Introduction

In today's fast-paced business landscape, the significance of quality control (QC) cannot be understated. A robust QC quality check ensures that products and services meet established standards, fostering customer trust and satisfaction. Understanding the nuances of quality assurance (QA) and its relationship with QC is essential for any organization aiming for success.

Understanding the Importance of QC

Quality control serves as a foundational pillar in various industries, from manufacturing to healthcare. By implementing effective QC practices, companies can minimize errors and defects, ultimately leading to enhanced operational efficiency. The ripple effect of a solid QC system extends beyond immediate outcomes; it builds a reputation for reliability and excellence in the market.

Key Elements of Quality Control

At the heart of effective quality control are several key elements that ensure consistent performance. These include establishing clear quality standards, conducting thorough inspections, and utilizing advanced tools for monitoring processes. Each element plays a crucial role in creating an environment where QA quality assurance thrives alongside stringent QC practices.

The Role of Quality Assurance in Success

Quality assurance is not merely an afterthought; it's integral to achieving long-term success in any business endeavor. By focusing on proactive measures rather than reactive fixes, QA assurance enhances the overall effectiveness of QC initiatives. This synergy between QA quality practices and QC processes cultivates a culture where continuous improvement becomes part of the organizational DNA.

What is QC and Why It Matters

Quality Control (QC) is a systematic process that ensures products or services meet specified requirements and standards. It acts as a safeguard against defects, ensuring that what reaches the customer is reliable and effective. Understanding QC quality checks is crucial in maintaining high levels of quality and assurance throughout production processes.

Defining QC Quality Check

A QC quality check refers to the procedures employed to assess whether products meet predetermined quality standards before they are released for sale or distribution. These checks can include inspections, tests, and evaluations designed to identify any discrepancies or defects in the product. By implementing thorough qc quality checks, businesses can enhance customer satisfaction and reduce costly returns due to poor quality.

Differentiating Quality Control and Assurance

While both Quality Control (QC) and Quality Assurance (QA) aim to ensure product excellence, they serve distinct purposes in the production process. QC focuses on identifying defects in finished products through inspections and testing, while QA encompasses the entire process of development to ensure that systems are in place for maintaining quality standards from start to finish. Understanding this difference helps organizations implement effective strategies for both qc quality control and qa assurance.

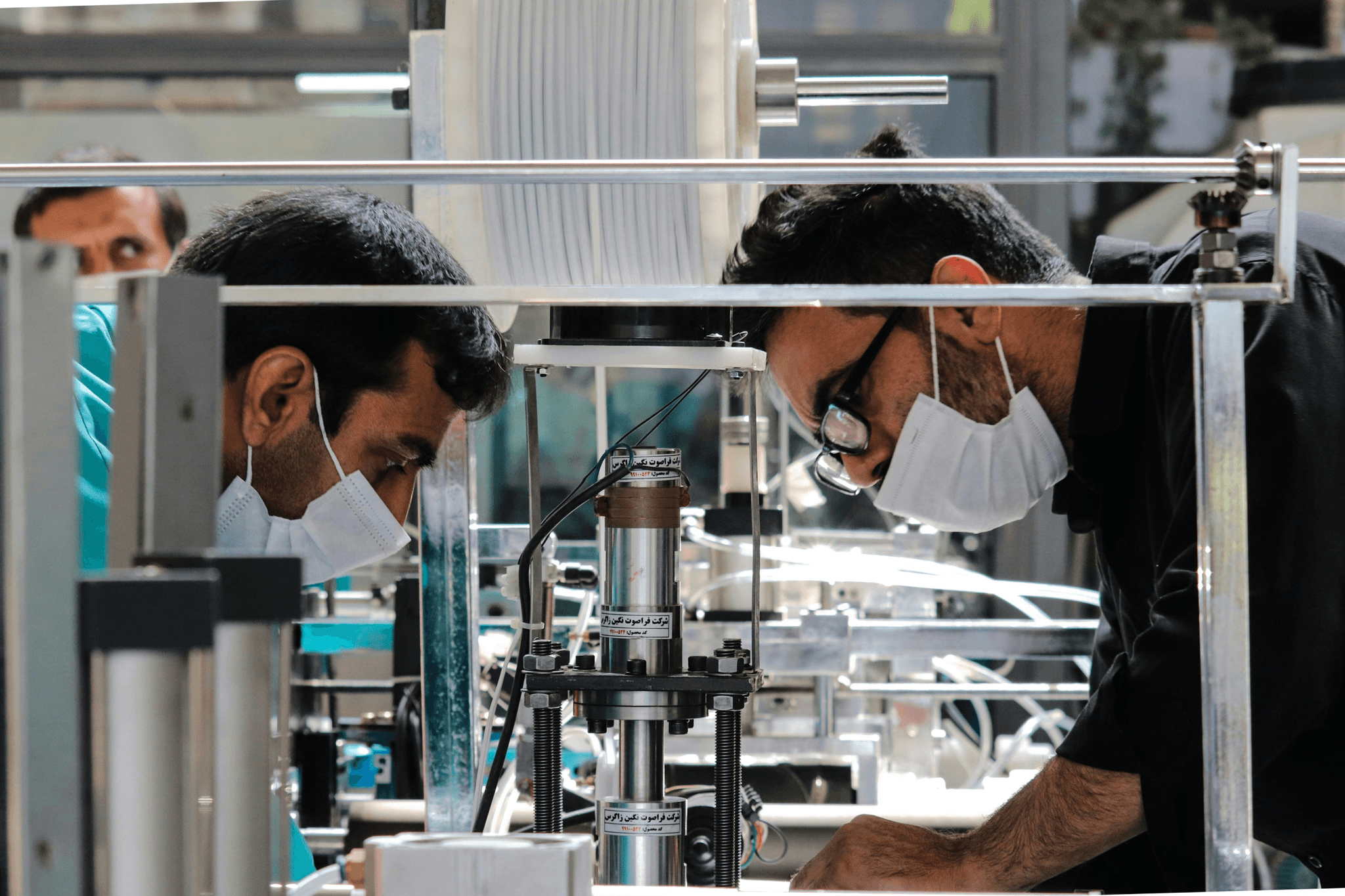

Importance of QC in Various Industries

The significance of QC extends across multiple industries—from manufacturing to healthcare—where ensuring consistent product reliability is paramount. In manufacturing, for instance, qc quality control processes help prevent defective products from reaching consumers, thereby protecting brand reputation and reducing waste. Similarly, in healthcare settings, rigorous qa quality measures ensure patient safety by maintaining high standards for medical devices and treatments.

Steps to Implementing QC Quality Control

Implementing effective QC quality control is essential for ensuring that products and services meet established standards of quality and assurance. This process involves several key steps that can help organizations maintain high standards while also fostering a culture of continuous improvement. Let’s delve into these steps to understand how they contribute to successful quality management.

Establishing Clear Quality Standards

The first step in the QC quality control process is establishing clear quality standards that align with industry regulations and customer expectations. These standards serve as a benchmark against which all products and services can be measured, ensuring consistency in quality assurance efforts. By defining specific criteria for what constitutes an acceptable level of quality, organizations can streamline their qc quality check processes, making it easier to identify deviations and implement corrective actions.

Involving stakeholders from different departments when setting these standards can lead to more comprehensive guidelines that reflect various perspectives within the organization. Additionally, revisiting these standards regularly helps keep them relevant as market conditions and consumer preferences evolve over time. Ultimately, well-defined quality standards are the foundation of effective qc quality control practices.

Training Your Team Effectively

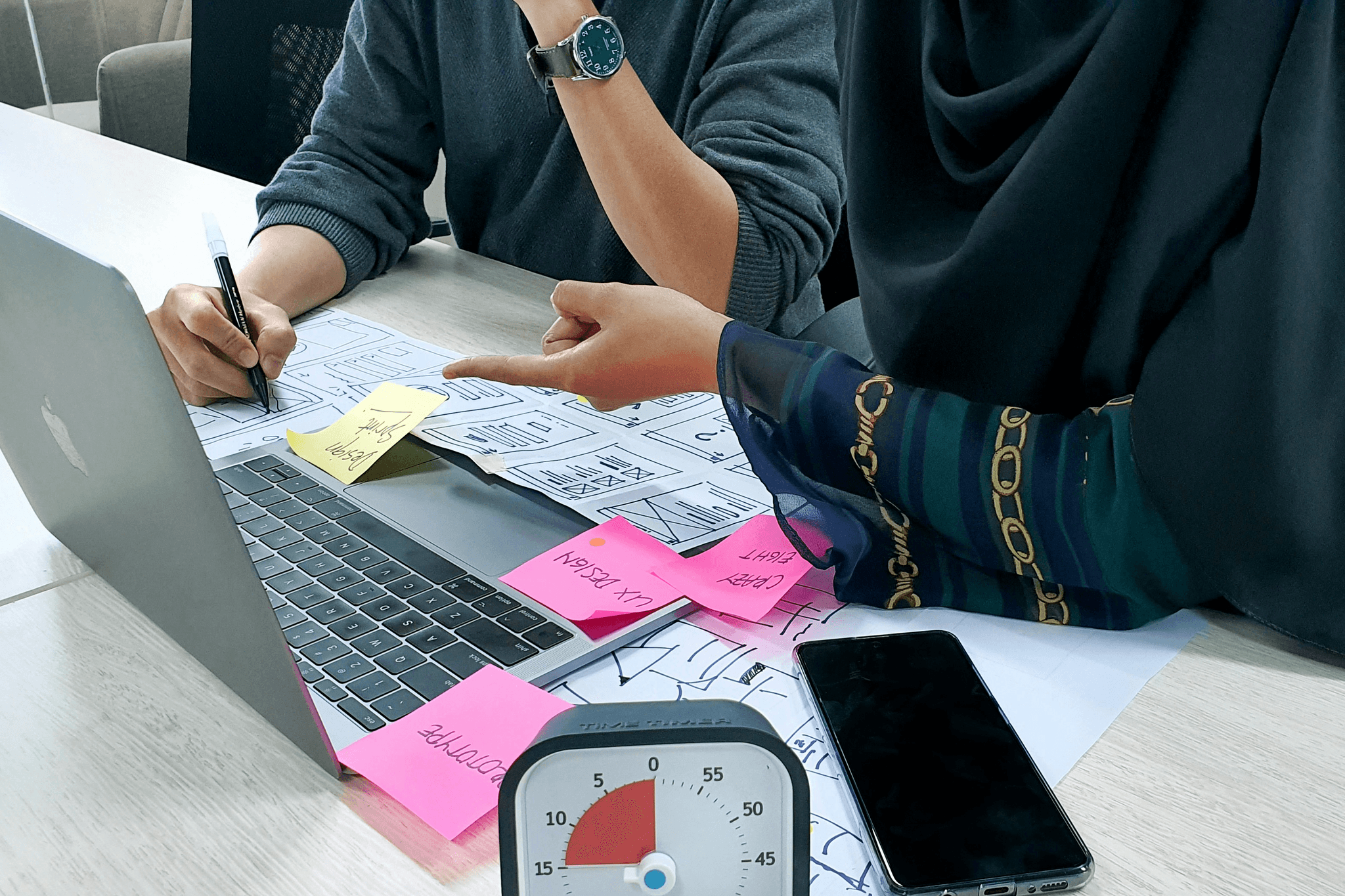

Once clear quality standards are established, the next crucial step is training your team effectively on these protocols. A well-informed workforce is vital for maintaining high levels of qc quality control; employees need to understand not only what the standards are but also why they matter in terms of overall product integrity and customer satisfaction. Regular training sessions ensure that everyone is on the same page regarding best practices in both qa assurance and qc processes.

Moreover, incorporating hands-on training allows team members to practice real-life scenarios where they can apply their knowledge in practical ways, enhancing retention and confidence in executing their roles. Encouraging a culture where questions are welcomed promotes an environment conducive to learning, ultimately leading to better performance in both qa quality assurance and general operational excellence.

Utilizing Quality Management Systems

To further enhance your qc processes, utilizing robust Quality Management Systems (QMS) can provide significant advantages in managing data related to qc quality checks effectively. A QMS helps streamline workflows by automating routine tasks such as documentation, reporting discrepancies, and tracking compliance with established standards—saving time while minimizing human error. With real-time data at your fingertips through a QMS platform, decision-making becomes more informed, allowing teams to respond quickly when issues arise.

Moreover, integrating a QMS fosters collaboration among departments by providing a centralized repository for all quality-related information; this encourages transparency throughout the organization regarding both successes and areas needing improvement within qa assurance efforts. Adopting modern technology solutions not only enhances efficiency but also positions your organization competitively within its industry by demonstrating a commitment to maintaining high-quality products or services.

Conducting Effective Quality Checks

In the realm of quality control, conducting effective quality checks is a cornerstone of ensuring that products meet established standards. This process not only helps in identifying defects but also reinforces the commitment to quality assurance throughout the organization. By implementing robust techniques for inspection, maintaining thorough documentation, and utilizing common tools, businesses can enhance their qc quality control processes significantly.

Techniques for Effective Quality Inspection

Effective quality inspection techniques are essential for any successful qc quality check. These methods can range from visual inspections to more sophisticated approaches such as automated testing and statistical sampling. The key is to choose techniques that align with the specific requirements of your product and industry while ensuring consistency in your quality assurance efforts.

One popular technique is the use of checklists, which help inspectors systematically evaluate each aspect of a product or process during qc quality control. Another effective method is employing metrics-based assessments, allowing teams to quantify performance and identify areas needing improvement. Ultimately, combining various techniques fosters an environment where both quality and assurance thrive.

Importance of Documentation in QC Processes

Documentation plays a vital role in the success of any qc quality check or overall quality control strategy. Properly recording findings not only provides a historical reference but also aids in identifying trends over time that can inform future decisions related to qa assurance practices. When issues arise, having detailed documentation allows teams to trace back through processes and pinpoint root causes efficiently.

Additionally, well-maintained records enhance accountability within teams by clearly outlining responsibilities associated with each step of the qc process. This transparency ensures that everyone involved understands their role in maintaining high standards of qa quality throughout production cycles. In essence, documentation transforms data into actionable insights that drive continuous improvement.

Common Tools for Quality Control

A variety of tools exist to support effective qc quality checks within organizations striving for excellence in their products and services. Some common tools include statistical process control (SPC) charts for monitoring performance over time, as well as failure mode and effects analysis (FMEA) for identifying potential risks before they become significant issues during production phases.

Other valuable resources include inspection software that streamlines data collection and reporting processes while reducing human error—ensuring accuracy in your qa assurance efforts is paramount! Additionally, utilizing digital dashboards facilitates real-time visibility into key performance indicators (KPIs), making it easier than ever to maintain high-quality standards across all operations.

Analyzing QC Findings

Once the QC quality check is complete, it's crucial to analyze the findings to ensure that quality control measures are effective. Interpreting these results accurately can help identify trends, pinpoint issues, and reinforce successful practices within your organization. By understanding what the data reveals about your processes or products, you can make informed decisions that contribute to continuous improvement and excellence in quality assurance.

Interpreting QC Quality Check Results

Interpreting the results of a QC quality check requires a keen eye for detail and an understanding of the established standards. Begin by comparing the findings against your predefined benchmarks; this will highlight areas where performance meets or exceeds expectations and where improvements are necessary. Additionally, look for patterns in defects or failures over time, as these insights can help you refine your processes and enhance overall quality control.

Making Informed Decisions Based on Data

Data-driven decision-making is essential in maintaining high standards of quality assurance and achieving operational success. When analyzing QC findings, consider not only what the data shows but also how it aligns with broader business objectives; this ensures that every action taken is strategically sound. For instance, if a specific defect rate is identified during a qc quality control process, targeted interventions can be designed to address those issues effectively rather than taking a generalized approach.

Continuous Improvement Through Analysis

Continuous improvement is at the heart of effective QA quality assurance practices; it’s an ongoing cycle of assessment and enhancement. By regularly analyzing QC findings, organizations can adapt their strategies based on real-time feedback from their operations or products. This iterative process not only fosters innovation but also reinforces a culture of accountability where everyone understands their role in achieving top-tier quality—because when it comes to qc quality checks, complacency is not an option!

Leveraging Expertise for Quality Assurance

In today's competitive landscape, leveraging expertise in quality assurance is not just an option; it's a necessity. Companies that collaborate with professionals, such as China Inspection Pro, can enhance their qc quality check processes significantly. By tapping into specialized knowledge and resources, businesses can ensure their quality control measures are robust and effective.

Collaborating with Professionals like China Inspection Pro

Partnering with experts like China Inspection Pro offers invaluable insights into the intricacies of qc quality control. These professionals bring experience from various industries, which helps in tailoring quality assurance practices to meet specific business needs. Their expertise not only streamlines the qc quality check process but also ensures compliance with international standards.

Moreover, collaborating with seasoned inspectors allows companies to identify potential pitfalls early in the production cycle. This proactive approach minimizes costly errors and enhances overall product reliability. As a result, businesses can focus on innovation while maintaining high standards of quality and assurance.

Benefits of Outsourcing Quality Control

Outsourcing quality control offers numerous advantages that can significantly impact a company's bottom line. First and foremost, it allows organizations to access specialized skills without the overhead costs associated with hiring full-time staff for qa quality assurance roles. This flexibility enables companies to allocate resources more efficiently while still ensuring rigorous qc quality checks are performed.

Additionally, outsourcing provides an objective perspective on product assessments, as third-party inspectors are less likely to be influenced by internal biases or pressures. This impartiality fosters trust among stakeholders and customers alike when it comes to product integrity and reliability. Ultimately, outsourcing enhances operational efficiency while upholding high standards of qa assurance.

Strategies for Maintaining High Standards

To maintain high standards in both qc quality control and qa quality assurance processes, organizations should implement several key strategies. First, establishing a culture that prioritizes continuous improvement is essential; this involves regular training sessions for employees on best practices in qc inspections and documentation methods. By keeping everyone informed about the latest industry trends and techniques, companies can foster an environment of excellence.

Next, utilizing technology such as automated systems for data collection can streamline qc checks and improve accuracy in reporting results. These tools facilitate real-time monitoring of production processes while ensuring compliance with established norms in quality assurance practices. Finally, regular audits of both internal processes and external partnerships will help identify areas needing improvement or adjustment.

By integrating these strategies into daily operations, businesses can create a sustainable framework that supports ongoing success in their commitment to delivering top-quality products consistently.

Conclusion

In wrapping up our exploration of quality control, it's crucial to recognize that QC is not just a checklist but a vital part of any successful operation. Effective quality checks ensure products meet standards and customer expectations, ultimately leading to business success. By integrating quality assurance into the fabric of your organization, you can foster a proactive approach to maintaining high standards.

Essential Takeaways for Successful QC

Successful QC hinges on establishing clear quality standards and ensuring everyone understands them. Quality control should be viewed as an ongoing process rather than a one-time effort; it requires regular assessments and adjustments based on data gleaned from qc quality checks. Remember, the goal is not just compliance but fostering an environment where quality becomes everyone's responsibility.

Building a Culture of Quality Assurance

Creating a culture centered around quality assurance involves engaging every team member in the process of qa quality assurance. This means providing training, encouraging feedback, and recognizing those who contribute to maintaining high-quality standards. When employees feel empowered and responsible for qa assurance, it leads to improved morale and better overall performance.

Future Trends in Quality Control and Assurance

Looking ahead, we can expect advancements in technology to further revolutionize how we approach qc quality control and assurance processes. Automation tools will streamline inspections while data analytics will provide deeper insights into performance trends, enabling smarter decision-making based on real-time information. As industries evolve, staying ahead with innovative approaches to quality will be key in maintaining competitive advantage.