Introduction

In the realm of laboratory operations, a robust quality control tests list serves as the backbone for ensuring accuracy and reliability in results. Quality control tests encompass a variety of assessments designed to evaluate both processes and outputs, from equipment inspections to parts inspection techniques. By implementing a comprehensive quality control framework, laboratories can effectively manage their workflows and uphold high standards of quality.

Overview of Quality Control Tests

Quality control tests are systematic procedures aimed at determining the integrity, reliability, and performance of laboratory processes and equipment. These tests can range from simple visual inspections to more complex analyses involving statistical methods. Understanding the difference between inspection and quality control is crucial; while inspection focuses on identifying defects or non-conformance at a single point in time, quality control encompasses ongoing monitoring to prevent issues before they arise.

Importance of Quality Control in Labs

The importance of quality control in labs cannot be overstated; it directly impacts the credibility of test results and overall laboratory efficiency. Inaccurate results can lead to misguided conclusions that may affect patient health or product safety, making adherence to an acceptance quality limit (AQL) essential for maintaining trustworthiness. Furthermore, rigorous quality management practices help streamline operations, reduce waste, and enhance customer satisfaction—critical factors for success in competitive environments like China FBA inspection.

Key Elements of a Quality Control Tests List

A well-structured quality control tests list should include several key elements that ensure comprehensive oversight of laboratory practices. This includes detailed descriptions of each test's purpose, frequency, and methodology along with clear criteria for evaluating outcomes based on AQL standards. Additionally, incorporating regular equipment inspections alongside parts inspection techniques into this list allows laboratories to proactively identify potential issues before they escalate into significant problems.

Understanding Quality Control

Quality control is a vital aspect of laboratory operations, ensuring that results are reliable and meet predefined standards. It encompasses a variety of practices and procedures designed to maintain the quality of products and services, particularly through a well-defined quality control tests list. This section delves into the definition of quality control, its role in laboratories, and clarifies the difference between inspection and quality control.

Definition of Quality Control

Quality control refers to the systematic processes employed to ensure that products or services meet specified requirements and standards. In laboratories, this includes implementing a quality control tests list that outlines specific tests to verify equipment functionality and the accuracy of results. The goal is to minimize errors, enhance reliability, and ensure compliance with industry regulations.

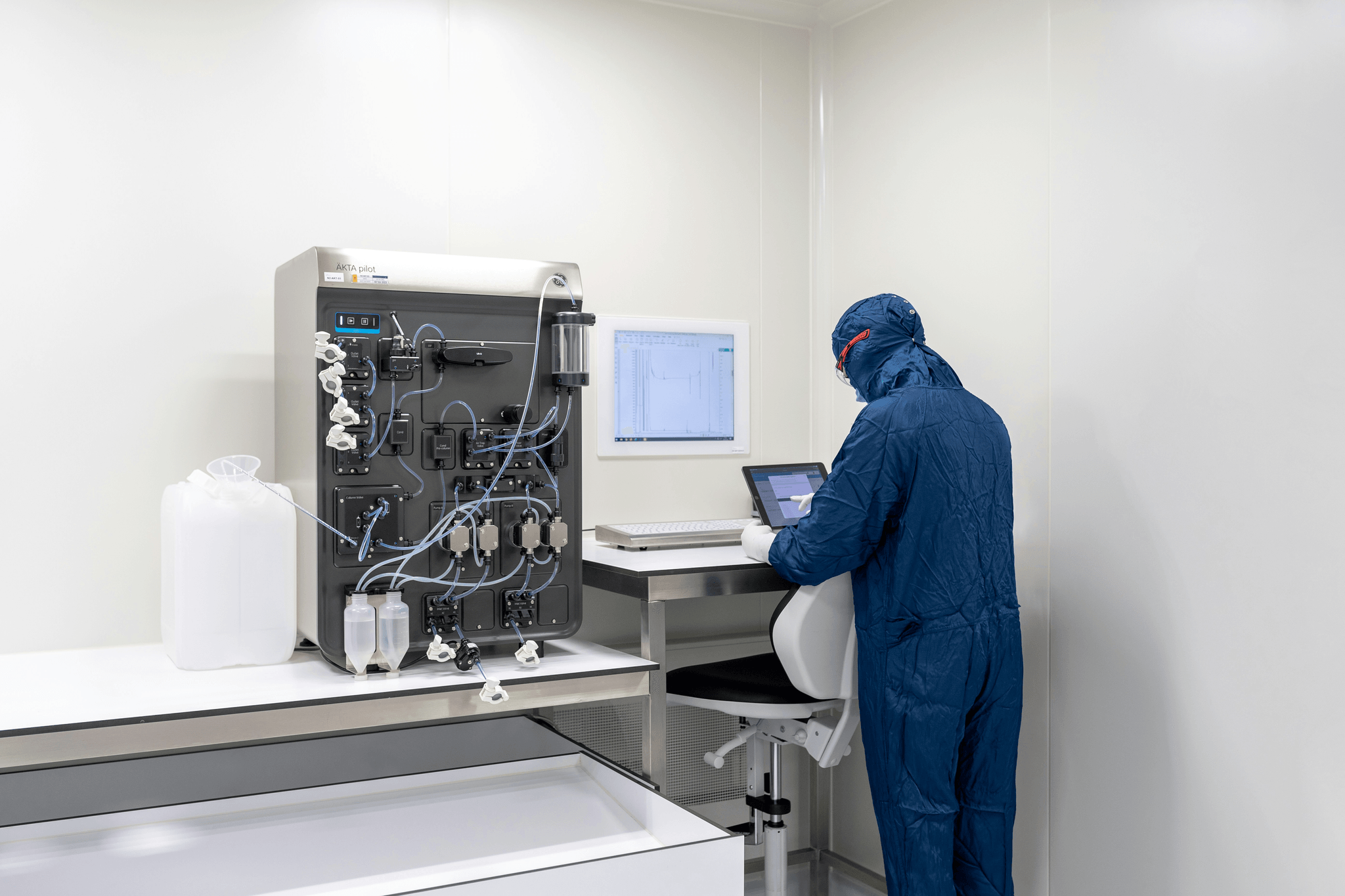

The Role of Quality Control in Laboratories

In laboratories, quality control plays an essential role in maintaining accuracy and precision in testing processes. It involves regular equipment inspections to confirm that instruments are functioning optimally while adhering to established protocols for parts inspection. By employing rigorous quality assurance measures such as AQL acceptable quality level criteria, labs can effectively manage risks associated with testing inaccuracies.

Difference Between Inspection and Quality Control

While both inspection and quality control aim at ensuring product integrity, they serve different purposes within laboratory settings. Inspection typically focuses on examining finished products or components against predefined standards without influencing the overall process—think of it as checking your homework after you've completed it! On the other hand, quality control is more proactive; it involves ongoing monitoring throughout various stages—including equipment inspections—to prevent defects before they occur.

Essential Quality Control Tests

Quality control tests are the backbone of any laboratory's operations, ensuring that results are reliable and meet industry standards. A well-curated quality control tests list not only enhances the accuracy of lab results but also minimizes risks associated with faulty equipment or procedures. In this section, we will explore common laboratory tests, equipment inspections, and parts inspection techniques that contribute to effective quality assurance.

Common Laboratory Tests and Their Purposes

Common laboratory tests play a vital role in determining the quality of products and processes. These tests include chemical analysis, microbiological testing, and physical property assessments, each serving distinct purposes in quality assurance. By incorporating these essential tests into your quality control tests list, labs can effectively monitor compliance with acceptance quality limits (AQL) and ensure that they consistently meet client expectations.

For instance, microbiological testing is crucial for industries like pharmaceuticals and food production where contamination can lead to serious health risks. Similarly, chemical analyses help identify impurities or deviations in product formulations that could affect performance or safety. Understanding the purpose behind each test allows labs to strategically implement them as part of their overall quality management strategy.

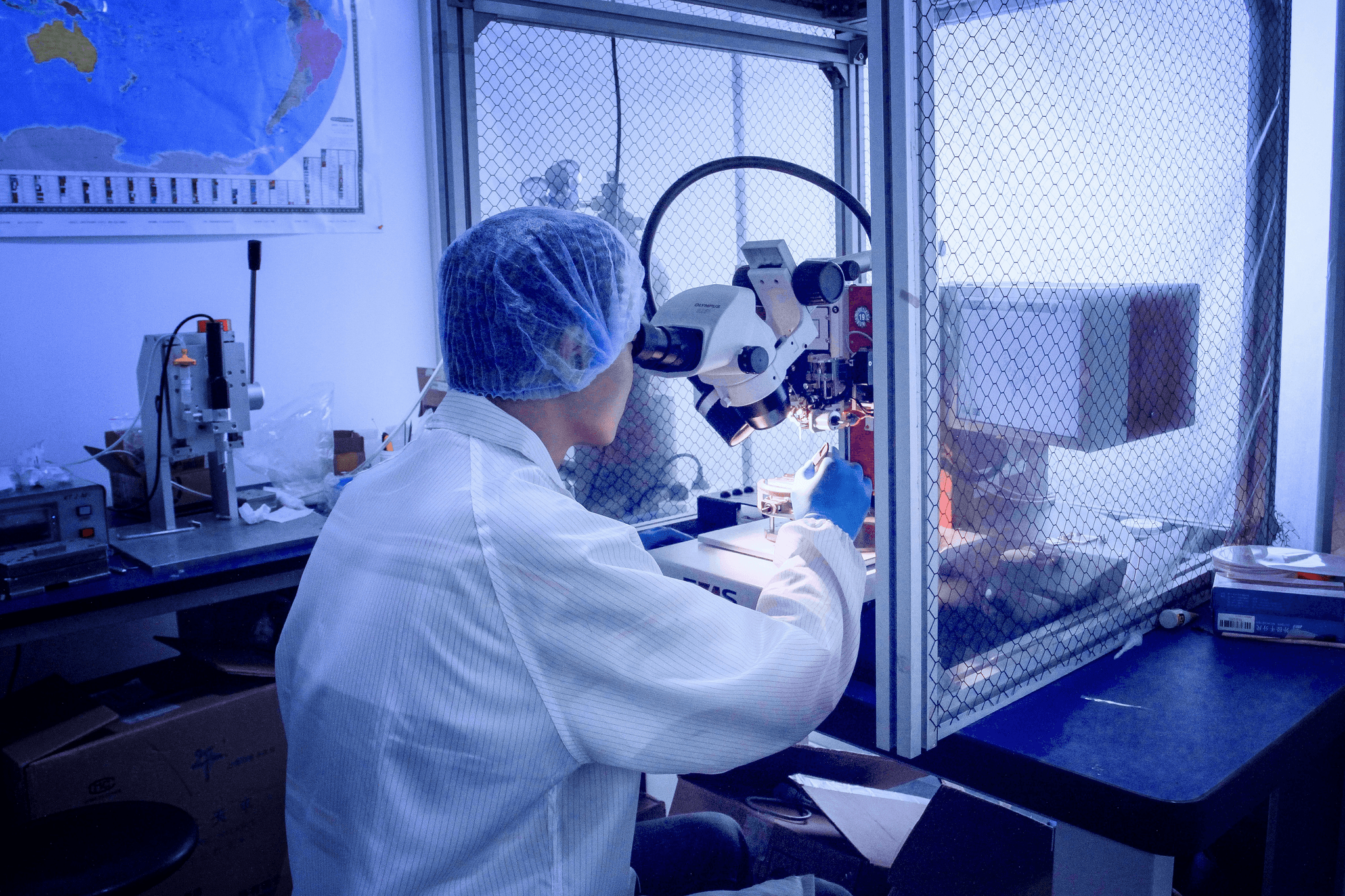

Equipment Inspections and Best Practices

Equipment inspections are a critical component of maintaining high-quality standards in laboratories. Regular checks help identify potential issues before they escalate into costly problems or affect test results—think of it as a preventative maintenance plan for your lab gear! Establishing best practices for equipment inspections ensures that all instruments operate within their specified parameters while also adhering to relevant regulations.

When conducting equipment inspections, it's important to document findings meticulously; this creates an audit trail that can be invaluable during compliance checks or when addressing discrepancies in test results. Additionally, implementing a routine schedule for these inspections minimizes downtime while maximizing reliability—after all, no one wants to be caught off guard by malfunctioning machinery during a crucial test! Remember: effective equipment inspections not only uphold the integrity of your quality control tests list but also contribute significantly to achieving acceptable quality levels (AQL).

Parts Inspection Techniques for Quality Assurance

Parts inspection techniques are essential for ensuring that every component used within laboratory processes meets stringent quality standards. From visual examinations to more advanced methods like non-destructive testing (NDT), various techniques can be employed depending on the nature of the parts being inspected. By incorporating these methods into your quality control framework, you enhance both product reliability and safety.

Understanding the difference between inspection and quality control is crucial here; while inspection focuses on identifying defects after production, effective parts inspection aims to prevent defects from occurring in the first place through rigorous testing protocols. This proactive approach not only saves time but also reduces waste—a win-win situation! Furthermore, establishing clear acceptance criteria helps streamline parts inspection processes by setting defined thresholds for what constitutes an acceptable product.

Acceptance Quality Limits

When it comes to maintaining high standards in laboratory settings, understanding Acceptance Quality Limits (AQL) is crucial. AQL serves as a benchmark for determining the maximum number of defective items considered acceptable during quality control tests. By incorporating AQL into your quality control tests list, you can streamline equipment inspections and ensure that parts inspection processes are both effective and efficient.

Defining Acceptance Quality Limit

Acceptance Quality Limit (AQL) is essentially a threshold that defines the maximum allowable defect rate in a batch of products or samples. In other words, it's the point at which a product's quality is deemed unacceptable based on predefined criteria. This concept plays a vital role in quality control tests list by ensuring that any deviations from expected standards are identified early, preventing costly errors down the line.

AQL Acceptable Quality Level Explained

The term AQL acceptable quality level refers to specific numerical values set within the context of a testing plan or inspection process. These values indicate how many defects are permissible before an entire batch is rejected during equipment inspections or parts inspection activities. Understanding this level helps laboratories maintain compliance with industry standards while also effectively managing risks associated with product defects.

How AQL Applies in Lab Settings

In laboratory settings, applying AQL can be particularly beneficial when conducting China FBA inspections or evaluating products for compliance with safety regulations. It allows labs to assess whether their processes meet established benchmarks without compromising on quality. By integrating AQL into your quality control tests list, you can create more robust protocols that differentiate between inspection and quality control—ensuring that only products meeting stringent criteria make it through to market.

Quality Control Processes

Quality control processes are essential for ensuring that laboratory results are accurate, reliable, and consistent. By establishing a structured approach to quality control, labs can minimize errors and enhance the overall quality of their outputs. This section will guide you through the steps in developing a quality control tests list, techniques for effective quality management, and how to implement these practices in China FBA inspections.

Steps in Developing a Quality Control Tests List

Creating a comprehensive quality control tests list is crucial for any laboratory aiming to maintain high standards. The first step involves identifying the specific tests that need to be performed based on the types of products or services offered by the lab. Once identified, it’s important to outline the acceptance quality limits (AQL) for each test, ensuring that everyone understands what constitutes acceptable performance.

Next, prioritize the tests based on their significance and impact on overall lab operations. For instance, equipment inspections should be conducted regularly to prevent breakdowns and ensure accuracy in measurements. Finally, document all procedures clearly; this not only helps with training new staff but also aids in maintaining consistency across various testing phases.

Techniques for Effective Quality Management

Effective quality management hinges on several key techniques that help maintain high standards throughout laboratory operations. One such technique is implementing regular training sessions for staff members focusing on both inspection procedures and understanding the difference between inspection and quality control itself. By equipping your team with knowledge about parts inspection methods and best practices, you foster an environment of continuous improvement.

Another technique involves utilizing statistical process control (SPC) methods to monitor ongoing processes actively. This allows labs to detect variations early on before they escalate into significant issues impacting product quality or compliance with AQL standards. Regular audits of both equipment inspections and testing protocols can also provide insights into areas needing improvement while reinforcing accountability among team members.

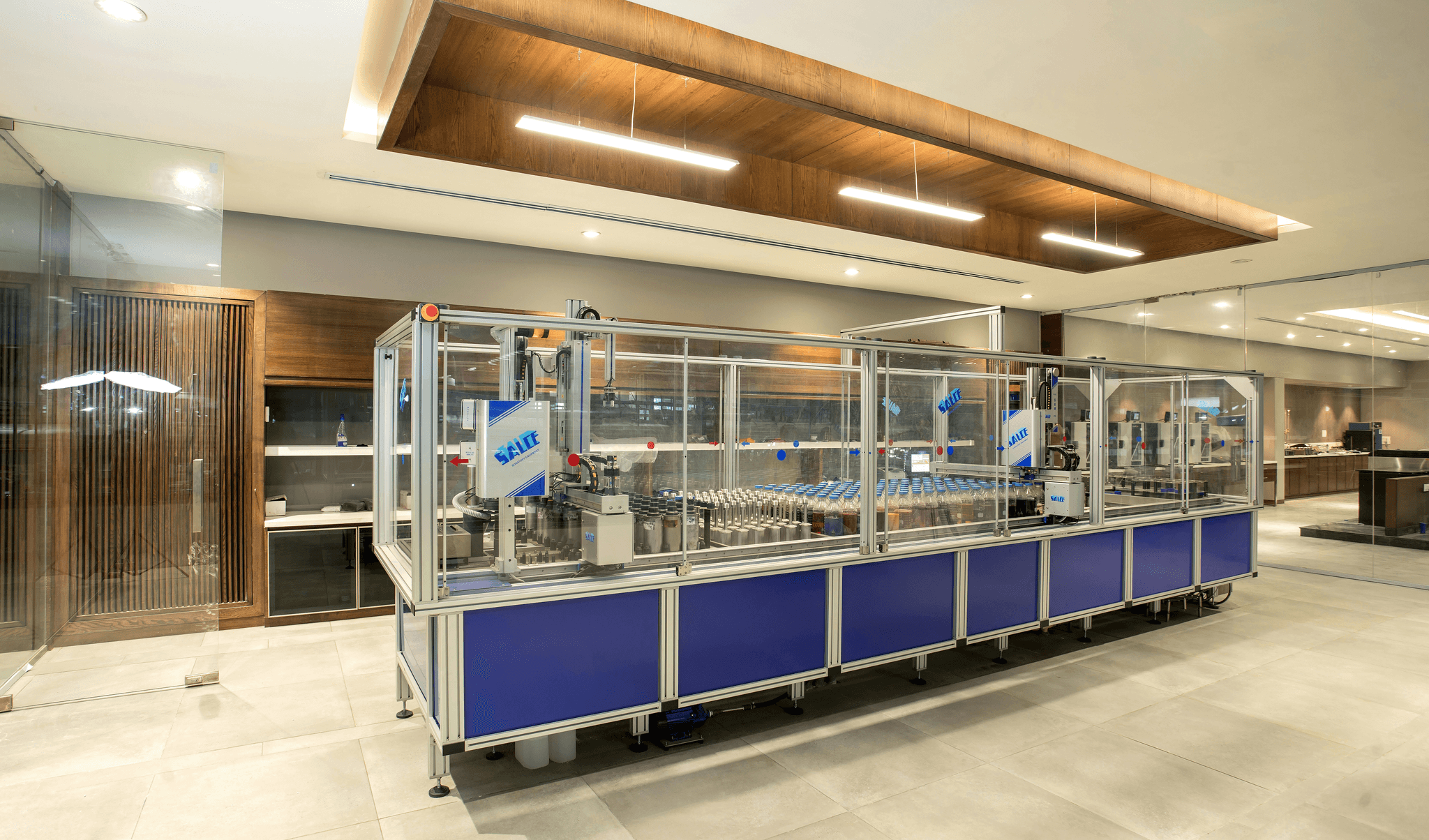

Implementing Quality Control in China FBA Inspection

First off, it's essential to familiarize yourself with local regulations regarding product safety and compliance; this ensures that your products meet both international standards and specific market requirements. Developing a tailored quality control tests list that addresses these needs will streamline your inspection process significantly.

Incorporating technology into your inspection procedures can also enhance efficiency dramatically—consider using software solutions designed specifically for managing quality assurance during overseas shipments. These tools can help automate parts inspection processes while providing real-time data regarding compliance levels against established AQL benchmarks. Ultimately, successful implementation hinges on collaboration between manufacturers and inspectors; clear communication about expectations will lead to better outcomes across all stages of production.

Best Practices for Quality Control Testing

Quality control testing is like the fine-tuning of a symphony; without it, the performance can fall flat. To ensure that your quality control tests list is not just a checkbox exercise but a robust framework for excellence, there are several best practices to consider. These practices will help you maintain high standards, minimize errors, and ultimately deliver products that meet or exceed expectations.

Tips for Conducting Rigorous Tests

When it comes to conducting rigorous tests, consistency is key. Start by ensuring that your quality control tests list includes standardized procedures for each test you perform, whether it's parts inspection or equipment inspections. This consistency helps mitigate the risk of variability in results and ensures that every item meets the acceptance quality limit (AQL) you’ve set.

Another tip is to use well-calibrated equipment during testing. If your tools aren’t up to par, even the most meticulous inspection can yield inaccurate results. Regularly scheduled maintenance and recalibration should be part of your quality control strategy to ensure that all aspects of testing adhere to the highest standards.

Finally, document everything! A thorough record-keeping system allows you to track trends over time and spot potential issues before they escalate. By maintaining detailed logs of all inspections and tests performed, you'll have valuable data at hand when analyzing performance against your AQL acceptable quality level benchmarks.

Importance of Training and Certification

Training and certification are vital components in establishing an effective quality control process. Employees who understand the difference between inspection and quality control are better equipped to identify defects early in production or testing phases. Investing in comprehensive training programs ensures that staff members are not only familiar with the equipment but also understand how their roles contribute to overall product quality.

Furthermore, certification programs can enhance credibility both internally and externally. When team members hold recognized certifications related to quality management or specific testing methodologies, it instills confidence among stakeholders regarding your commitment to maintaining high-quality standards throughout production processes.

Lastly, ongoing education should be a part of your culture—quality assurance isn’t static; it evolves with technology and industry standards. Encouraging employees to pursue further training keeps everyone updated on best practices while reinforcing a strong commitment to excellence within your organization.

Utilizing China Inspection Pro for Quality Assurance

When navigating the complexities of global supply chains—especially with China FBA inspection—it’s crucial to leverage tools like China Inspection Pro for effective quality assurance measures. This platform offers tailored solutions specifically designed for various stages of product development while ensuring compliance with international standards on your quality control tests list.

By utilizing such specialized services, you can streamline parts inspection processes while benefiting from local expertise in handling cultural nuances during inspections—an often overlooked aspect when dealing with overseas suppliers! This ensures not only adherence to acceptance quality limits but also enhances communication between parties involved in production.

Moreover, integrating advanced software solutions into your workflow allows real-time tracking of inspections against predefined AQL acceptable quality levels. With this level of oversight at hand, you can quickly identify any discrepancies before they become costly problems down the line—because nobody wants surprises when it comes time for delivery!

Conclusion

In the realm of laboratory operations, a comprehensive quality control tests list is not just a luxury; it's a necessity. This list serves as a roadmap for ensuring that all processes meet stringent standards, ultimately safeguarding the integrity of results. Without it, laboratories risk compromising their credibility and the trust of their stakeholders.

Importance of a Comprehensive Quality Control Tests List

A well-structured quality control tests list is pivotal in identifying potential flaws in both equipment inspections and processes before they escalate into significant issues. By systematically documenting each test, including parts inspection techniques, labs can ensure compliance with established protocols and standards. Moreover, such lists help streamline operations, making it easier to train staff on the essential aspects of quality management.

The inclusion of acceptance quality limits (AQL) within this framework further enhances its effectiveness by providing clear benchmarks against which performance can be measured. Understanding the difference between inspection and quality control also plays a crucial role; while inspection may catch defects post-production, quality control aims to prevent them from occurring in the first place. Therefore, integrating these elements into your quality control tests list is vital for achieving optimal outcomes.

Future Trends in Quality Control Testing

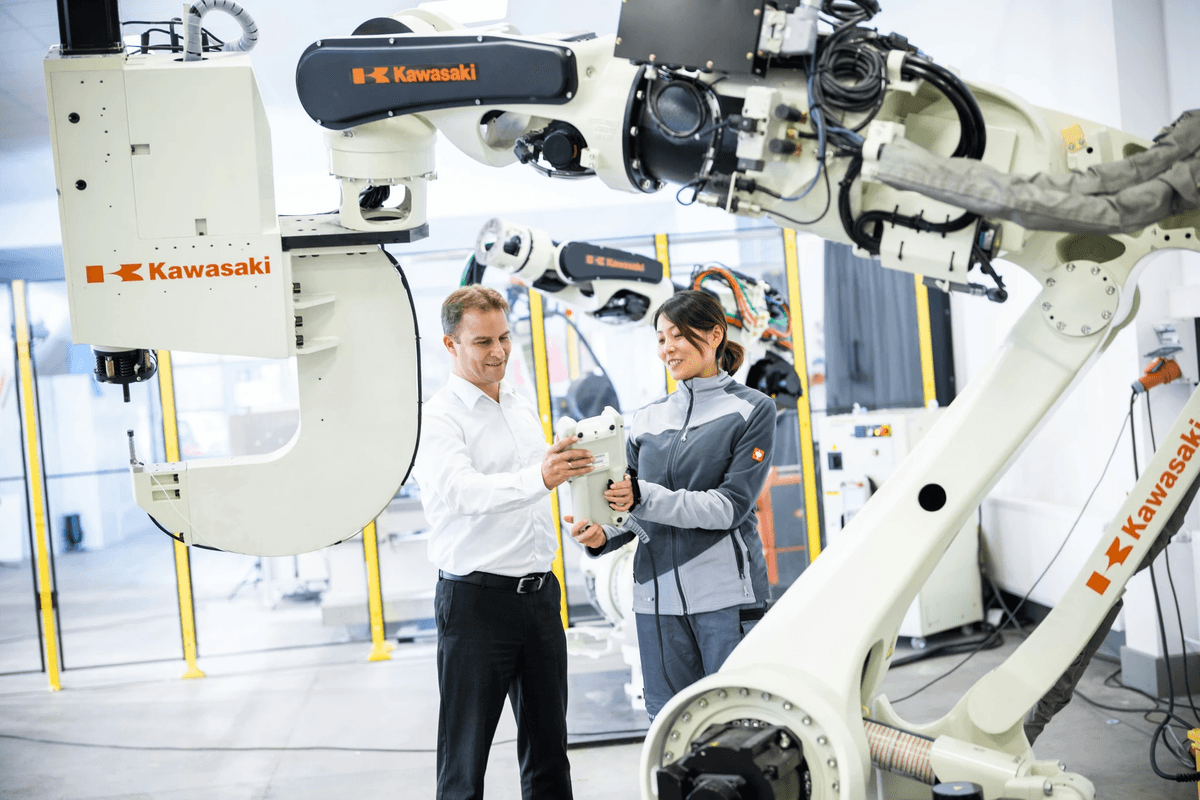

As technology continues to evolve, so too does the landscape of quality control testing. One emerging trend involves utilizing artificial intelligence and machine learning to enhance precision in equipment inspections and data analysis. These advancements promise to revolutionize how laboratories conduct parts inspection, making processes faster and more reliable than ever before.

Additionally, with globalization expanding markets like China FBA inspection services, laboratories must adapt their practices to meet diverse regulatory requirements across different regions. The emphasis on AQL acceptable quality levels will likely increase as companies strive for consistency in product delivery worldwide. This shift will necessitate continuous training for personnel to stay updated on best practices and emerging technologies.

Key Takeaways for Effective Quality Management

To foster effective quality management within laboratories, it's crucial to maintain an updated and comprehensive quality control tests list that incorporates various testing methods tailored to specific needs. Regularly reviewing equipment inspections alongside parts inspection techniques ensures that any potential issues are caught early on—before they affect overall lab performance or product integrity.

Moreover, understanding acceptance quality limits (AQL) enables labs to set realistic expectations while minimizing waste and maximizing efficiency—a win-win scenario! Ultimately, by prioritizing these strategies within your operational framework, you can significantly enhance your lab's credibility while navigating future trends with confidence.