Introduction

In the world of product delivery, packaging reliability is a critical factor that can make or break a brand's reputation. This is where the drop test for packaging plays a pivotal role, serving as a benchmark for evaluating how well packaging can withstand the inevitable bumps and drops during transit.

Understanding Packaging Reliability

Packaging reliability refers to the ability of packaging materials and designs to protect their contents from damage throughout their lifecycle, from production to consumer use. It encompasses various factors, including material strength, design integrity, and resistance to environmental conditions. By grasping these elements, businesses can better assess how their products will fare when subjected to real-world handling scenarios.

The Importance of Drop Testing

Drop testing is a crucial process that helps determine how well products and their packaging can endure impacts from falls or drops during transportation and storage. Essentially, it answers the question: what is the drop test for packaging? This testing not only safeguards product quality but also enhances consumer safety by ensuring that items arrive intact and functional. In an age where online shopping reigns supreme, understanding drop testing becomes even more vital for maintaining customer trust.

Key Standards in Testing

When discussing drop tests, it's important to consider established standards that guide these evaluations—one of which includes the IEC standard for drop test protocols. These standards provide frameworks that ensure consistency and reliability in testing methods across different industries. By adhering to these key standards in testing, companies can demonstrate compliance with safety regulations while also reinforcing their commitment to quality assurance in global markets.

What is the Drop Test for Packaging?

Definition and Purpose

So, what is the drop test for packaging? It’s a systematic evaluation designed to measure how well a package can withstand accidental drops from various heights and angles. The primary purpose of this test is to identify weaknesses in packaging designs before they hit the market, ensuring that products remain safe during their journey from warehouse to consumer.

The drop test serves as a critical checkpoint in product safety protocols. By revealing potential failure points in packaging, manufacturers can make informed decisions about materials and designs that will better protect their goods. Ultimately, this helps reduce returns due to damage and enhances overall consumer trust in the brand.

Common Items Tested

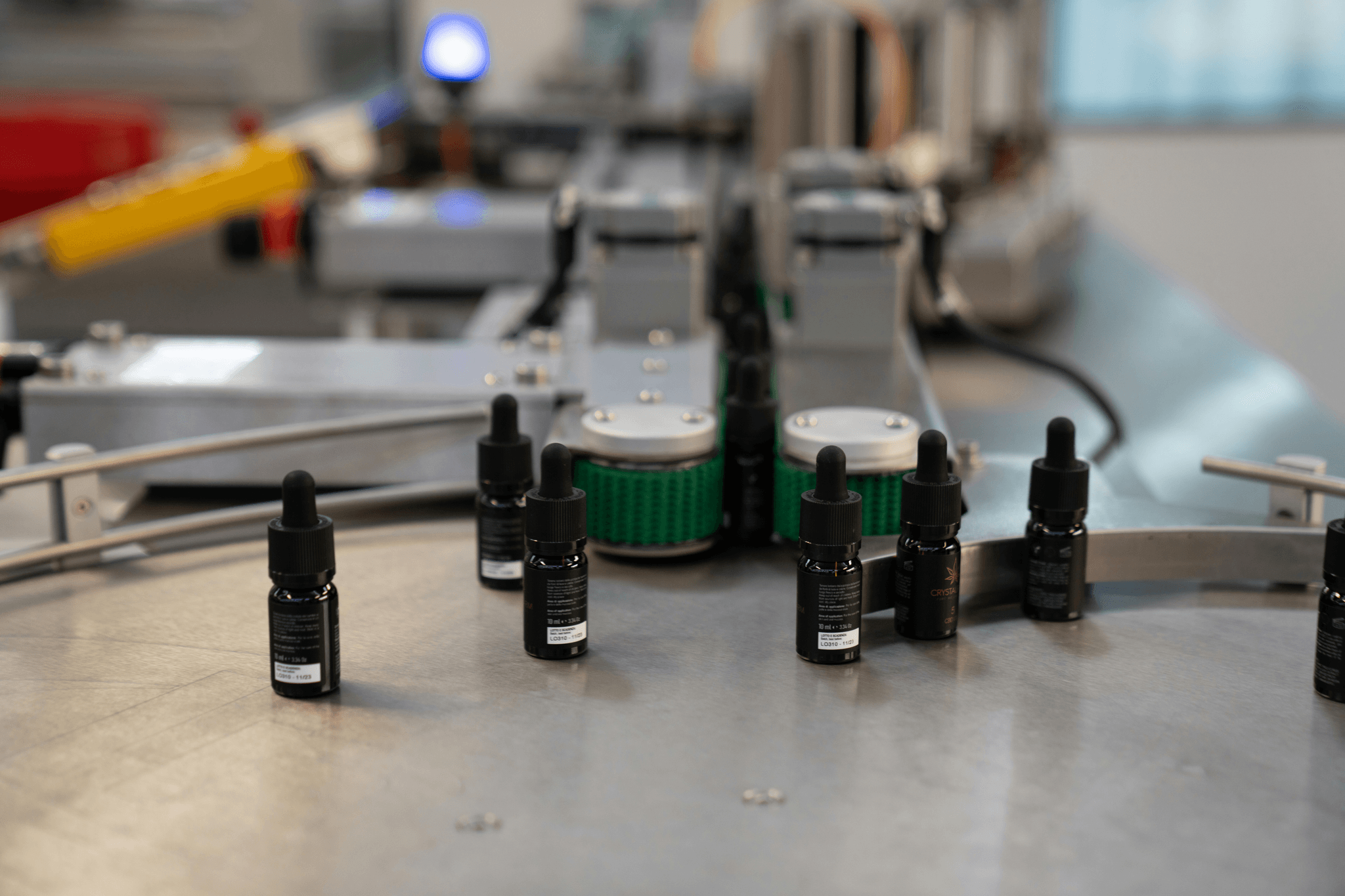

In the realm of drop testing, various items are put under scrutiny to ensure their protective packaging holds up under pressure. Common items tested include electronics like smartphones and laptops, fragile goods such as glassware or ceramics, and even food products packaged for retail sale. Each category has unique requirements based on its susceptibility to impact damage.

What is the drop test for packaging used on these items? Essentially, it helps determine whether they will survive typical mishaps during shipping or handling without sustaining damage. Manufacturers often use these tests not only on finished products but also on prototypes during development phases.

From consumer electronics to delicate cosmetics, understanding which items require rigorous testing ensures that companies invest wisely in their packaging solutions. This proactive approach minimizes losses related to damaged goods while maximizing customer satisfaction through reliable delivery experiences.

Role in Product Safety

The role of drop tests in product safety cannot be overstated; they provide invaluable insights into how well an item’s packaging performs under real-world conditions. When considering what is the IEC standard for drop test procedures, it becomes clear that adhering to established guidelines ensures consistency across industries globally. These standards help maintain high levels of safety by outlining specific methodologies for conducting effective tests.

By incorporating regular drop testing into their quality assurance processes, companies can identify potential hazards before products reach consumers' hands—ultimately leading to safer shopping experiences and reduced liability risks associated with damaged goods reaching customers’ homes or stores.

Furthermore, performing a drop test not only protects consumers but also reinforces brand integrity by demonstrating commitment towards delivering quality products consistently over time—fostering long-term relationships built on trust between businesses and customers alike.

What is the IEC Standard for Drop Test?

When we talk about the drop test for packaging, it’s essential to understand the framework provided by international standards, particularly those set by the International Electrotechnical Commission (IEC). The IEC standards help ensure that packaging can withstand the rigors of shipping and handling, ultimately protecting products and consumers alike. But what is the IEC standard for drop test? Let’s dive into this crucial aspect of packaging reliability.

Overview of IEC Standards

IEC standards are globally recognized guidelines that define best practices in electrical and electronic engineering, including testing methods like the drop test for packaging. These standards provide a comprehensive approach to assessing how well a package can endure impacts during transportation and handling. By adhering to these guidelines, manufacturers can ensure their products meet safety requirements while optimizing their packaging strategies.

The specific IEC standard relevant to drop testing outlines procedures for evaluating how packages perform when subjected to drops from various heights and angles. This systematic approach allows businesses to identify vulnerabilities in their packaging designs before products hit store shelves or customer doorsteps. Understanding these standards is vital for anyone asking, What is the drop test test? as it provides clarity on what constitutes effective testing protocols.

Compliance and Significance

Compliance with IEC standards regarding drop tests signifies that a company prioritizes product safety and quality assurance in its operations. Meeting these benchmarks not only helps in building consumer trust but also reduces potential liability issues stemming from damaged goods or injuries caused by inadequate packaging. Therefore, knowing how to perform a drop test according to these guidelines is essential for any business looking to enhance its product reliability.

Moreover, compliance with established IEC standards can be a competitive advantage in today’s market where consumers are increasingly concerned about product integrity during transit. Retailers often look for proof of compliance when selecting suppliers; thus, demonstrating adherence to these standards can open doors to new business opportunities. It’s clear that understanding what is the IEC standard for drop test isn't just academic—it's a practical necessity in modern commerce.

Real-World Applications

Real-world applications of the IEC standard for drop tests are abundant across various industries, from consumer electronics to pharmaceuticals and beyond. Companies routinely conduct these tests on their packaging solutions before launching new products or entering new markets, ensuring they meet both local and international regulations concerning safety and durability. For instance, electronics manufacturers often face stringent requirements due to the delicate nature of their products; hence rigorous testing becomes paramount.

Additionally, logistics companies utilize insights gained from these tests to optimize their shipping processes—reducing costs associated with damaged goods while improving overall customer satisfaction rates through reliable delivery experiences. As businesses increasingly globalize their operations, understanding how to perform a drop test effectively becomes crucial not only within individual companies but across supply chains worldwide.

In summary, familiarity with what is the IEC standard for drop test equips businesses with knowledge necessary for navigating today's complex marketplace successfully while ensuring safe delivery of products across borders.

How to Perform a Drop Test?

When it comes to ensuring the integrity of your packaging, knowing how to perform a drop test is essential. This testing method simulates the real-world conditions that products might face during shipping and handling. By understanding what is involved in a drop test for packaging, you can enhance product safety and reliability.

Preparation for Testing

Before diving into the actual drop test procedure, it's crucial to prepare adequately. Start by selecting the packaging items you want to test; this could include boxes, containers, or even individual products. Ensure that you have all necessary documentation on hand, including specifications related to what is the IEC standard for drop tests, as this will guide your testing process.

Next, create a controlled environment where external factors like temperature or humidity won’t affect your results. Mark out designated drop zones and ensure that your testing area is clear of obstructions. Finally, establish baseline measurements; knowing the original condition of your packaging will help you assess any changes after performing the drop test.

Step-by-Step Procedure

Once you're ready for action, follow these steps on how to perform a drop test effectively. First, position your packaging item at the predetermined height—this could range from 1 meter (3 feet) to several meters depending on product specifications and standards relevant to what is the drop test for packaging? Next, release the item without applying any additional force; gravity should do its job here.

After dropping the item onto a suitable surface (like concrete or wood), examine it immediately for visible damage such as dents or tears. Document every observation meticulously so you can analyze data later; this is crucial in identifying weaknesses in design or materials used in what is known as a drop test for packaging. Repeat this process multiple times at different heights or angles to gather comprehensive data.

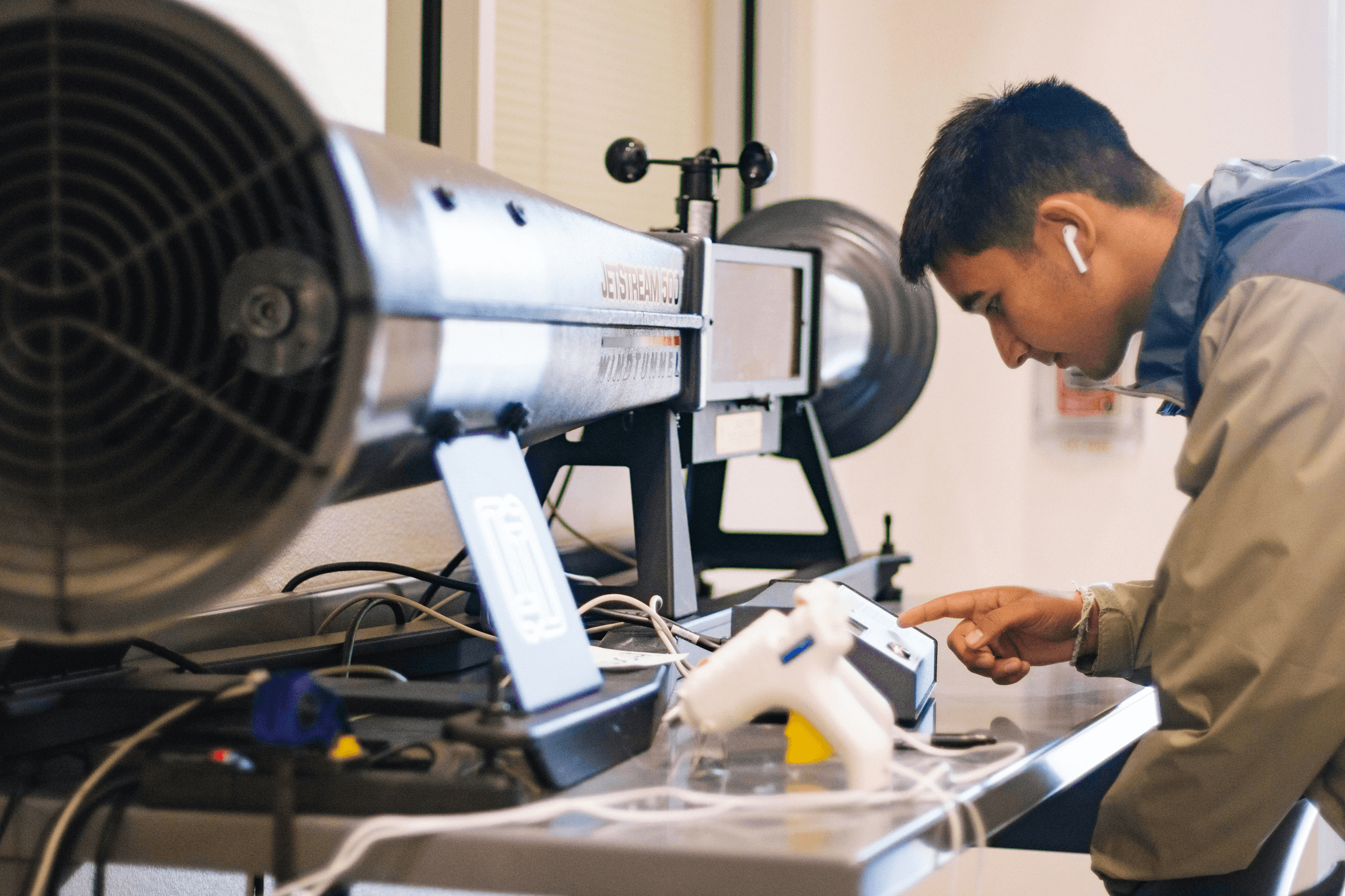

Equipment Needed

To conduct an effective drop test for packaging, you'll need some specialized equipment alongside basic tools. A digital scale can help measure weight accurately since heavier items may require different handling than lighter ones during testing phases of what is the drop test? Additionally, using measuring tapes ensures consistency in determining heights from which items are dropped.

You’ll also need protective gear like gloves and goggles—safety first! Depending on your setup's complexity, consider investing in a calibrated impact tester that can provide precise measurements post-drop impact according to IEC standards related to such tests. Lastly, make sure you have recording tools handy—like cameras or note-taking devices—to capture each step and result efficiently.

Interpreting Drop Test Results

Interpreting the results of a drop test for packaging is crucial for ensuring that products can withstand the rigors of transportation and handling. A thorough analysis not only reveals how well the packaging performed during the test but also highlights areas for improvement. Understanding these results is essential for manufacturers who want to enhance their product safety and reliability.

Analyzing Data

When it comes to analyzing data from a drop test for packaging, you need to look at various metrics such as impact force, damage severity, and failure points. Each data point provides insights into how well the packaging absorbed shock and protected its contents. By comparing these results against established benchmarks, such as those outlined in the IEC standard for drop test, companies can gauge their packaging's effectiveness.

In addition to numerical data, visual evidence from the drop tests—like photographs of damaged packages—can be instrumental in understanding performance failures. This combination of quantitative and qualitative analysis equips manufacturers with a comprehensive view of their packaging's reliability. Ultimately, this detailed examination informs decisions on whether to maintain current designs or explore new ones.

Identifying Weaknesses

Identifying weaknesses in your packaging after conducting a drop test is like finding hidden gems in a treasure hunt; it’s all about improving your product’s safety profile! Common weaknesses may include inadequate cushioning materials or structural flaws that lead to breakage upon impact. Pinpointing these vulnerabilities allows manufacturers to take proactive steps toward enhancing their designs.

Weaknesses might manifest in various forms: cracks on outer shells, compromised seals, or even complete structural failure under stress. By systematically addressing these issues through targeted testing and analysis, companies can ensure that they are not just meeting minimum standards but exceeding them. Remember, identifying weaknesses is not just about fixing problems; it's about creating opportunities for innovation.

Making Improvements

Once weaknesses have been identified through rigorous testing procedures like what is the drop test for packaging?, it’s time to roll up your sleeves and make improvements! This might involve re-evaluating materials used in construction or redesigning certain aspects of the package itself to better absorb impacts during transit. The goal here is not only compliance with existing standards but also achieving superior performance that sets your product apart from competitors.

Incorporating feedback from previous tests into new prototypes ensures continuous improvement within your product line. For instance, if you discover that certain materials perform better under specific conditions outlined by what is the IEC standard for drop test?, integrating those materials into future designs could significantly enhance durability. Ultimately, making improvements based on solid data helps build trust with consumers who rely on safe delivery of products.

The Role of China Inspection Pro

In the world of packaging, ensuring reliability and safety is paramount. This is where third-party inspection services like China Inspection Pro come into play. Their expertise in conducting the drop test for packaging helps companies meet industry standards while enhancing product safety.

Importance of Third-Party Inspection

However, relying solely on internal testing can lead to biased results or overlooked flaws. Third-party inspections provide an unbiased perspective, ensuring that all aspects of the drop test are conducted rigorously and according to established protocols.

Ensuring Consistency and Quality

One of the key questions businesses often ask is: what is the IEC standard for drop test? These standards ensure that products are tested consistently across different manufacturers and regions. By adhering to these guidelines, companies can maintain quality assurance throughout their supply chain while minimizing risks associated with subpar packaging.

Trust in Global Trade

Knowing how to perform a drop test effectively can bolster a company's reputation among consumers and partners alike. With third-party inspections from organizations like China Inspection Pro, businesses can confidently demonstrate their commitment to quality control in every shipment they send out.

Conclusion

The drop test for packaging is a critical component in ensuring that products reach consumers safely and intact. Understanding the nuances of what is the drop test for packaging allows manufacturers to mitigate risks associated with shipping and handling. As we’ve explored, adhering to established standards, such as the IEC standard for drop test, is essential for maintaining product integrity and consumer trust.

Key Takeaways on Drop Testing

In summary, the drop test for packaging serves as a vital assessment tool that evaluates how well a product can withstand impacts during transit. Knowing how to perform a drop test can save companies from costly returns and damaged goods, making it an investment worth considering. Moreover, understanding what is the drop test helps businesses ensure compliance with safety regulations while enhancing their reputation in the marketplace.

Future of Packaging Standards

Looking ahead, it's clear that packaging standards will continue to evolve alongside advancements in technology and consumer expectations. The question of what is the IEC standard for drop test will likely become more prominent as industries strive for higher quality and safety benchmarks. Innovations in materials and testing methods may also shape future protocols, making it crucial to stay informed about how to perform a drop test effectively.

Building Trust Through Testing

Building trust through testing goes beyond just meeting regulatory requirements; it's about fostering confidence among consumers and stakeholders alike. By implementing rigorous procedures like the drop test for packaging, companies can demonstrate their commitment to quality assurance and customer satisfaction. Ultimately, transparency in testing processes not only enhances brand loyalty but also paves the way for successful global trade relationships.