Introduction

In the fast-paced world of automotive manufacturing, car manufacturers play a pivotal role in delivering vehicles that meet consumer expectations and regulatory standards. As they navigate the complexities of production, the importance of automotive inspections cannot be overstated. Quality control is not merely a checkbox; it ensures that every component functions seamlessly, contributing to overall vehicle performance and safety.

Understanding the Role of Car Manufacturers

Car manufacturers are at the forefront of innovation and engineering excellence, responsible for designing and producing vehicles that appeal to a global market. Their commitment to quality is evident in their approach to automotive parts inspections, where meticulous attention is given to each component's functionality and durability. By prioritizing robust testing methods, manufacturers can identify potential issues before they reach consumers, safeguarding both brand reputation and customer satisfaction.

Why Quality Control Matters in Automotive

Automotive quality control serves as the backbone of a successful manufacturing operation, directly influencing brand trust and consumer loyalty. When car manufacturers inspecting their products adhere to stringent quality standards, they not only minimize long-term costs associated with recalls but also enhance product performance and safety features. In an industry where precision is paramount, effective quality control measures ensure that every vehicle on the road meets rigorous safety regulations.

Key Aspects of Automotive Parts Inspections

Automotive parts inspections encompass various critical elements designed to uphold industry standards and consumer expectations. These inspections involve thorough evaluations using advanced testing methods such as dynamic testing for real-world scenarios and durability testing for longevity under stress conditions. By focusing on these key aspects during automotive parts inspections, car manufacturers can deliver reliable vehicles while reinforcing their commitment to quality assurance.

The Necessity of Automotive Quality Control

In the competitive landscape of the automotive industry, quality control is not just a luxury; it's a necessity. Car manufacturers inspecting their products through rigorous automotive parts inspections ensure that every vehicle meets high standards. This commitment to quality fosters brand trust and safeguards reputations in an era where consumers are increasingly discerning.

Building Brand Trust and Reputation

Brand trust is built on consistency, reliability, and the assurance that products will perform as expected. When car manufacturers prioritize automotive quality control, they send a clear message to consumers: We care about your safety. By investing in thorough automotive parts inspections, companies can enhance their public image and cultivate long-term customer loyalty.

A single defect can lead to recalls and tarnish a manufacturer’s reputation overnight. Thus, proactive measures like regular testing methods not only prevent potential issues but also reinforce consumer confidence in the brand’s integrity. Ultimately, when customers feel secure in their choice of vehicle, they become brand ambassadors—sharing their positive experiences with others.

Reducing Long-Term Costs Issues

Quality control is an investment that pays dividends over time by reducing long-term costs associated with defects and recalls. Car manufacturers inspecting every aspect of production can identify problems before they escalate into costly repairs or liability claims. By implementing comprehensive automotive parts inspections early in the process, manufacturers can avoid financial pitfalls down the line.

Moreover, addressing quality issues at the source minimizes waste and streamlines production processes. The importance of automotive inspections cannot be overstated; they serve as a safety net against unforeseen expenses that could jeopardize profitability. In short, prioritizing quality today saves money tomorrow.

Enhancing Product Performance and Safety

At its core, automotive quality control is about ensuring vehicles perform optimally while keeping passengers safe on the road. Testing methods such as dynamic testing simulate real-world scenarios to evaluate how well vehicles handle various conditions—essential for both performance and safety assessments. When car manufacturers take these steps seriously, they contribute to a culture of excellence within the industry.

Safety testing goes beyond compliance; it reflects a commitment to protecting lives—a value that resonates deeply with consumers seeking reliable transportation options. Therefore, effective automotive parts inspections not only enhance product performance but also elevate overall safety standards across the board. As awareness grows regarding vehicle safety features, manufacturers must adapt by prioritizing rigorous inspection protocols to meet evolving consumer expectations.

Key Testing Methods Used in Automotive Inspections

In the world of automotive quality control, testing methods play a pivotal role in ensuring that vehicles meet the highest standards of performance and safety. Car manufacturers inspecting their products utilize various testing techniques to assess everything from functionality to durability. Understanding these methods is crucial for both manufacturers and consumers, as they directly impact the quality of automotive parts inspections.

Dynamic Testing for Real-World Scenarios

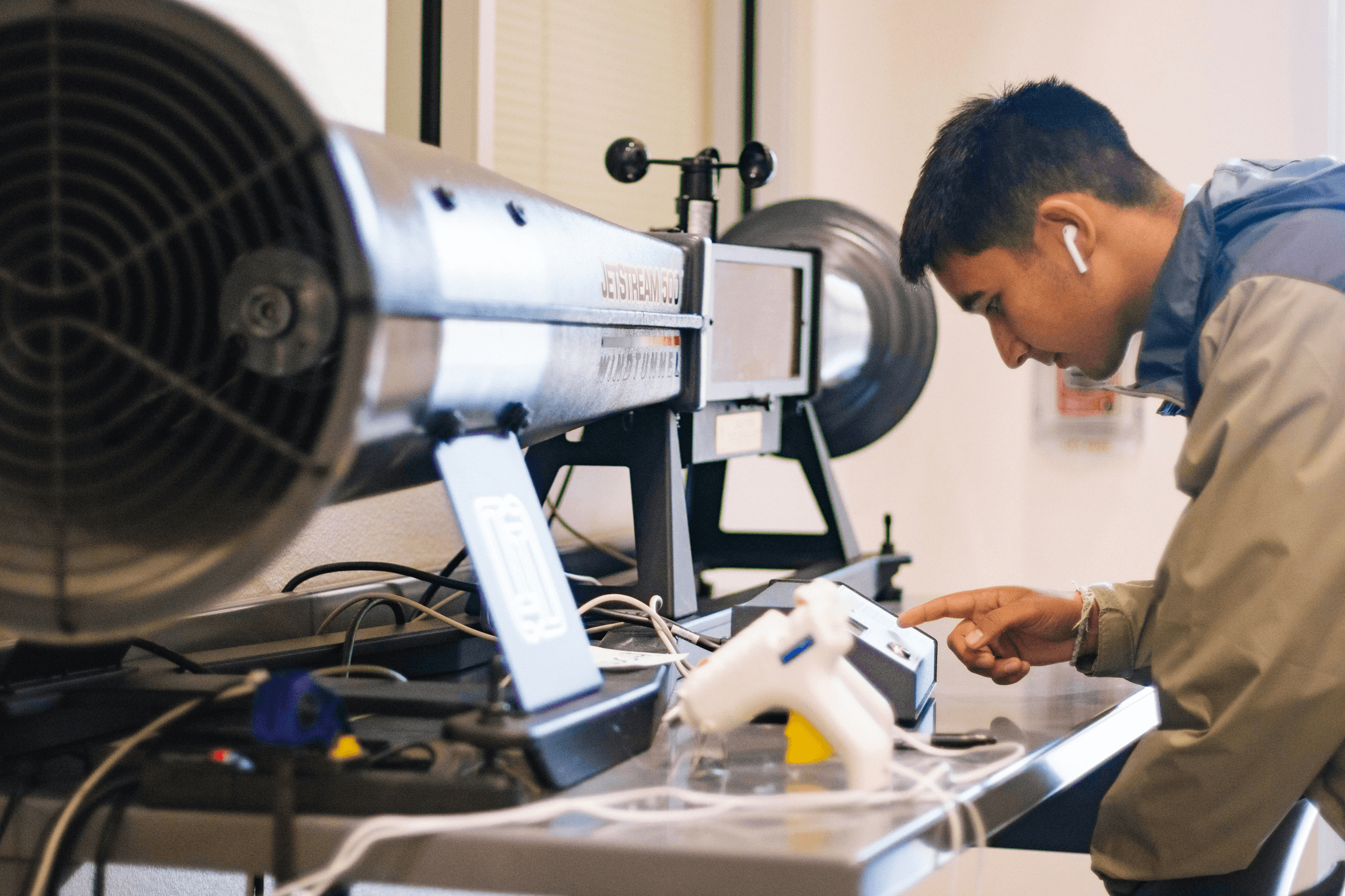

Dynamic testing simulates real-world conditions that vehicles will encounter during their lifecycle. This method involves evaluating components under various dynamic loads, such as acceleration, braking, and cornering forces, to mimic actual driving experiences. By employing dynamic testing, car manufacturers inspecting parts can identify potential failures before they occur on the road, ultimately enhancing automotive quality control.

Moreover, this type of testing provides invaluable data that helps engineers refine designs and improve overall vehicle performance. It allows for adjustments based on how parts react under stress and ensures that they can withstand everyday driving conditions. As a result, dynamic testing is an essential aspect of automotive parts inspections that contributes significantly to consumer safety.

Durability Testing for Longevity

Durability testing focuses on assessing how well automotive components can endure wear and tear over extended periods. This method often involves subjecting parts to extreme conditions—like high temperatures or corrosive environments—to determine their lifespan and reliability. For car manufacturers inspecting their products, durability testing is vital in reducing long-term costs associated with product failures.

By understanding how different materials respond to stressors over time, manufacturers can make informed decisions about material selection and design enhancements. This proactive approach not only improves product longevity but also fosters consumer confidence in the brand’s commitment to quality assurance. Ultimately, durability testing plays a significant role in maintaining high standards within automotive quality control processes.

Safety Testing for Consumer Protection

Safety testing is perhaps one of the most critical aspects of automotive inspections because it directly influences consumer protection measures. This method evaluates key safety features—such as airbags, brakes, and structural integrity—to ensure they function correctly during emergency situations or accidents. Car manufacturers inspecting these elements must adhere strictly to industry regulations to guarantee that their vehicles are safe for public use.

Furthermore, rigorous safety tests help identify vulnerabilities that could lead to catastrophic failures or injuries on the road. By prioritizing safety through comprehensive inspections and tests, companies not only comply with legal requirements but also build trust with consumers who expect reliable vehicles from reputable brands. Thus, safety testing remains an indispensable component within the broader scope of automotive quality control.

Industry Standards for Automotive Parts Inspections

In the realm of automotive manufacturing, adhering to industry standards is not just a recommendation; it’s a necessity. Car manufacturers inspecting their products must comply with stringent regulations to ensure that every component meets the highest quality benchmarks. This commitment to automotive quality control not only safeguards consumer safety but also enhances brand reputation and trust.

Compliance with ISO and SAE Regulations

ISO (International Organization for Standardization) and SAE (Society of Automotive Engineers) set forth critical guidelines that govern automotive parts inspections. By aligning with these standards, car manufacturers inspecting their production processes can ensure consistency and reliability in their offerings. Compliance with these regulations is essential for maintaining automotive quality control, as it outlines specific testing methods that validate product integrity and performance.

Importance of Certification from Recognized Bodies

Certification from recognized bodies serves as a badge of honor in the competitive automotive landscape. It signifies that a manufacturer has met rigorous testing methods and quality assurance protocols, which is crucial for building trust with consumers. Without such certification, car manufacturers inspecting their parts may find themselves facing significant challenges in demonstrating their commitment to automotive quality control, ultimately impacting marketability.

Case Studies on Compliance Failures

The consequences of failing to adhere to industry standards can be dire, as evidenced by several high-profile case studies in the automotive sector. For instance, when a major car manufacturer overlooked compliance during inspections, it led to widespread recalls due to faulty components—an expensive blunder that tarnished its reputation and customer trust. These compliance failures highlight the importance of thorough automotive parts inspections and the critical role they play in maintaining safety and performance standards across the industry.

The Role of Technology in Inspections

In the fast-evolving landscape of automotive manufacturing, technology plays a pivotal role in enhancing the quality control processes that car manufacturers implement. As the demand for superior automotive parts inspections rises, leveraging advanced technologies becomes essential for maintaining high standards. By integrating innovative tools and methodologies, manufacturers can ensure their products not only meet but exceed industry expectations.

Utilizing AI for Precision in Inspections

Artificial Intelligence (AI) has emerged as a game-changer in automotive quality control, allowing car manufacturers to refine their inspection processes significantly. With machine learning algorithms capable of analyzing vast amounts of data, AI can identify potential defects in automotive parts inspections with remarkable accuracy. This precision not only reduces human error but also accelerates the testing methods employed during inspections, ensuring that every component adheres to stringent quality standards.

AI's ability to learn from previous inspections means it continually improves over time, adapting to new challenges and requirements within the industry. As car manufacturers utilize AI-driven solutions, they enhance their overall efficiency while fostering greater confidence among consumers regarding product reliability and safety. Ultimately, this technological advancement underscores the importance of automotive inspections as a critical component of maintaining brand integrity.

The Impact of Automation on Inspection Efficiency

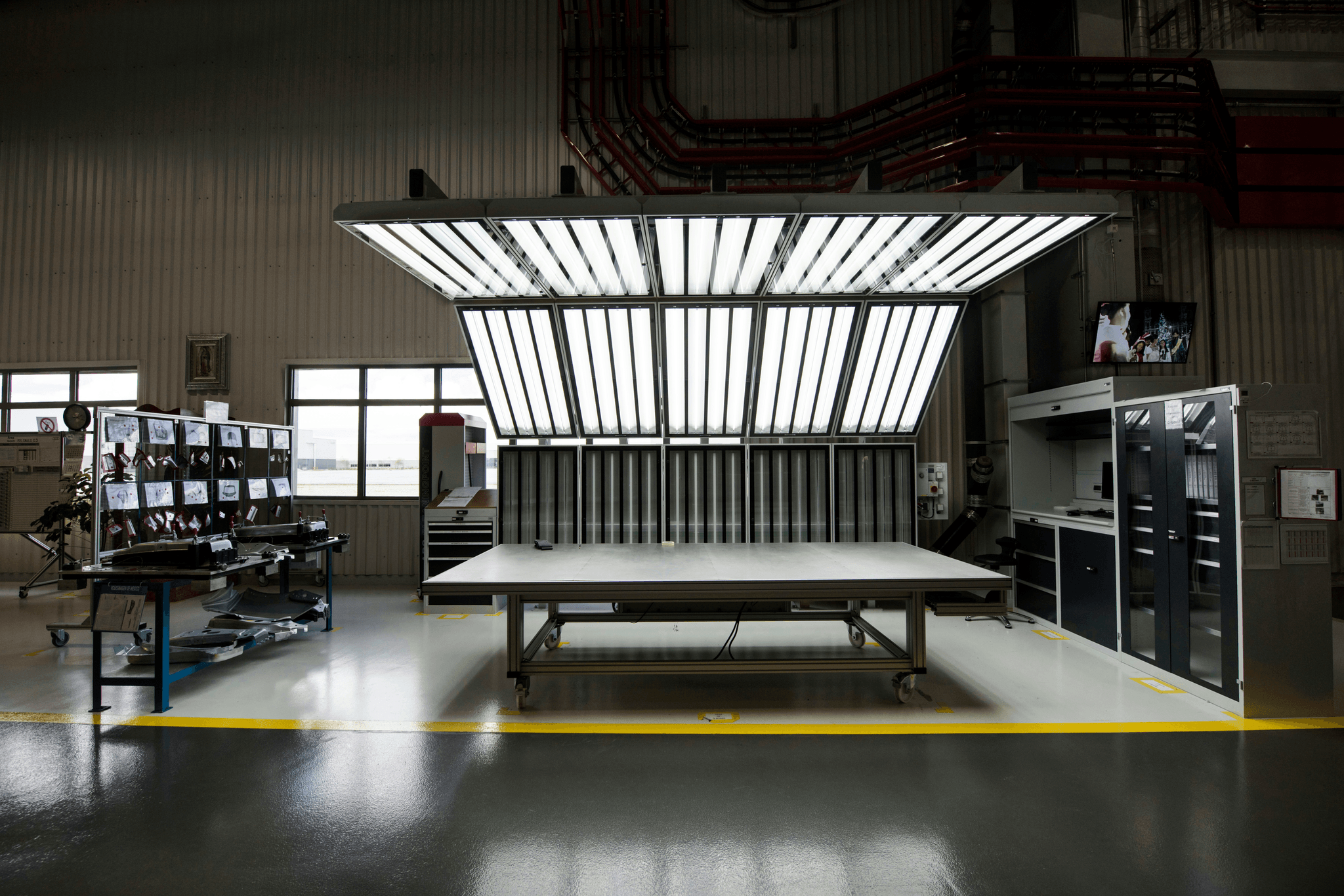

Automation is revolutionizing how car manufacturers approach automotive quality control by streamlining inspection processes and increasing throughput. Automated systems can perform repetitive tasks with unmatched speed and consistency, allowing human inspectors to focus on more complex evaluations that require critical thinking and expertise. This shift not only enhances efficiency but also reduces labor costs associated with traditional inspection methods.

Moreover, automated inspection technologies are equipped with advanced sensors and imaging systems that capture detailed data about each component being tested. These capabilities enable real-time monitoring and immediate feedback on potential issues during production runs—an invaluable asset for ensuring high-quality standards are met consistently across all automotive parts inspections. In this way, automation reinforces the importance of thorough inspections as part of an effective quality assurance strategy.

Real-Time Data Analytics in Quality Control

The integration of real-time data analytics into automotive quality control represents another significant advancement for car manufacturers inspecting their products meticulously. By collecting data continuously throughout the production process, manufacturers gain insights into performance metrics that inform decision-making at every level—from design adjustments to supply chain optimizations. This proactive approach ensures any deviations from established standards are addressed before they escalate into larger issues.

Real-time analytics allows for immediate detection of trends or anomalies within inspection results, enabling teams to respond quickly and implement corrective actions when necessary—ultimately safeguarding product integrity and consumer trust alike. As such, it highlights how crucial effective automotive inspections are in upholding safety regulations while fostering innovation within manufacturing practices. With companies like China Inspection Pro leading the charge through comprehensive solutions tailored to these needs, the future looks bright for enhanced quality assurance across the industry.

How China Inspection Pro Enhances Quality Assurance

In the ever-evolving landscape of automotive manufacturing, ensuring top-notch quality control is paramount. Car manufacturers inspecting their products need a partner who understands the intricacies of automotive parts inspections. That’s where China Inspection Pro steps in, providing expertise that elevates the standards of automotive quality control.

Expertise in Automotive Parts Inspections

China Inspection Pro brings a wealth of experience to the table when it comes to automotive parts inspections. Their specialists are well-versed in various testing methods that ensure every component meets stringent industry standards. With a keen eye for detail, they help car manufacturers inspecting their products identify potential issues before they escalate into costly problems.

The importance of automotive inspections cannot be overstated; they serve as a crucial line of defense against defects that could compromise vehicle safety and performance. By leveraging advanced methodologies and deep industry knowledge, China Inspection Pro ensures that each inspection is thorough and precise. This commitment to excellence not only boosts product quality but also enhances brand reputation among consumers.

Comprehensive Quality Control Solutions

China Inspection Pro offers comprehensive quality control solutions tailored specifically for the automotive sector. Their services encompass everything from initial material assessments to final product evaluations, ensuring a holistic approach to automotive quality control. By integrating various testing methods into their processes, they provide car manufacturers inspecting their supply chains with invaluable insights into potential vulnerabilities.

This robust framework is designed to minimize risks while maximizing efficiency — essential components for any manufacturer striving for excellence in today’s competitive market. The importance of automotive inspections becomes evident as these solutions not only enhance product reliability but also streamline production timelines and reduce long-term costs associated with recalls or repairs. With China Inspection Pro at the helm, manufacturers can confidently navigate complex regulatory landscapes while adhering to best practices.

Transformative Recommendations for Manufacturers

In addition to rigorous inspections, China Inspection Pro excels at offering transformative recommendations tailored for each manufacturer’s unique challenges. By analyzing inspection data and identifying trends, they provide actionable insights that empower car manufacturers inspecting their operations to make informed decisions about process improvements and risk management strategies.

These recommendations often lead to enhanced testing methods that further bolster product integrity and consumer safety — two pillars upon which successful brands are built. The importance of automotive inspections extends beyond compliance; it shapes the overall perception and trustworthiness of a brand in the eyes of consumers who demand nothing less than excellence from their vehicles.

Ultimately, by partnering with China Inspection Pro, car manufacturers can elevate their standards significantly while staying ahead of industry trends in quality assurance practices.

Conclusion

In the ever-evolving automotive industry, the significance of automotive inspections cannot be overstated. Car manufacturers inspecting their products with rigorous quality control measures ensures that every vehicle meets safety and performance standards. By prioritizing automotive parts inspections, manufacturers not only safeguard their reputation but also enhance customer trust and satisfaction.

The Critical Importance of Automotive Inspections

Automotive inspections play a crucial role in maintaining high-quality standards within the industry. The importance of automotive inspections extends beyond mere compliance; they are essential for identifying potential defects before vehicles hit the market. When car manufacturers inspecting their components prioritize thorough testing methods, they ultimately protect consumers and contribute to overall road safety.

Elevating Standards in the Car Manufacturing Industry

As competition intensifies, elevating standards in the car manufacturing industry is more important than ever. Manufacturers must adopt comprehensive automotive quality control practices to differentiate themselves from competitors while ensuring consumer safety. By investing in advanced testing methods and fostering a culture of continuous improvement, companies can set new benchmarks for excellence that resonate throughout the entire supply chain.

Future Trends in Automotive Quality Control

Looking ahead, several trends are poised to shape the future of automotive quality control significantly. Innovations such as AI-driven inspections and enhanced automation will streamline processes and improve accuracy in detecting defects during automotive parts inspections. As technology continues to evolve, car manufacturers inspecting their products will likely embrace real-time data analytics to make informed decisions that elevate product quality while minimizing costs.

In conclusion, by focusing on robust automotive quality control measures and recognizing the importance of automotive inspections, manufacturers can ensure they meet market expectations while adhering to regulatory requirements—ultimately leading to safer vehicles on our roads today.