Introduction

In the world of piping systems, ensuring safety and compliance is paramount. Third-party inspections play a crucial role in verifying that these systems meet industry standards and function effectively. By utilizing an objective set of eyes, organizations can uncover potential issues that might otherwise go unnoticed, making the piping inspection checklist an essential tool in maintaining quality and safety.

The Importance of Third Party Inspections

Third-party inspections provide an unbiased assessment of piping systems, which is vital for identifying defects or non-compliance with regulations. These inspections not only help in maintaining operational integrity but also protect against costly failures that could arise from overlooked issues. Ultimately, a well-executed inspection ensures that all components adhere to the stringent requirements outlined in the piping inspection checklist.

What to Expect During an Inspection

When preparing for a third-party inspection, it's important to know what to expect during the process. Inspectors will typically review documentation, assess physical conditions, and ensure compliance with relevant standards laid out in your piping inspection checklist. This thorough approach helps organizations gain insights into their systems' performance while addressing any immediate concerns.

Understanding the Piping Inspection Checklist

The piping inspection checklist serves as a roadmap for inspectors and facility managers alike, detailing critical aspects to evaluate during an assessment. Familiarizing yourself with this checklist not only streamlines the inspection process but also enhances understanding of key areas that require attention. By recognizing its importance and integrating it into routine assessments, organizations can proactively address potential problems before they escalate.

What to Include in Your Piping Inspection Checklist

Creating an effective piping inspection checklist is not just a good idea; it’s essential for maintaining the integrity of your piping systems. A well-structured checklist can help you identify potential issues before they escalate, ensuring safety and compliance. Let’s break down what you should include to make your inspections thorough and effective.

Essential Items for Every Inspection

When crafting your piping inspection checklist, start with the essentials that every inspection should cover. This includes checking for leaks, corrosion, and any signs of wear or damage on pipes and fittings. Don’t forget to assess joint integrity and support structures, as these are often overlooked yet critical components in maintaining system reliability.

Additionally, ensure that you include checks for insulation condition and proper drainage around pipe systems. Documenting temperature readings can also provide insights into potential thermal expansion issues. Remember, a comprehensive piping inspection checklist will save time and money by preventing minor problems from turning into major headaches.

Industry Standards to Consider

Your piping inspection checklist should also align with relevant industry standards to ensure compliance with safety regulations. Familiarize yourself with standards set by organizations such as the American Society of Mechanical Engineers (ASME) or the American Petroleum Institute (API). Following these guidelines not only ensures legality but also enhances the credibility of your inspections.

Moreover, different industries may have specific requirements; for instance, oil and gas sectors have stringent protocols due to the nature of their operations. Incorporating these standards into your checklist demonstrates professionalism and commitment to quality assurance. Ultimately, adhering to industry benchmarks can mitigate risks associated with non-compliance.

Common Oversights in Inspections

Even seasoned inspectors can overlook critical elements during assessments; thus, recognizing common oversights is key to refining your piping inspection checklist. One frequent mistake is neglecting documentation—failing to record findings or update maintenance logs can lead to future complications down the line. Always ensure that each inspection is meticulously documented for accountability.

Another common pitfall involves skipping visual inspections in hard-to-reach areas where problems often lurk unnoticed. Additionally, underestimating environmental factors like temperature fluctuations or chemical exposure can result in significant damage over time if not addressed promptly. By being aware of these oversights, you can enhance your process and achieve more reliable outcomes.

The Benefits of Hiring Third Party Specialists

When it comes to ensuring the integrity and safety of piping systems, hiring third-party specialists can be a game changer. These professionals bring a wealth of experience and expertise that can significantly enhance the quality of your inspections. Not only do they provide an unbiased perspective, but they also help ensure that your piping inspection checklist is comprehensive and effective.

Why Use Third Party Inspector

Engaging a third-party inspector for your piping needs can save you time, money, and headaches down the line. These inspectors are trained to identify issues that internal teams might overlook due to familiarity or bias. By using an outside expert, you ensure that your piping inspection checklist is scrutinized with fresh eyes, leading to more accurate assessments.

Moreover, third-party inspectors often have access to advanced technologies and methodologies that may not be available in-house. This means you get a thorough evaluation based on industry best practices, which can lead to improved compliance with regulations and standards. In short, hiring a third-party inspector is an investment in peace of mind.

The Value of Objectivity

One of the most significant benefits of third-party inspections lies in their objectivity. Internal teams may unintentionally miss critical flaws due to personal biases or preconceived notions about their work. A neutral party brings an unbiased approach; they assess findings against your piping inspection checklist without any emotional attachment.

This impartiality not only enhances the reliability of the inspection results but also fosters trust among stakeholders involved in the project. When everyone knows that an independent expert has conducted the evaluation, it reduces disputes over findings and recommendations. Ultimately, this objectivity leads to better decision-making based on clear evidence rather than subjective opinions.

Case Study: Success with China Inspection Pro

To illustrate these benefits in action, consider the success story involving China Inspection Pro (CIP). This company specializes in providing high-quality third-party inspections for various industries including oil and gas, construction, and manufacturing. Recently, CIP was hired by a major pipeline operator who faced significant compliance challenges due to outdated internal procedures.

By utilizing a detailed piping inspection checklist tailored specifically for this project, CIP identified several critical areas needing attention—areas that had been overlooked by internal teams for years! The result? Not only did they help rectify compliance issues swiftly but also established new protocols that enhanced overall operational efficiency moving forward. This case underscores how engaging skilled third-party specialists can transform your approach to inspections while ensuring adherence to industry standards.

Types of Pipe Inspections Available

When it comes to ensuring the integrity and safety of piping systems, various types of inspections are available to suit different needs. Understanding these inspection methods can help you develop a comprehensive piping inspection checklist that covers all bases. Let’s dive into the most common types of pipe inspections and what each entails.

Visual Inspections Explained

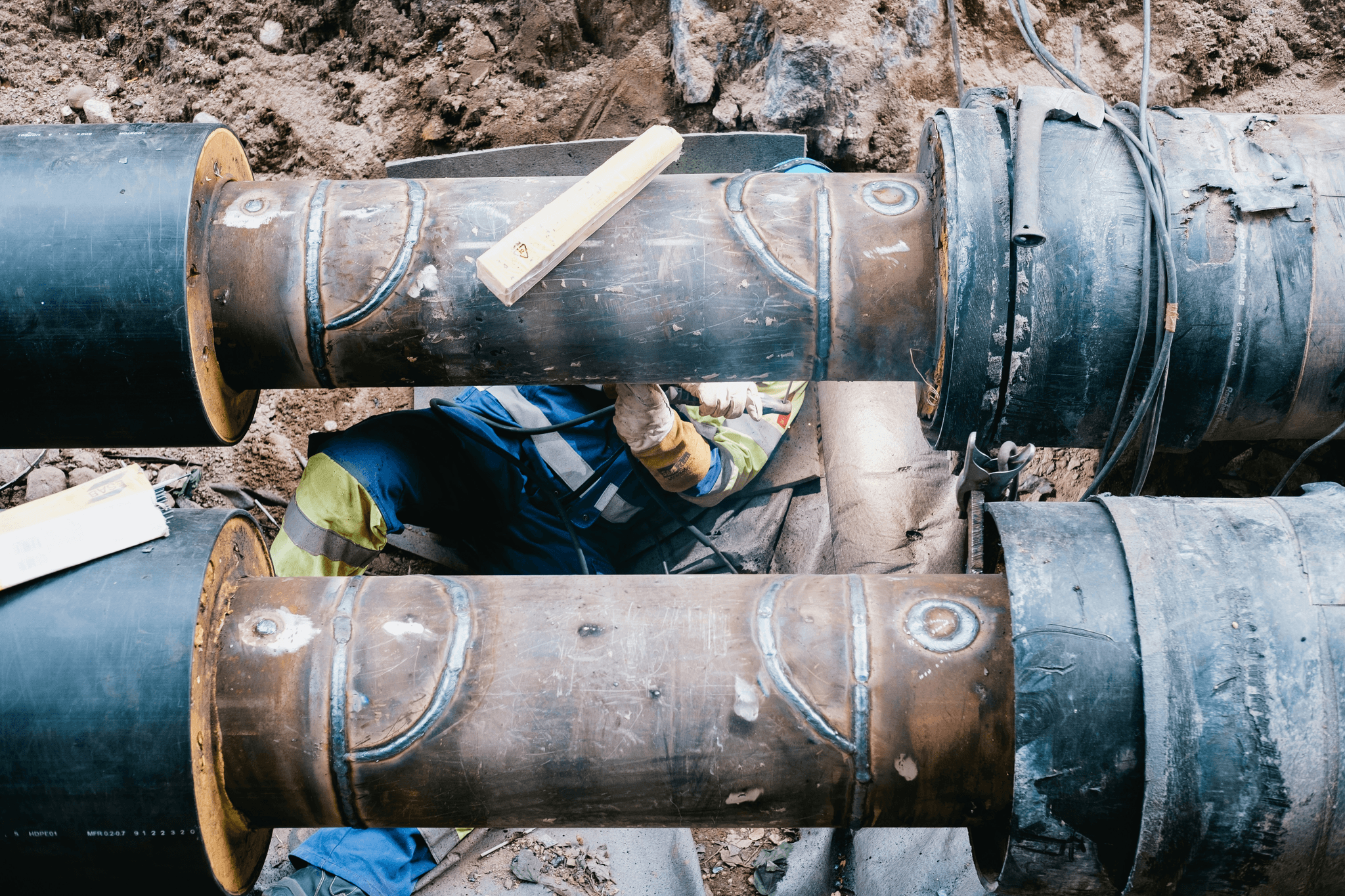

Visual inspections are the bread and butter of pipe assessments, offering a straightforward way to identify potential issues. During this type of inspection, trained professionals look for visible signs of wear, corrosion, leaks, or any other irregularities that could compromise the system's integrity. While visual inspections may seem simple, they provide essential insights that should always be noted in your piping inspection checklist.

A thorough visual examination can often reveal problems before they escalate into costly repairs or failures. Inspectors will typically use tools like magnifying glasses or borescopes to get a closer look at hard-to-reach areas. This method is not only cost-effective but also serves as an excellent preliminary step before diving into more complex testing methods.

Nondestructive Testing: A Deeper Look

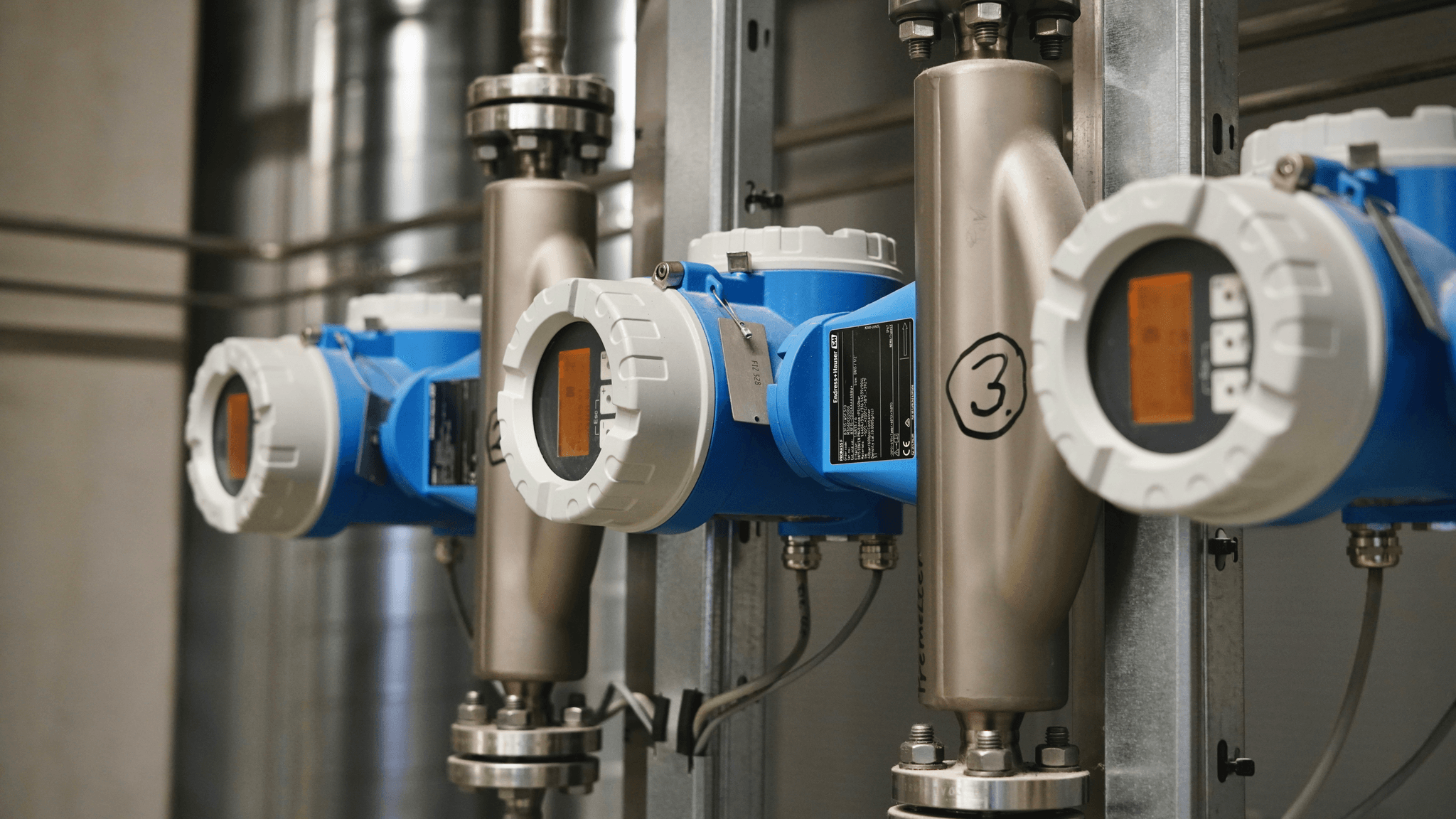

Nondestructive testing (NDT) takes pipe inspections up a notch by allowing inspectors to evaluate materials without causing damage. This technique employs various methods such as ultrasonic testing, radiographic testing, and magnetic particle inspection to assess the structural integrity of pipes without compromising their functionality. Including NDT in your piping inspection checklist ensures that you don’t miss hidden flaws that might not be visible during standard visual checks.

One major advantage of NDT is its ability to detect internal defects—like cracks or voids—that could lead to catastrophic failures if left unchecked. Moreover, many industries require compliance with specific standards that mandate regular NDT evaluations for critical infrastructure components. Therefore, incorporating these tests into your overall inspection strategy can enhance reliability while also meeting regulatory requirements.

Advanced Technologies in Pipe Inspection

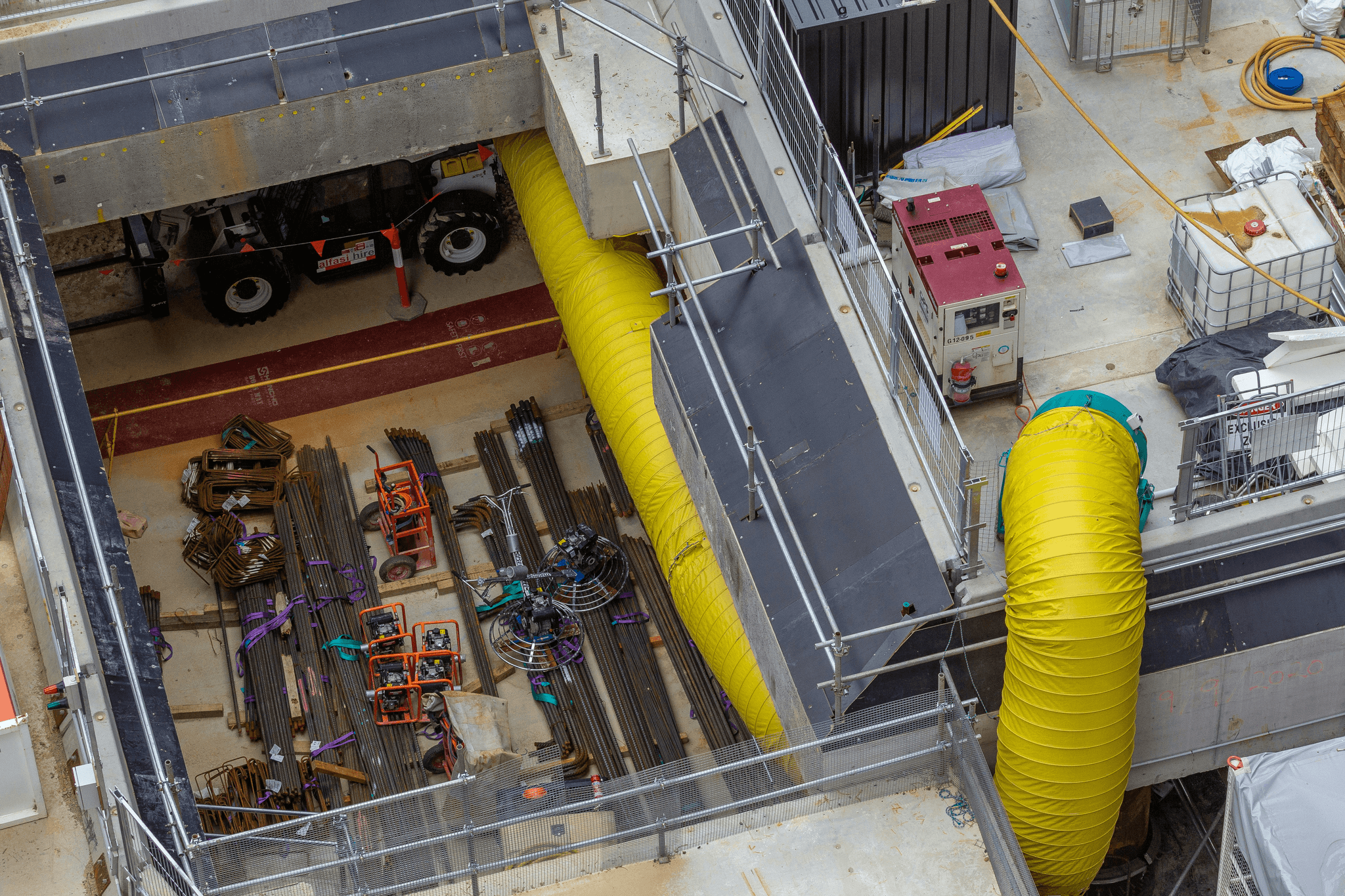

In today’s fast-paced world, advanced technologies have revolutionized how we conduct pipe inspections—making them faster and more accurate than ever before! Techniques such as laser scanning and drones provide high-resolution imagery and data collection capabilities previously thought impossible for traditional methods. If you're updating your piping inspection checklist, consider including these cutting-edge technologies for a more comprehensive evaluation process.

Laser scanning offers 3D models that allow inspectors to visualize complex piping systems from multiple angles while drones can access hard-to-reach areas with ease—saving time and reducing risks associated with manual inspections at height or in confined spaces. These innovations not only streamline the process but also enhance data accuracy and reliability significantly compared to conventional techniques alone.

Incorporating advanced technologies into your pipeline assessment strategy ensures thoroughness while keeping pace with industry advancements—a worthy investment for any organization committed to maintaining high safety standards!

Preparing for a Third Party Inspection

Preparing for a third-party inspection is crucial to ensure everything goes smoothly and efficiently. This phase sets the stage for a successful inspection, helping you avoid unnecessary delays and potential issues down the line. By following a structured approach, you can ensure that your piping inspection checklist is comprehensive and ready for scrutiny.

Gathering Required Documentation

Before the inspector arrives, it’s essential to gather all necessary documentation related to your piping systems. This includes maintenance records, previous inspection reports, and any relevant certifications that demonstrate compliance with industry standards. A well-organized set of documents not only facilitates the inspection process but also helps in addressing any questions or concerns that may arise.

Incorporating these documents into your piping inspection checklist ensures that nothing is overlooked during the review process. It’s wise to double-check that all records are up-to-date and accurately reflect your current operations. Remember, thorough documentation can make or break an inspection's outcome!

Pre-Inspection Site Walkthrough

Conducting a pre-inspection site walkthrough is an excellent way to familiarize yourself with the areas that will be inspected. This allows you to identify any potential issues beforehand, such as leaks or corrosion, which could raise red flags during the actual inspection. Plus, it gives you an opportunity to ensure that all equipment is accessible and in good working order.

During this walkthrough, use your piping inspection checklist as a reference guide to make sure no critical areas are missed. Engaging staff in this process can also provide valuable insights into any ongoing maintenance challenges they face daily. A proactive approach here can significantly enhance the overall efficiency of the upcoming third-party inspection.

Training Staff to Facilitate the Process

Training your staff on what to expect during a third-party inspection can greatly improve communication and cooperation throughout the process. Make sure they understand their roles and responsibilities clearly; this includes knowing how to present documentation and answer questions from inspectors confidently. Consider hosting a brief training session focused on key points from your piping inspection checklist.

Moreover, instilling an understanding of why inspections matter fosters a culture of compliance within your organization—everyone plays a part in maintaining quality standards! Encourage staff members to ask questions about procedures so they feel prepared when inspectors arrive on-site. With everyone on board and informed, you're setting yourself up for success!

Interpreting Inspection Results

Once the inspection is complete, interpreting the results is crucial for ensuring your piping systems are up to par. The inspection report will provide a detailed analysis of the findings, highlighting areas that meet industry standards and those that require attention. A thorough understanding of this report can help you make informed decisions about maintenance and upgrades.

Understanding the Report

The inspection report typically includes a summary of findings, photographs, and specific observations related to your piping systems. Familiarize yourself with the terminology used in the report; terms like “corrosion,” “leakage,” or “joint integrity” will frequently appear. By grasping these concepts, you can better assess which items on your piping inspection checklist need immediate action.

Reports may also categorize issues into urgent, moderate, or minor concerns. This categorization helps prioritize repairs based on severity and potential impact on operations. Don't hesitate to ask your inspector for clarification on any points that seem unclear; understanding every detail is essential for effective follow-up.

Actionable Recommendations to Consider

After digesting the inspection results, it’s time to pivot towards actionable recommendations that can be derived from them. These recommendations will often include immediate repairs needed as well as long-term strategies for maintenance and monitoring of your piping systems. Make sure these recommendations align with your existing piping inspection checklist; if not, it might be time to revise it.

Consider implementing a timeline for addressing each recommendation based on urgency and available resources. For example, if an issue is categorized as urgent but requires specialized skills or materials not readily available, you may need a temporary workaround until full repairs can be executed. Staying proactive rather than reactive can save both time and money in the long run.

How to Address Common Issues

Common issues identified during inspections often include leaks, corrosion, or improper installation practices—each requiring different strategies for resolution. For leaks specifically noted in your piping inspection checklist, immediate repairs are essential to prevent further damage or safety hazards down the line. Engage qualified professionals who specialize in leak detection and repair; their expertise will ensure proper handling.

Corrosion is another frequent culprit that could lead to significant problems if left unchecked; regular monitoring should be part of any comprehensive maintenance plan derived from your inspections’ findings. Consider upgrading materials or applying protective coatings where corrosion has been identified as an issue on your checklist—prevention is always better than cure!

Lastly, ensure all staff involved are trained adequately so they know how to respond swiftly when common issues arise after an inspection concludes—this could involve everything from routine checks to emergency protocols depending on severity levels noted in reports.

Conclusion

In conclusion, a thorough understanding of piping inspections is essential for maintaining safety and efficiency in any operation involving pipelines. By grasping the key aspects of a piping inspection checklist, companies can ensure they are not only compliant with industry standards but also prepared to tackle potential issues before they escalate. Remember, prevention is always better than cure, especially when it comes to the integrity of your piping systems.

Key Takeaways from Pipe Inspections

The primary takeaway from pipe inspections is the critical role they play in ensuring operational safety and reliability. Regular inspections using a well-structured piping inspection checklist can help identify problems early on, ultimately saving time and resources while preventing costly downtime. Additionally, engaging third-party inspectors adds an extra layer of assurance that your systems meet all necessary regulations and standards.

Creating an Effective Piping Inspection Checklist

Creating a robust piping inspection checklist involves including essential items tailored to your specific needs while adhering to industry standards. Start by identifying critical components that require regular monitoring and consider incorporating common oversights that often lead to issues down the line. An effective checklist should be dynamic—regularly updated based on past findings and evolving regulations—to ensure ongoing compliance and optimal performance.

Ensuring Compliance and Quality Standards

Ensuring compliance with quality standards hinges on diligent inspections backed by a comprehensive piping inspection checklist. It’s crucial to stay informed about industry regulations that can impact your operations; this awareness enables you to proactively address any potential gaps or deficiencies in your system. Ultimately, committing to rigorous inspections not only protects your assets but also enhances overall operational integrity.