Introduction

In the ever-evolving landscape of the food industry, quality control is not just a buzzword; it's a necessity. Understanding quality control in food industry practices ensures that consumers receive safe, nutritious, and high-quality products. With increasing scrutiny from regulatory bodies and heightened consumer awareness, the importance of robust quality assurance practices has never been more critical.

Understanding Quality Control in Food Industry

Quality control in the food industry encompasses a range of processes designed to maintain standards in production and handling. This includes everything from raw material sourcing to final product delivery, ensuring that every step meets stringent safety and quality benchmarks. By implementing effective quality control measures, businesses can significantly reduce risks associated with foodborne illnesses and product recalls.

Importance of Quality Assurance Practices

Quality assurance practices are essential for building consumer trust and loyalty in a competitive market. These practices not only help ensure compliance with legal standards but also enhance operational efficiency by minimizing waste and reducing costs associated with poor quality products. Ultimately, investing in quality assurance translates into better customer satisfaction and improved brand reputation.

Role of Quality Control and Quality Assurance

The roles of quality control and quality assurance are intertwined yet distinct; together, they create a comprehensive framework for maintaining product integrity. While quality control focuses on identifying defects during production through rigorous testing methods such as quality inspection, quality assurance takes a proactive approach by establishing systems to prevent issues before they arise. The collaboration between these two functions is vital for achieving excellence in food safety and overall product reliability.

Implementing Effective Quality Control Systems

In the food industry, effective quality control systems are essential for ensuring that products meet safety standards and consumer expectations. By implementing structured processes and leveraging technology, organizations can enhance their quality assurance practices, ultimately leading to improved product outcomes. This section delves into establishing standard operating procedures, integrating technology for quality management, and adopting continuous improvement techniques.

Establishing Standard Operating Procedures

Standard Operating Procedures (SOPs) are the backbone of any robust quality control in the food industry. They provide a clear framework for operations, detailing every step from sourcing ingredients to final product delivery, thereby minimizing variability and errors. By having well-defined SOPs in place, companies can ensure that all employees understand their roles in maintaining quality assurance and adhere to consistent practices.

Moreover, these procedures serve as a reference point during training sessions for new staff or ongoing workshops for existing employees. Quality assurance specialists often play a pivotal role in developing these SOPs by incorporating best practices from both regulatory guidelines and industry standards. Ultimately, effective SOPs not only streamline processes but also foster a culture of accountability within the organization.

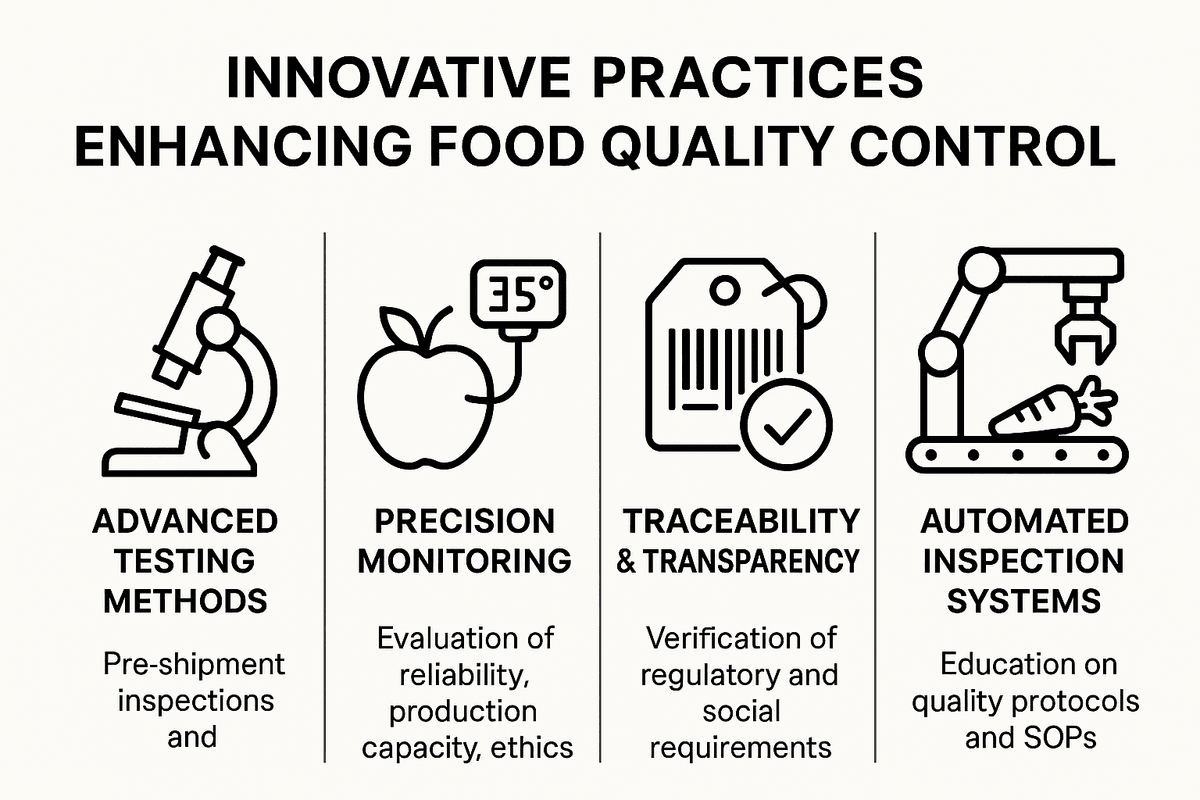

Integrating Technology for Quality Management

Integrating technology into quality management is revolutionizing how businesses approach quality control and quality assurance in the food industry. Advanced tools such as automated inspection systems can rapidly identify defects or inconsistencies that human inspectors might miss—this enhances overall efficiency without sacrificing accuracy. Additionally, software solutions that track production metrics can provide invaluable data analytics to help identify trends or areas needing improvement.

The use of IoT devices allows real-time monitoring of environmental conditions during storage and transportation—ensuring products remain within safe parameters throughout their lifecycle. By harnessing data analytics alongside traditional quality assurance testing methods, companies can proactively address potential issues before they escalate into larger problems. This technological integration not only boosts productivity but also reinforces consumer trust through demonstrable commitment to high-quality standards.

Continuous Improvement Techniques

Continuous improvement techniques are vital in maintaining high levels of quality control within the food industry while adapting to changing market demands or regulations. Utilizing methodologies like Six Sigma or Total Quality Management (TQM) encourages teams to regularly assess processes and identify opportunities for enhancement—ensuring that both product safety and customer satisfaction remain top priorities. These techniques often involve iterative cycles of testing new approaches followed by measurable evaluations based on defined performance indicators.

Furthermore, fostering an environment where feedback is welcomed empowers employees at all levels to contribute ideas toward refining existing processes related to quality inspection and assurance testing protocols. Regularly scheduled reviews help keep everyone aligned with evolving standards while promoting innovation among teams dedicated to achieving excellence in their work outputs. Ultimately, embracing continuous improvement creates a resilient organization capable of thriving amidst challenges while consistently delivering superior products.

Training and Development of Staff

Training and development are pivotal in ensuring that quality control in the food industry is not just a set of procedures but a culture embedded within the organization. The role of quality assurance specialists becomes increasingly important as they provide expertise, guidance, and support to maintain high standards throughout production processes. Investing in staff training enhances understanding of quality assurance practices, ultimately leading to improved product safety and consumer satisfaction.

Importance of Quality Assurance Specialists

Quality assurance specialists are the backbone of any effective quality control system in the food industry. These professionals possess specialized knowledge that helps identify potential hazards and implement preventive measures to ensure compliance with both internal standards and regulatory requirements. Their expertise in quality inspection allows organizations to navigate complex challenges, ensuring that products meet safety guidelines while fostering consumer trust.

Conducting Regular Quality Control Workshops

Regular quality control workshops serve as an essential tool for reinforcing best practices among staff members involved in food production. These workshops create opportunities for employees to engage with new techniques, share experiences, and discuss challenges related to quality assurance testing. By facilitating continuous learning, organizations can enhance their overall approach to quality control and quality assurance, empowering employees to take ownership of their roles in maintaining high standards.

Fostering a Quality Culture Among Employees

Fostering a culture centered around quality is crucial for long-term success within the food industry. This involves encouraging open communication about quality issues, celebrating achievements related to quality control, and providing recognition for employees who excel in their roles as advocates for food safety. When every team member understands their contribution to achieving effective quality assurance and testing outcomes, it creates an environment where excellence thrives.

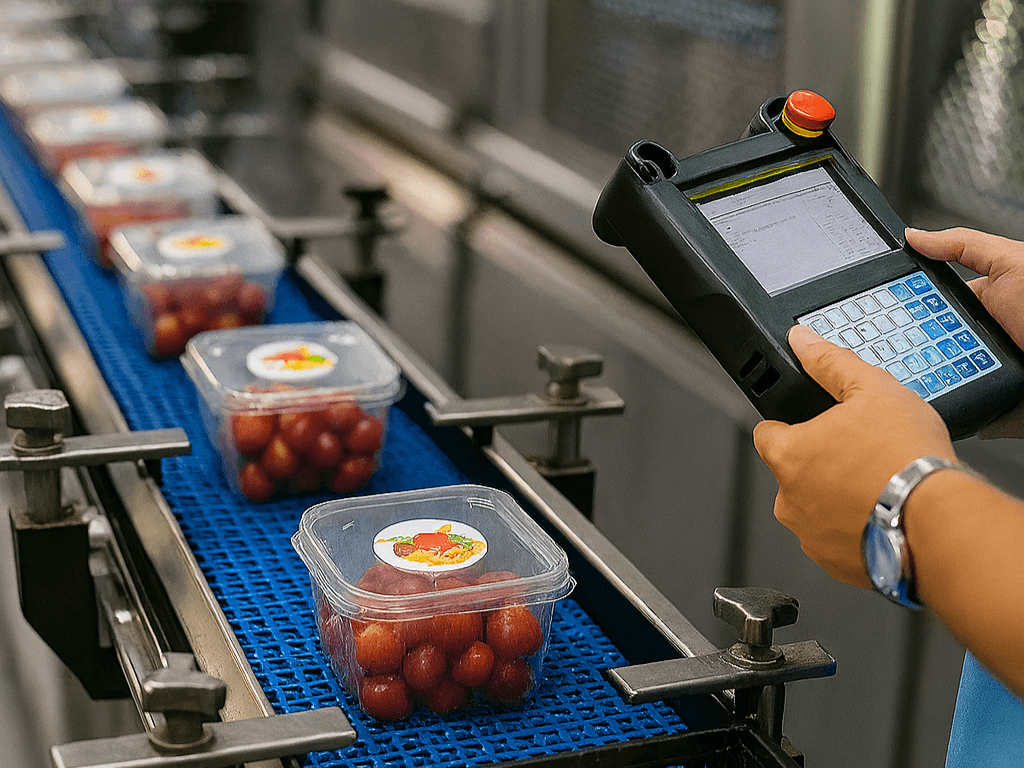

The Role of Quality Inspection

Quality inspection is a pivotal component in the quality control in food industry, ensuring that products meet established standards before reaching consumers. This process not only safeguards public health but also reinforces the integrity of brands. By implementing effective quality inspection practices, companies can enhance their quality assurance efforts and build a reputation for reliability.

Best Practices in Quality Inspection

To maximize the effectiveness of quality inspection, organizations should adhere to several best practices. First, developing clear and comprehensive checklists tailored to specific products can streamline the inspection process and ensure consistency in evaluations. Additionally, regular training sessions for quality assurance specialists help reinforce best practices and keep staff updated on new regulations and techniques related to quality control and quality assurance.

Another essential practice is fostering open communication between production teams and inspectors. This collaboration allows for immediate feedback on potential issues, enabling quick resolutions that prevent major problems down the line. Lastly, utilizing technology such as automated inspection tools can enhance accuracy while reducing human error—a critical factor in maintaining high standards in quality assurance testing.

Utilizing Third-Party Inspections: China Inspection Pro

Engaging third-party inspections like China Inspection Pro can significantly bolster a company's commitment to robust quality control processes. These independent entities bring an objective perspective to the evaluation of products, ensuring compliance with international standards without any bias from internal stakeholders. This impartiality is crucial for businesses looking to expand into global markets while maintaining trust in their brand's commitment to quality assurance.

Moreover, third-party inspections often come equipped with advanced technology and expertise that may not be available internally, allowing companies to leverage specialized knowledge for better outcomes in their quality control measures. By incorporating these external resources into their operations, businesses can enhance their overall efficiency and reliability when it comes to product safety and compliance with regulatory requirements.

The Impact of Quality Inspection on Consumer Trust

The relationship between rigorous quality inspection practices and consumer trust cannot be overstated; it is foundational for success in today's competitive market landscape. When consumers see consistent evidence of thorough inspections—backed by certifications or reports—they are more likely to develop confidence in a brand’s products over time. This trust translates into customer loyalty, repeat purchases, and positive word-of-mouth recommendations.

Furthermore, transparency regarding inspection processes fosters an environment where consumers feel informed about what they are buying—an invaluable asset when navigating the complexities of food safety concerns today. In essence, effective quality inspection acts as a bridge between manufacturers and consumers; it reassures buyers that they are making safe choices while encouraging companies to uphold high standards through ongoing commitment to excellence in both quality control and quality assurance.

Quality Assurance Testing Techniques

In the food industry, quality assurance testing techniques are essential for maintaining high standards and ensuring consumer safety. These practices not only help in identifying potential issues before products reach the market but also reinforce the overall integrity of quality control in food industry operations. By implementing robust quality assurance testing methods, businesses can enhance their reputation and build lasting consumer trust.

Different Types of Quality Assurance Testing

Quality assurance in the food industry encompasses various testing methodologies tailored to ensure product safety and compliance with regulatory standards. From microbiological testing to chemical analysis, each type plays a critical role in quality control and quality assurance processes. For instance, sensory evaluation tests assess taste, texture, and appearance—essential attributes that influence customer satisfaction and brand loyalty.

Another vital aspect is shelf-life testing, which determines how long a product remains safe and maintains its intended qualities under specific storage conditions. This type of quality assurance testing helps manufacturers optimize their supply chain while minimizing waste—an increasingly important factor in today’s sustainability-conscious market. Ultimately, diverse testing approaches contribute to a comprehensive understanding of product performance throughout its lifecycle.

Role of Data Analytics in Quality Assurance

Data analytics is transforming the landscape of quality control in food industry practices by providing actionable insights from vast amounts of data collected during production processes. By leveraging advanced analytics tools, organizations can identify trends that may indicate potential issues before they escalate into significant problems requiring costly interventions. This proactive approach enhances both quality assurance and testing efficiency while reducing risks associated with human error.

Moreover, data-driven decision-making enables companies to fine-tune their processes continuously, fostering an environment where innovation thrives alongside stringent quality standards. Analytics also plays a crucial role in tracking compliance with regulations—ensuring that all products meet necessary guidelines set forth by governing bodies like the FDA or ISO standards for food safety. In essence, integrating data analytics into quality control systems reinforces an organization's commitment to excellence.

Case Studies of Successful Quality Assurance

Examining case studies highlights how effective quality assurance practices have led to remarkable successes within the food industry. For example, a renowned snack manufacturer implemented rigorous quality inspection protocols combined with advanced technology solutions resulting in a significant reduction in product recalls due to contamination issues. This not only safeguarded consumer health but also bolstered brand loyalty through consistent delivery of high-quality snacks.

Another compelling case involves a beverage company that utilized real-time data monitoring systems during production processes to enhance their overall product consistency and safety measures significantly. By employing dedicated quality assurance specialists who analyzed this information regularly, they were able to adjust parameters promptly—leading to fewer deviations from established standards and improved customer satisfaction ratings over time. Such examples illustrate how prioritizing robust quality assurance testing techniques can yield tangible benefits across the board.

Regulatory Compliance and Standards

In the food industry, regulatory compliance and standards are paramount to ensure the safety and quality of products. Quality control in food industry practices must align with established regulations to maintain consumer trust and meet legal requirements. This section delves into the critical aspects of FDA regulations, ISO standards, and the necessity of staying updated with industry changes.

Understanding FDA Regulations

The Food and Drug Administration (FDA) plays a crucial role in regulating food safety in the United States. Understanding FDA regulations is essential for any quality assurance specialist working within the food sector, as these guidelines dictate everything from manufacturing practices to labeling requirements. Compliance with these regulations not only ensures product safety but also enhances overall quality control and quality assurance processes.

FDA regulations encompass a wide range of areas including sanitation, personnel hygiene, and hazard analysis critical control points (HACCP). By adhering to these standards, companies can implement effective quality inspection measures that prevent contamination and ensure product integrity. Ultimately, understanding FDA regulations helps businesses navigate potential pitfalls while maintaining high-quality products that consumers can trust.

Importance of ISO Standards in Food Safety

ISO (International Organization for Standardization) standards represent a benchmark for quality assurance in various industries, including food safety. The adoption of ISO standards provides a structured approach to quality control in food industry operations by establishing clear guidelines for processes like production, storage, and distribution. These internationally recognized standards help organizations demonstrate their commitment to maintaining high levels of quality assurance testing.

Implementing ISO standards not only improves operational efficiency but also enhances customer confidence through consistent product quality. Companies that achieve ISO certification often experience increased marketability as consumers become more aware of their dedication to safety and excellence in quality control. In an era where transparency is key, adhering to these standards can differentiate brands from competitors.

Keeping Up with Industry Changes

The landscape of food safety is constantly evolving due to new research findings, technological advancements, and changing consumer expectations. To maintain effective quality control and quality assurance systems, it’s imperative for organizations to stay informed about industry changes that could impact their operations. This vigilance allows businesses to adapt their practices accordingly while ensuring compliance with updated regulations.

Regularly attending workshops or training sessions focused on regulatory updates can empower staff members—including quality assurance specialists—to remain knowledgeable about best practices in the field. Additionally, engaging with industry associations or subscribing to relevant publications can provide insights into emerging trends related to quality inspection techniques or innovative testing methodologies. By keeping pace with changes within the industry landscape, companies position themselves as leaders committed to excellence in both product safety and consumer satisfaction.

Conclusion

In the ever-evolving landscape of the food industry, quality control stands as a cornerstone for building consumer trust and ensuring product safety. The interplay between quality control and quality assurance is crucial; together, they create a robust framework that not only meets regulatory standards but also fosters confidence among consumers. By emphasizing quality inspection and maintaining stringent quality assurance practices, food companies can safeguard their reputation while delivering safe, high-quality products.

Building Trust Through Quality Control

Trust is the currency of the food industry, and effective quality control is its foundation. Consumers are increasingly aware of what goes into their food and are more likely to choose brands that prioritize safety and transparency through rigorous quality assurance measures. When companies invest in skilled quality assurance specialists who implement comprehensive quality inspection protocols, they not only ensure compliance but also cultivate loyalty among consumers who value integrity in their food sources.

The Future of Quality Assurance in Food Industry

As technology advances, the future of quality assurance in the food industry looks promising yet challenging. Innovations such as real-time data analytics for quality assurance testing will likely become standard practice, allowing companies to proactively address potential issues before they escalate. Furthermore, with increasing regulatory scrutiny and consumer demand for transparency, businesses must adapt by continuously enhancing their processes related to both quality control and quality assurance.

Key Takeaways for Effective Quality Control Practices

To thrive in today’s competitive market, adopting effective quality control practices is non-negotiable for any food business. Prioritizing training for staff on best practices in both quality inspection and overall safety can lead to significant improvements in product reliability. Lastly, staying informed about evolving regulations and standards will ensure that companies remain compliant while reinforcing their commitment to excellence through consistent application of quality assurance testing techniques.