Introduction

In the realm of quality assurance, understanding non conformity reports is crucial for maintaining high standards and ensuring compliance. These reports serve as vital tools in identifying deviations from expected norms, allowing organizations to rectify issues promptly. As businesses strive for excellence, the role of a quality assurance compliance specialist becomes increasingly significant in navigating these complexities.

Understanding Non Conformity Reports

So, what is a non conformity report? Essentially, it’s a formal document that outlines instances where products or processes fail to meet specified requirements. This documentation not only highlights the discrepancies but also serves as a foundation for corrective actions and continuous improvement within an organization.

Importance in Quality Assurance

The importance of non conformity reports in quality assurance cannot be overstated; they are essential for ensuring that products and services meet established standards. By systematically addressing non conformities, organizations can enhance their reputation and customer satisfaction while reducing waste and inefficiencies. Moreover, these reports facilitate communication among teams, including quality control (QC) inspectors who play a pivotal role in identifying issues during the testing of electronic components.

Role in Compliance and Auditing

Non conformity reports are integral to compliance and auditing processes across industries. They help ensure that organizations adhere to regulatory requirements while fostering transparency and accountability within operations. Additionally, social compliance auditing often incorporates these reports to evaluate ethical practices within supply chains, further underscoring their significance in promoting responsible business conduct.

What Is a Non Conformity Report?

Understanding what a non conformity report (NCR) entails is crucial for maintaining quality standards across various industries. An NCR serves as a formal document that identifies deviations from established norms or specifications, providing clarity on issues that may affect production and compliance. This section will explore the definition, purpose, and real-world applications of non conformity reports.

Definition and Key Features

A non conformity report is a detailed account of any discrepancies found during inspections or audits, particularly in the realm of quality assurance. Key features of an NCR include a clear description of the non-conformity, the criteria it failed to meet, and suggested corrective actions. By documenting these elements, quality assurance compliance specialists can effectively track issues and implement necessary changes to enhance product quality.

Purpose of Non Conformity Reports

The primary purpose of non conformity reports is to ensure that organizations adhere to established standards in their operations. By identifying areas where products or processes do not meet specified requirements, NCRs facilitate timely interventions that can prevent further complications down the line. Moreover, they serve as valuable tools for continuous improvement in the production of quality goods and services by highlighting systemic flaws.

Real-world Applications

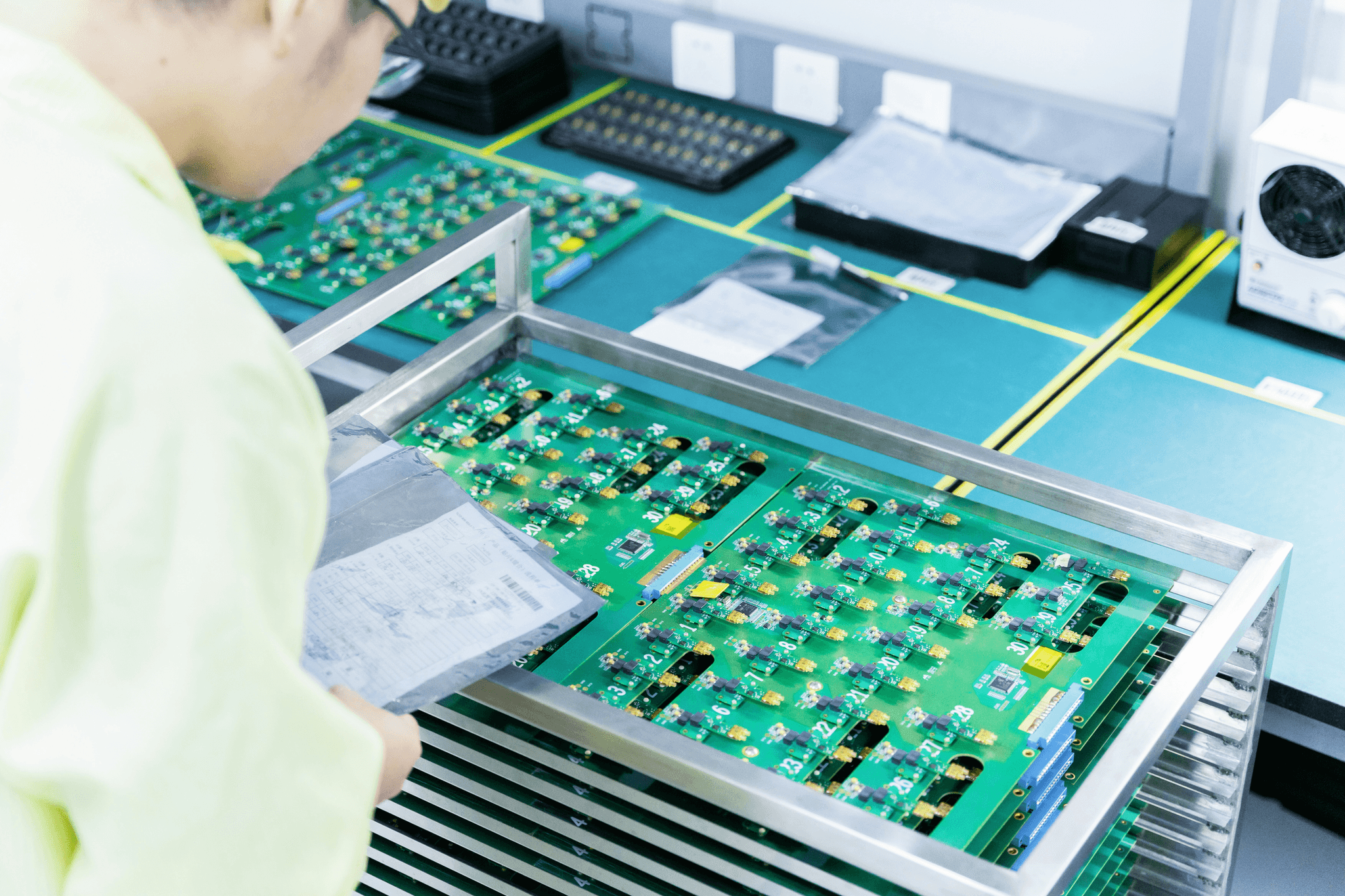

For instance, in electronics manufacturing, an NCR might be issued if components fail to meet performance specifications during testing phases. Additionally, these reports play a vital role in social compliance auditing by ensuring that companies adhere to ethical practices while maintaining high-quality standards.

The Process of Filing a Non Conformity Report

Filing a Non Conformity Report (NCR) is an essential step in maintaining the integrity of quality assurance processes. Understanding how to effectively document non conformities ensures that organizations can identify issues and implement corrective actions efficiently. This section will guide you through the steps, highlight the role of quality assurance compliance specialists, and provide best practices for effective reporting.

Steps to Document Non Conformities

The first step in documenting non conformities is to clearly identify and define the issue at hand. This involves gathering all relevant information about what is wrong, including specific details about the product or service that deviates from established standards. Once identified, it’s crucial to categorize the non conformity—whether it’s related to testing of electronic components, production processes, or any other aspect affecting quality goods and services.

Next, you'll want to record your findings in a structured format that includes essential elements such as date, description of the non conformity, its location within the production process, and potential impact on overall quality. This documentation should be as detailed as possible; after all, clarity can make all the difference when it comes time for resolution. Lastly, ensure that you communicate this report promptly to relevant stakeholders—including your quality assurance compliance specialist—to kickstart corrective measures.

Involvement of Quality Assurance Compliance Specialists

Quality assurance compliance specialists play a pivotal role in managing non conformity reports effectively. These professionals are trained to analyze NCRs meticulously and determine root causes behind each issue reported. Their expertise not only helps streamline corrective actions but also aids in preventing future occurrences by implementing robust quality control measures.

In addition to analyzing reports, these specialists often collaborate with QC inspectors who are responsible for monitoring production processes on-site. Together they ensure that any deviations from standards are addressed swiftly and thoroughly—maintaining high levels of compliance throughout operations. By leveraging their insights into what is a non conformity report and its implications for production quality, organizations can foster an environment committed to continuous improvement.

Best Practices for Effective Reporting

To maximize the effectiveness of your Non Conformity Reports, adhering to certain best practices is key. Firstly, always maintain objectivity in reporting; stick strictly to facts rather than opinions or assumptions about what caused the issue at hand. This impartial approach not only enhances credibility but also ensures accurate assessments during social compliance auditing processes.

Another best practice involves regular training sessions for staff on how to recognize discrepancies early on—this proactive stance can significantly reduce lengthy investigations down the line! Additionally, employing digital tools or platforms designed specifically for NCR management can simplify tracking progress on resolutions while providing valuable data analytics over time regarding recurring issues in testing of electronic components or other areas impacting overall service delivery.

Lastly—and perhaps most importantly—foster open communication channels within your organization so everyone feels empowered to report issues without fear of repercussions; this transparent culture ultimately contributes positively towards achieving high-quality goods and services across all departments.

The Role of QC Inspectors

When it comes to ensuring the integrity of products and processes, QC inspectors are the unsung heroes of quality assurance. They play a pivotal role in identifying non-conformities, which are deviations from established standards or specifications. Understanding what is a QC inspector is essential for anyone involved in the production of quality goods and services, as they are integral to maintaining high standards.

What Is a QC Inspector?

A QC inspector is a professional tasked with monitoring and evaluating products during various stages of production. Their primary goal is to ensure that everything meets predetermined quality criteria and complies with industry regulations. By understanding what is non conformity report, QC inspectors can effectively identify issues that might compromise product quality or safety.

Duties and Responsibilities

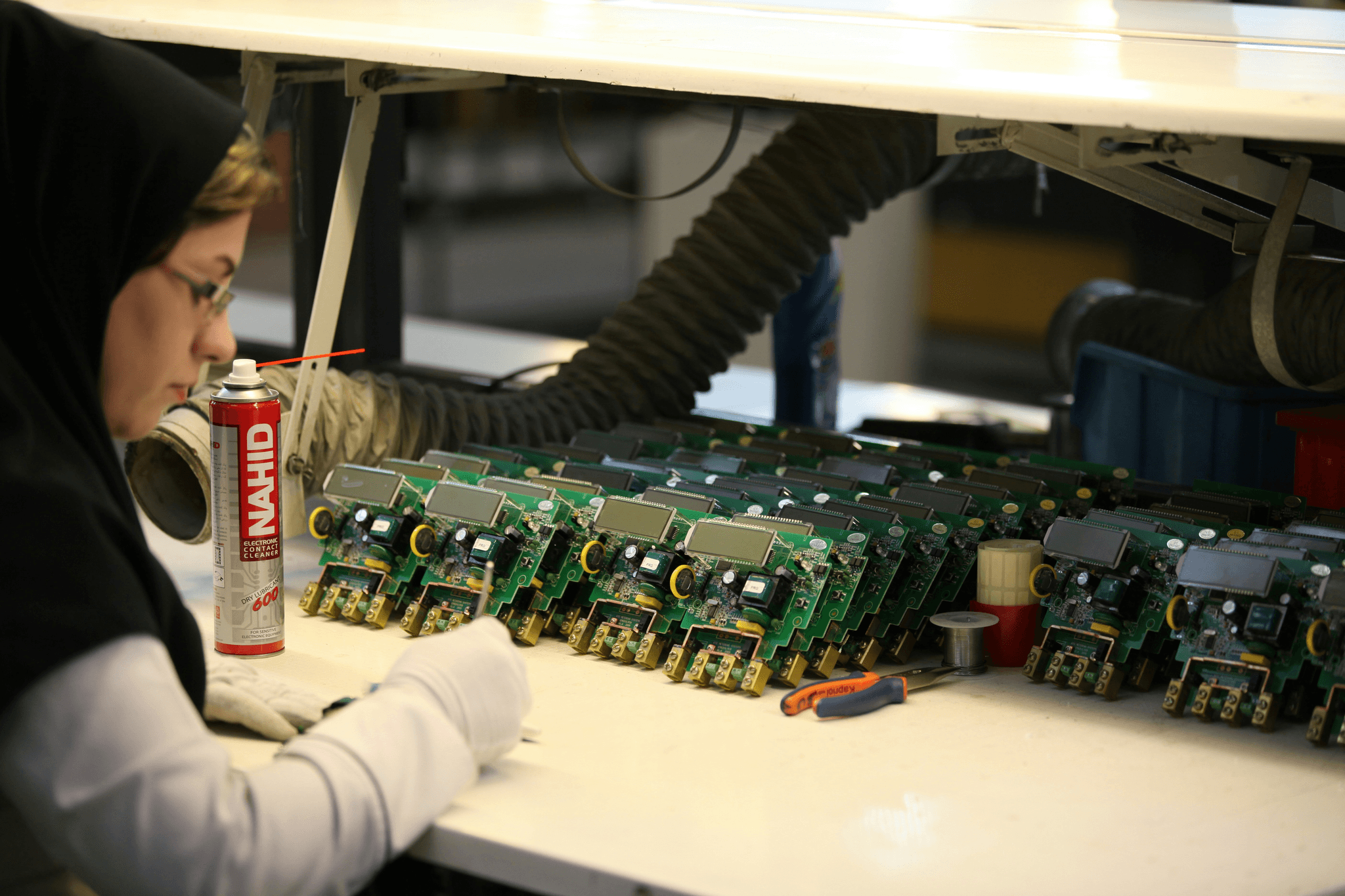

The duties of a QC inspector extend beyond mere observation; they involve rigorous testing and evaluation processes, especially in industries like electronics where testing of electronic components is crucial. They conduct inspections, document findings, and often collaborate with quality assurance compliance specialists to address any identified non-conformities swiftly. This collaborative effort ensures that any discrepancies are rectified before products reach consumers, thereby enhancing the overall production of quality goods and services.

Collaborating with Non Conformity Reports

Collaboration between QC inspectors and non conformity reports is vital for effective quality management strategies. When an inspector identifies an issue during testing or evaluation, they document it in a non conformity report to formally communicate the problem to relevant stakeholders. This synergy not only helps in resolving immediate concerns but also contributes to long-term improvements in processes through social compliance auditing practices that ensure adherence to ethical standards.

Non Conformity Reports in Testing of Electronic Components

When it comes to the testing of electronic components, non conformity reports play a pivotal role in ensuring that products meet industry standards and specifications. These reports act as vital documentation that highlights deviations from expected performance or quality criteria. In an industry where precision is paramount, understanding what is a non conformity report can significantly impact the production of quality goods and services.

Importance in Electronics Manufacturing

In electronics manufacturing, maintaining high standards is crucial, as even minor defects can lead to significant failures down the line. Non conformity reports serve as essential tools for quality assurance compliance specialists who monitor adherence to these standards throughout the production process. By identifying issues early on, manufacturers can mitigate risks and ensure that their products not only comply with regulations but also meet customer expectations.

Case Studies of Non Conformities in Electronics

Several case studies illustrate how non conformity reports have been instrumental in addressing issues within electronics manufacturing. For instance, a leading smartphone manufacturer encountered recurring failures with its battery components; by utilizing non conformity reports, they identified a flaw in their supplier's materials that compromised safety and performance. This proactive approach not only resolved the immediate issue but also reinforced the importance of collaboration among QC inspectors and suppliers to uphold quality assurance.

Ensuring Compliance through Non Conformity Reports

Ensuring compliance through non conformity reports involves systematic documentation and analysis of discrepancies found during testing of electronic components. Quality assurance compliance specialists work closely with QC inspectors to investigate these discrepancies thoroughly and implement corrective actions promptly. Moreover, integrating social compliance auditing into this process enhances transparency and accountability within organizations, ultimately fostering a culture committed to producing quality goods and services.

Impact on the Production of Quality Goods and Services

The production of quality goods and services is significantly influenced by non-conformities that arise during various processes. When a non-conformity report is filed, it highlights deviations from established standards, which can lead to delays and increased costs if not addressed promptly. Understanding what a non-conformity report entails is crucial for maintaining efficiency in production lines, especially in industries like electronics where precision is paramount.

How Non Conformities Affect Production

Non-conformities can disrupt the entire workflow in manufacturing environments, particularly in the testing of electronic components. If a product fails to meet quality standards, it may lead to recalls or rework, which not only strains resources but also impacts delivery timelines. This ripple effect can tarnish a company's reputation and customer trust, making it essential for quality assurance compliance specialists to identify and rectify these issues swiftly.

Strategies for Mitigating Non Conformities

To mitigate non-conformities effectively, organizations should implement robust processes that include regular audits and training for their teams, including what is QC inspector roles within their operations. By fostering an environment where employees are encouraged to report discrepancies without fear of repercussions, companies can address issues proactively before they escalate into larger problems. Additionally, integrating social compliance auditing practices ensures that ethical standards are met while maintaining high-quality production levels.

Long-term Benefits for Businesses

Addressing non-conformities leads to long-term benefits such as enhanced operational efficiency and reduced costs associated with waste or rework. Companies that prioritize understanding what is a non-conformity report often find themselves better positioned in competitive markets due to their commitment to quality assurance practices. Ultimately, this focus not only improves the production of quality goods and services but also builds stronger relationships with customers who value reliability and excellence.

Social Compliance Auditing and Non Conformity Reports

Social compliance auditing is a critical process that ensures organizations adhere to ethical standards and regulatory requirements. The integration of non conformity reports (NCRs) into these audits plays a pivotal role in identifying areas where companies may fall short in their commitments to quality assurance and social responsibility. By systematically documenting discrepancies, quality assurance compliance specialists can provide actionable insights that drive improvement.

Integration of Non Conformity Reports in Audits

When embarking on social compliance audits, what is a non conformity report? It serves as a formal document that highlights deviations from established standards or regulations during the audit process. Quality assurance compliance specialists utilize these reports to track non conformities, ensuring that issues are not only identified but also addressed effectively.

The incorporation of NCRs into auditing practices allows for a structured approach to problem-solving. This documentation aids auditors in pinpointing specific areas of concern, whether it involves labor practices or environmental impact. As such, non conformity reports become essential tools not just for identifying problems but also for fostering continuous improvement.

Benefits of Social Compliance Auditing

Social compliance auditing offers numerous benefits for organizations striving to enhance their reputation while ensuring ethical practices. By implementing robust NCR processes, businesses can identify gaps in their operations related to the production of quality goods and services. This proactive approach not only helps mitigate risks but also enhances overall organizational performance.

Additionally, effective social compliance auditing fosters transparency and accountability within an organization’s supply chain. Companies can demonstrate their commitment to ethical practices by addressing non conformities promptly and thoroughly through NCRs. This not only builds trust with stakeholders but also strengthens partnerships with suppliers who prioritize similar values.

Enhancing Corporate Responsibility through Reporting

In today's business landscape, corporate responsibility is more than just a buzzword; it’s an expectation from consumers and investors alike. Non conformity reports play an instrumental role in enhancing corporate responsibility by providing clear evidence of adherence—or lack thereof—to established standards during the testing of electronic components or other manufacturing processes. These reports help organizations showcase their dedication to ethical practices while addressing any shortcomings that may arise.

Moreover, utilizing NCRs as part of social compliance auditing encourages a culture of accountability within organizations. When employees understand the importance of reporting discrepancies, they become more engaged in maintaining high standards across all operations related to the production of quality goods and services. Ultimately, this leads to improved outcomes not just internally but across the entire supply chain.

Conclusion

In wrapping up our exploration of non conformity reports, it’s clear that these documents play a pivotal role in maintaining the integrity of quality assurance processes. They not only help identify deviations from expected standards but also serve as a crucial tool for quality assurance compliance specialists to implement corrective actions. This ensures that organizations can consistently produce quality goods and services that meet or exceed customer expectations.

Key Takeaways on Non Conformity Reports

So, what is a non conformity report? It’s essentially a formal record of any discrepancies found during inspections or audits, particularly in the context of testing electronic components. These reports are vital for driving improvements and ensuring compliance with established standards, making them indispensable for businesses striving for excellence.

Non conformity reports are not just bureaucratic paperwork; they are actionable insights that lead to better practices and enhanced product quality. The involvement of QC inspectors is essential here, as they play a critical role in documenting these non conformities and collaborating with teams to rectify issues swiftly. By understanding the nuances of what is a non conformity report, organizations can foster an environment where continuous improvement is not just encouraged but expected.

The Future of Quality Assurance Practices

Looking ahead, the future of quality assurance practices will likely see an even greater integration of technology in the reporting process. As industries evolve, so too will the methods used by quality assurance compliance specialists to track and analyze non conformities more effectively. This evolution may include advanced data analytics tools that provide real-time insights into production processes, ultimately improving the testing of electronic components.

Moreover, social compliance auditing will become increasingly important as consumer awareness grows regarding ethical production practices. Companies will need to adapt by implementing robust non conformity reporting systems that address both product quality and social accountability simultaneously. The proactive management of these reports will be key to sustaining competitive advantage while ensuring adherence to regulatory requirements.

How China Inspection Pro Elevates Standards

China Inspection Pro has emerged as a leader in elevating industry standards through meticulous attention to detail and commitment to transparency in non conformity reporting. Their expertise helps companies navigate the complexities associated with compliance while ensuring that every aspect—from testing electronic components to overall production—meets stringent criteria for quality goods and services.

By leveraging their knowledge as quality assurance compliance specialists, China Inspection Pro assists organizations in developing effective strategies for mitigating non conformities before they escalate into larger issues. This proactive approach not only enhances operational efficiency but also reinforces corporate responsibility through diligent social compliance auditing practices.