Introduction

In today's fast-paced manufacturing environment, the significance of a robust visual inspection procedure cannot be overstated. This meticulous process serves as the first line of defense in ensuring that products meet established quality standards before they reach consumers. By implementing effective visual inspections, companies can enhance their production of quality goods and services, ultimately fostering customer trust and satisfaction.

Understanding Visual Inspection Procedures

Visual inspection procedures are essential for identifying defects or irregularities in products during various stages of production. These procedures typically involve trained professionals examining items closely to ensure they adhere to specific quality benchmarks. A well-structured visual inspection process not only streamlines operations but also minimizes the risk of costly recalls or customer complaints.

The Role of Quality Assurance Compliance Specialists

Quality assurance compliance specialists play a pivotal role in maintaining high standards throughout the production cycle. Often referred to as QC inspectors, these professionals are responsible for overseeing that all visual inspection procedures are executed correctly and efficiently. Their expertise ensures that products not only comply with industry regulations but also meet consumer expectations for reliability and safety.

Key Benefits of Effective Testing

The testing of electronic components through rigorous visual inspections offers numerous advantages for manufacturers and consumers alike. Effective testing helps identify potential issues early on, reducing waste and saving time during the production process. Additionally, it enhances overall product quality, leading to increased customer satisfaction and loyalty—key factors in today’s competitive market landscape.

Importance of Visual Inspection in Quality Assurance

Visual inspection procedures play a pivotal role in ensuring the quality of products across various industries. By identifying defects or inconsistencies early in the production process, these procedures help maintain high standards and minimize waste. Quality assurance compliance specialists rely on effective visual inspections to uphold the integrity of goods and services produced.

Defining Visual Inspection Procedure

A visual inspection procedure entails a systematic approach to examining products for quality assurance. This method involves assessing items based on predefined criteria, focusing on appearance, functionality, and safety. By employing trained professionals, such as what is QC inspectors, companies can ensure that their visual inspection procedures are thorough and reliable.

Why Quality Assurance Matters

Quality assurance is crucial because it directly impacts customer satisfaction and brand reputation. When organizations prioritize effective visual inspection procedures, they not only enhance the quality of their goods but also foster trust among consumers. In turn, this commitment to quality drives repeat business and encourages positive word-of-mouth referrals.

Common Industries Utilizing Visual Inspections

Numerous industries benefit from implementing rigorous visual inspections as part of their quality assurance processes. Sectors such as electronics manufacturing heavily rely on the testing of electronic components to ensure functionality and safety before products reach consumers. Additionally, sectors like automotive manufacturing and food production utilize visual inspection procedures to maintain high standards in the production of quality goods and services while adhering to social compliance auditing practices.

Essential Steps in the Visual Inspection Procedure

Visual inspection procedures are critical in maintaining quality standards across various industries. The process not only involves keen observation but also a structured approach to ensure that every aspect of the product meets regulatory and customer expectations. This section will delve into the essential steps involved, highlighting the role of a quality assurance compliance specialist and emphasizing the significance of thorough checks.

Preparing for the Inspection

Preparation is key when it comes to executing an effective visual inspection procedure. Before any inspection begins, it's crucial to gather all necessary tools and documentation, ensuring that everything from checklists to previous inspection reports is readily available. A quality assurance compliance specialist often leads this phase, determining what specific aspects need attention based on past findings or potential risks associated with the testing of electronic components.

Equipped with a clear understanding of what is expected during the inspection, inspectors can streamline their efforts toward identifying defects or areas that require improvement. This preparation phase sets the tone for a successful visual inspection procedure by aligning team members on objectives and methodologies. Remember, proper preparation not only enhances efficiency but also significantly contributes to the production of quality goods and services.

Conducting Thorough Visual Checks

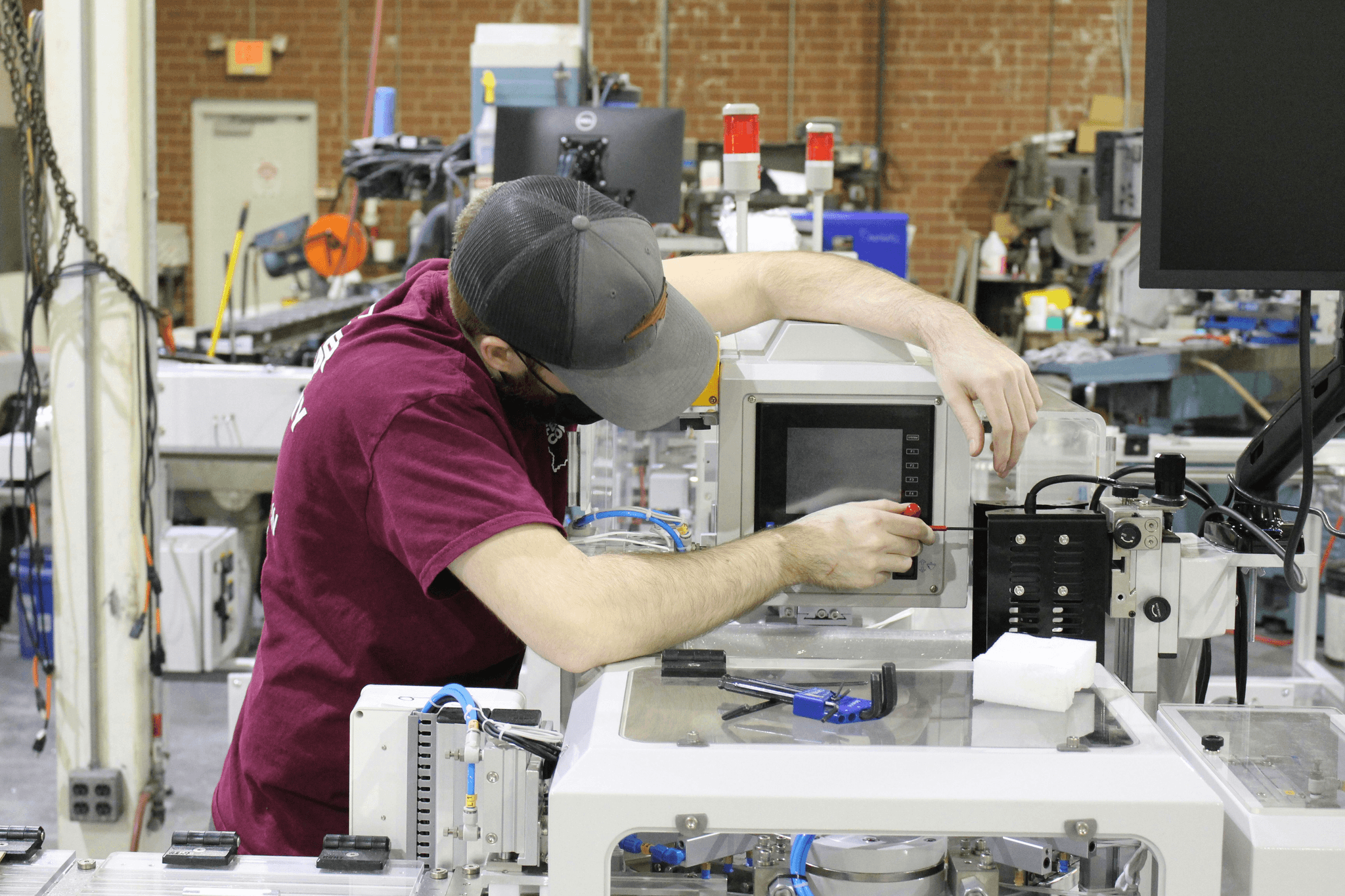

Once preparation is complete, it's time to dive into conducting thorough visual checks—a pivotal step in any visual inspection procedure. Inspectors must scrutinize every detail, from surface finishes to component placements, ensuring that no defect goes unnoticed. The role of a QC inspector here cannot be overstated; their trained eye is essential for identifying discrepancies that could affect product integrity or safety.

During these checks, inspectors should employ systematic techniques such as using magnifying tools or lighting aids to enhance visibility and accuracy in their assessments. This meticulous approach ensures comprehensive coverage of all aspects under review, especially when dealing with complex electronic components where small flaws can lead to significant issues down the line. Such diligence not only safeguards product quality but also reinforces trust in social compliance auditing practices within organizations.

Documenting Findings and Recommendations

After conducting thorough visual checks, documenting findings and recommendations becomes paramount in closing out an effective visual inspection procedure. Accurate records serve as vital references for future inspections while providing valuable insights into recurring issues or trends affecting production quality. Quality assurance compliance specialists play an instrumental role here by synthesizing observations into actionable recommendations aimed at enhancing processes.

This documentation should encompass detailed descriptions of any identified defects along with suggested corrective actions tailored specifically for each issue noted during inspections—especially relevant in testing electronic components where precision is non-negotiable! Furthermore, sharing these findings with relevant stakeholders fosters transparency and collaboration toward continuous improvement in producing high-quality goods and services.

In conclusion, following these essential steps—preparation for inspections, conducting thorough checks, and meticulous documentation—ensures a robust visual inspection procedure that upholds industry standards while promoting excellence across various sectors.

The Role of a Quality Assurance Compliance Specialist

Quality Assurance Compliance Specialists play a pivotal role in ensuring that products meet industry standards and regulations. Their responsibilities often include overseeing visual inspection procedures, monitoring compliance, and facilitating the testing of electronic components to ensure quality. In essence, they act as the guardians of quality, making certain that every product that leaves the production line meets stringent criteria.

What is a QC Inspector?

A QC Inspector, or Quality Control Inspector, is a professional tasked with assessing products to ensure they meet specified standards of quality. This role typically involves conducting visual inspections and testing of electronic components to identify any defects or areas for improvement. Essentially, QC Inspectors are the vigilant eyes in the production process, ensuring that each item adheres to both company policies and external regulations.

Skills and Training Required for Success

To excel as a quality assurance compliance specialist or QC inspector, one must possess a unique blend of skills and training. Key competencies include attention to detail, analytical thinking, and familiarity with various testing methods associated with visual inspection procedures. Additionally, formal training in quality assurance methodologies and social compliance auditing can significantly enhance an inspector's ability to perform thorough evaluations.

Impact on Production of Quality Goods and Services

The influence of quality assurance compliance specialists on the production of quality goods and services cannot be overstated. By implementing rigorous visual inspection procedures and adhering to social compliance standards, these professionals help minimize defects in products before they reach consumers. Their work not only enhances product reliability but also fosters trust between manufacturers and customers by ensuring consistent delivery of high-quality goods.

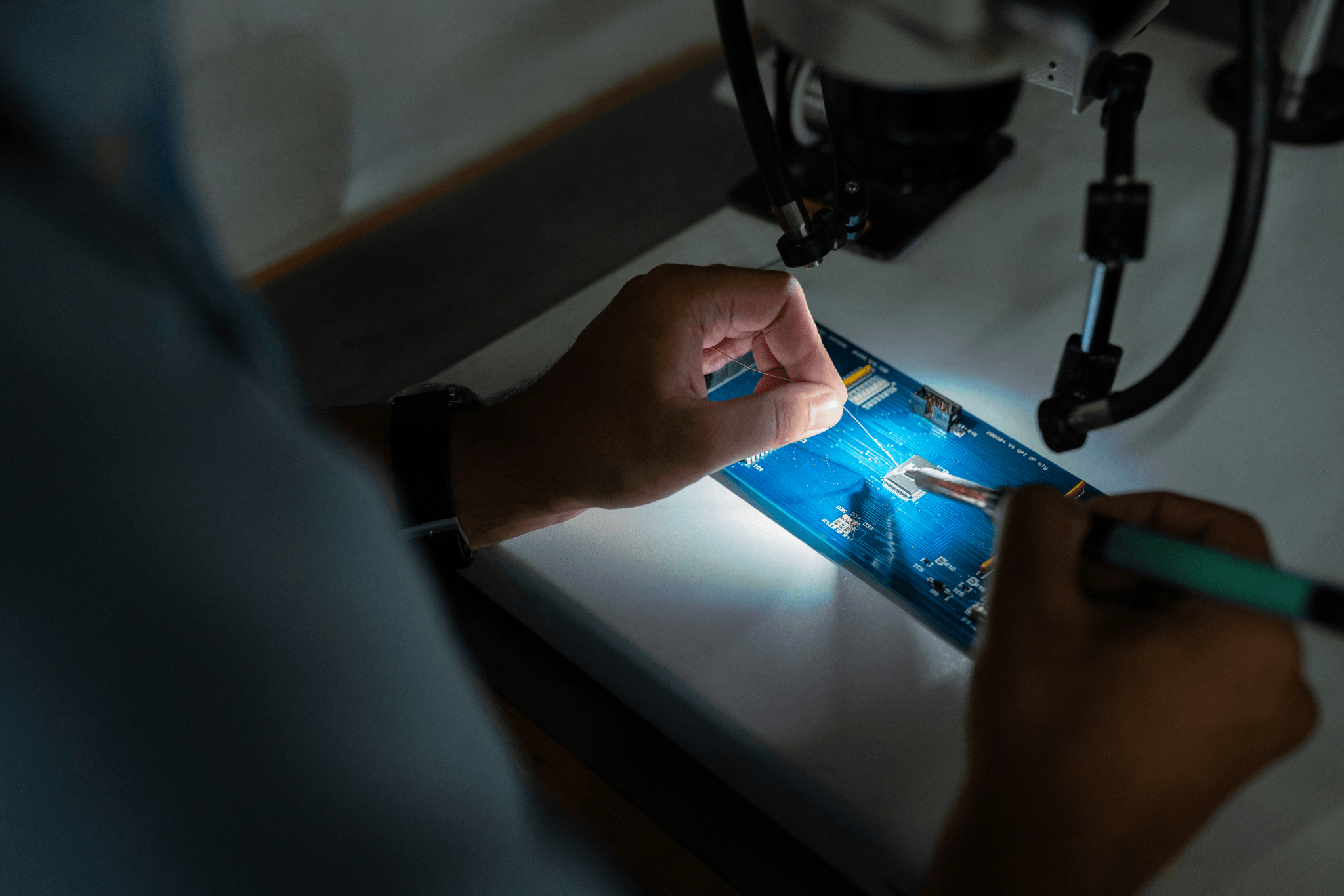

Best Practices for Testing Electronic Components

When it comes to the testing of electronic components, adhering to best practices is crucial for ensuring the production of quality goods and services. A structured approach helps identify potential issues early on, thus preventing costly errors down the line. By focusing on key testing parameters and incorporating thorough visual inspection procedures, manufacturers can enhance their quality assurance processes.

Identifying Key Testing Parameters

The first step in effective testing is identifying the key parameters that need assessment during the visual inspection procedure. These parameters typically include electrical performance metrics, physical dimensions, and material properties that are critical to functionality. Quality assurance compliance specialists often emphasize these factors as they directly impact product reliability and customer satisfaction.

Moreover, understanding what constitutes acceptable limits for these parameters is essential for a successful evaluation process. This knowledge allows QC inspectors to quickly pinpoint deviations that could signal defects or performance issues in electronic components. By establishing clear benchmarks, manufacturers can streamline their testing processes and ensure consistent quality across products.

Ensuring Accuracy in Measurements

Once key testing parameters are identified, ensuring accuracy in measurements becomes paramount. Utilizing calibrated instruments and standardized measurement techniques allows quality assurance compliance specialists to obtain reliable data during inspections. This level of precision is vital not only for detecting anomalies but also for maintaining compliance with industry standards.

Moreover, regular calibration checks on measuring equipment help uphold accuracy over time, reducing the risk of human error during inspections. In this context, what is a QC inspector's role? They must be well-versed in both measurement techniques and troubleshooting potential inaccuracies that could affect test results.

Ultimately, meticulous attention to detail during this phase reinforces confidence in the overall testing process while safeguarding against defects that may compromise product integrity.

Interpreting Results for Quality Assurance

Interpreting results from visual inspections requires a blend of analytical skills and an understanding of industry standards related to electronic components. Quality assurance compliance specialists analyze data collected from tests to determine whether products meet established specifications or if further action is needed—whether that's reworking components or conducting additional tests.

Furthermore, effective communication of findings among team members is essential; it ensures everyone involved understands any issues detected during inspections and how they impact production timelines or costs associated with social compliance auditing efforts. A collaborative environment fosters quicker resolutions and enhances overall product quality.

In conclusion, mastering best practices for testing electronic components not only streamlines operations but also significantly contributes to the production of quality goods and services that meet consumer expectations while adhering to regulatory requirements surrounding visual inspection procedures.

Social Compliance Auditing in Visual Inspections

In the realm of quality assurance, social compliance auditing plays a pivotal role in ensuring that companies uphold ethical standards while conducting their operations. This aspect of auditing goes beyond mere product quality; it encompasses the treatment of workers, adherence to labor laws, and environmental responsibility. For a quality assurance compliance specialist, understanding these standards is crucial to integrating them into the visual inspection procedure effectively.

Understanding Social Compliance Standards

Social compliance standards are guidelines designed to ensure that businesses operate ethically and responsibly within their communities. These standards often include regulations regarding fair labor practices, workplace safety, and environmental sustainability. For QC inspectors, familiarity with these benchmarks is essential not only for maintaining product integrity but also for safeguarding the rights and welfare of employees involved in the production of quality goods and services.

By grasping what constitutes social compliance, QC inspectors can better assess whether a company meets these ethical expectations during their visual inspection procedure. This knowledge enables them to identify potential areas of concern that may affect both worker satisfaction and overall operational efficiency. Ultimately, understanding social compliance standards contributes significantly to fostering a positive corporate image and building consumer trust.

Integrating Compliance into Visual Inspections

Integrating social compliance into visual inspections requires a systematic approach that aligns ethical considerations with traditional quality checks. Quality assurance compliance specialists must develop comprehensive checklists that encompass both product specifications and social responsibility criteria during the testing of electronic components or any other goods produced by the company. This dual focus ensures that not only are products meeting quality benchmarks but also that they are produced under socially responsible conditions.

During inspections, QC inspectors should be trained to look for evidence of compliance with labor laws and environmental regulations alongside their usual assessments of product functionality and safety features. By embedding these factors into the visual inspection procedure, organizations can take proactive steps toward addressing any issues before they escalate into larger problems that could jeopardize both brand reputation and employee morale.

The integration process can also involve regular training sessions for all staff involved in inspections to keep them updated on current social compliance regulations and best practices within their industry. By fostering an environment where ethical considerations are part of everyday operations, companies can enhance their commitment to producing high-quality goods while ensuring they do so responsibly.

Benefits of Comprehensive Auditing

Comprehensive auditing practices provide numerous benefits for organizations committed to maintaining high standards in both product quality and social responsibility. Firstly, such audits help identify gaps in current processes related to both visual inspection procedures and adherence to social compliance standards—allowing companies to address weaknesses proactively before they lead to significant issues or regulatory penalties.

Moreover, thorough audits foster transparency within an organization by creating clear documentation regarding how products are manufactured—providing reassurance not just internally but also externally among consumers who increasingly prioritize ethical sourcing when choosing brands. This transparency builds trust between businesses and customers while supporting efforts toward sustainable production practices across industries.

Finally, engaging in comprehensive auditing enhances overall productivity by streamlining operations through improved processes derived from insights gained during inspections—ultimately leading to higher-quality outputs without compromising on ethical responsibilities associated with the production of quality goods and services.

Conclusion

In the realm of quality assurance, the importance of a thorough visual inspection procedure cannot be overstated. Detailed inspections enhance product reliability and safety while ensuring that the production of quality goods and services meets industry standards. By employing skilled quality assurance compliance specialists, businesses can elevate their commitment to excellence and customer satisfaction.

Enhancing Quality Through Detailed Inspections

A robust visual inspection procedure serves as the backbone of any effective quality assurance strategy. By meticulously examining products before they reach consumers, companies can catch defects early and prevent costly recalls or reputational damage. This proactive approach not only safeguards the integrity of goods but also fosters trust between manufacturers and their customers, ultimately enhancing brand loyalty.

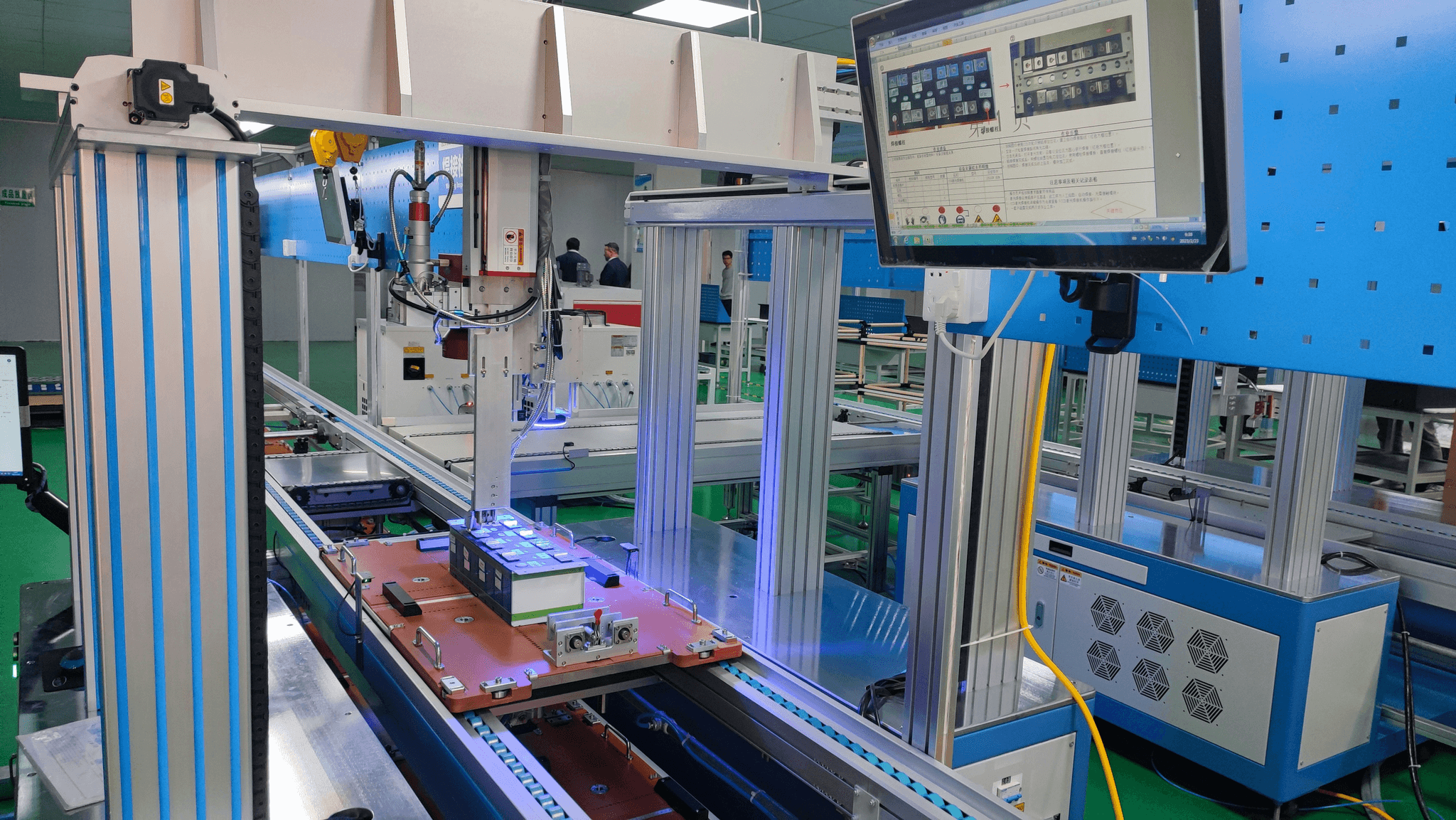

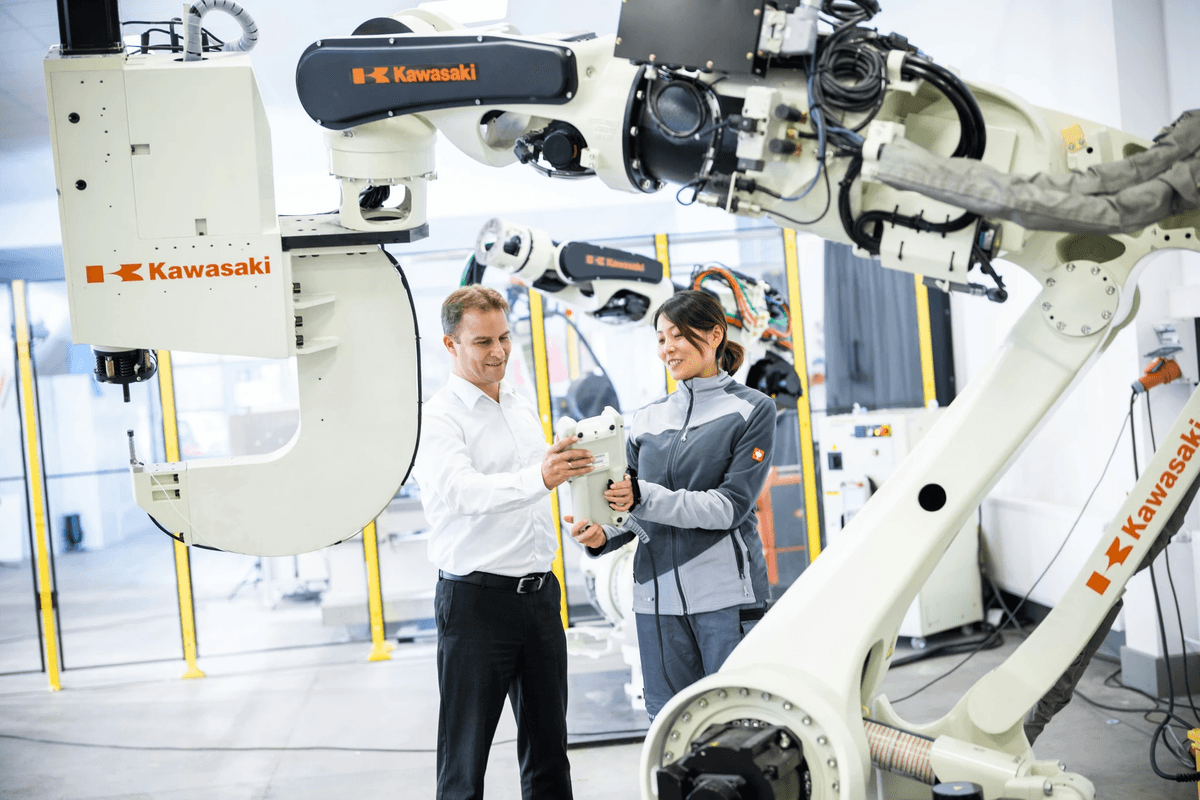

The Future of Visual Inspection Techniques

As technology advances, so do the techniques used in visual inspections. The future promises a blend of traditional methods with cutting-edge innovations like AI-driven analytics and automated systems that streamline the testing of electronic components. Such advancements will empower quality assurance compliance specialists to perform even more precise evaluations, ensuring that products meet rising consumer expectations in an ever-evolving marketplace.

Collaborating with China Inspection Pro for Success

Partnering with seasoned experts like China Inspection Pro can significantly bolster your visual inspection procedure's effectiveness. Their extensive experience in social compliance auditing ensures that not only are products inspected for quality but also adhere to ethical manufacturing practices. Collaborating with such professionals guarantees a comprehensive approach to quality assurance, paving the way for sustainable production practices and superior goods.