows manufacturers to address problems before they escalate into larger concerns.

Impact of Poor Workmanship on Reliability

The impact of poor workmanship on reliability cannot be overstated; it often results in increased warranty claims and customer dissatisfaction. When consumers experience breakdowns or inefficiencies due to manufacturing flaws, their trust in the brand diminishes significantly. This not only affects sales but also tarnishes the reputation of manufacturers who fail to prioritize quality during their Washing Machine Quality Inspections.

Strategies for Avoiding Workmanship Issues

To avoid workmanship issues, manufacturers should implement rigorous training programs for assembly line workers, emphasizing the importance of precision and attention to detail during production processes. Regular audits and field tests can help identify potential weaknesses in workmanship before products reach consumers, ensuring higher standards are met consistently. Additionally, maintaining comprehensive Reference Notes and Photos from previous inspections can serve as a valuable resource for continuous improvement efforts.

Conducting Field Tests and Measurements Pending

Conducting field tests and measurements is a critical step in the Washing Machine Quality Inspections process. These tests provide real-world data that can reveal how well the washing machines perform under various conditions, ensuring they meet consumer expectations and regulatory standards. The insights gained from these evaluations are invaluable for identifying issues early, especially when linked to Inspection Setup and Overall Findings.

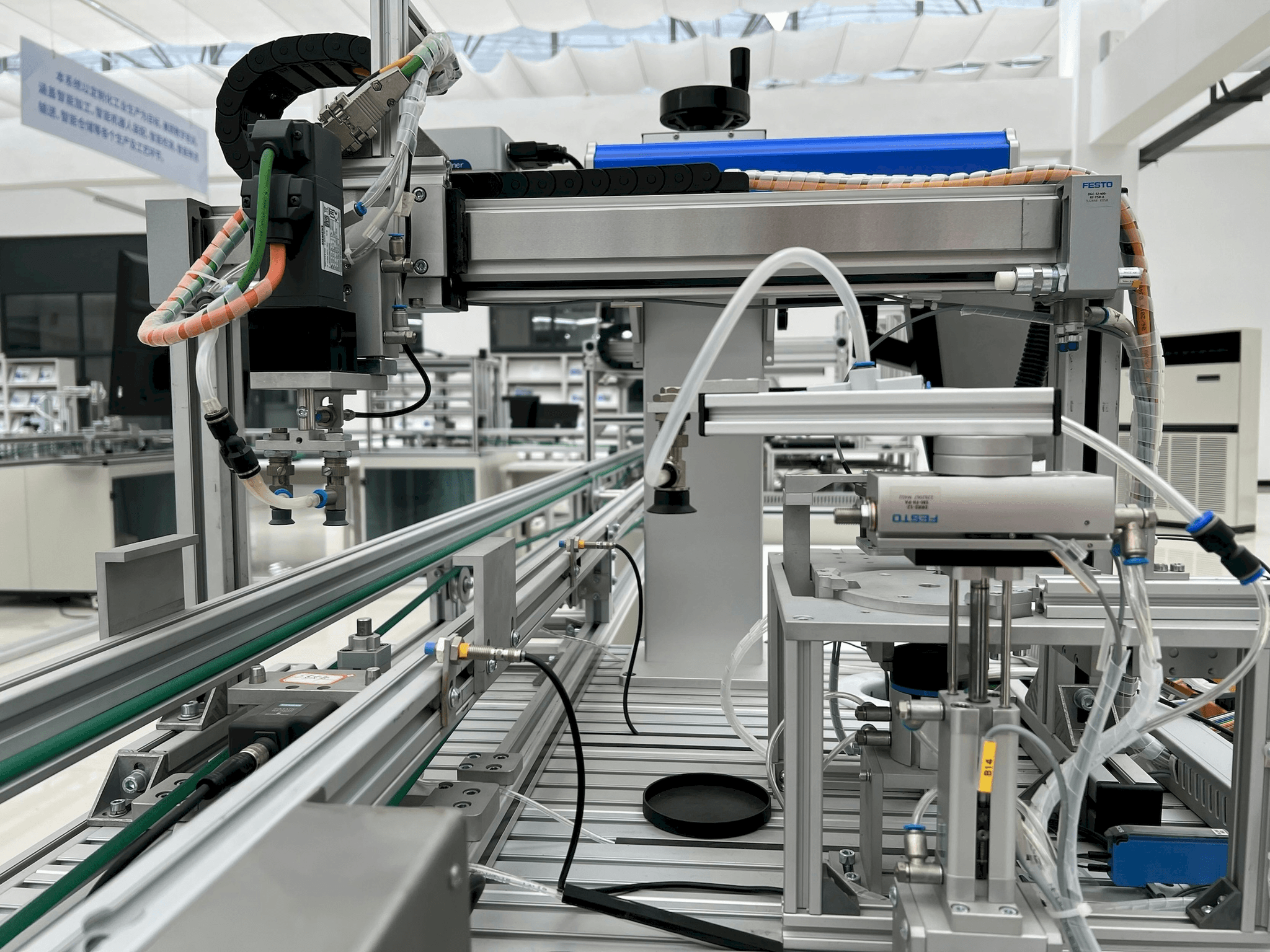

Designing Effective Field Tests

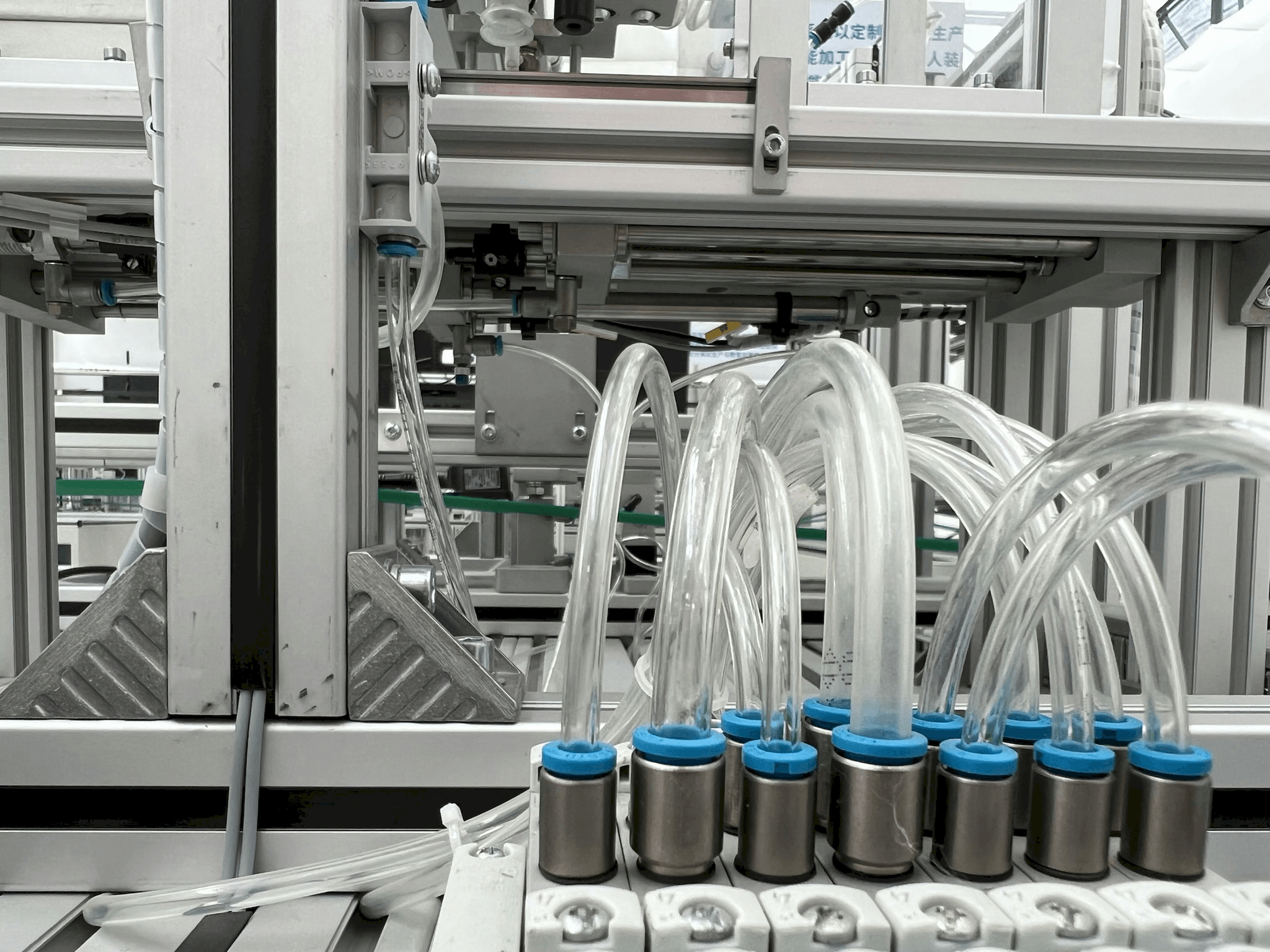

Designing effective field tests involves understanding the specific performance criteria that washing machines must meet. This means creating scenarios that mimic typical usage patterns, such as varying load sizes, water temperatures, and detergent types. By incorporating these variables into the testing framework, manufacturers can better assess potential Workmanship Issues that may arise during actual use.

Field tests should also include a variety of environments—different water qualities, electrical voltages, and even climatic conditions—to ensure comprehensive evaluation. The goal is to simulate real-life situations where a washing machine will be used most frequently. This thorough approach not only enhances the reliability of test results but also aligns with the objectives outlined in Packaging and Shipping Marks to ensure safe transit of appliances.

Measuring Performance and Efficiency

Once field tests are designed, measuring performance and efficiency becomes essential in assessing washing machine capabilities accurately. Key metrics include cycle time, energy consumption, water usage, stain removal effectiveness, and noise levels during operation. Each measurement provides insight into how well the machine performs its intended functions while adhering to compliance standards set forth in Washing Machine Quality Inspections.

Additionally, it's important to compare these measurements against industry benchmarks to gauge competitiveness within the market. For instance, if one model consistently uses more water or energy than others while delivering subpar cleaning results, it highlights significant Workmanship Issues that need addressing immediately. This data-driven approach not only helps manufacturers improve their products but also reinforces their commitment to quality assurance through effective inspection processes.

Analyzing Data for Quality Assurance

Analyzing data gathered from field tests is crucial for drawing actionable conclusions regarding product quality and performance reliability. By utilizing statistical methods and software tools designed for data analysis, manufacturers can identify trends or anomalies that indicate potential problems with workmanship or design flaws. This analytical phase ties back into Outcomes and Resolutions by providing concrete evidence needed for making informed decisions about product improvements.

Moreover, maintaining detailed Reference Notes and Photos during this phase allows teams to document findings comprehensively for future reference or audits. These records serve as an essential resource when addressing any issues identified during inspections or testing phases—ensuring nothing falls through the cracks amid ongoing quality control efforts. Ultimately, leveraging this analytical process enhances overall product reliability while fostering consumer confidence in manufactured goods.

Importance of Packaging and Shipping Marks

When it comes to Washing Machine Quality Inspections, the importance of packaging and shipping marks cannot be overstated. Proper packaging ensures that appliances reach their destination without damage, maintaining the integrity of the product throughout transit. Additionally, clear shipping marks facilitate efficient handling, reducing the risk of mishaps during transportation.

Ensuring Safe Transit of Appliances

Safe transit is critical for washing machines, which are often heavy and bulky items. Effective packaging protects these appliances from physical shocks, moisture, and other environmental factors that could lead to damage or malfunction. By implementing robust packaging solutions during Inspection Setup and Overall Findings, manufacturers can significantly reduce the likelihood of products arriving damaged at retail locations or customers' homes.

Compliance with Safety Standards

Compliance with safety standards is a non-negotiable aspect of manufacturing washing machines. Packaging must adhere to specific regulations that ensure consumer safety during shipping and handling. This compliance not only protects consumers but also enhances brand reputation—something that can be jeopardized by poorly packaged products leading to Workmanship Issues down the line.

Role of Packaging in Quality Control

Packaging plays a pivotal role in quality control processes during Washing Machine Quality Inspections. Well-designed packages serve as an additional layer of protection against potential defects that may arise from rough handling or environmental exposure during transport. Furthermore, effective use of Reference Notes and Photos documenting packaging integrity can provide valuable insights for continuous improvement efforts aimed at minimizing future shipping-related issues.

Keeping Reference Notes and Photos

When it comes to Washing Machine Quality Inspections, documenting inspection evidence is not just a formality; it’s an essential step in ensuring that every detail is accounted for. Taking reference notes and photos during the inspection process provides a visual and written record of the condition of appliances at various stages of quality control. This documentation serves as an invaluable resource for identifying trends, recurring issues, and areas needing improvement.

Documenting Inspection Evidence

The art of documenting inspection evidence involves capturing both qualitative and quantitative data about washing machines throughout the Inspection Setup and Overall Findings phase. Detailed notes on workmanship issues, field tests, and measurements pending can highlight specific problems that may arise during manufacturing or transit. Moreover, photographs taken during inspections can serve as visual proof of compliance with packaging and shipping marks or reveal defects that might otherwise go unnoticed.

Importance in Quality Assurance

Reference notes and photos play a pivotal role in quality assurance by creating a comprehensive archive that stakeholders can refer back to when assessing product performance over time. They help ensure that all aspects of Washing Machine Quality Inspections are thoroughly evaluated, leading to more informed decisions about product reliability and safety compliance. Additionally, having this documentation readily available fosters accountability among team members involved in both the manufacturing process and subsequent inspections.

Utilizing Notes for Future Improvements

The real magic happens when we utilize our reference notes for future improvements; they become a roadmap for enhancing processes in subsequent production cycles. By analyzing past inspection findings alongside documented evidence from previous workmanship issues, manufacturers can implement targeted changes to reduce defects significantly. Continuous improvement is not just a buzzword; it’s a necessary strategy to ensure long-term reliability in washing machines while boosting consumer confidence through consistent quality assurance practices.

Outcomes and Resolutions

The journey of Washing Machine Quality Inspections does not end with the conclusion of the inspection process; rather, it sets the stage for crucial outcomes and resolutions. Addressing the inspection findings is an essential step in ensuring that any identified issues are rectified promptly. By focusing on these findings, manufacturers can enhance product reliability and consumer satisfaction.

Addressing Inspection Findings

Upon completion of the Inspection Setup and Overall Findings, it’s vital to dive into the specifics of what was uncovered during Washing Machine Quality Inspections. This includes identifying any workmanship issues that may have been flagged, such as misaligned components or faulty wiring. Addressing these findings not only prevents future complications but also reinforces a commitment to quality that consumers expect.

Implementing Improvements

Once inspection findings are thoroughly understood, implementing improvements becomes the next logical step in maintaining high standards for washing machines. Manufacturers should prioritize rectifying workmanship issues identified during inspections and refine their processes based on feedback from field tests and measurements pending. Continuous improvements not only streamline production but also ensure compliance with packaging and shipping marks that guarantee safe transit for appliances.

Ensuring Long-term Reliability

To ensure long-term reliability, manufacturers must adopt a proactive approach following Washing Machine Quality Inspections by consistently reviewing reference notes and photos taken during inspections. These documents serve as invaluable resources for understanding past mistakes and preventing them in future production runs. By fostering a culture of quality assurance through regular evaluations, companies can build trust with consumers while enhancing product durability over time.

Conclusion

In the competitive world of appliance manufacturing, the importance of Washing Machine Quality Inspections cannot be overstated. A thorough inspection setup and overall findings not only identify potential defects but also enhance the reliability and performance of the product. By prioritizing quality inspections, manufacturers can ensure that their washing machines meet consumer expectations and industry standards.

The Impact of Quality Inspections on Performance

Quality inspections have a direct impact on the performance of washing machines, as they help to uncover workmanship issues before products reach consumers. When inspections are conducted meticulously, they lead to a reduction in defects and an increase in overall efficiency, translating into better customer satisfaction. Furthermore, addressing these issues during the inspection process ensures that any necessary field tests and measurements pending are performed effectively to validate product reliability.

Enhancing Consumer Confidence through Inspections

Washing Machine Quality Inspections play a crucial role in building trust with consumers by ensuring that products are safe and reliable. When customers see a commitment to quality through rigorous inspection processes—including detailed assessments of packaging and shipping marks—they feel more confident in their purchases. This confidence is further bolstered by transparent documentation practices, such as keeping reference notes and photos that highlight quality assurance efforts.

Partnering with China Inspection Pro for Quality Assurance

To achieve optimal results in washing machine manufacturing, partnering with experts like China Inspection Pro is invaluable for maintaining high-quality standards throughout production processes. Their expertise ensures comprehensive coverage from inspection setup and overall findings to addressing workmanship issues effectively. With their support in conducting field tests and measurements pending, manufacturers can streamline operations while reinforcing compliance with safety standards—ultimately leading to successful outcomes and resolutions.