Introduction

In the fast-paced world of manufacturing, ensuring product quality is paramount. The quality inspection process serves as a crucial checkpoint, identifying defects and maintaining standards throughout production. By integrating effective quality control measures, companies can enhance their reputation and customer satisfaction while minimizing costly recalls.

Understanding the Quality Inspection Process

The quality inspection process encompasses a series of systematic evaluations designed to assess product integrity at various stages of production. This includes everything from pre-production checks to final inspections, ensuring that every item meets established specifications. By employing robust quality management software, businesses can streamline these processes and foster a culture of compliance and excellence.

Importance of Quality Inspection in Manufacturing

Quality inspection plays an indispensable role in manufacturing by safeguarding against defects that could lead to financial losses or reputational damage. Regular inspections not only ensure compliance with industry standards but also enhance operational efficiency by identifying issues early on. Ultimately, consistent quality control translates into increased consumer trust and loyalty, making it a vital component of any successful manufacturing strategy.

Role of Quality Control Companies

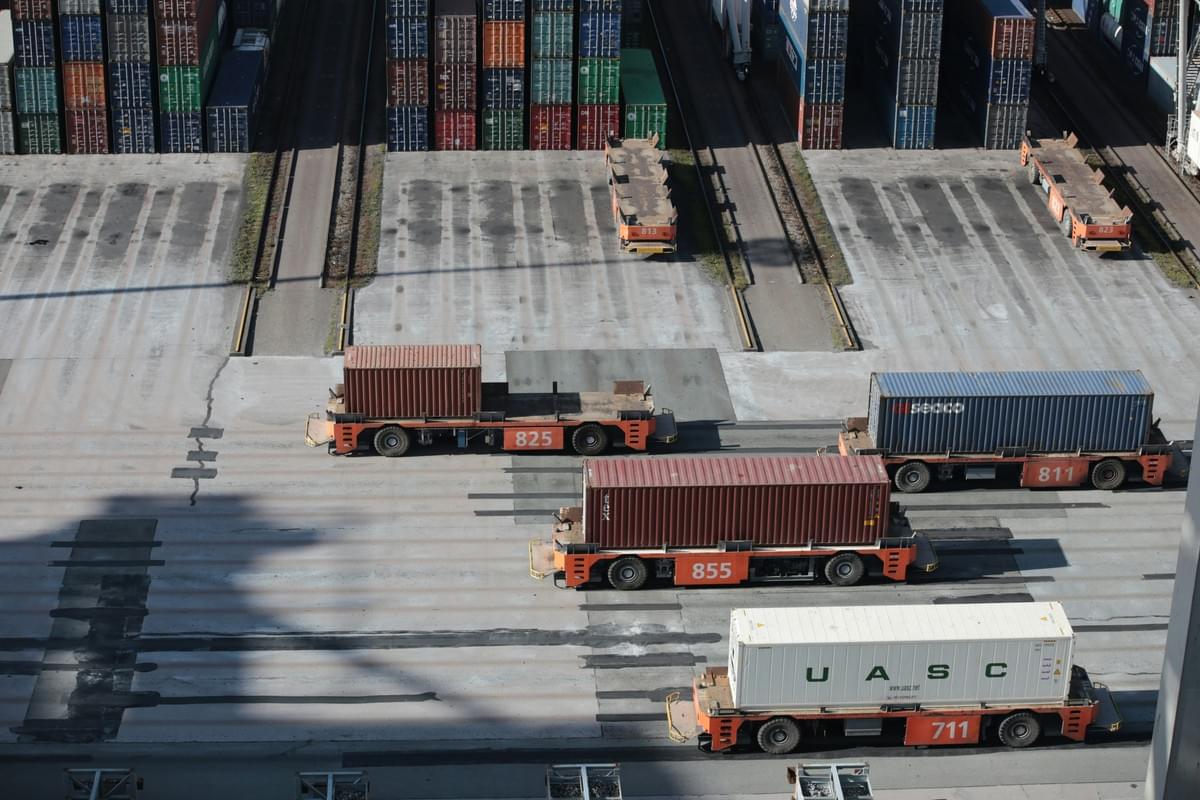

Quality control companies specialize in providing expertise and resources necessary for effective quality management systems within organizations. These companies offer tailored solutions that include training personnel, implementing advanced quality control software, and conducting thorough inspections throughout the supply chain. By partnering with these experts, manufacturers can leverage their knowledge to elevate their own quality inspection processes and achieve long-term success.

Define Quality Standards

Defining quality standards is a crucial step in the quality inspection process, as it sets the foundation for what constitutes acceptable products. Establishing clear product specifications ensures that everyone involved—manufacturers, suppliers, and quality control companies—has a consistent understanding of expectations. By doing so, businesses can streamline their operations and minimize the risk of defects.

Establishing Product Specifications

Establishing product specifications is essential for any successful quality control strategy. These specifications outline the characteristics that products must meet to be deemed acceptable, including dimensions, materials, and performance criteria. When these standards are clearly defined at the outset of production, it enables inspectors to carry out thorough quality inspections and helps prevent costly rework or returns later on.

Collaborating with Quality Control Experts

Collaboration with quality control experts can significantly enhance the effectiveness of your quality inspection process. Quality control companies bring a wealth of experience and specialized knowledge to the table, allowing manufacturers to refine their standards based on industry best practices. Engaging these professionals not only helps in establishing realistic benchmarks but also ensures compliance with relevant regulations and market demands.

Utilizing Quality Management Software

In today’s digital age, utilizing quality management software is indispensable for maintaining high standards throughout production cycles. This software allows organizations to track compliance with established specifications efficiently while providing real-time data analysis to identify trends or issues early on. With advanced features like automated reporting and integration capabilities, quality control management software streamlines communication among teams and enhances overall productivity in the quality inspection process.

Develop a Quality Inspection Plan

Creating a robust quality inspection plan is essential for any manufacturing process. This plan serves as the backbone of your quality inspection process, ensuring that every step is meticulously outlined and executed. A well-developed quality inspection plan not only enhances product quality but also minimizes risks associated with defects and non-compliance.

Outlining Inspection Procedures

Outlining clear and precise inspection procedures is the first step in developing your quality inspection plan. Each procedure should detail specific checkpoints during the production process where inspections will occur, such as pre-production, in-process, and final inspections. Utilizing quality management software can streamline this outlining process by providing templates and frameworks tailored to your industry’s needs.

Moreover, these procedures must be easily accessible to all team members involved in the quality control process. By establishing a standardized approach to inspections through documented procedures, you empower your team to maintain consistency and reliability in their assessments. Quality control companies often recommend regular reviews of these procedures to adapt them as necessary based on evolving industry standards or internal findings.

Scheduling Inspections Effectively

Effective scheduling of inspections is crucial for maintaining an efficient workflow while adhering to the established quality standards. This involves strategically planning when each type of inspection will take place throughout the production cycle, ensuring minimal disruption while maximizing oversight. Quality control management software can assist in automating this scheduling, allowing for timely reminders and adjustments based on real-time production data.

Additionally, it’s important to consider factors such as lead times for materials and potential bottlenecks in production when creating your schedule. Flexibility within your schedule can also help accommodate unforeseen circumstances without compromising product quality or delivery timelines. Remember, a proactive approach in scheduling inspections ultimately enhances your overall quality management system.

Ensuring Compliance with Regulations

Compliance with industry regulations is non-negotiable when it comes to the quality inspection process; failing to adhere can result in hefty fines or loss of reputation. It’s essential that your quality inspection plan incorporates all relevant regulatory requirements applicable to your products or services—whether they be local, national, or international standards. Regular training sessions for inspectors on compliance issues can help ensure that everyone involved understands their responsibilities within the framework of regulations.

Furthermore, leveraging advanced quality control software can help keep track of compliance documentation and audit trails efficiently; this ensures that you have all necessary records readily available during inspections or audits by regulatory bodies. Continuous monitoring through these systems allows for immediate corrective actions if any compliance issues arise during the manufacturing process—keeping you one step ahead of potential pitfalls. Ultimately, integrating compliance into every aspect of your quality management system fosters a culture of excellence within your organization.

Train Your Quality Team

Training your quality team is a cornerstone of an effective quality inspection process. Skilled inspectors are essential for identifying and rectifying issues before they escalate, ensuring that products meet established quality standards. Investing in a knowledgeable team not only enhances the overall efficiency of the quality control process but also fosters a culture of excellence within your organization.

Importance of Skilled Inspectors

Skilled inspectors are the backbone of any successful quality control operation. They possess the expertise to navigate complex production environments, using their knowledge to conduct thorough inspections and apply quality management software effectively. By recognizing subtle defects or deviations early on, these professionals help maintain high standards throughout the manufacturing process, ultimately safeguarding your brand's reputation.

Implementing a Quality Management System

A robust quality management system (QMS) is crucial for streamlining the quality inspection process and ensuring compliance with industry regulations. Implementing such a system allows for better documentation, tracking, and analysis of inspection data, which can be managed through specialized quality control software. By integrating this technology into daily operations, companies can enhance collaboration among teams and improve overall productivity in their quality control efforts.

Continuous Training and Development

Continuous training and development are vital for keeping your team sharp in an ever-evolving manufacturing landscape. Regular workshops and seminars on new technologies, including updates to quality control management software, ensure that inspectors remain well-versed in best practices. Moreover, fostering an environment of ongoing learning promotes adaptability within your workforce—an essential trait when addressing emerging challenges in the quality inspection process.

Conduct Pre-Production Inspections

Before diving into the manufacturing process, conducting pre-production inspections is essential to ensure that everything is set up for success. This stage of the quality inspection process focuses on assessing raw materials and components, allowing manufacturers to catch potential issues before they become costly problems. By implementing effective quality control measures during this phase, businesses can save time and resources while enhancing their overall product quality.

Assessing Raw Materials and Components

The first step in pre-production inspections involves a thorough assessment of raw materials and components to ensure they meet established quality standards. This means closely examining the specifications provided by suppliers against what is actually delivered, utilizing quality management software for accurate tracking and documentation. Quality control companies often assist in this process by providing expertise in evaluating materials, ensuring that only the best inputs are used in production.

Early Detection of Quality Issues

Early detection of quality issues can be a game-changer for manufacturers looking to maintain high standards throughout their production processes. By identifying defects or discrepancies at this stage, companies can implement corrective actions before significant investments are made in production runs. Leveraging quality control management software can streamline this process by providing real-time data analysis and reporting capabilities, making it easier to spot trends or recurring problems early on.

Communicating with Suppliers

Effective communication with suppliers is crucial during pre-production inspections to ensure alignment on quality expectations and specifications. Regular discussions about material performance and any concerns identified during assessments help build strong relationships with suppliers, fostering a collaborative approach toward maintaining product integrity. Utilizing a robust IT quality management system can facilitate these communications by centralizing information and providing easy access to inspection results, enhancing transparency between parties.

Perform In-Process Quality Inspections

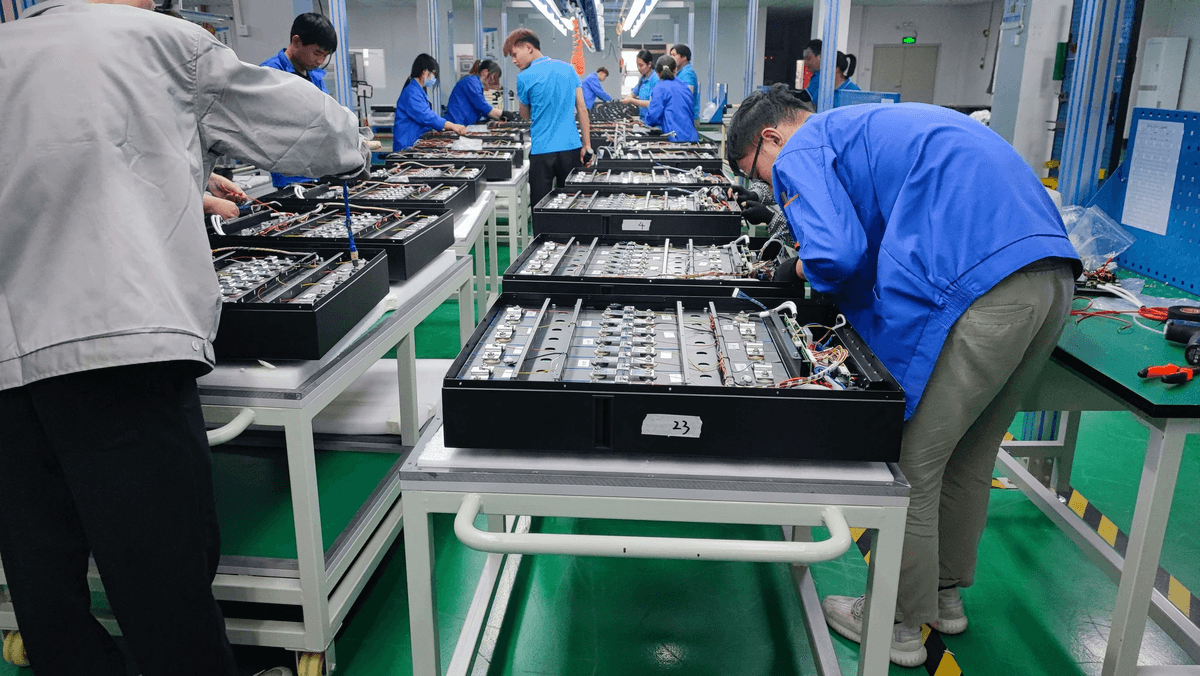

In-process quality inspections are crucial for maintaining standards throughout the production lifecycle. These inspections allow manufacturers to identify defects and variances in real-time, ensuring that products meet established quality benchmarks before they reach the final stages of production. By integrating these checks into the workflow, companies can significantly reduce waste and enhance overall efficiency.

Monitoring Production Processes

Monitoring production processes is essential for a successful quality inspection process. This involves closely observing various stages of manufacturing to ensure adherence to quality control standards. Regular monitoring not only helps in identifying potential issues early on but also fosters a culture of accountability among employees, making them more aware of their role in maintaining product quality.

Utilizing Quality Control Management Software

Leveraging quality control management software can revolutionize how businesses approach their inspection processes. This software provides real-time data collection, analysis, and reporting tools that streamline the entire quality inspection workflow. With features tailored for effective monitoring and compliance tracking, it empowers teams to make informed decisions quickly while keeping track of their progress against predefined quality standards.

Adjusting Procedures Based on Findings

Adjusting procedures based on findings from in-process inspections is vital for continuous improvement within any manufacturing operation. When issues are detected during inspections, it's important to analyze the root causes and implement corrective actions immediately. By doing so, companies not only enhance their product quality but also refine their overall quality management system to prevent similar problems in future production runs.

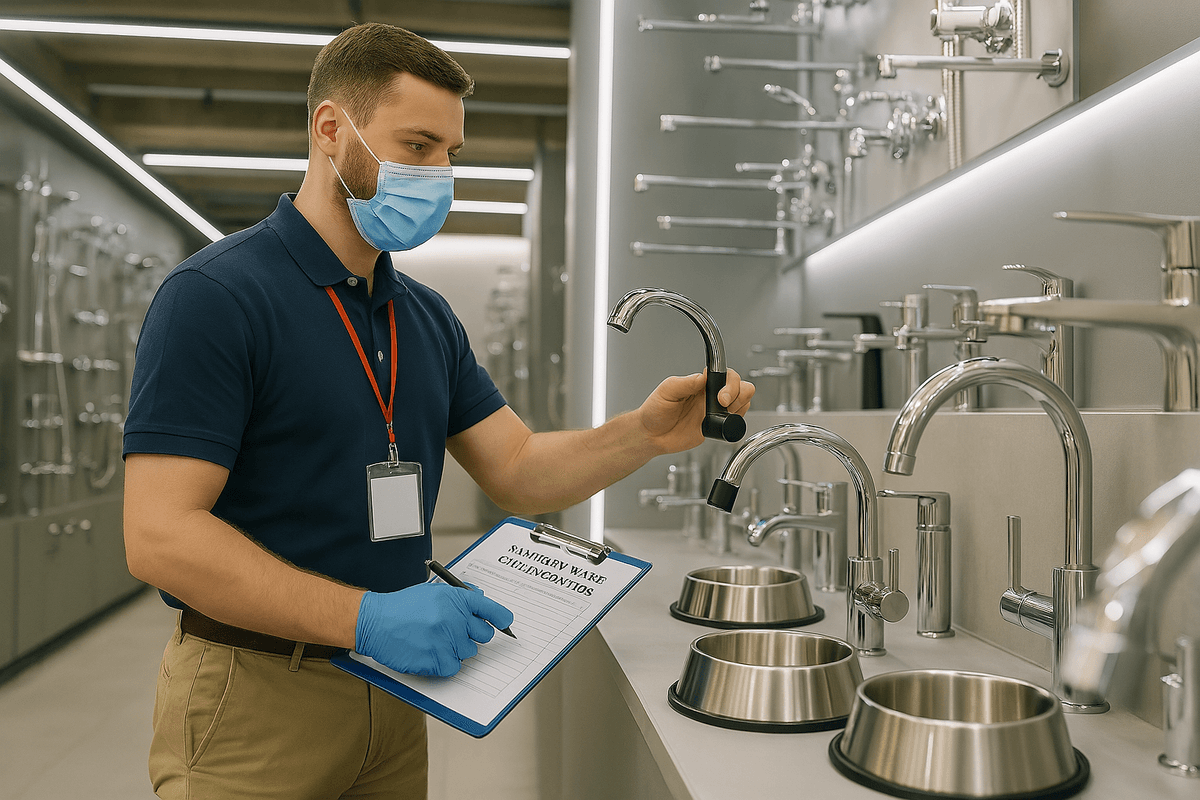

Execute Final Inspections

Executing final inspections is the last line of defense in the quality inspection process, ensuring that products meet all established quality standards before they reach customers. This stage is crucial as it validates the entire manufacturing effort and helps to maintain a brand's reputation for quality. By implementing a thorough final inspection, manufacturers can catch any lingering issues that could compromise product integrity.

Verifying Compliance with Quality Standards

Verifying compliance with quality standards involves a meticulous review of the finished products against predefined specifications. This step ensures that every item adheres to both industry regulations and customer expectations, which is essential for maintaining trust in your brand. Utilizing quality management software during this verification process can streamline data collection and analysis, making it easier to identify trends or recurring issues.

Utilizing China Inspection Pro for Expertise

When it comes to executing final inspections, partnering with specialized quality control companies like China Inspection Pro can provide invaluable expertise. These professionals bring extensive knowledge of local manufacturing practices and regulatory requirements, ensuring that your products not only meet international standards but also local nuances. Their experience enhances the overall quality inspection process by offering insights that might be overlooked by internal teams.

Documenting Inspection Results

Documenting inspection results is a key aspect of any effective quality control strategy; it creates a record that can be referenced for future audits and continuous improvement efforts. Quality control management software simplifies this task by allowing teams to capture data efficiently and generate comprehensive reports on inspection outcomes. This documentation not only supports compliance but also fosters accountability within your organization by tracking performance over time.

Implement Continuous Improvement

In the ever-evolving landscape of manufacturing, implementing continuous improvement is essential for maintaining a robust quality inspection process. This involves not just a one-off effort but an ongoing commitment to refining quality control measures and enhancing overall product integrity. By leveraging insights gained from the quality inspection process, companies can foster an environment where quality management becomes second nature.

Analyzing Inspection Data

The first step in continuous improvement is analyzing inspection data collected throughout the production cycle. Utilizing advanced quality management software allows teams to sift through vast amounts of data efficiently, identifying trends and patterns that might indicate underlying issues in the manufacturing process. Quality control companies often emphasize the importance of this analysis, as it provides actionable insights that can drive strategic decisions regarding quality control adjustments.

Moreover, regular analysis of inspection data helps in benchmarking performance against industry standards and internal goals. By understanding how products fare during various stages of production, manufacturers can pinpoint areas needing enhancement while celebrating successes that reinforce effective practices. This analytical approach ensures that every facet of the quality inspection process contributes to improved outcomes.

Adjusting Quality Control Strategies

Once insights from data analysis are gathered, it’s time to adjust your quality control strategies accordingly. This may involve tweaking existing procedures or adopting new methodologies altogether based on findings from inspections and feedback from skilled inspectors who understand the nuances of production processes. Quality control management software can facilitate these adjustments by providing real-time updates and tracking changes over time.

Implementing changes isn’t merely about reacting; it's about proactivity in anticipating potential issues before they arise in future production runs. Engaging with quality control companies for expert advice on best practices can also enhance your strategy adjustments, ensuring they align with industry benchmarks and innovations. The goal is to create a dynamic framework where strategies evolve alongside market demands and technological advancements.

Ensuring Long-term Quality Management

Long-term success hinges on establishing a culture of continuous improvement within your organization’s framework for quality management systems (QMS). By integrating ongoing training sessions for inspectors and regularly updating your quality inspection protocols based on new findings, you reinforce a commitment to excellence across all levels of production. This proactive stance not only enhances product reliability but also strengthens relationships with suppliers who appreciate consistency in their partnerships.

Moreover, embedding continuous improvement into your company ethos encourages employees at all levels to take ownership of their roles within the quality inspection process. Encouraging feedback loops where team members share insights fosters innovation and ensures everyone feels invested in maintaining high standards through effective use of IT quality management systems or other relevant tools like specialized quality control software.

Ultimately, ensuring long-term quality management means viewing every challenge as an opportunity for growth—because when it comes down to it, today’s improvements lay the groundwork for tomorrow’s successes.

Conclusion

Wrapping up our discussion on the quality inspection process, it's clear that a robust approach to quality control can significantly impact manufacturing success. From defining quality standards to implementing continuous improvement, each step plays a crucial role in ensuring products meet or exceed expectations. By leveraging quality management software and collaborating with quality control companies, businesses can streamline their processes for optimum efficiency.

Recap of Quality Inspection Steps

Throughout this guide, we’ve explored essential steps in the quality inspection process, starting from establishing product specifications to executing final inspections. Training your quality team and developing a comprehensive inspection plan are vital components that ensure consistency and compliance with regulations. Ultimately, conducting thorough pre-production and in-process inspections helps identify issues early on, safeguarding product integrity before reaching consumers.

Importance of Ongoing Quality Control

Ongoing quality control is not just an afterthought; it’s integral to maintaining product excellence over time. As market demands evolve and consumer expectations rise, businesses must adapt their strategies accordingly through regular assessments and adjustments. Continuous monitoring using effective quality control management software allows organizations to stay ahead of potential issues while fostering a culture of improvement within their teams.

Selecting the Right Quality Control Software

When it comes to selecting the right quality control software, understanding your specific needs is paramount. Look for features that align with your existing processes—whether that's real-time data analysis or customizable reporting tools—to enhance your IT quality management system effectively. A well-chosen solution will not only streamline your operations but also empower your team to uphold high standards throughout the entire production cycle.