Introduction

In the fast-paced world of manufacturing and production, understanding quality check standards is essential for maintaining product integrity and customer satisfaction. Quality checks serve as the backbone of a successful operation, ensuring that every product meets predefined specifications before it reaches the market. By implementing a robust quality check process, businesses can not only enhance their reputation but also minimize costly errors and defects.

Understanding Quality Check Standards

Quality check standards outline the criteria that products must meet to be deemed acceptable for sale or distribution. These standards vary by industry but generally include specific measurements, tolerances, and performance benchmarks that a quality check product must satisfy. Familiarity with these standards is crucial for companies aiming to maintain compliance and ensure their offerings are both safe and effective.

The Importance of Quality Control

Quality control is more than just a buzzword; it’s a vital aspect of any business strategy aimed at achieving excellence. By distinguishing between quality check vs quality control, we can see that while quality checks focus on assessing products at various stages, quality control encompasses broader organizational processes aimed at improving overall output. Investing in effective quality control measures ultimately leads to increased customer trust and loyalty, which are invaluable assets in today's competitive landscape.

How Quality Check Impacts Businesses

The impact of thorough quality checks on businesses is profound; they not only prevent defective products from reaching consumers but also foster continuous improvement within operations. A well-structured quality check process can lead to significant cost savings by reducing waste and enhancing efficiency across production lines. Furthermore, when customers receive high-quality products consistently, it strengthens brand reputation and drives repeat business—an undeniable win-win for any organization.

Defining Quality Check

Quality checks are essential components of any production process, ensuring that products meet established standards before they reach consumers. A quality check product encompasses a series of evaluations and inspections designed to identify defects, inconsistencies, or potential issues. Understanding the key elements of a quality check is vital for maintaining high standards and building customer trust.

Key Elements of a Quality Check

The key elements of a quality check revolve around precision, documentation, and consistency. Firstly, precise measurement tools are crucial for accurate assessments during the quality check process; these tools help in identifying deviations from desired specifications. Secondly, employing a well-structured quality check sheet can streamline the documentation process, making it easier to track findings and decisions throughout production.

Consistency is another cornerstone of effective quality checks; implementing standardized procedures ensures that every product undergoes the same rigorous evaluation. This uniformity not only enhances reliability but also provides clear benchmarks for performance over time. Ultimately, these key elements work together to create an efficient framework that supports ongoing improvements in product quality.

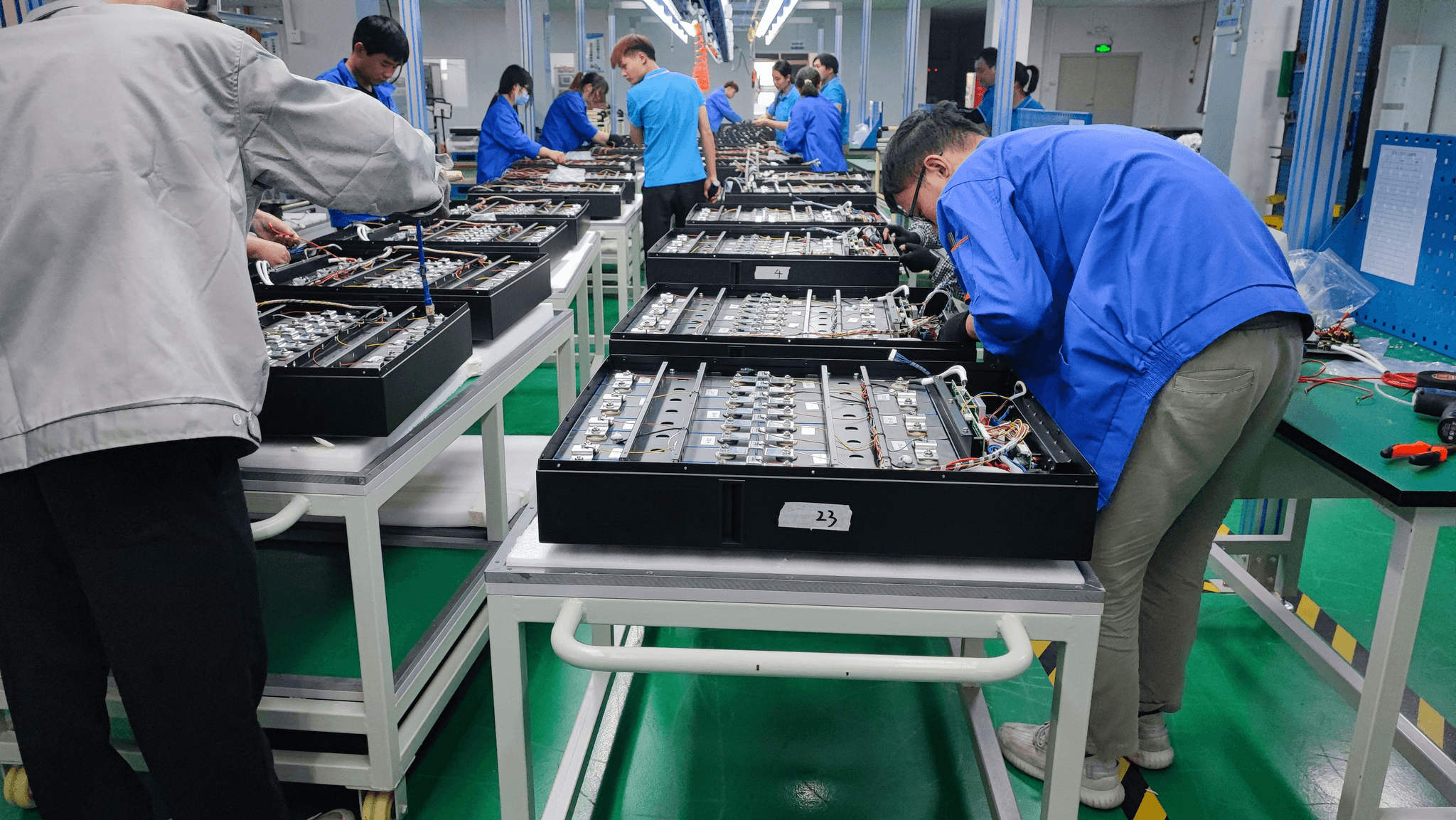

The Role of Quality Check in Manufacturing

In manufacturing, the role of a quality check cannot be overstated; it serves as a gatekeeper between production and market entry. By systematically evaluating each item against predetermined criteria during the quality check process, manufacturers can significantly reduce waste and rework costs caused by defects or non-conformance. This proactive approach helps maintain brand reputation and fosters long-term customer loyalty.

Moreover, regular quality checks contribute to continuous improvement initiatives within manufacturing processes by identifying areas where efficiency can be enhanced or errors minimized. When manufacturers adopt various quality check types tailored to specific stages or components of production, they can achieve even greater levels of assurance in their outputs. Thus, integrating robust quality checks into manufacturing not only safeguards product integrity but also drives operational excellence.

Quality Check vs Quality Control: What’s the Difference?

While quality check and quality control are often used interchangeably in conversation, they refer to distinct concepts within the realm of product assurance. A quality check typically refers to specific evaluations conducted at various stages throughout the production process—think inspections or tests performed on individual products or batches using defined criteria like those outlined on a quality check sheet. In contrast, quality control encompasses broader strategies aimed at ensuring that entire processes consistently produce high-quality results over time.

Quality control involves systematic monitoring and adjusting manufacturing processes based on data collected from multiple quality checks across different stages—this includes setting up corrective actions when issues arise and refining protocols based on findings from previous evaluations. Understanding this difference is crucial for businesses aiming to implement effective systems that ensure both immediate compliance through frequent checks as well as long-term sustainability through comprehensive control measures. In summary, while both play vital roles in assuring product excellence, their approaches differ significantly in scope and execution.

The Quality Check Process Explained

Understanding the quality check process is crucial for maintaining high standards in any production environment. It encompasses a series of systematic steps designed to ensure that products meet predetermined specifications and quality benchmarks. By implementing a robust quality check process, businesses can minimize defects, enhance customer satisfaction, and ultimately boost their bottom line.

Steps in the Quality Check Process

The quality check process typically begins with planning, where specific criteria for the quality check product are established based on industry standards. Next comes the inspection phase, where products are evaluated against these criteria using various methods such as visual inspections or testing equipment. Finally, any discrepancies found during this evaluation lead to corrective actions or adjustments in production processes to prevent future issues.

Incorporating regular reviews of the quality check process itself is also essential; this helps refine procedures and adapt to new challenges as they arise. This cyclical approach ensures that every aspect of production aligns with both company goals and customer expectations. Ultimately, a well-defined series of steps within the quality check process fosters consistency and reliability across all products.

Best Practices for Effective Quality Checks

To maximize effectiveness during a quality check, it’s vital to establish clear guidelines that delineate roles and responsibilities within your team. Training personnel on both the importance of each step in the quality check process and how to utilize various tools can significantly improve outcomes. Additionally, fostering open communication among team members about potential issues or improvements encourages a proactive approach to maintaining product standards.

Another best practice involves regularly updating your methods based on feedback from previous checks; this could include revising your quality check sheet to reflect new insights gained from past experiences. Implementing technology such as automated tracking systems can also streamline processes and reduce human error during inspections—think of it as giving your QC team an upgrade! Ultimately, embracing best practices not only enhances efficiency but also reinforces a culture of continuous improvement within an organization.

Utilizing Quality Check Sheets for Efficiency

Quality check sheets serve as invaluable tools in streamlining the entire quality check process by providing structured documentation for inspections and evaluations. These sheets help teams quickly identify defects by categorizing different types of errors or issues encountered during inspections—making it easier than ever to analyze trends over time! Moreover, having a standardized format allows for consistent data collection across various teams or departments.

When designing your own quality check sheet, be sure to include relevant fields like product specifications, inspection dates, findings from previous checks, and corrective action notes—this ensures nothing slips through the cracks! Additionally, utilizing digital formats can further enhance efficiency by enabling easy sharing among team members while minimizing paperwork clutter (and let’s be honest—who doesn’t love that?). In summary, effectively leveraging quality check sheets not only boosts productivity but also enhances overall accountability within your organization’s commitment to excellence.

Exploring Quality Check Types

Quality checks are essential in ensuring that products meet the required standards before reaching consumers. Various types of quality checks serve different purposes, from verifying raw materials to inspecting finished goods. Understanding the different quality check types can help businesses optimize their quality assurance processes and enhance product reliability.

Different Types of Quality Checks

There are several quality check types, each tailored for specific phases of the production process. First, we have **incoming inspection**, which evaluates raw materials before they enter production—this is crucial for maintaining high-quality standards from the start. Next is **in-process inspection**, where ongoing assessments during manufacturing ensure that any deviations from the expected quality check process are caught early, reducing waste and rework.

Finally, there’s **final inspection**, which examines finished products to confirm they meet all specifications before shipping. This type of quality check is often done using a detailed **quality check sheet** to systematically record findings and ensure nothing slips through the cracks. Each type plays a vital role in achieving overall product excellence and minimizing defects.

When to Use Each Quality Check Type

Knowing when to implement each type of quality check can significantly impact a company's efficiency and product reliability. For instance, an incoming inspection should be standard practice whenever new materials arrive at your facility; this prevents subpar components from entering your production line and affecting final output quality. In-process inspections are ideal during critical stages of manufacturing where minor errors could lead to significant defects later on—think of it as a safety net that catches issues before they escalate.

Final inspections should always be conducted just before products leave your facility; after all, this is the last chance to ensure that every item meets customer expectations and complies with industry standards. By strategically applying these various quality check types throughout your operations, you can create a robust framework for maintaining high-quality standards while minimizing costs associated with returns or rework.

Case Studies of Quality Check Types in Action

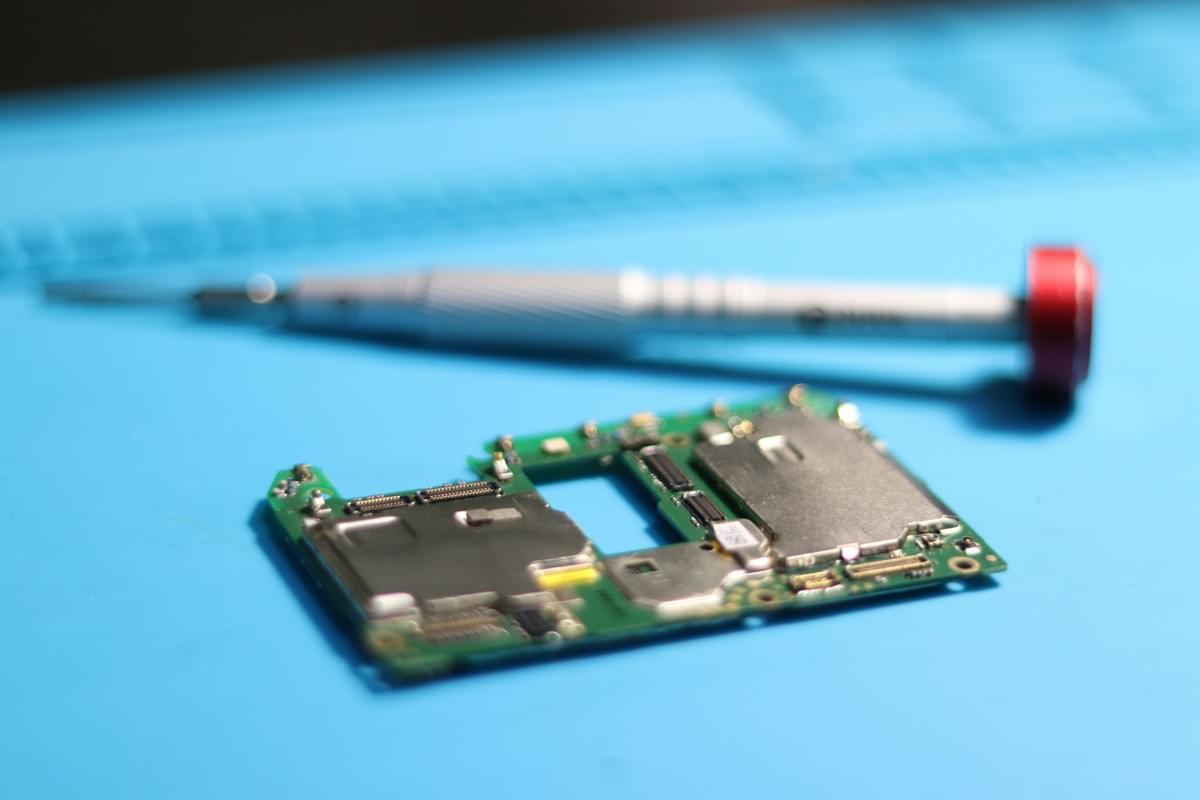

Let’s dive into some real-world examples showcasing how different quality check types have made a difference in various industries. In one case study involving an electronics manufacturer, implementing rigorous incoming inspections led to a 30% reduction in defective components entering their assembly line—saving both time and money while enhancing overall product reliability through effective use of the **quality check qc** process.

Another example comes from a food processing company that adopted regular in-process inspections during its packaging phase; this resulted in improved compliance with health regulations and significantly decreased customer complaints about packaging errors or contamination issues. Finally, consider a clothing manufacturer that switched to comprehensive final inspections using detailed **quality check sheets**; they reported an increase in customer satisfaction ratings due to fewer returns stemming from sizing or material discrepancies.

These case studies illustrate how leveraging various quality check types not only ensures compliance but also boosts consumer confidence by delivering reliable products consistently.

The Role of Quality Check in Product Standards

Quality checks are essential for maintaining product standards across various industries. They serve as a systematic approach to ensure that products meet specific requirements and regulations, thereby safeguarding both manufacturers and consumers alike. Without robust quality checks, businesses risk delivering subpar products that could lead to compliance issues and significant financial losses.

How Quality Checks Ensure Compliance

Quality checks act as gatekeepers in the manufacturing process, ensuring that every product adheres to industry regulations and standards. By implementing a thorough quality check process, companies can identify non-compliance issues early on, which helps avoid costly recalls or legal repercussions later. Moreover, these checks provide documented evidence of compliance through quality check sheets, which can be invaluable during audits or inspections.

Quality Check’s Impact on Product Reliability

When executed effectively, quality checks significantly enhance product reliability by identifying defects before they reach the consumer. This proactive approach not only minimizes returns but also builds brand loyalty as customers come to trust the quality of the products they purchase. In essence, a rigorous quality check process transforms a good product into a reliable one that meets consumer expectations consistently.

Real-World Examples of Quality Check Success

Numerous companies have reaped the benefits of implementing comprehensive quality check types in their operations. For instance, an electronics manufacturer improved its defect rate by 30% after introducing multiple stages of quality checks throughout its production line. Similarly, a food processing company boosted its compliance rates by utilizing specialized quality check sheets tailored for each type of food item produced—demonstrating how effective these practices can be in real-world scenarios.

Partnering with Experts: China Inspection Pro

In the realm of quality assurance, partnering with experts can significantly elevate your standards. China Inspection Pro stands out as a leader in the field, providing comprehensive quality check services that ensure products meet rigorous benchmarks. With their expertise, businesses can enhance their quality check process and confidently navigate the complexities of manufacturing.

How China Inspection Pro Elevates Quality Standards

China Inspection Pro specializes in delivering top-notch quality checks tailored to various industries. Their team employs advanced methodologies and tools to conduct thorough quality check inspections that go beyond mere compliance; they ensure product excellence at every stage. By integrating innovative practices into their quality check types, they help businesses maintain consistent standards and improve overall reliability.

Benefits of Professional Quality Checks

Engaging professionals like China Inspection Pro for your quality checks offers numerous advantages that can transform your operations. First and foremost, these experts provide an objective assessment of your products through systematic quality check processes, identifying potential issues before they escalate. Additionally, using a professional service reduces the burden on internal resources while enhancing efficiency through well-structured quality check sheets designed for optimal results.

Testimonials from Satisfied Clients

Clients who have partnered with China Inspection Pro often rave about the transformative impact on their production lines and product offerings. Many have noted significant improvements in product reliability after implementing recommended changes based on detailed reports from their quality checks. The testimonials highlight how understanding the distinction between quality check vs quality control has empowered businesses to make informed decisions that drive success.

Conclusion

In the world of manufacturing and product development, the importance of a robust quality check cannot be overstated. A well-implemented quality check process not only ensures compliance with industry standards but also enhances product reliability and customer satisfaction. As we wrap up our exploration of quality checks, it's clear that understanding the nuances between quality check types and their applications is vital for any business striving for excellence.

Key Takeaways on Quality Checking

When considering a quality check, one must grasp its key elements: thoroughness, accuracy, and consistency. The distinction between quality check vs quality control is crucial; while both aim to enhance product standards, a quality check focuses on evaluating specific attributes before final approval. Utilizing tools like a quality check sheet can streamline this process, ensuring that no detail is overlooked during inspections.

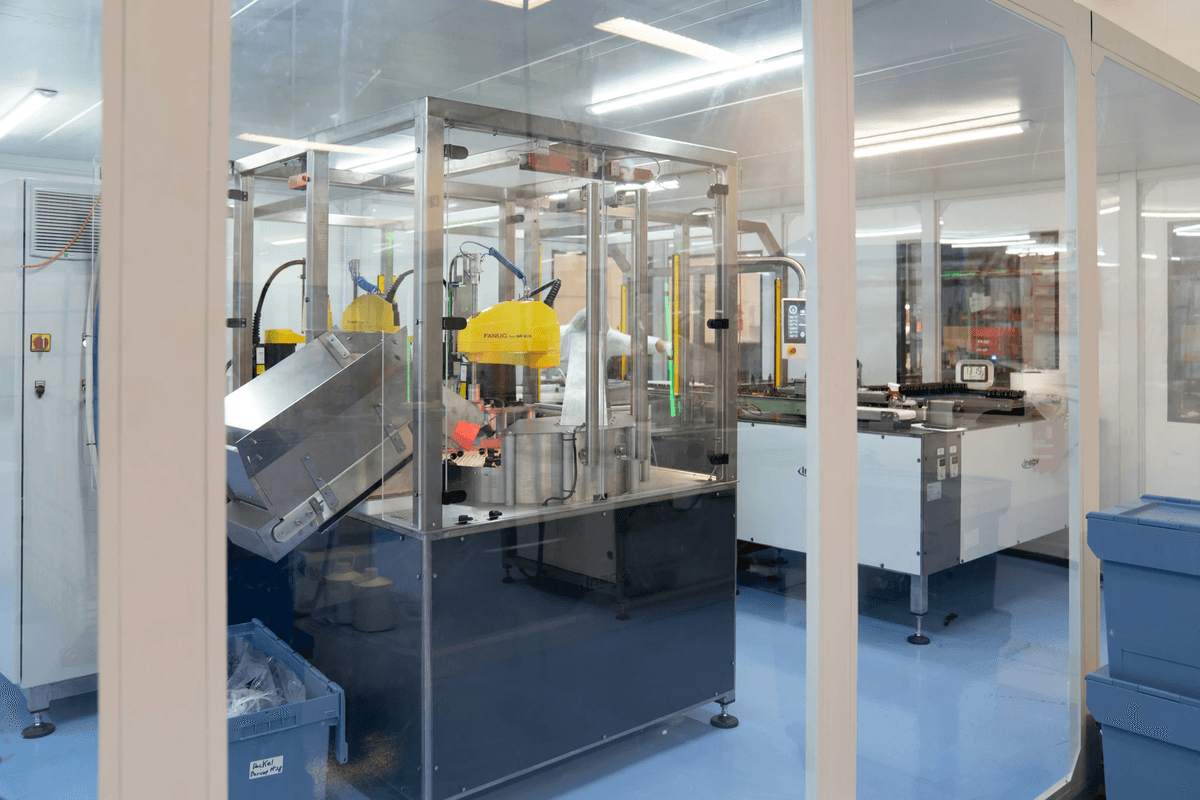

The Future of Quality Checks in Industry

Looking ahead, the evolution of technology promises to transform the landscape of quality checks dramatically. Automation and artificial intelligence are set to play significant roles in enhancing the efficiency and accuracy of the quality check process. As industries become more interconnected globally, embracing diverse quality check types will be essential for maintaining competitive advantage and meeting ever-evolving consumer expectations.

Final Thoughts on Ensuring Product Excellence

Ultimately, ensuring product excellence hinges on a steadfast commitment to rigorous quality checks at every stage of production. By partnering with professionals who specialize in conducting thorough inspections—such as China Inspection Pro—businesses can elevate their standards significantly. In an era where customer trust is paramount, investing in comprehensive quality checks will yield long-term benefits that resonate throughout an organization.