Introduction

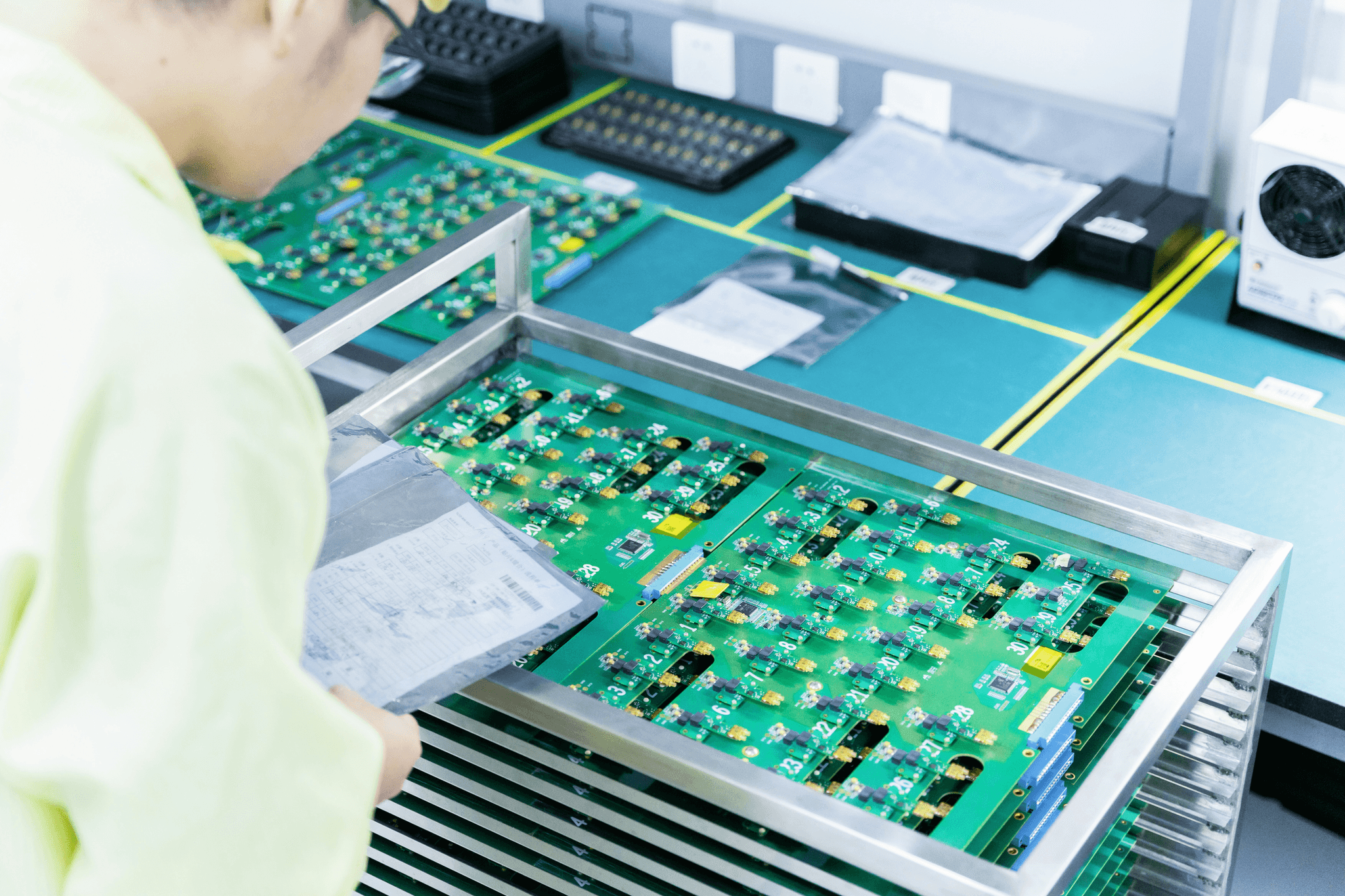

In a world where quality and safety are paramount, third party inspection agencies have emerged as critical players in the manufacturing landscape. These agencies provide an essential layer of oversight, ensuring that products meet defined standards before they reach consumers. With the complexities of global supply chains, particularly in regions like China, FBA inspection has become increasingly vital for businesses aiming to maintain high-quality benchmarks.

Understanding Third Party Inspection Agencies

Third party inspection agencies serve as impartial evaluators in the manufacturing process, offering services that range from initial assessments to final inspections before shipment. Their role is especially crucial when navigating the intricacies of acceptance quality limits (AQL), which set the standard for acceptable quality levels in production runs. By engaging these agencies, companies can ensure that their products not only comply with regulations but also resonate with consumer expectations for reliability and safety.

The Role of Safety in Industry

Safety is not just a regulatory requirement; it’s a foundational principle that drives business success across industries. Third party inspection agencies play an instrumental role in safeguarding this principle by conducting thorough evaluations that identify potential hazards before they escalate into serious issues. In sectors where parts inspection is critical—such as automotive or aerospace—these inspections help prevent costly recalls and enhance overall public trust.

Importance of Quality Control

Quality control is more than a buzzword; it’s an ongoing commitment to excellence that distinguishes successful companies from their competitors. By implementing rigorous quality control measures backed by third party inspections, businesses can effectively manage risks associated with product defects and non-compliance issues. Understanding the difference between inspection and quality control is essential; while inspections verify compliance at specific points in time, quality control encompasses continuous monitoring throughout the production process to ensure consistent performance.

The Function of Third Party Inspection Agencies

In a world where quality can make or break a business, third party inspection agencies play a pivotal role in ensuring products meet stringent standards. These agencies provide objective assessments that not only verify compliance but also enhance the credibility of manufacturers. By employing rigorous evaluation methods, they help businesses maintain high-quality levels and adhere to safety regulations.

Objective Assessments for Quality Assurance

Objective assessments from third party inspection agencies are crucial for establishing reliable quality assurance protocols. These inspections utilize standardized criteria, such as the acceptance quality limit (AQL), to determine whether products meet predetermined specifications. For instance, in the case of China FBA inspection, these agencies meticulously evaluate goods before they reach consumers, ensuring that only items meeting AQL standards are shipped.

The difference between inspection and quality control becomes apparent when considering these objective assessments. While quality control focuses on processes within a company, third party inspections provide an unbiased external review that can highlight potential issues before they escalate. This dual approach not only fortifies product integrity but also reassures clients about the quality of what they're purchasing.

Building Trust with Clients and Consumers

Building trust is essential in any business relationship, and third party inspection agencies excel at fostering this trust through transparency and accountability. When clients know their products undergo thorough evaluations by independent inspectors, it instills confidence in the manufacturing process and final output. This trust is especially vital when dealing with overseas suppliers; for example, businesses relying on China FBA inspection can mitigate risks associated with international trade.

Moreover, consumers today demand transparency regarding product sourcing and safety standards—something that third party inspectors readily provide through detailed reports and certifications. This level of scrutiny helps companies differentiate themselves in crowded markets by demonstrating their commitment to quality assurance practices. Ultimately, when businesses partner with reliable inspection agencies, they create a ripple effect of trust that extends from suppliers to end-users.

Case Studies: Success Stories in Various Industries

Numerous industries have reaped significant benefits from collaborating with third party inspection agencies—especially those reliant on parts inspection for manufacturing excellence. Take the automotive industry as an example; here, rigorous inspections ensure that each component meets safety regulations while adhering to AQL standards for performance reliability. Companies like Ford have successfully implemented third party evaluations across their supply chains to maintain high-quality benchmarks.

In another instance, consider electronics manufacturers who utilize thorough inspections to avoid costly recalls due to defective components—a scenario no one wants to face! By leveraging the expertise of third party inspectors who specialize in parts inspection and adherence to acceptance quality limits (AQL), these manufacturers can significantly reduce risks associated with faulty products entering the market. Such success stories underscore how vital these partnerships are across various sectors striving for excellence.

The Process of Inspection

When it comes to ensuring quality and safety in manufacturing, the process of inspection is paramount. Third party inspection agencies play a crucial role in this process, providing an objective lens through which products and components can be evaluated. This section will delve into the key steps involved in inspections, what to expect from expert evaluations, and real-world examples that highlight the effectiveness of these agencies.

Key Steps in the Inspection Procedure

The inspection procedure typically begins with a thorough pre-inspection planning phase. Third party inspection agencies will review product specifications and quality standards to establish a clear framework for evaluation. Following this, inspectors conduct on-site assessments, focusing on various criteria such as adherence to AQL (Acceptable Quality Level) standards and compliance with industry regulations.

Once the inspection is underway, inspectors meticulously examine samples according to predetermined acceptance quality limits (AQL). This step is critical because it ensures that any defects or deviations are identified early on, preventing potential issues down the line. After completing the inspections, agencies compile detailed reports that outline findings and recommendations for improvement.

Finally, feedback sessions are held with manufacturers to discuss results and strategies for enhancing product quality. This collaborative approach not only fosters transparency but also builds trust between third party inspection agencies and clients seeking assurance about their products' safety and reliability.

Expert Evaluations: What to Expect

When engaging with third party inspection agencies for expert evaluations, clients can expect a comprehensive assessment conducted by seasoned professionals. These experts come equipped with specialized knowledge of industry standards and practices related to parts inspection. Their experience allows them to identify potential pitfalls that may not be immediately apparent during standard quality control checks.

During inspections, evaluators employ various techniques tailored to specific industries or products—whether it's checking dimensional accuracy in manufacturing or assessing material integrity in construction materials like composite decking. Clients can anticipate receiving insightful feedback that goes beyond mere pass/fail metrics; these evaluations often include actionable recommendations aimed at improving overall product quality.

Moreover, transparency is key during expert evaluations; clients should feel empowered to ask questions throughout the process. This open dialogue helps demystify the difference between inspection and quality control while ensuring everyone involved understands how each contributes uniquely toward achieving safety objectives.

Examples of Third Party Inspections in Action

To illustrate how effective third party inspections can be across different sectors, let’s look at some compelling case studies showcasing their impact. In one instance involving China FBA inspections for electronics manufacturers, third party inspectors identified significant flaws during pre-shipment checks—preventing defective products from reaching consumers’ hands and safeguarding brand reputation.

Another notable example comes from automotive parts suppliers who engaged third party inspection agencies for routine assessments of their components before assembly lines began running full throttle. By adhering closely to AQL standards during parts inspections—particularly regarding acceptance quality limits—the suppliers were able to significantly reduce recall rates due to faulty parts.

Lastly, consider a food processing plant where thorough inspections by independent agencies ensured compliance with health regulations while maintaining high-quality production standards. These real-world applications highlight how partnering with third party inspection agencies not only enhances product safety but also instills confidence among consumers regarding what they purchase.

Understanding AQL and Acceptance Quality Level

In the world of manufacturing, the concept of Acceptance Quality Level (AQL) plays a crucial role in ensuring that products meet established quality standards. AQL refers to the maximum number of defective items considered acceptable during random sampling inspections. This standard is particularly important for third party inspection agencies, as it helps them determine whether a batch meets quality requirements before it reaches consumers.

Defining AQL and Its Importance

AQL is essentially a statistical measure that defines the threshold for acceptable quality in manufactured goods. It acts as a safety net, allowing manufacturers to assess their products while minimizing risks associated with defects. By understanding AQL, businesses can maintain high-quality standards and foster trust with clients, particularly in industries like electronics or textiles where even minor defects can lead to significant issues.

For third party inspection agencies, adhering to AQL standards ensures an objective evaluation process during parts inspection. This not only protects consumers but also enhances the reputation of manufacturers who prioritize quality control. Ultimately, establishing clear AQL benchmarks is vital for companies looking to thrive in competitive markets.

How Third Party Agencies Use AQL Standards

Third party inspection agencies employ AQL standards as part of their comprehensive assessment processes when evaluating products from various manufacturers. These agencies utilize statistical sampling techniques based on predetermined acceptance levels to evaluate batches effectively. When conducting inspections—such as China FBA inspection—they analyze samples against established criteria to determine if they fall within acceptable limits.

By leveraging these standards, third party inspectors provide valuable insights into product quality and help identify areas for improvement. This collaborative approach between manufacturers and third party agencies ultimately leads to enhanced safety measures and reduced risks associated with defective products reaching consumers’ hands. With clear definitions around acceptance quality limits, both parties can work together towards achieving optimal outcomes.

Real-World Applications of AQL in Manufacturing

In practice, real-world applications of AQL can be observed across various industries where product integrity is paramount—think automotive parts or consumer electronics manufacturing. For instance, an automotive manufacturer might set an AQL standard of 1% for critical components; this means that out of every 100 parts inspected, only one may be defective without triggering further action from the supplier or manufacturer.

Similarly, companies involved in textile production often use specific AQL levels tailored to different fabric types or end-use applications—ensuring that garments meet customer expectations upon delivery while minimizing returns due to defects. These practices illustrate how effective implementation of acceptance quality levels by third party inspection agencies can lead directly to improved safety outcomes and customer satisfaction across diverse sectors.

The Difference Between Inspection and Quality Control

Understanding the distinction between inspection and quality control is crucial for anyone involved in manufacturing or product development. While both processes aim to ensure product safety and quality, they adopt different approaches and techniques. This section will clarify key terminology, explore how each process contributes to safety, and provide real-world examples that illustrate their differences.

Clarifying Key Terminology

Inspection refers to the systematic examination of products or components to determine their conformity with specified requirements. Third party inspection agencies often conduct these inspections, providing an unbiased assessment of quality before products reach consumers. On the other hand, quality control encompasses a broader scope, focusing on the entire production process to prevent defects from occurring in the first place.

In essence, while inspection is a snapshot of product quality at a given moment, quality control is an ongoing process aimed at continuous improvement. Terms like acceptance quality limit (AQL) come into play here; AQL defines the maximum number of defective items considered acceptable during random sampling inspections. By understanding these terms, businesses can better navigate their roles in ensuring high standards.

How Each Process Contributes to Safety

Both inspection and quality control play vital roles in maintaining safety within manufacturing environments. Third party inspection agencies help identify potential hazards by examining products against established standards before they hit the market—think of it as a safety net that catches issues early on. Quality control systems proactively address potential failures throughout production cycles by implementing preventive measures based on data analysis.

For example, effective parts inspection can prevent defective components from making it into final assemblies, thus safeguarding end-users from risks associated with faulty products. The difference between inspection and quality control ultimately lies in their timing; while inspections are reactive assessments that catch problems after they occur, quality control seeks to eliminate those problems before they arise altogether. Both strategies are essential for building trust with consumers and ensuring compliance with industry regulations.

Real-World Examples: Inspection vs. Quality Control

To illustrate the difference between inspection and quality control more vividly, consider two scenarios involving third party inspection agencies engaged in China FBA inspections for e-commerce sellers. In one case, an agency conducts a pre-shipment inspection where they evaluate product samples against AQL standards; this ensures that only acceptable quantities of defects are shipped out according to predetermined acceptance levels.

In contrast, another company implements robust internal quality control measures throughout its manufacturing processes—monitoring everything from raw material selection to final assembly checks—to minimize any risk of defects occurring at all. While both companies benefit from improved safety and consumer confidence through their respective approaches, one relies heavily on third party inspections for external validation while the other emphasizes proactive internal controls.

In conclusion, recognizing the difference between inspection and quality control enables businesses to make informed decisions about how best to ensure product safety and maintain high-quality standards throughout their operations.

Parts Inspection: A Critical Component

Parts inspection is an essential aspect of manufacturing that ensures products meet the required specifications and standards. By focusing on the quality of individual components, manufacturers can prevent defects from cascading down the production line. This process is particularly crucial in industries where safety and reliability are non-negotiable, making third party inspection agencies vital partners in maintaining high quality.

Importance of Parts Inspection in Manufacturing

In manufacturing, parts inspection serves as a gatekeeper for quality assurance, ensuring that each component meets predetermined standards before assembly. The role of third party inspection agencies becomes even more significant when dealing with suppliers from regions like China, where FBA (Fulfillment by Amazon) inspection services help maintain product integrity. By adhering to acceptance quality limits (AQL), manufacturers can significantly reduce the risk of defects reaching consumers, thereby enhancing brand reputation and customer trust.

Techniques Used by Third Party Inspectors

Third party inspectors employ a variety of techniques to evaluate parts effectively and efficiently. These methods often include visual inspections, dimensional checks, and functional testing to ensure compliance with industry standards. Additionally, using statistical sampling methods based on AQL helps inspectors determine whether a batch meets the acceptable quality level or if further action is needed to rectify issues before products hit the market.

Composite Decking Inc: Maintaining Quality Through Inspection

Composite Decking Inc serves as an exemplary case study showcasing how rigorous parts inspection contributes to overall product excellence. By partnering with third party inspection agencies, they ensure that every piece of decking material undergoes thorough evaluation against strict AQL criteria before distribution. This commitment not only sets them apart from competitors but also reinforces their dedication to safety and quality control—illustrating the clear difference between mere inspection processes and comprehensive quality control measures.

Conclusion

In conclusion, the partnership with third party inspection agencies is not just a smart move; it's an essential strategy for businesses aiming to thrive in today's competitive landscape. These agencies provide an unbiased eye on quality, ensuring that products meet the necessary standards before they hit the market. By leveraging their expertise, companies can enhance their reputation and build stronger relationships with clients and consumers alike.

Benefits of Partnering with Third Party Agencies

The benefits of collaborating with third party inspection agencies are manifold. First and foremost, they offer objective assessments that help establish confidence in product quality, which is crucial for maintaining customer trust. Moreover, services like China FBA inspection provide manufacturers with peace of mind by ensuring compliance with international standards and reducing costly errors related to the acceptance quality limit.

Additionally, these agencies are well-versed in understanding the difference between inspection and quality control, allowing them to tailor their services effectively to meet specific needs. This partnership can lead to significant improvements in efficiency and product reliability while minimizing risks associated with poor quality or safety issues. Ultimately, engaging third party inspectors fosters a culture of accountability within organizations.

The Future of Safety and Quality Assurance

Looking ahead, the future of safety and quality assurance appears promising as industries increasingly recognize the importance of rigorous inspections. With advancements in technology such as AI-driven analysis and real-time monitoring systems, third party inspection agencies will be better equipped to deliver accurate evaluations promptly. These innovations will likely enhance adherence to AQL acceptable quality levels across various sectors.

Moreover, as global markets expand, businesses must adapt by prioritizing compliance with international regulations—something that third party inspectors excel at facilitating. The integration of sustainable practices into manufacturing processes will also play a pivotal role in shaping future inspections; expect these agencies to evolve alongside emerging industry standards focused on environmental responsibility.

Making Informed Decisions in Manufacturing

Making informed decisions in manufacturing requires a comprehensive understanding of both parts inspection techniques and overall production processes. Companies should prioritize collaboration with reputable third party inspection agencies that offer transparency throughout their evaluation procedures—this ensures all stakeholders are aligned on expectations regarding product quality and safety measures.

Furthermore, understanding concepts like AQL acceptable quality level is paramount for manufacturers aiming to maintain high standards without compromising efficiency or cost-effectiveness. By distinguishing between inspection methods and traditional quality control practices, organizations can adopt strategies that optimize performance while safeguarding consumer interests.

In summary, embracing partnerships with third party inspection agencies is crucial for navigating today's complex manufacturing landscape while ensuring product integrity remains front and center.